Composite elastic filament core-spun yarn fabric and preparation method thereof

A technology of elastic filament and silk wrap, applied in the direction of fabric, filament/thread forming, yarn, etc., can solve the problems of poor tolerance, loss of elasticity, poor weather resistance of spandex fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A composite elastic filament core-spun yarn fabric, the preparation steps of which are as follows:

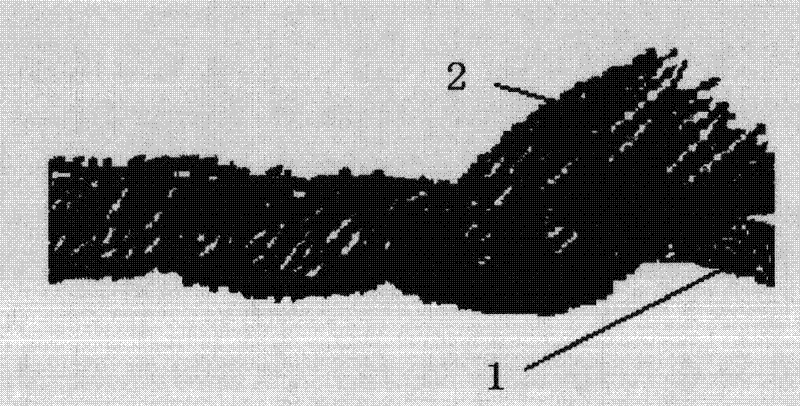

[0037] A. Core-spun yarn spinning: 50dtex / 24f PTT / PET parallel composite elastic filaments are introduced into the front roller of the spinning frame, and the weight ratio of PTT:PET in the PTT / PET parallel composite elastic filaments is 50:50, and PTT / PET is parallel The cross-section of the composite elastic filament is racetrack-shaped. The long-staple cotton is used as the outsourcing fiber, and the roving is introduced from the drafting device of the spinning frame, meets the elastic filament at the front roller, and is twisted to form a core-spun yarn.

[0038] At the front roller of the ordinary spinning frame, the positioning device controls the elastic filament to be located in the center of the twisting triangle to achieve the most uniform cotton fiber covering; the PTT / PET side-by-side composite elastic filament controls the initial tension through a tension c...

Embodiment 2

[0046] A composite elastic filament core-spun yarn fabric, the preparation steps of which are the same as in Example 1 except for the following differences.

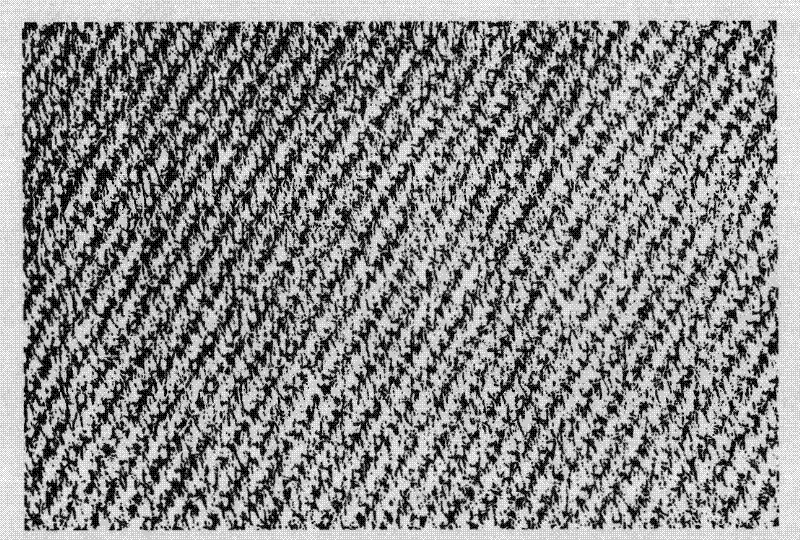

[0047] The warp is wool / polyester 70 / 3090Nm / 2. Single yarn twist is 820 twists / m, Z direction, ply twist is 1000 twists / m, S direction. The weft yarn is 50dt / 36f PET / PTT side-by-side composite elastic filaments (the weight ratio of PET:PTT is 60:40) outsourcing combed wool slivers to form 90Nm elastic core-spun yarn, and then plying into strands. The cross-section of the PTT / PET side-by-side composite elastic filaments is flat. In the core-spun yarn, the weight ratio of PTT / PET side-by-side composite elastic filaments to wool fibers is 45:55. Single yarn twist is 820 twists / m, Z direction, ply twist is 1000 twists / m, S direction. In order to prevent the yarn from kinking under the action of untwisting torque, the yarn was steamed at 75°C for 30 minutes and cooled for 5 minutes. No. 139 reed is used for weaving, with ...

Embodiment 3

[0050] A composite elastic filament core-spun yarn fabric, the preparation steps of which are the same as in Example 1 except for the following differences.

[0051] Warp yarn is long-staple cotton 40S / 2 yarn. Single yarn twist: 900 twists / m, Z direction, ply twist: 880 twists / m, S direction. The weft yarn is 40dt / 36f PET / PTT side-by-side composite elastic filaments, in which the weight ratio of PET:PTT is 40:10, which is wrapped with combed long-staple cotton to form 40S elastic core-spun yarn, and then plied into strands. The cross-section of the PTT / PET side-by-side composite elastic filaments is flat. In the core-spun yarn, the weight ratio of PTT / PET side-by-side composite elastic filaments to cotton fibers is 30:70. Single yarn twist is 850 twists / m, Z direction, ply twist is 880 twists / m, S direction. In order to prevent the yarn from twisting under the action of untwisting torque, the yarn was steamed at 70°C for 20 minutes and cooled for 5 minutes. No. 130 reed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com