Bismuth-zirconium alloy

A technology of zirconium alloys and alloys, applied in the field of bismuth-containing zirconium alloys, to achieve excellent corrosion resistance and low hydrogen absorption

Inactive Publication Date: 2012-05-02

国核宝钛锆业股份公司 +1

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the fuel consumption reaches 60GWd / tU, the improved Zr-4 alloy can no longer meet the requirements, and a new zirconium alloy must be used to make the cladding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

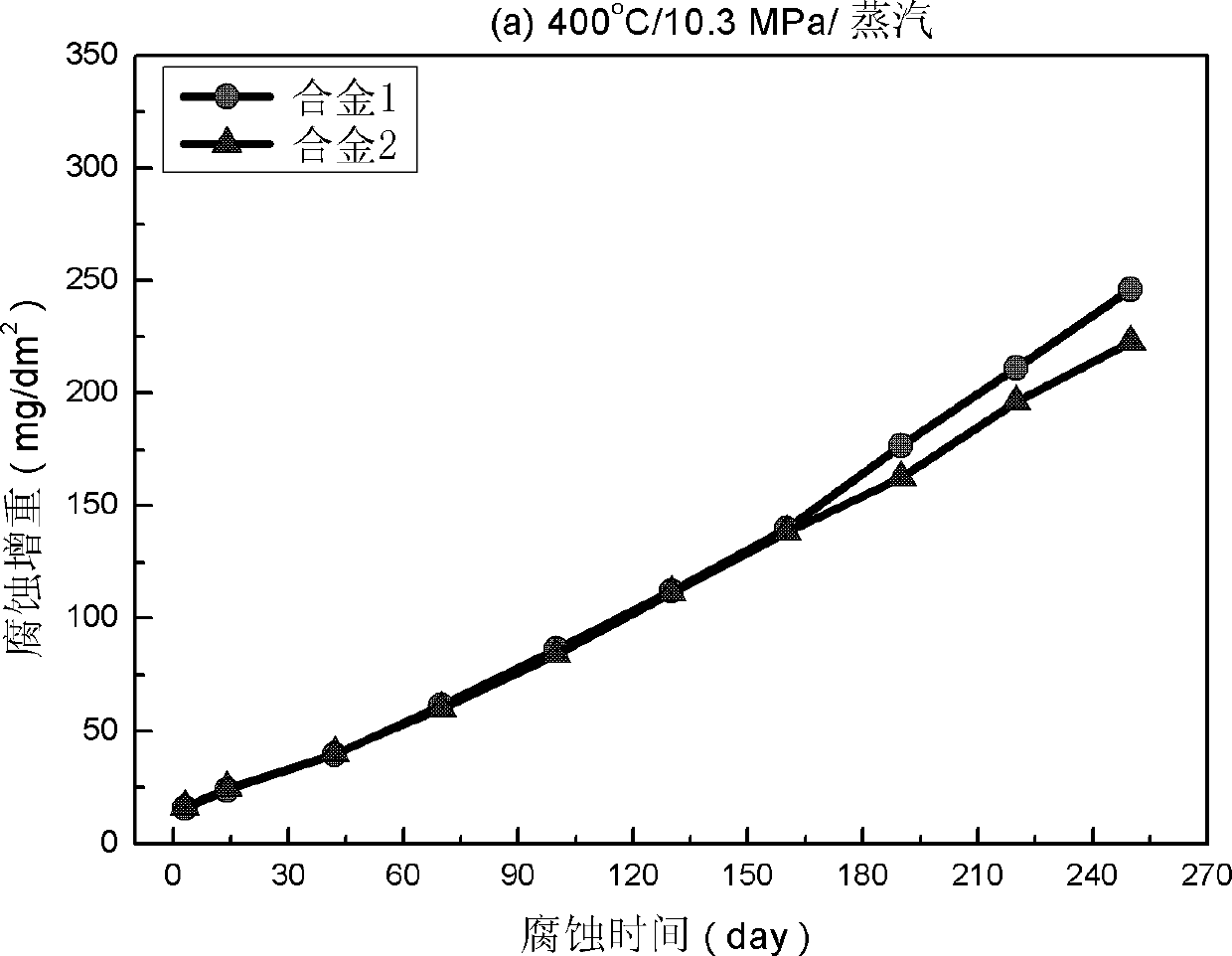

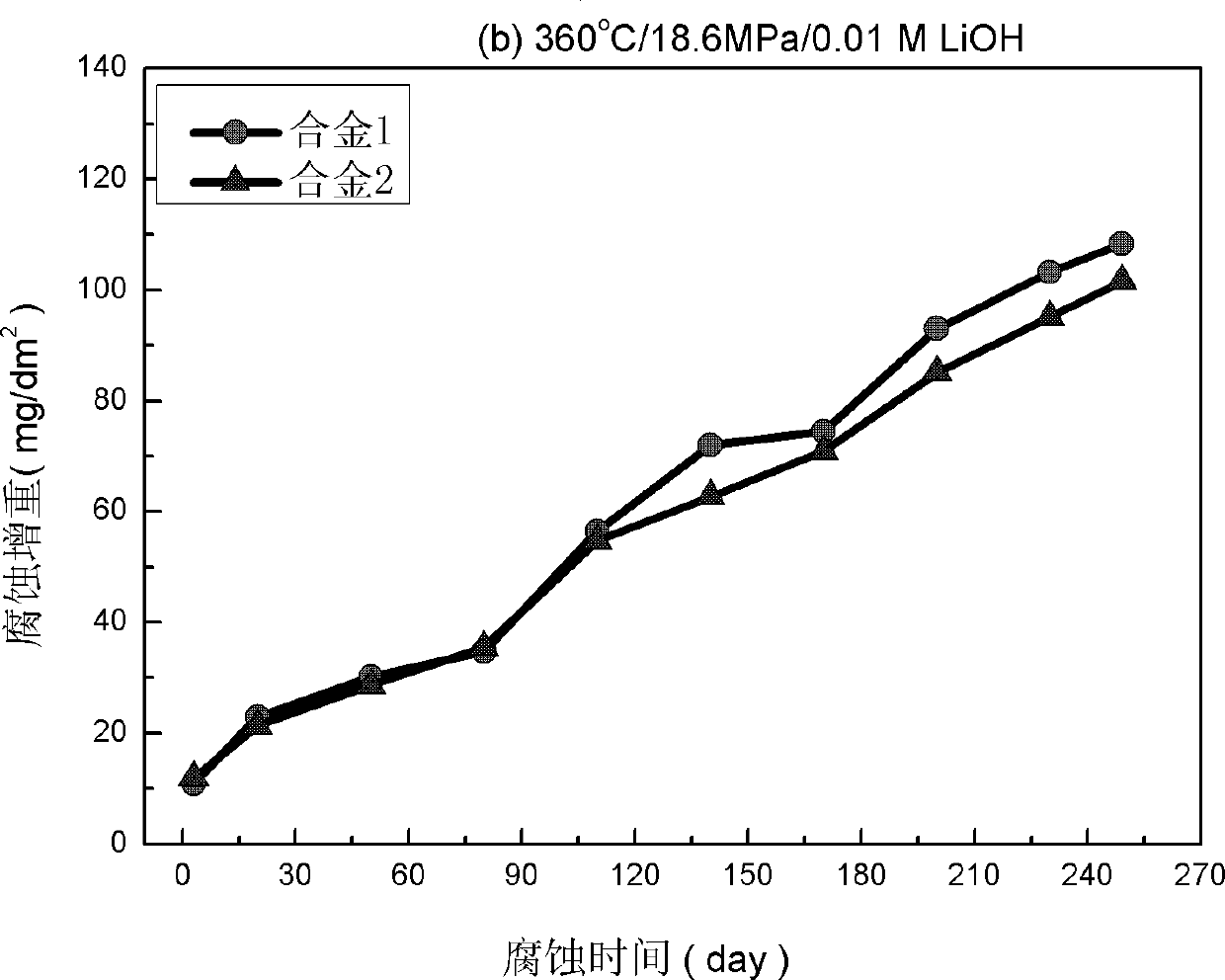

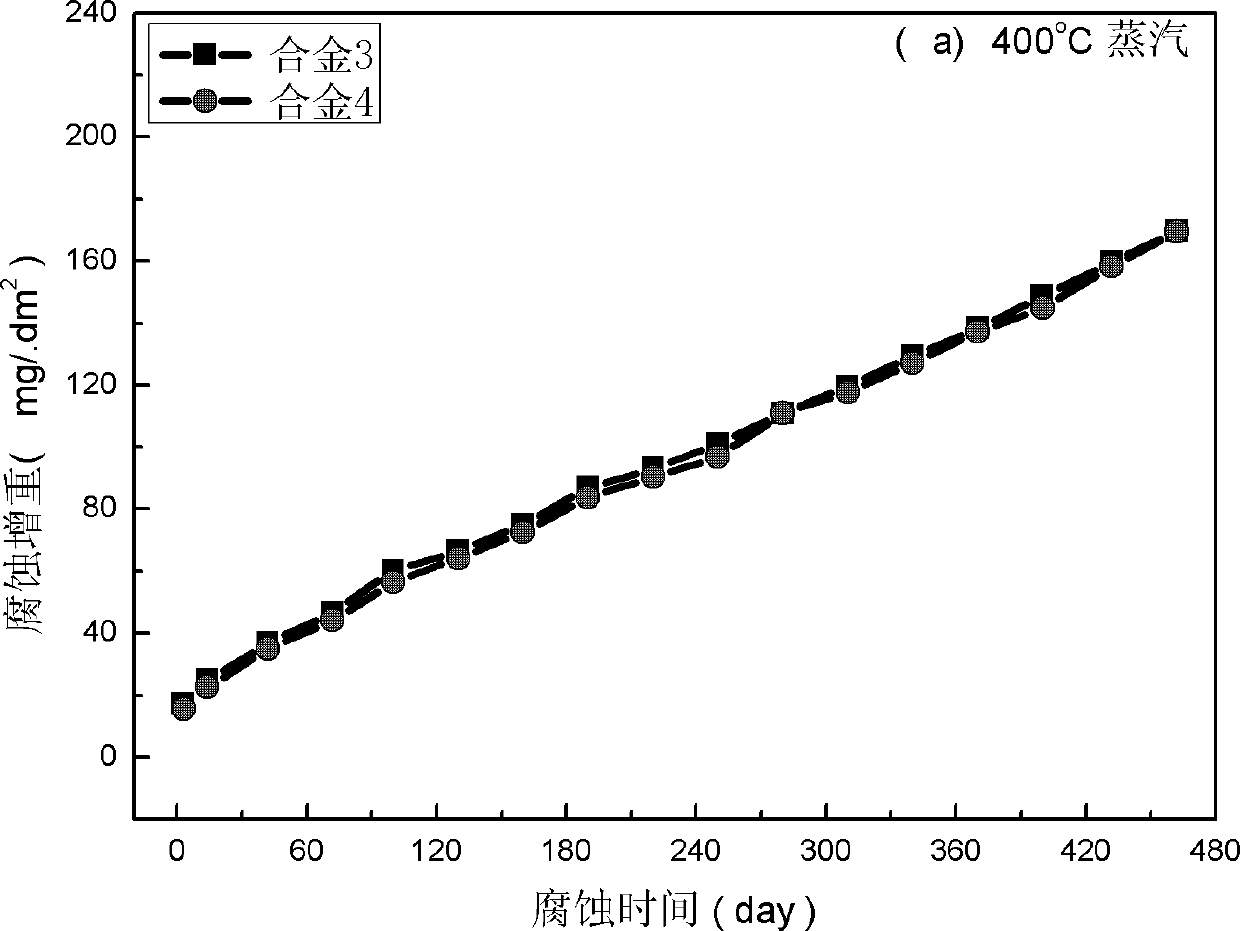

The invention discloses a bismuth-zirconium alloy, which consists of the following components in percentage by weight: 0.4 to 1.0 percent of Sn, 0.2 to 1.2 percent of Nb, 0.2 to 0.4 percent of Fe, 0.05 to 0.3 percent of Cr, 0.005 to 0.4 percent of Bi, and the balance of Zr and inevitable impurities. The bismuth-zirconium alloy shows excellent corrosion resistance under two hydro-chemical conditions, namely 0.01 mol / L LiOH aqueous solution at the temperature of 360 DEG C and under the pressure of 18.6MPa and superheated steam at the temperature of 400 DEG C and under the pressure of 10.3MPa; and the corrosion resistance of the bismuth-zirconium alloy is obviously superior to that of a ZIRLO alloy. The bismuth-zirconium alloy can be used as a material for reactor core structures such as fuel element jackets, grillages and the like in pressurized water reactors of nuclear power plants.

Description

technical field [0001] The invention belongs to the technical field of alloy materials, in particular to a bismuth-containing zirconium alloy. Background technique [0002] Zirconium alloy is an important core structure material in nuclear reactors, used as nuclear fuel element cladding and so on. In order to reduce the cost of nuclear power, it is required to further increase the burnup of nuclear fuel, so it is necessary to prolong the residence time of nuclear fuel assemblies in the core, which puts forward higher requirements on the corrosion resistance of cladding materials. [0003] At present, the zirconium alloys developed internationally mainly include three series: Zr-Sn, Zr-Nb and Zr-Sn-Nb. After adding Fe, Cr, Ni, Cu and other alloy elements on this basis, zirconium alloys such as Zr-2, Zr-4, Zr-2.5Nb, E110, M5, ZIRLO, E635, etc. Foreground zirconium alloys such as N18, N36, and HANA. Zr-2 and Zr-4 are the earliest developed alloys, which belong to the Zr-Sn s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C16/00

Inventor 袁改焕周邦新王练姚美意赵文金李忠奎刘庆李瑞锋岳强张金龙戴训周军栾佰峰宋建力

Owner 国核宝钛锆业股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com