Method evaluating membrane chemical cleaning recovery performance

A chemical cleaning and performance technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the time-consuming and labor-intensive problems of cleaning chemicals, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

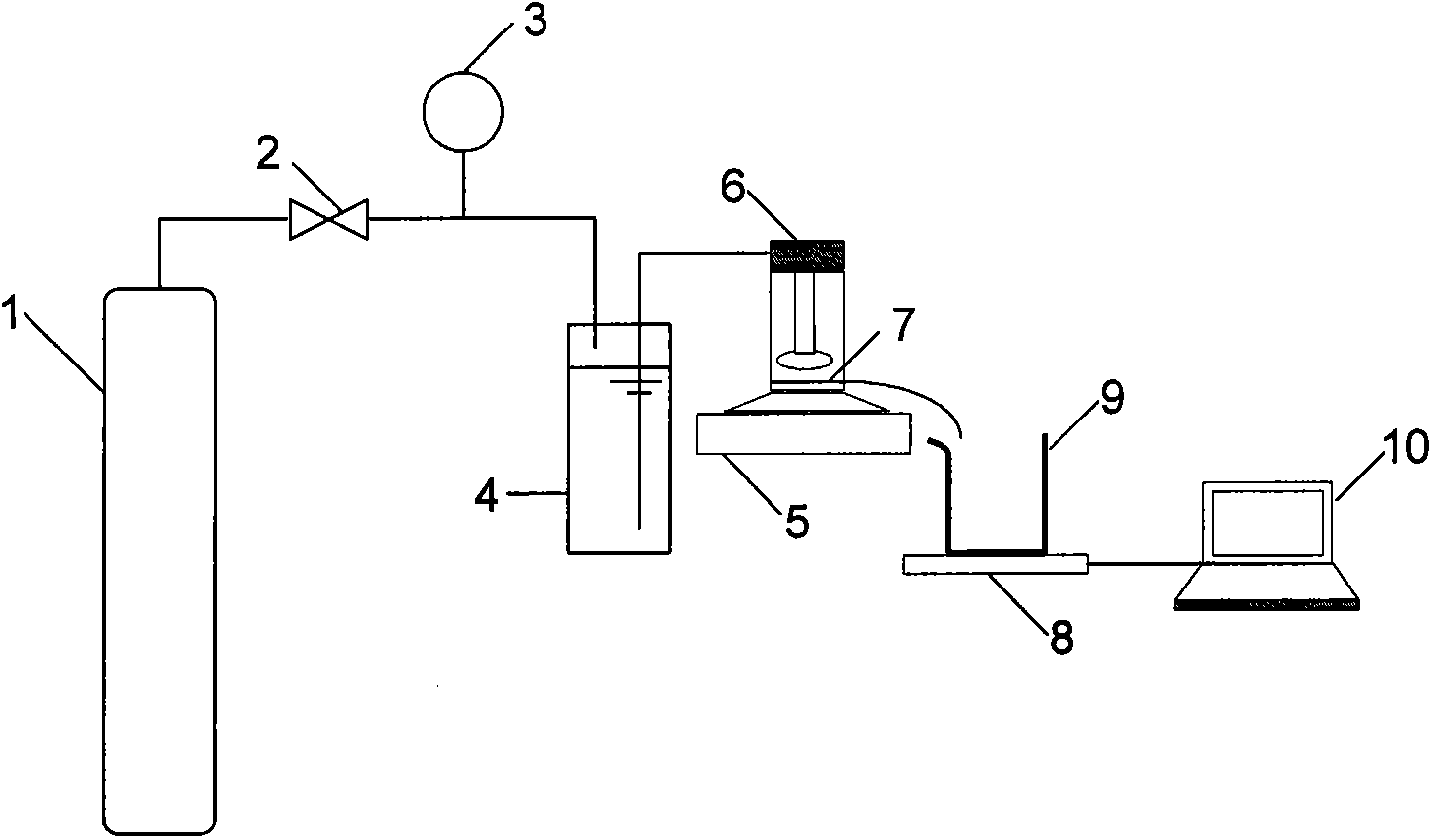

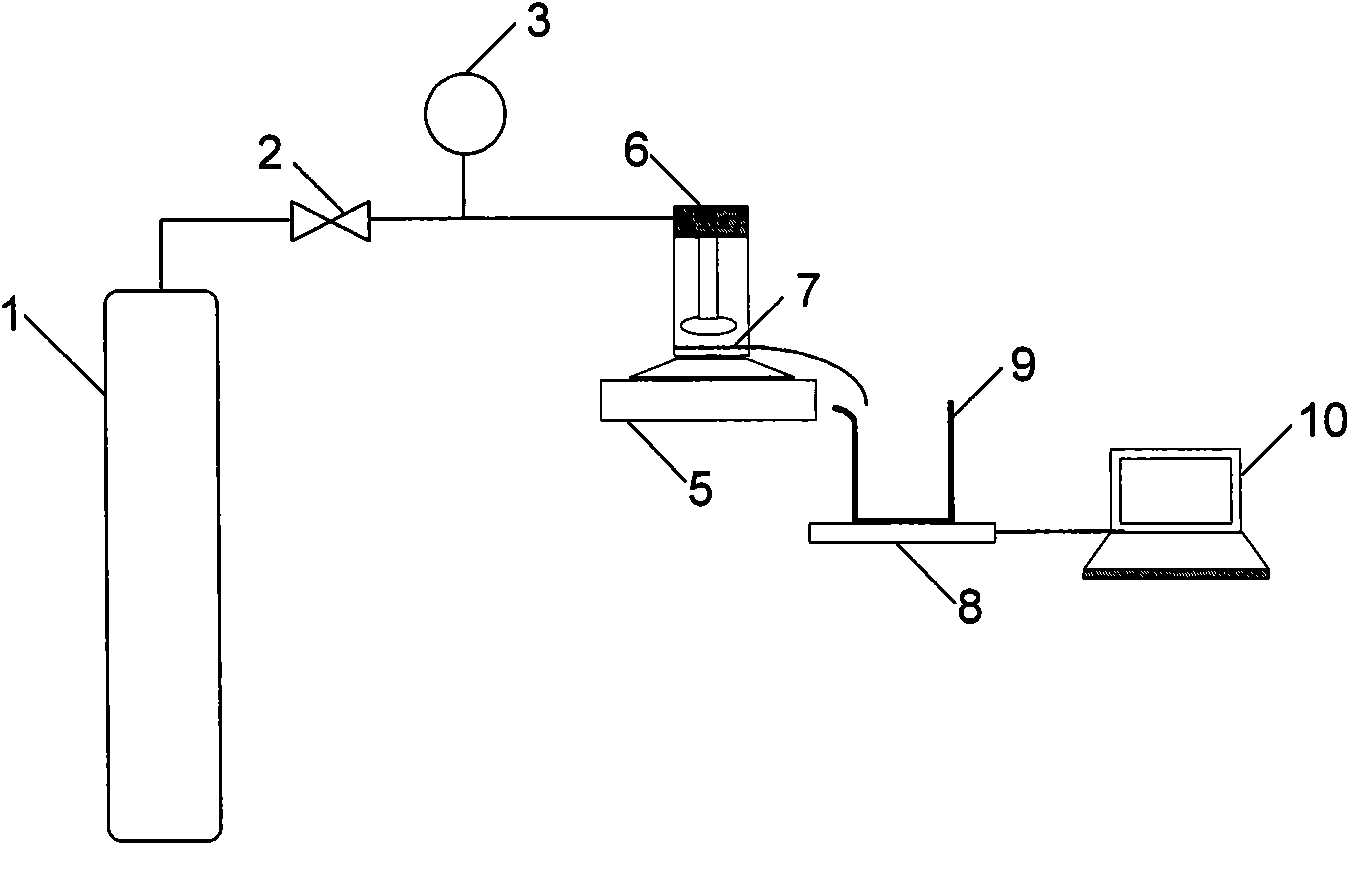

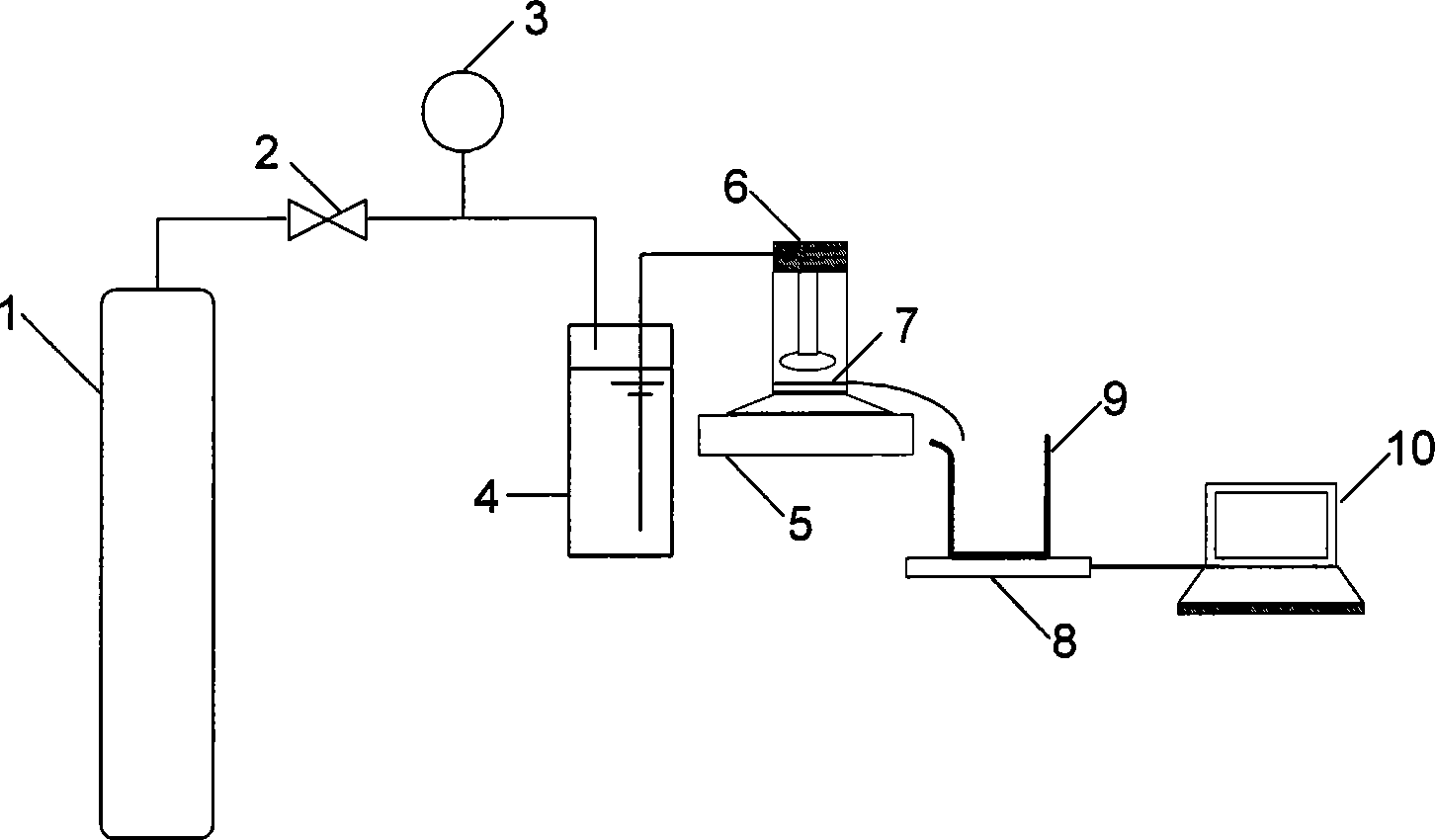

Method used

Image

Examples

Embodiment 1

[0038] The test sludge is sludge from a papermaking wastewater treatment plant, and the sludge concentration is 2000mg / L. Firstly, the flux J1 of the membrane in pure water was measured to be 9.39m / d 5KPa, and the initial membrane resistance R1 of the membrane was calculated by Darcy's law; the membrane was washed with pure water after repeating the sludge filtration test 20 times, and the measured The flux J2 of the membrane in pure water is 0.84m / d 5KPa, and the membrane resistance R2 of the membrane after contamination is calculated by Darcy's law; the membrane is taken out and immersed in an oxalic acid solution with a concentration of 1000mg / L for 20h , the flux J3 of the membrane in pure water measured after chemical cleaning is 6.35m / d 5KPa, and the membrane resistance R3 of the membrane after chemical cleaning is calculated by Darcy's law. The test data are shown in Table 1. By calculating It is known that the chemical cleaning recovery rate of the membrane is (R2-R3) / ...

Embodiment 2

[0046] The test sludge is sludge from a printing and dyeing wastewater treatment plant, and the sludge concentration is 3000mg / L. First, the flux J1 of the membrane in pure water is measured to be 9.00m / d 5KPa, and the flux of the membrane is calculated by Darcy's law. Initial membrane resistance R1; after repeating the sludge filtration test 20 times, the membrane was washed with pure water, and the flux J2 of the membrane in pure water was measured to be 0.93m / d 5KPa, and the membrane flux after pollution was calculated by Darcy's law Membrane resistance R2, the diaphragm is taken out and immersed in a sodium hypochlorite solution of 1000mg / L in terms of available chlorine concentration for 10h. After chemical cleaning, the flux J3 of the diaphragm in pure water is measured to be 3.13m / d 5KPa. The law calculates the membrane resistance R3 of the membrane after chemical cleaning, and the test data is shown in Table 3. The recovery rate of the membrane chemical cleaning of the ...

Embodiment 3

[0058] The test sludge is sludge from a landfill leachate treatment plant, and the sludge concentration is 2000mg / L. First, the flux J1 of the membrane in pure water is measured to be 9.39m / d 5KPa, and the membrane is calculated by Darcy's law After repeating the sludge filtration test 15 times, the membrane was washed with pure water, and the flux J2 of the membrane in pure water was measured to be 0.57m / d 5KPa. Calculated by Darcy's law, the Membrane resistance R2, the diaphragm is taken out, first soaked in the sodium hypochlorite solution of 600mg / L in terms of available chlorine concentration for 20h, after chemical cleaning, the flux J3 of the diaphragm in pure water is measured to be 1.05m / d 5KPa, passed The membrane resistance R3 of the membrane after chemical cleaning is calculated by Darcy's law, and the test data are shown in Table 7. The recovery rate of membrane chemical cleaning of the membrane is (R2-R3) / (R2-R1)*100%=48.7% . Then soak in 2000mg / L citric acid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com