Fuel management method of pressurized water reactor core formed by 177 fuel assemblies

A fuel assembly and fuel management technology, which is applied in the field of fuel management of pressurized water reactor cores, can solve problems such as failure to quickly realize long-term refueling of power plants, and failure to improve the availability of power plants. Utilization and load factor, smooth process, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

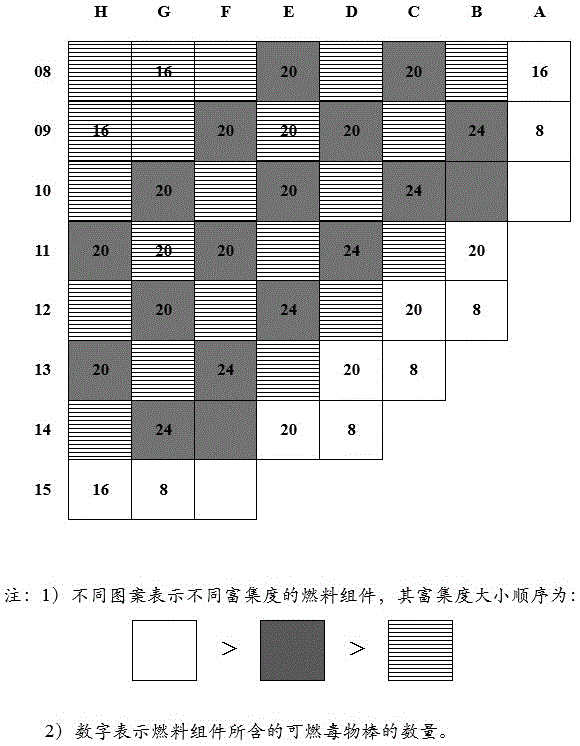

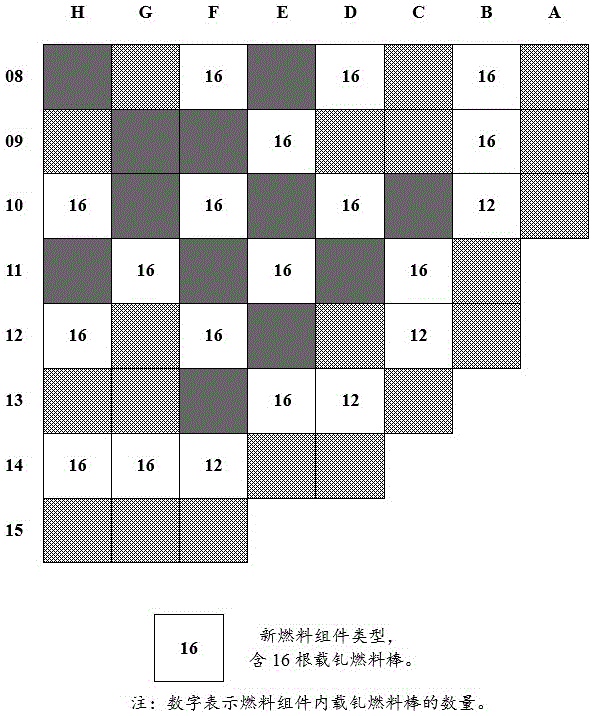

[0030] This embodiment is aimed at a reactor core of a mega-kilowatt nuclear power plant, and the core is composed of 177 fuel assemblies. For the fuel management of a complete nuclear power plant core, the core loading mode of a series of core fuel cycles from the first cycle to the balance cycle should be determined in an overall manner according to the established objectives and given core parameter constraints or guidelines, and Perform relevant neutron physics calculations. The specific content covers: the determination of the enrichment degree of several different fuels used in the first cycle, the determination of the enrichment degree of the new fuel assembly in the subsequent cycle, the selection of the solid burnable poison type in each cycle, and the arrangement of the core fuel assembly and the solid burnable poison and optimization, preliminary safety evaluation, etc.

[0031] For the loading of the first cycle core, three different fuel assemblies with a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com