Wet metallurgical method with comprehensive reclamation, basically no three wastes and zero discharge

A hydrometallurgy and zero-emission technology, applied in the direction of process efficiency improvement, etc., can solve the problems of not paying attention to, maintaining and managing the responsibility and concept of the earth, and the concept of less investment, so as to achieve large profits, realize circular economy, and reduce costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0041] Example two stibnite

[0042] 3 kg of stibnite, crushed to ≥80 mesh, the main element content of the raw material is shown in Table 4.

[0043] Table 4 Composition and content of stibnite

[0044] name

Sb

S

Fe

SiO 2

Pb

Bi

Zn

Cu

As

Au

content(%)

15.0

18.1

15.98

35.2

3.1

0.8

1.5

1.2

0.01

2.5g / t

[0045] Raw material 3kg was leached in 3 times, 1kg for each leaching, the first raw material was added with 0.3L of water, and 1:1 HCl was added to keep the remaining acidity of the solution at ≥ 1mol / L; add NH 4 Cl 10g, reaction temperature 50-70°C, reaction 4h. After the leaching of the first raw material is completed, filter and wash, use 0.3L of the leaching liquid and washing liquid for the leaching of the second 1kg raw material, add 1:1 HCl to keep the remaining acidity of the solution at ≥ 1mol / L; add NH 4 The amount of Cl is such that the NH in the solut...

Embodiment 3

[0056] Embodiment three copper ore

[0057] 10kg of copper ore, grind to ≥80 mesh, the main element content of the raw material is shown in Table 7.

[0058] Table 7 Composition and content of copper ore

[0059] name

Cu

SiO 2

Fe

Pb

Zn

co

Ni

Al

Ca

content(%)

0.51

45.20

18.10

0.2

0.4

0.01

0.1

5.10

3.10

name

Mg

Mo

WO 3

sn

Bi

Ag

Au

S

content(%)

1.50

0.01

0.05

0.04

0.05

1.5g / t

0.3g / t

1.5

[0060] Leaching method and result:

[0061] The raw material is divided into 10 parts, each 1kg.

[0062] Each part of raw material is stirred and leached in a closed reaction vessel. Add 2dm to the 1st ingredient 3 Water, subsequent raw materials are recycled using the leachate, so only when less than 2dm of the leachate is returned 3 When, just add water to supplement; Add the concentrated ...

example 4

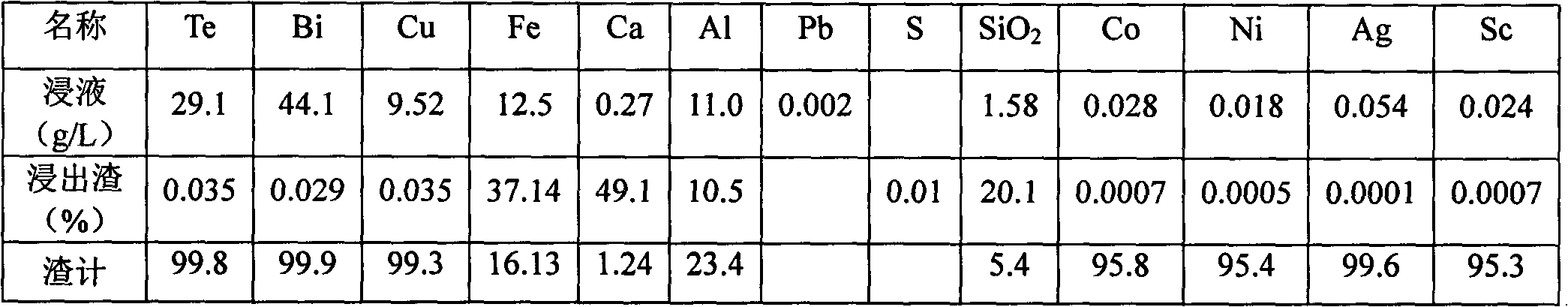

[0074] Example four molybdenum nickel ore

[0075] 400g of nickel-molybdenum ore, crushed to ≥300 mesh, the main components in the raw material are shown in Table 9.

[0076] Table 9 Molybdenum nickel ore composition and content

[0077]

[0078] The raw material is divided into 4 parts for acid oxidation leaching, each part is 100g, and the liquid-solid ratio is 2:1. When the first raw material is leached, the leaching solution is 200ml water, 50g concentrated H 2 SO 4 , add 1gNH 4 Cl as complexing agent, adding NaClO 3 40g as oxidizing agent. When the last 3 raw materials are leached, the leaching solution is used for recycling. When the volume of the leaching solution used for recycling is less than 200ml, water is added. According to the last leaching consumption of H 2 SO 4 amount, add concentrated H accordingly 2 SO 4 , making the solution concentrated in H 2 SO 4 The amount is 50% of raw material weight; Test condition and result are as shown in table 10. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com