High-temperature and high-pressure water vapor environment structural material testing device

A test device, high temperature and high pressure technology, applied in the direction of measuring device, analyzing materials, testing wear resistance, etc., can solve problems such as inability to test and evaluate pipe samples, unsolved stress corrosion, and stress corrosion of steam generator heat exchange tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

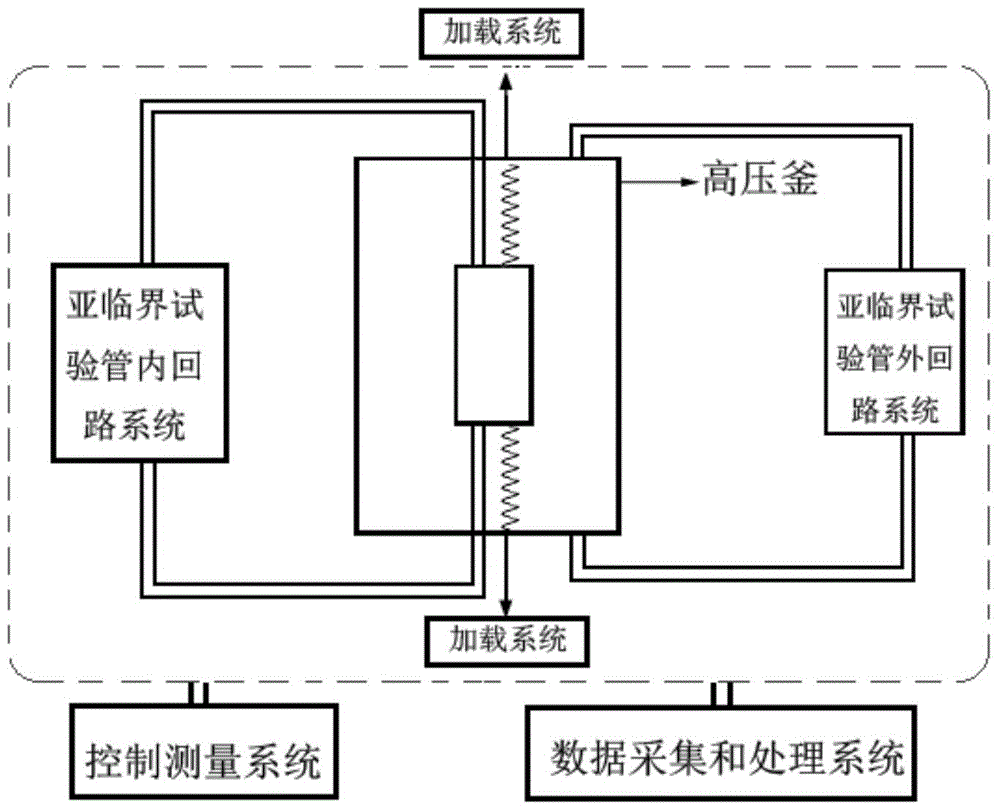

[0011] The test device has a pipe with high-temperature water flowing inside and outside. The test device includes an autoclave, a test tube inner loop system, a test tube outer loop system, a tube sample loading system, a control measurement system, and a data acquisition and processing system. The system is connected to the inside of the test sample tube to form a high-temperature and high-pressure water environment inside the test tube; the test tube external loop system is connected to the inside of the autoclave to form a high-temperature and high-pressure water environment outside the test tube in the autoclave; the test tube loading system It is used to complete the static and dynamic loading (constant load, slow stretching and low frequency fatigue loading) of the tubular sample in the high temperature and high pressure water vapor environment; the control measurement system is used for the autoclave loading system, the test tube inner loop system and the test tube outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com