Control method of lateral thick difference of cold-rolling strip steels

A technology of lateral thickness difference and control method, applied in the direction of rolling force/roll gap control, metal rolling, profile control, etc., can solve the problems of frequent adjustment of feedback control of the end stand, lack of reasonable division of labor, etc., to ensure stability , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] Below is an actual embodiment of the present invention, realizes the lateral thickness difference feed-forward control of incoming strip steel in the first stand of a five-stand tandem cold rolling mill, specifically as follows:

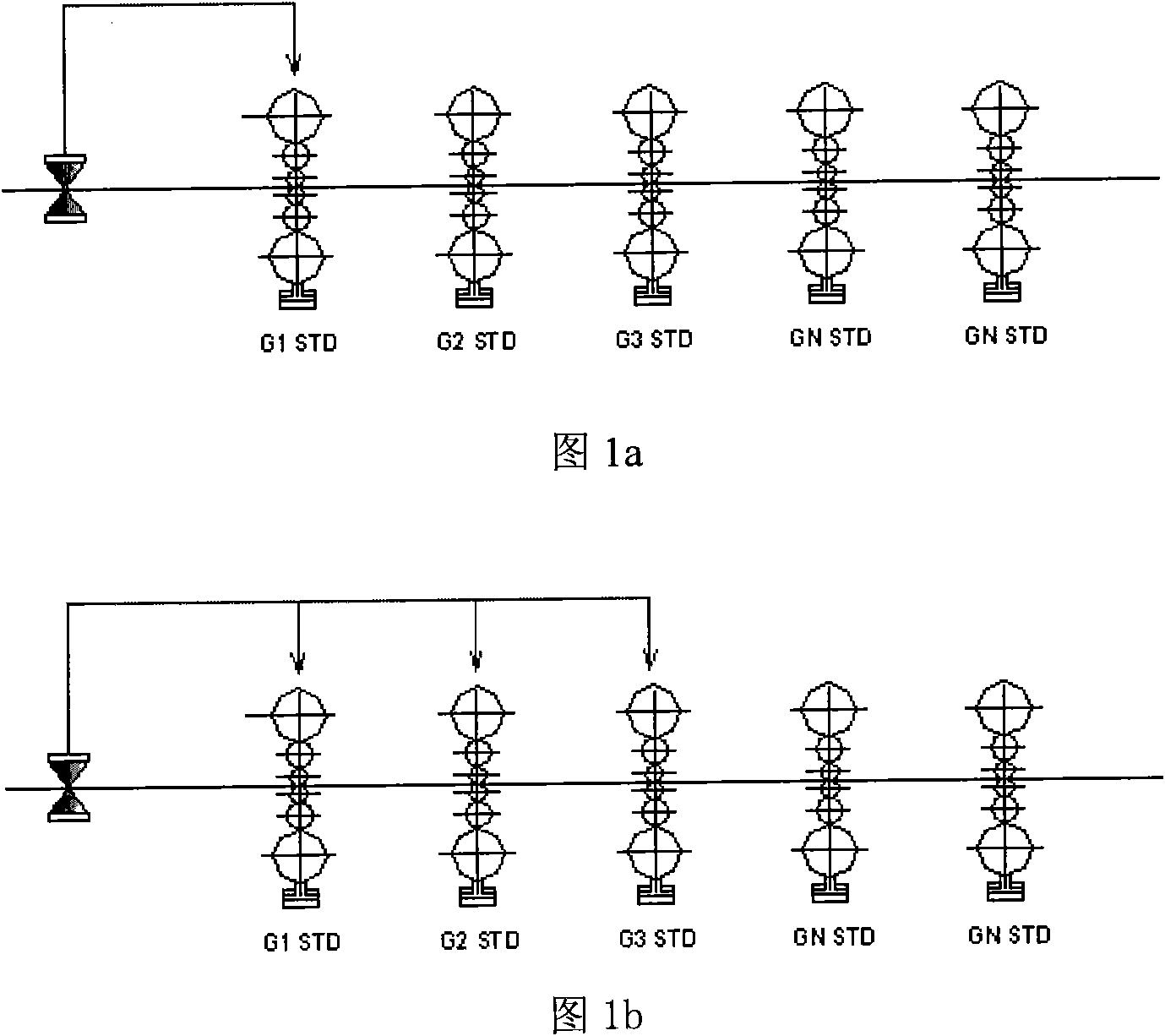

[0107] 1. The hardware configuration scheme of the special measuring instrument for lateral thickness difference

[0108] Arrange a profiler at the entrance of the five-stand cold rolling mill, see Figure 4 .

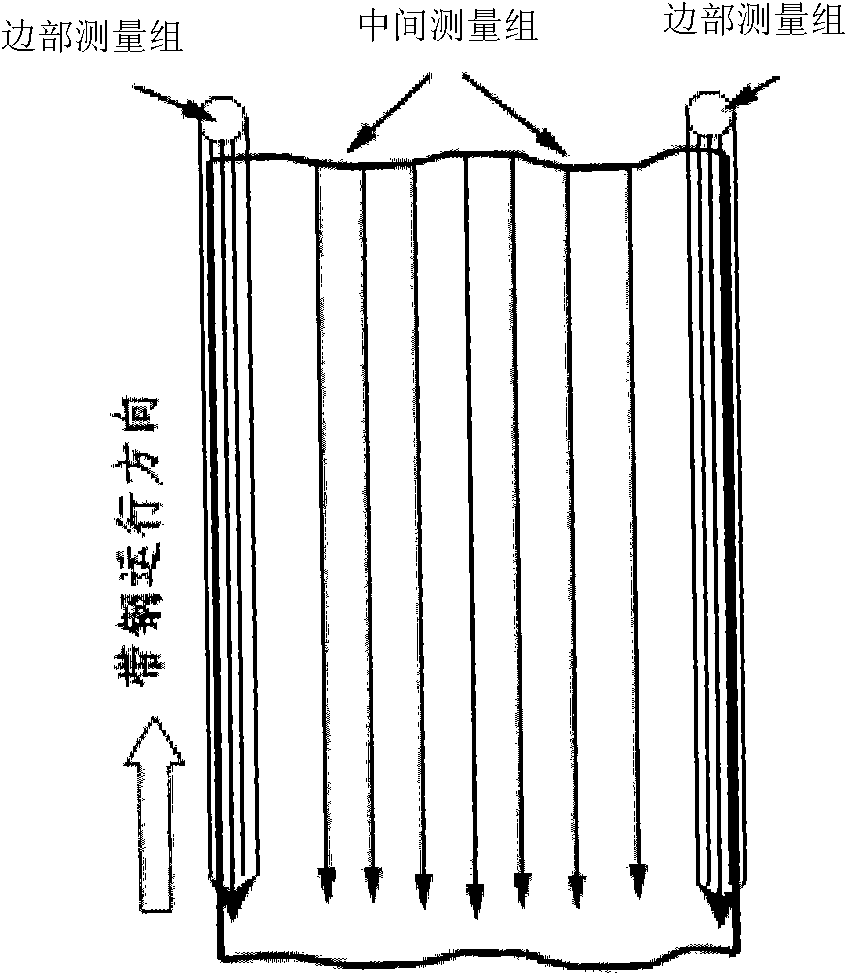

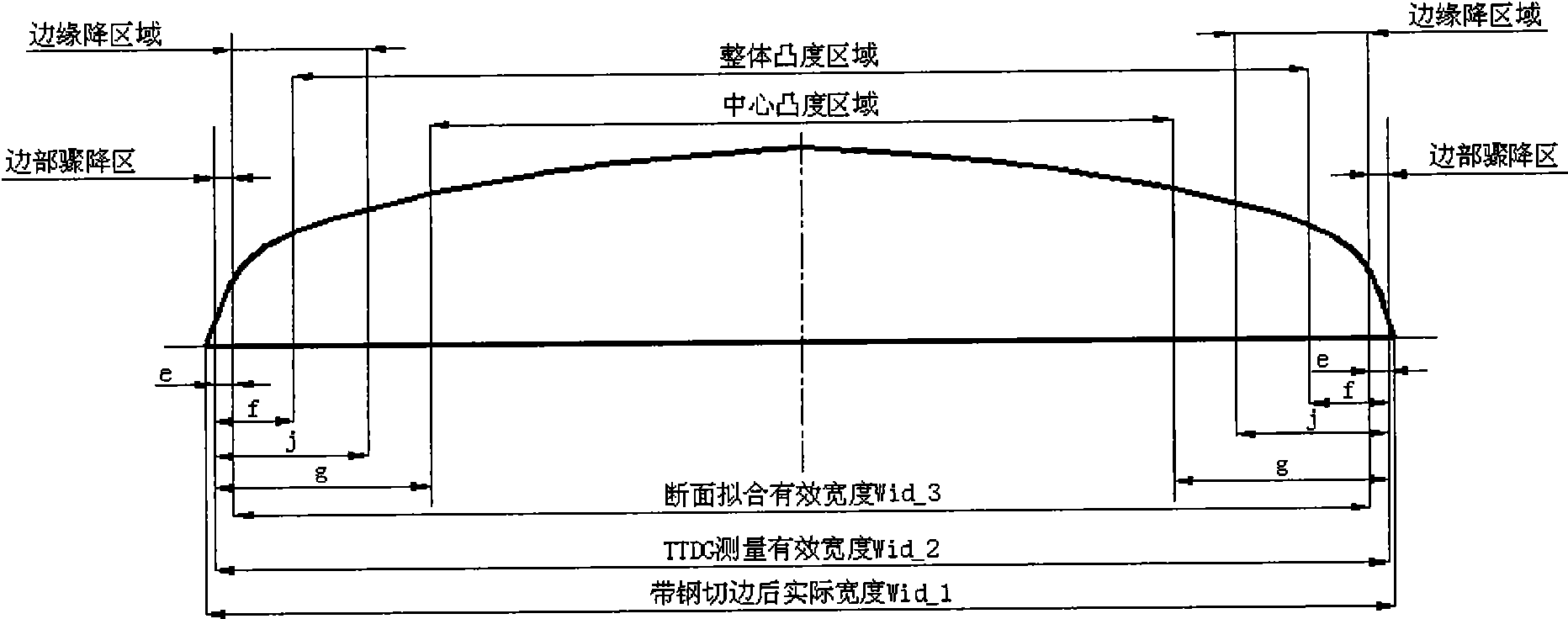

[0109] The distribution of the measurement points of the profiler, the configuration scheme of the proposed measurement points is as follows: (see figure 2 )

[0110] The maximum width of the strip is 1300mm, the measurement distance G of the edge measurement group 1 =15mm (average), number N 1 =15; the measurement distance G of the middle measurement group 2 =80mm, then the number of intermediate measurement points N 2 is calculated as follows:

[0111] The maximum effective measuring width of the strip is B max , where B ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com