Nanometer fiber filter material and preparation method thereof

A nanofiber, filter material technology, applied in the field of nanofiber filter material and its preparation, can solve problems such as damage to the body and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

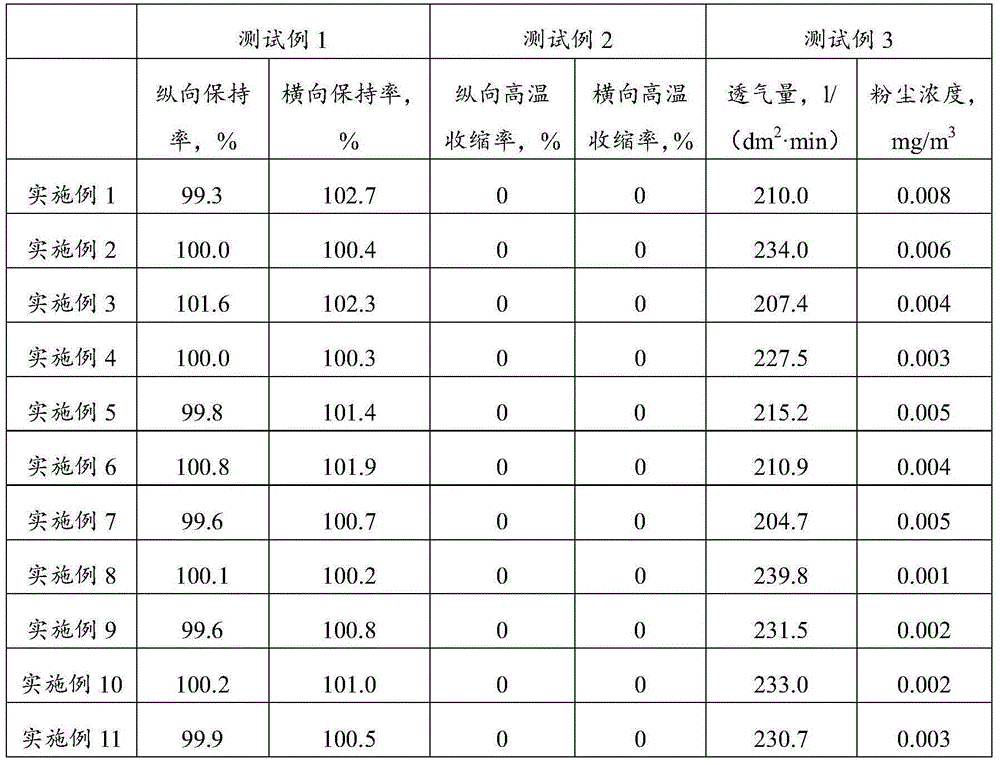

Examples

Embodiment 1

[0033]Use PSA fiber as the surface fiber material, put it into the mixing box, open it through the opener and feed it into the carding machine. The fiber web obtained after full carding is passed through the cross-winding equipment, so that the short fiber web is transformed into a cross-laminated multi-layer fiber layer, and 120gsm100% PTFE base cloth is placed in the two layers of the above-mentioned multi-layer fiber layer, and the above structure is processed by Qingdao Textile After pre-punching and strengthening with the machine needle loom, the pre-punching structure is double-sided needling according to the main needling density of 750 needles / min to obtain a 550gsm filter substrate. After the above-mentioned filter felt is singed, it is cut into rolls with a width of 55 cm according to the designed width. Dissolve polyphenylsulfone terephthalamide in DMAC solvent at a concentration of 50%, and add the solute into the electrospinning device after the solute is complete...

Embodiment 2

[0035] Using glass fiber filament spinning, according to the weight of 350gsm, according to the design width of 55cm, weave glass fiber woven fabric with twill weave as the filter substrate, and install it on the electrospinning equipment. Dissolve polyphenylsulfone terephthalamide in DMAC solvent with a concentration of 50%. After the solute is completely dissolved, add it to the electrospinning equipment. According to the weight of 5gsm, open 6 spinning nozzles at a speed of 0.43m / min After the nanofiber layer is formed on the glass fiber woven fabric filter substrate, the nanofiber layer is closely combined with the filter substrate through a hot rolling process to form the filter material of Example 2.

Embodiment 3

[0037] Using 2D×51mm PSA fiber, through opening, carding, drawing, roving, spun yarn, plying and other conventional spinning processes, processed into 18s / 3 yarn, using 1.5D×51mm PSA fiber, through opening, carding, Conventional spinning processes such as drawing, roving, spun yarn, and plying are processed into yarns of 40s / 2. The above yarns are woven into sulfonamide woven fabrics with double-layer fabrics according to the design width of 55cm and weight of 350gsm. The filter substrate, one of which is woven with 40s / 2 yarn, is a nanofiber composite layer, and one layer is woven with 18s / 3 yarn, which is a strong support layer. The filter substrate was mounted on an electrospinning device. Dissolve polyphenylsulfone terephthalamide in DMAC solvent with a concentration of 20%. After the solute is completely dissolved, add it to the electrospinning equipment. According to the weight of 10gsm, open 8 spinning nozzles at a speed of 0.3m / min , after forming a nanofiber layer on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com