Scintillation element, scintillation array and method for producing the same

A scintillation array and element technology, applied in the field of scintillation elements and scintillation arrays, can solve the problems of high duration, long reconstruction image, etc., and achieve the effects of increasing light output, reducing afterglow, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

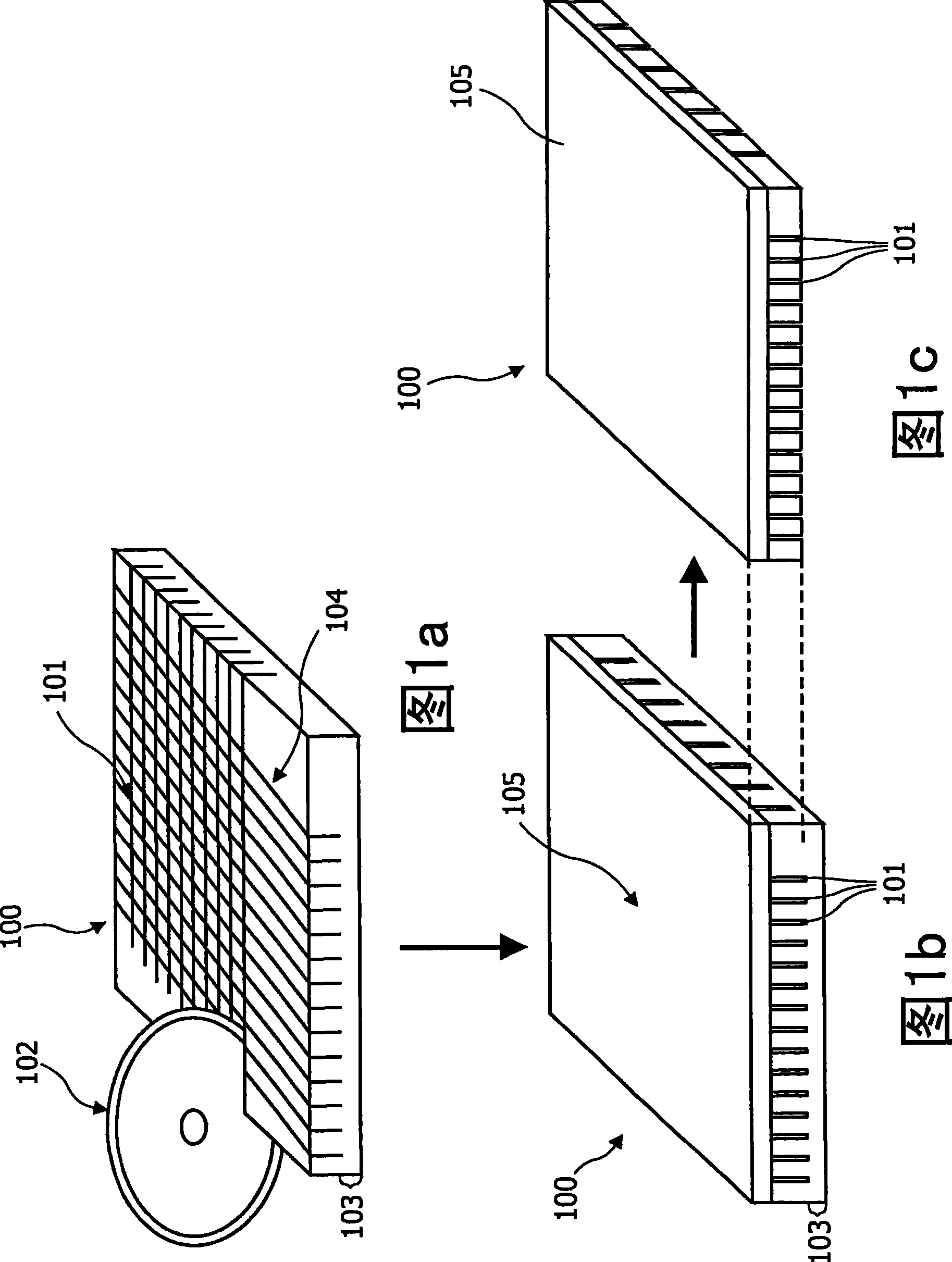

[0045] Figure 1 schematically shows the scintillation array, specifically the structured and coated Gd 2 o 2 Preparation method of S(GOS) scintillation array. GOS powder is used as raw material, which is preferably doped with praseodymium (Pr) and cerium (Ce). Then, lithium fluoride (LiF) is added in a small amount, eg at a relatively low concentration. Typically, Gd 2 o 2 The Pr concentration in S is in the range of 100-2000 wtppm of GOS (most preferably between 500-1000 wtppm), while the Ce concentration is based on Gd 2 o 2 S is between 0.1-100 ppm by weight and is selected according to the Eu content of GOS, which is most preferably based on Gd 2 o 2 S is 1 weight ppm or less. The flux LiF has a Gd based 2 o 2 S is at a concentration of 0.001-1 wt.%, most preferably 0.02 wt.%. when Ce 3+ With the addition of cerium to compensate for the effect of europium and the addition of Pr as an ion associated with the scintillation process, LiF is added as a sintering aid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com