Sludge chemical conditioning deep dewatering method

A technology of deep dehydration and chemical conditioning, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing sludge subsequent transportation costs, sludge disposal costs, inability to use compost, land Use and landscaping, sludge pH value changes and other problems, to achieve the effect of safe and convenient dosing method, low dosage of chemicals, and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

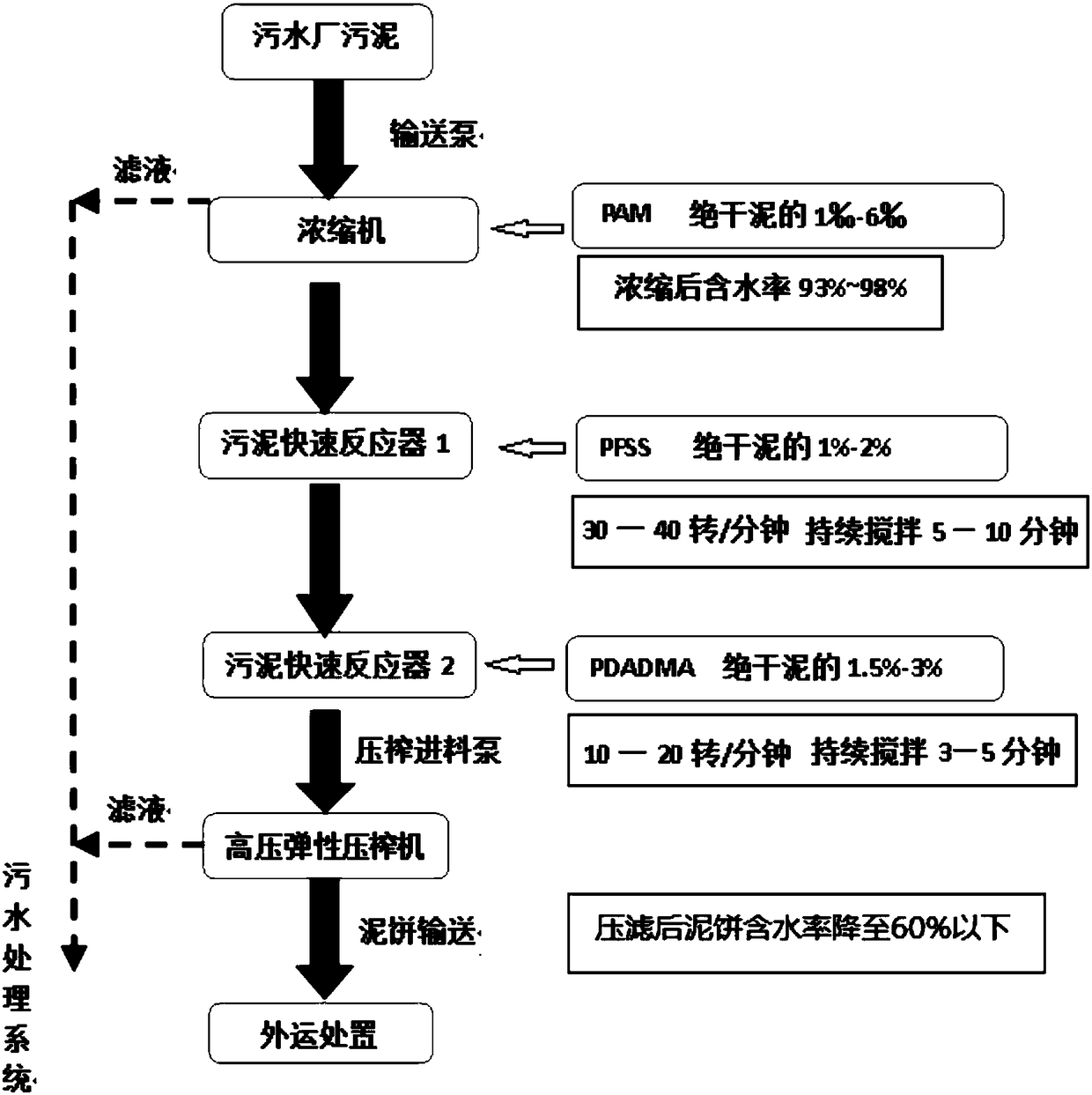

[0049] A large urban sewage plant in Shenzhen actually treats about 350,000 tons of sewage per day, and produces 54 tons of dry sludge (secondary sedimentation tank sludge) with a moisture content of 99.0%. The sludge is pumped into the thickener with a delivery pump, and polyacrylamide (PAM) is added according to 0.3% of the absolute dry sludge amount, and the sludge is concentrated. The moisture content of the sludge after concentration treatment is 95.6%. First, pump the concentrated sludge into the sludge fast reactor 1, add PFSS according to 1.5% of the sludge dry basis (that is, the amount of absolute dry sludge), and mix and stir for 5 minutes at a speed of 40r / min. Carry out a conditioning; then pump the sludge after the first conditioning into the sludge fast reactor 2, add PDADMA according to 2% of the dry basis of the sludge, mix and stir for 5 minutes at a speed of 10r / min, and perform a second conditioning ; After that, pump the sludge after secondary conditioning...

Embodiment 2

[0051] A large urban sewage plant in Zhangzhou actually treats about 130,000 tons of sewage per day, and produces 48 tons of dry sludge (secondary sedimentation tank sludge) with a moisture content of 98.0%. The sludge is pumped into the thickener with a delivery pump, and polyacrylamide (PAM) is added according to 0.1% of the absolute dry sludge amount, and the sludge is concentrated. The moisture content of the sludge after concentration treatment is 95.4%. First, pump the concentrated sludge into sludge fast reactor 1 with a transfer pump, add PFSS according to 1% of the sludge dry basis (that is, the amount of absolute dry sludge), and stir for 10 minutes at a speed of 30r / min. Carry out a conditioner; then pump the sludge after the first conditioner into the sludge fast reactor 2, add PDADMA at 1.5% of the dry basis of the sludge, stir for 3 minutes at a speed of 20r / min, and perform a second conditioner ; After that, pump the sludge after secondary conditioning into an u...

Embodiment 3

[0053] A large urban sewage plant in Qinhuangdao actually treats about 100,000 tons of sewage per day, and produces 60 tons of dry sludge (secondary sedimentation tank sludge) with a water content of 99.9%. The sludge is pumped into the thickener with a delivery pump, and polyacrylamide (PAM) is added according to 0.6% of the absolute dry sludge amount, and the sludge is concentrated. The moisture content of the sludge after concentration treatment is 96.3%. First, pump the concentrated sludge into sludge fast reactor 1 with a transfer pump, add PFSS at 2% of the sludge dry basis (that is, the amount of absolute dry sludge), mix and stir at 40r / min for 10min, and carry out Primary conditioning; then pump the sludge after primary conditioning into sludge fast reactor 2, add PDADMA according to 3% of the dry basis of sludge, stir for 5 minutes at a speed of 20r / min, and perform secondary conditioning; Afterwards, pump the sludge after secondary conditioning into the diaphragm pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com