Low-temperature matte reaction glaze and production method thereof

A production method and light reaction technology, applied in the field of ceramic glazes, can solve the problems of poor hardness of the glaze surface, resistance to scratching by knives and forks, etc., and achieve the effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

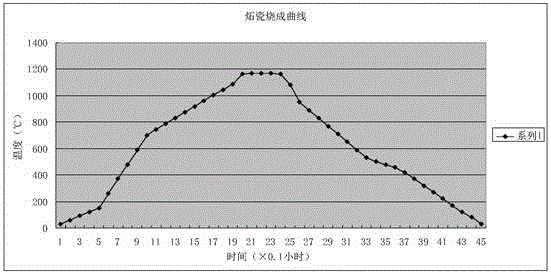

Image

Examples

Embodiment 1

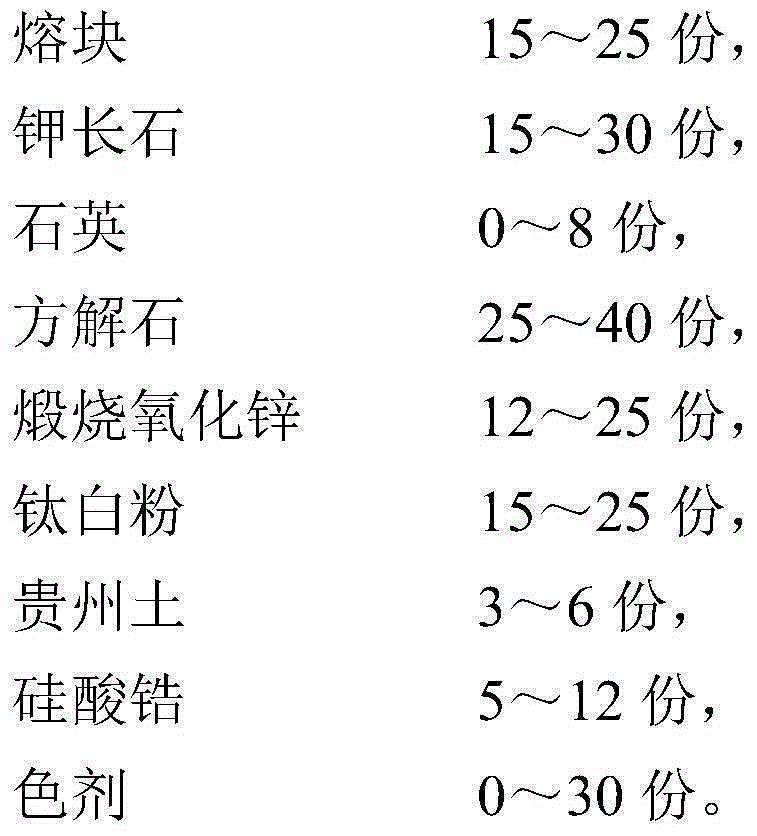

[0026] The low-temperature matt reactive glaze provided by the invention is composed of the following raw materials in proportions by weight:

[0027]

[0028] Wherein, the above proportions are all calculated by weight of dry material. The frit is in the form of fine particles, mainly composed of oxides of eight elements including potassium, sodium, calcium, boron, magnesium, silicon, aluminum and zinc, and does not contain harmful elements such as lead and cadmium. The potassium feldspar is in the form of dry powder, which is obtained from natural potassium feldspar ore through rough grinding and fine processing, and comes from Pingjiang County, Hunan Province. The quartz, produced in Liling, fine sand, SiO 2 Content ≥ 98%, water content 1-8%. The calcite is produced in Guangxi, and the CaO content is ≥ 53%. The calcined zinc oxide is produced in Zhuzhou, Hunan, and is in powder form with a slight yellow tone. TiO in the titanium dioxide 2 Content ≥ 90%. The Guizhou...

Embodiment 2

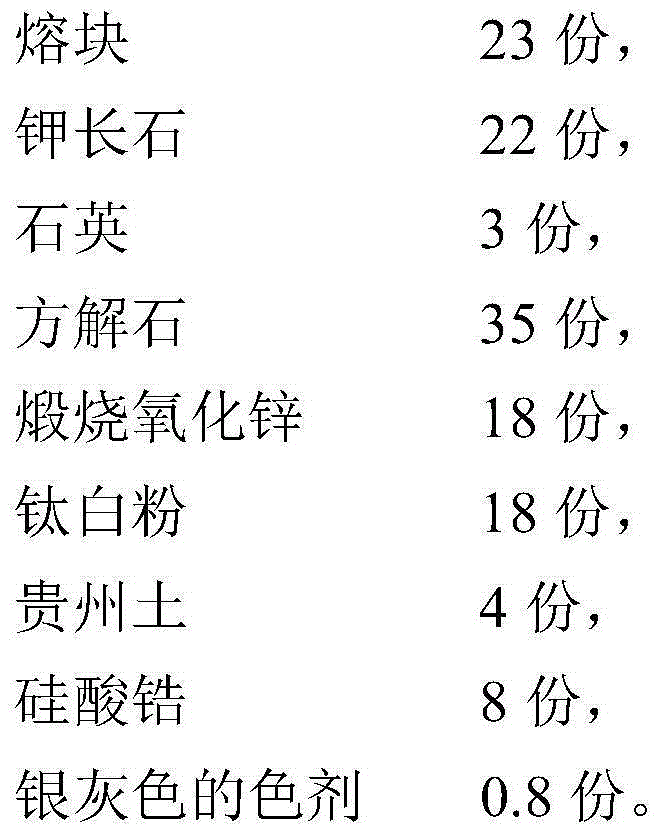

[0035] The low-temperature matt reactive glaze provided by the invention is composed of the following raw materials in proportions by weight:

[0036]

[0037] Wherein, the above proportions are all calculated by weight of dry material. The frit is in the form of fine particles, mainly composed of oxides of eight elements including potassium, sodium, calcium, boron, magnesium, silicon, aluminum and zinc, and does not contain harmful elements such as lead and cadmium. The potassium feldspar is in the form of dry powder, which is obtained from natural potassium feldspar ore through rough grinding and fine processing, and comes from Pingjiang County, Hunan Province. The calcite is produced in Guangxi, and the CaO content is ≥ 53%. The calcined zinc oxide is produced in Zhuzhou, Hunan, and is in powder form with a slight yellow tone. TiO in the titanium dioxide 2 Content ≥ 90%. The Guizhou soil is produced from kaolin in Guizhou, Al 2 o 3 Content ≥ 35%. The zirconium sil...

Embodiment 3

[0044] The low-temperature matt reactive glaze provided by the invention is composed of the following raw materials in proportions by weight:

[0045]

[0046]

[0047] Wherein, the above proportions are all calculated by weight of dry material. The frit is in the form of fine particles, mainly composed of oxides of eight elements including potassium, sodium, calcium, boron, magnesium, silicon, aluminum and zinc, and does not contain harmful elements such as lead and cadmium. The potassium feldspar is in the form of dry powder, which is obtained from natural potassium feldspar ore through rough grinding and fine processing, and comes from Pingjiang County, Hunan Province. The quartz, produced in Liling, fine sand, SiO 2 Content ≥ 98%, water content 1-8%. The calcite is produced in Guangxi, and the CaO content is ≥ 53%. The calcined zinc oxide is produced in Zhuzhou, Hunan, and is in powder form with a slight yellow tone. TiO in the titanium dioxide 2 Content ≥ 90%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com