Sample preparation method for measuring aluminium electrolysis capacitor electric pole foil microscopic appearance

An aluminum electrolytic capacitor and micro-topography technology, which is applied in the preparation of test samples, instruments, measuring devices, etc., can solve problems such as scientific analysis of difficult micro-morphological parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

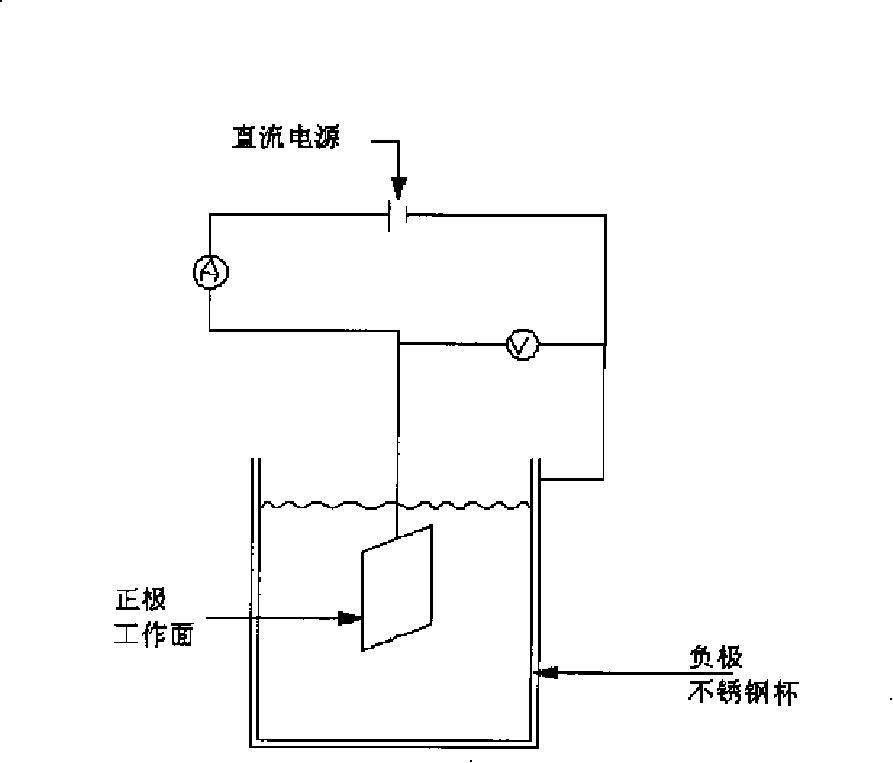

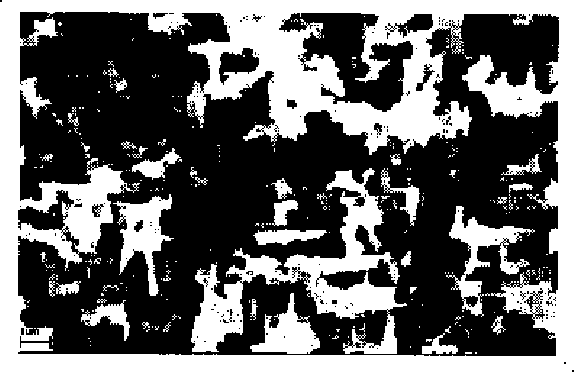

[0024] Embodiment 1, the method for measuring the microscopic appearance of the high-voltage corrosion foil (that is, no foil formed) of the electrode foil for an aluminum electrolytic capacitor: a, sample cutting: the foil is cut into a sample of 4 mm × 8 mm; b, Electropolishing treatment: the electrode foil is placed in the polishing solution, treated at 70°C or 80°C or 85°C or 90°C for 90 seconds or 100 seconds or 150 seconds or 180 seconds, and the current density is 0.1A / cm² or 0.3A / square centimeter or 0.5 A / square centimeter, and clean it with deionized water, dry it, and set it aside. The electrolytic polishing device is as attached figure 1 c. Detection: Place the sample under an electron microscope to take pictures to obtain the required electron microscope photos, and detect the microscopic appearance. Wherein, the electrolytic polishing liquid mainly contains 70% phosphoric acid and 20% chromium trioxide aqueous solution by weight percentage, or the electrolyti...

Embodiment 2

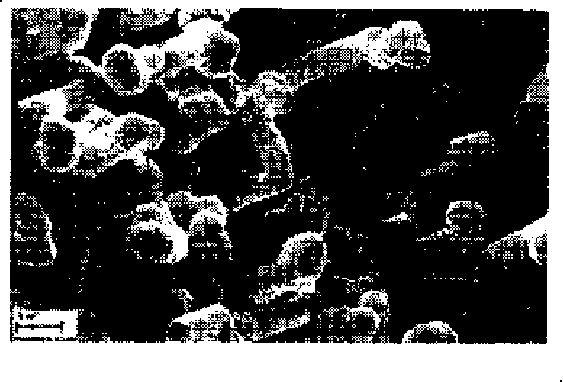

[0025] Example 2, the method for measuring the microscopic appearance of the low-voltage foil of the electrode foil for aluminum electrolytic capacitors: a. Sample cutting: the electrode foil is placed in the electrolytic polishing solution, and the foil is cut into 4mm×8mm sample pieces ; b. Electropolishing treatment: the electrode foil is placed in a polishing solution, and treated at 70°C or 80°C or 85°C or 90°C for 90 seconds or 100 seconds or 150 seconds or 180 seconds, and the current density is 0.1 A / cm2 Or 0.3 A / cm2 or 0.5 A / cm2, and cleaned with deionized water, dried, and set aside; c. Detection: Place the sample under an electron microscope to take pictures to obtain the required electron microscope photos, and detect the microscopic appearance. Wherein, the electrolytic polishing liquid mainly contains 70% phosphoric acid and 20% chromium trioxide aqueous solution by weight percentage, or the electrolytic polishing liquid mainly contains 75% phosphoric acid and 15%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com