Preparation method of high-orientation nanometer hydroxyapatite crystalline colloidal array

A technology of nano-hydroxyapatite and crystal array, applied in the field of nano-manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

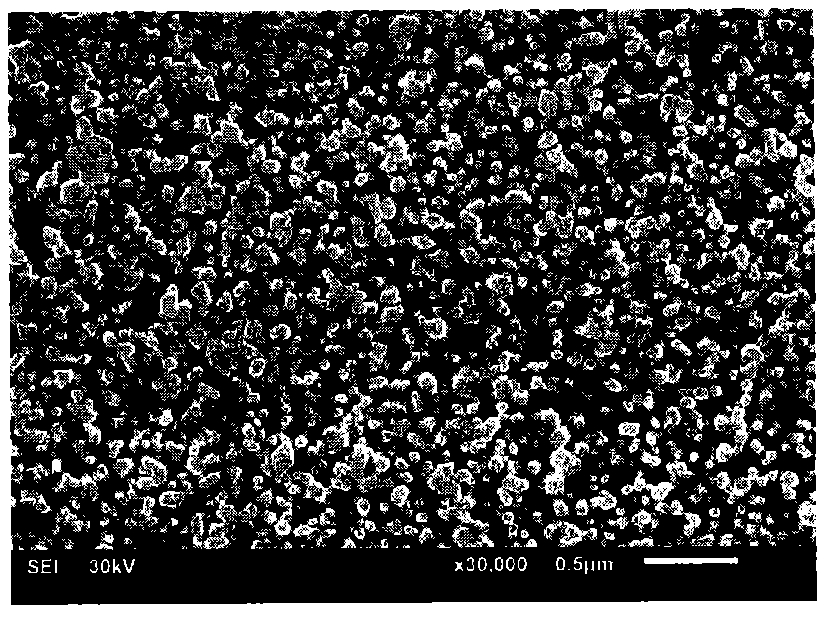

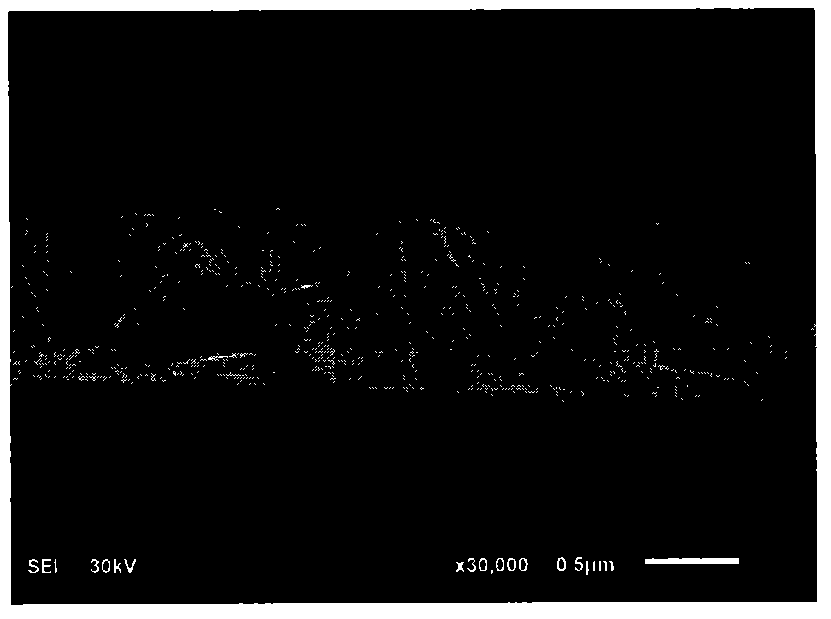

[0020] Take an ordinary glass slide, immerse it in 4mol / L sodium hydroxide solution at 60°C, take it out after 8 hours, wash it with deionized water, and dry it at room temperature. Submerge the hot-alkali-treated sample in 10ml of calcium chloride aqueous solution with a concentration of 1.0mol / L, react at 60°C for 8h, take the sample out and place it in an oven at 80°C for drying. Then immerse the sample in 10ml of disodium hydrogen phosphate solution with a concentration of 0.02mol / L and a pH of 10, keep it warm at 90°C for 12h, take out the sample and wash it with deionized water, then dry it with warm air, and observe the surface structure with SEM. It can be seen that a large area of nano-hydroxyapatite crystals with a hexagonal structure has been generated on the surface of the glass slide, and the size of the hydroxyapatite crystals is uniform, with a diameter of 80.3 ± 3.7nm ( figure 1 ), it can be seen from the cross-sectional SEM that the length of nano-hydroxyapa...

Embodiment 2

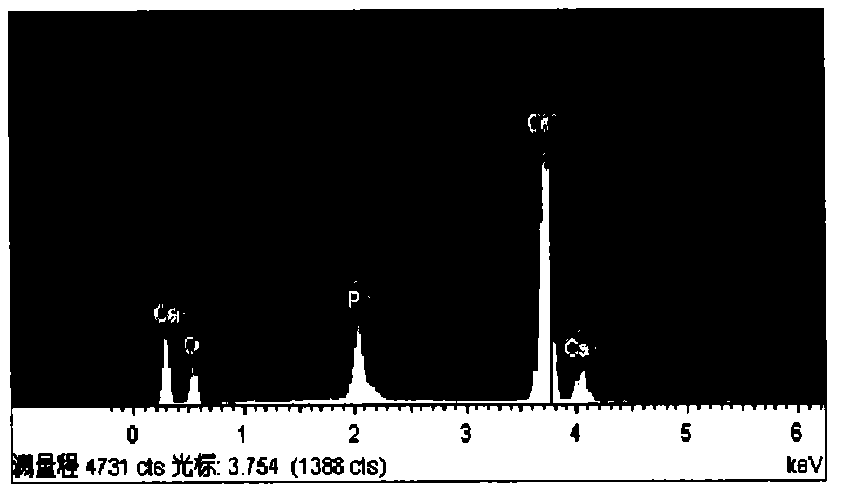

[0022] The size is 2×20×80mm 3 Immerse the quartz glass in 8mol / L potassium hydroxide solution at 60°C, take it out after 10h, wash it with deionized water three times, and dry it in an oven at 60°C. Then immerse the hot-alkali-treated sample in 10ml of calcium chloride aqueous solution with a concentration of 2.0mol / L, react at 60°C for 8h, take the sample out and place it directly in an oven at 80°C for drying. Then immerse the sample in 10ml of disodium hydrogen phosphate solution with a concentration of 0.03mol / L and a pH of 11, soak for 24h at 37°C, take out the sample and wash it with deionized water, then dry it at room temperature, and observe the surface structure with SEM , it can be seen that nano-hydroxyapatite crystals with a large area of hexagonal sheet structure are formed on the surface of the sample, and the size of the hydroxyapatite crystals is uniform, and the thickness is 38.0±8.9nm ( Figure 4 ), the EDS spectrum shows that the crystals are mainly com...

Embodiment 3

[0024] The size is 2×20×80mm 3 The conductive glass was immersed in a 6mol / L sodium hydroxide solution at 80°C, taken out after 5 hours, cleaned with deionized water, and dried in an oven at 60°C. Then the sample was immersed in 10ml of calcium nitrate aqueous solution with a concentration of 2.0mol / L, reacted at 80°C for 4h, and the sample was taken out and directly dried in an oven at 60°C. Then immerse the sample in 10ml of potassium dihydrogen phosphate solution with a concentration of 0.05mol / L and a pH of 10, soak for 24 hours at 85°C, take out the sample and wash it with deionized water, then dry it with warm air, and observe the surface structure with SEM , it can be seen that nano-hydroxyapatite crystals with a large area of needle-like structure are formed on the surface of the sample. The size of the hydroxyapatite crystals is uniform, with a diameter of 45.2±3.2nm and a length of 548.2±23.5nm. The EDS spectrum shows that the crystals are mainly composed of calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com