Conditioner for combinedly conditioning sludge and method for dehydrating sludge through utilizing conditioner

A sludge dehydration and combined technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of high moisture content of factory sludge, high cost of sludge dehydration, large chemical dosage, etc., and achieve improved sludge Dehydration performance, beneficial to subsequent sludge incineration and disposal, and the effect of high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

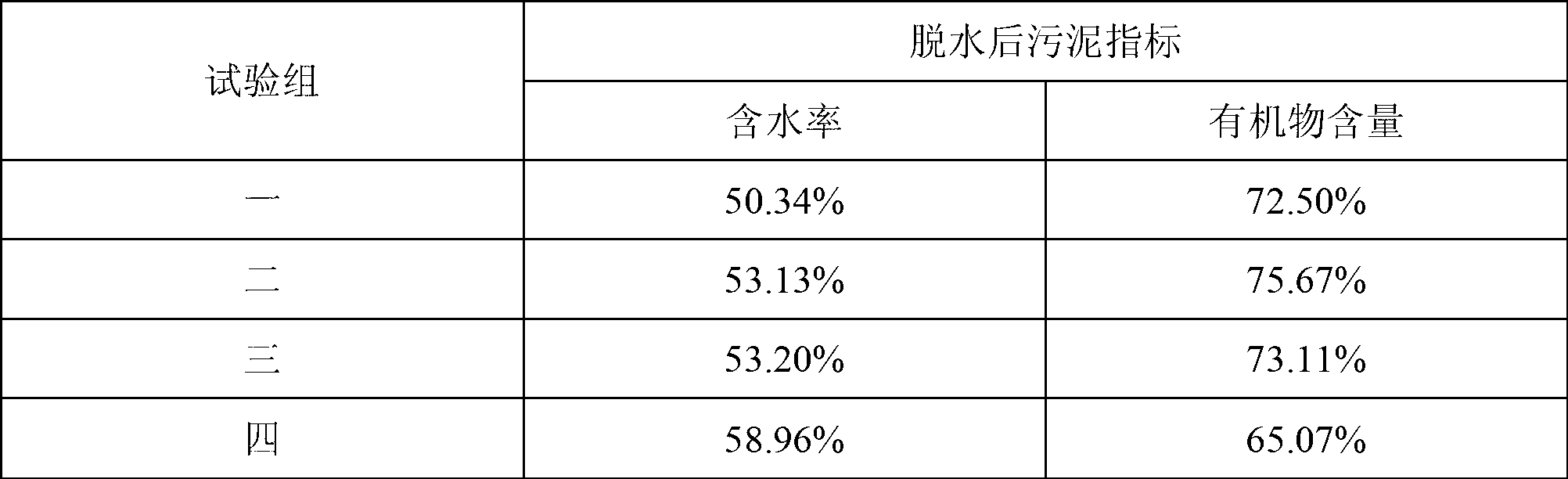

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: In this embodiment, a conditioner for combined conditioning sludge is composed of a separately packaged chemical conditioner and a separately packaged physical conditioner, and the individually packaged chemical conditioner is composed of a separately packaged Composed of cationic polyacrylamide CPAM and individually packaged polyaluminum chloride PACl, the individually packaged physical conditioning agent is wood chips, wherein the particle size of the wood chips is 10 mesh to 100 mesh, and the moisture content of the wood chips is <20%.

[0011] The conditioner described in this embodiment reduces the specific resistance of sludge through chemical conditioning, improves sludge dewatering performance, enhances the strength of sludge flocs through physical conditioning, improves the compressibility of sludge cake, and improves sludge Dewatering properties during extrusion.

[0012] The conditioner described in this embodiment reduces the consum...

specific Embodiment approach 2

[0013] Embodiment 2: In this embodiment, the method of sludge dehydration using the conditioner of the combined conditioning sludge of Embodiment 1 is completed according to the following steps:

[0014] 1. Chemical conditioning: first add the pre-dewatered sludge with a moisture content of 90% to 99% into the mixing tank, and then add the individually packaged chemical conditioner to the pre-dehydrated sludge. The packaged chemical conditioning agent is composed of separately packaged cationic polyacrylamide CPAM and separately packaged polyaluminum chloride PACl, and the separately packaged cationic polyacrylamide CPAM and separately packaged polyaluminum chloride PACl are added at the same time Add it to the sludge before dehydration, stir and mix for 1min~5min under the condition of stirring speed of 60rpm~100rpm, stop stirring, and obtain the sludge after chemical conditioning; 2. Physical conditioning: separate packaged physical The conditioning agent is added to the slu...

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the sludge plate and frame filter press dehydration described in step three is completed according to the following steps: ① one-time extrusion: open the sludge screw pump, Under the condition of 20rpm~60rpm, the conditioned sludge is pumped into the diaphragm plate and frame filter press through the sludge screw pump. With the injection of sludge, the pumping pressure of the sludge screw pump increases from 0Mpa to 0.5Mpa, the pumping time is 0.5h~1h, open the pressure filter water valve of the diaphragm plate and frame filter press to discharge the pressure filter water out of the system, and close the sludge screw pump after the mud feeding is completed, that is, a squeeze is completed; ② Two Secondary extrusion: Turn on the water inlet pump, inject tap water into the diaphragm chamber of the diaphragm plate and frame filter press to dehydrate the sludge with secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com