Patents

Literature

42results about How to "Low technical transformation cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

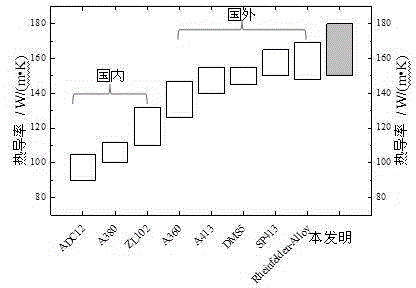

High-strength cast aluminium-silicon alloy reinforced via cryogenic treatment, and preparation method thereof

InactiveCN106498245AImprove solubilityAdvantages of mechanical propertiesSolubilitySolution treatment

The invention discloses a high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment, and a preparation method thereof, and belongs to the technical field of aluminium-silicon alloy. The invention also discloses chemical composition of the high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment. The preparation method comprises steps of chemical composition controlling, melting process controlling, casting technology controlling, and cryogenic treatment. The step of cryogenic treatment comprises following steps: solution treatment is carried out for 5 to 6h at 470 to 490 DEG C, and then quenching in hot water of 60 to 90 DEG C is carried out; cryogenic thermal insulation is carried out for 24h at -145 to -165 DEG C, and the temperature of an obtained product is increased to room temperature in the air; aging treatment is carried out for 5 to 6h at 170 to 180 DEG C, and the processed product is cooled to room temperature in the air so as to obtain the high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment. According to the preparation method, cryogenic treatment is capable of increasing solubility of alloy elements in cast aluminium-silicon alloy greatly, and more fine strengthening phases are formed by a plurality of added alloy elements, so that the mechanical properties of the high-strength cast aluminium-silicon alloy are much better than that of other cast aluminium-silicon alloy.

Owner:NANJING LONGHAO NEW MATERIAL TECH CO LTD

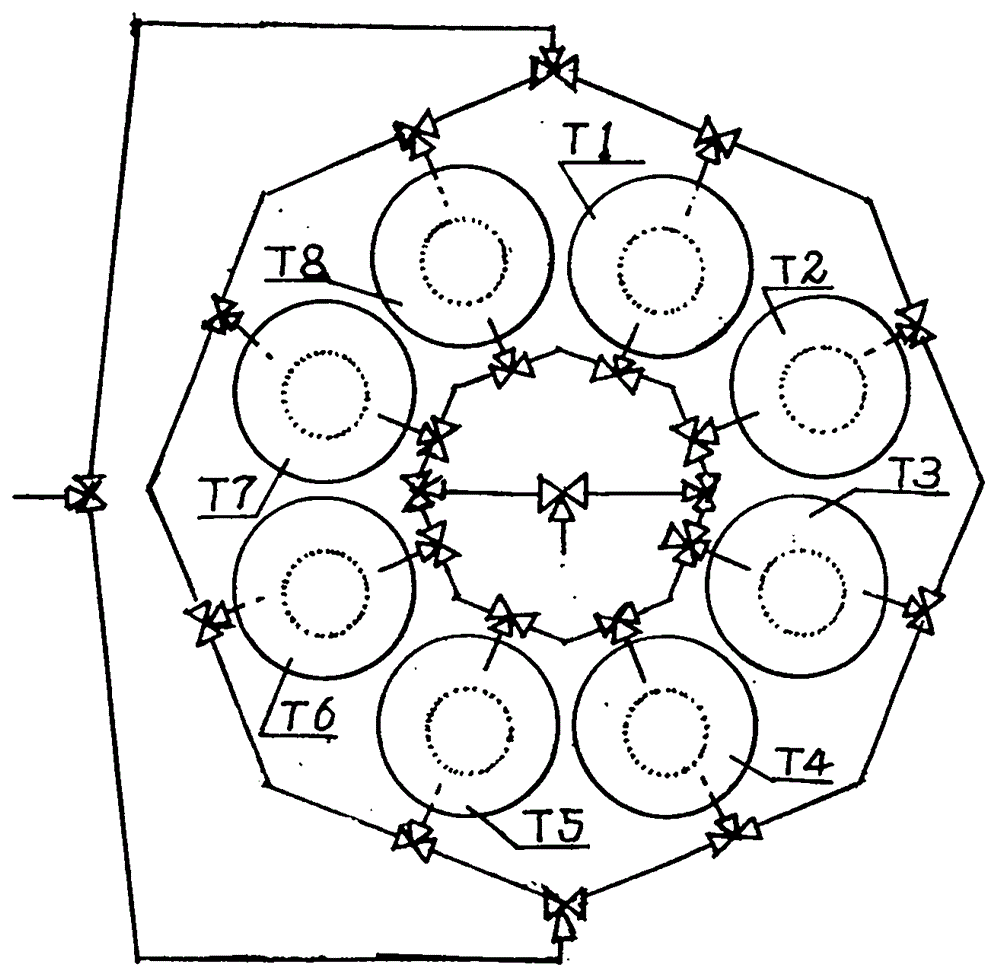

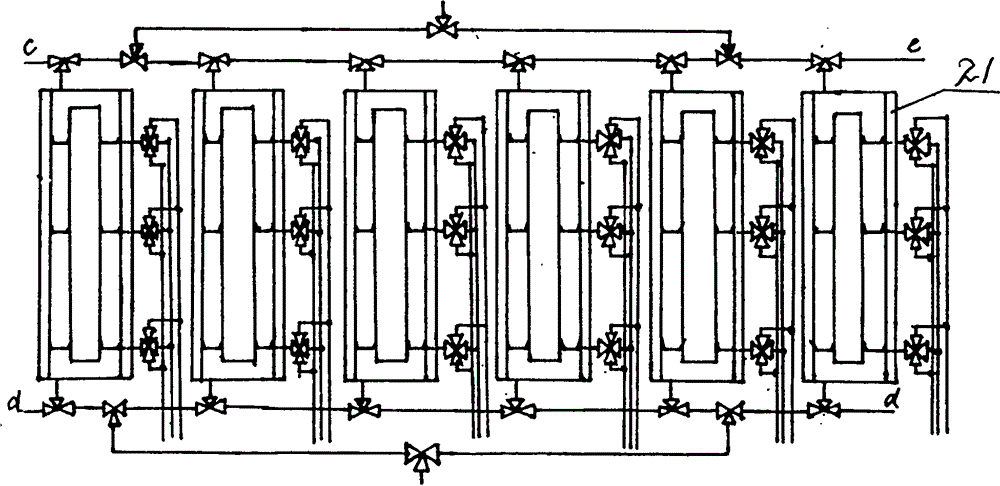

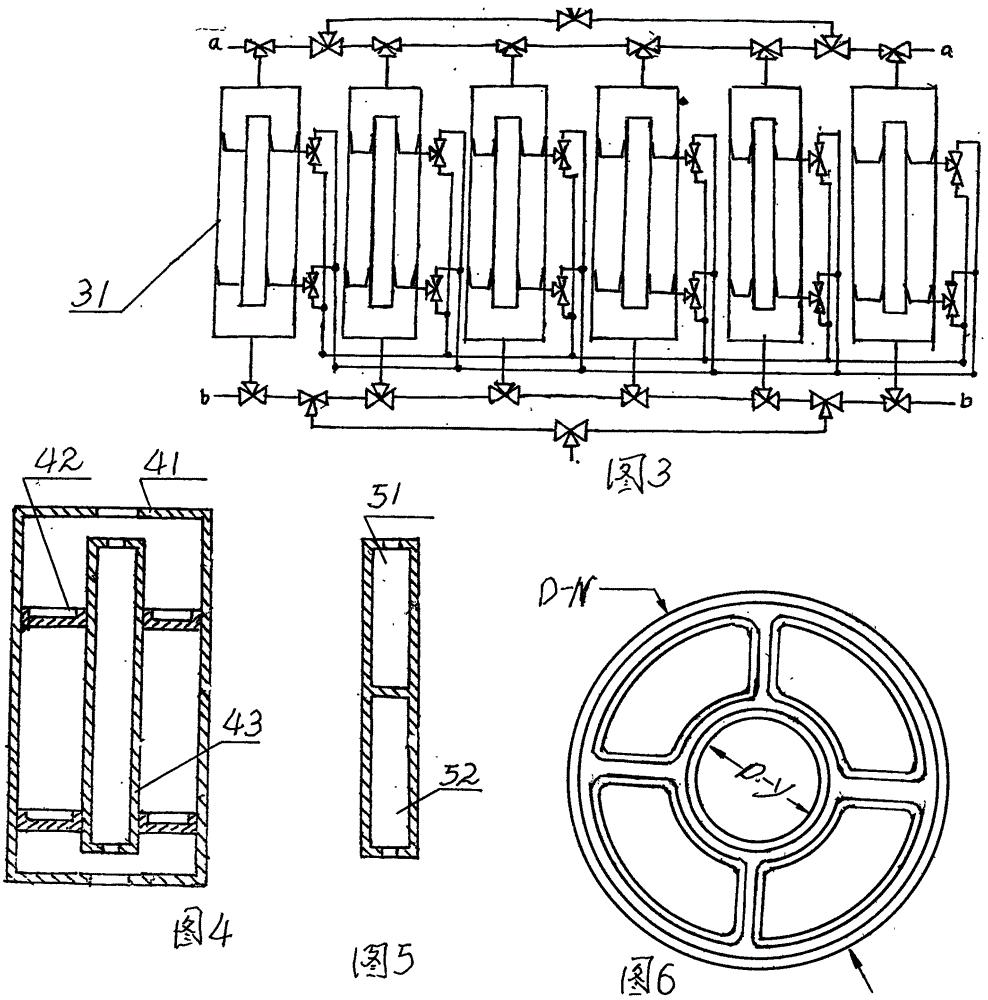

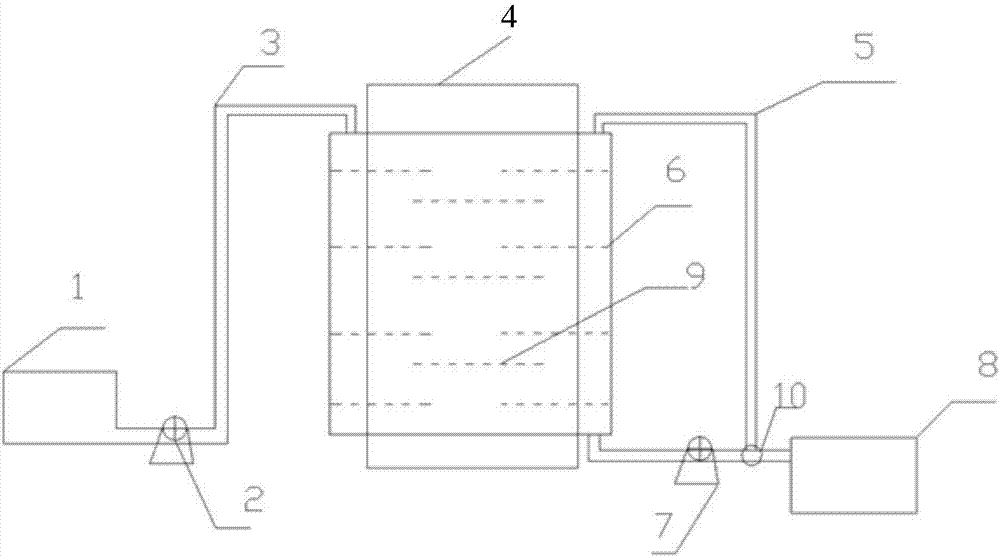

Mixed gas separation, mass storage, pressure rise and energy storage device and method and utility system

ActiveCN105299945AGuaranteed uptimeReduce emergency start timeCompression machinesSteam engine plantsBiomassMixed gas

The invention belongs to the field of energy storage, and discloses a mixed gas separation, mass storage, pressure rise and energy storage device and a method and a utility system, and a heat exchange pressure equalizer. The separation of mixed gas, the pressure rise, the energy storage, the heat exchange and the conversion of gas and liquid are finished in one device, so that the equipment is simplified, the efficiency is improved, and the heat energy is reduced; the cold energy is lost; the energy storage and the energy release can be separately or synchronously performed, so that the emission of carbon dioxide is reduced; and a nitrogen oxide, a sulfur oxide, heavy metal [pm 2.5] and the like are collected for storage and utilization to change harmful substances to useful substances. The invention discloses a gas (air and smoke) condensation, separation and energy storage power station, a wind-electricity plant air separation and energy storage power station, a photovoltaic power generation plant air separation and energy storage power station, a solar heat power air energy storage power station, a wind-electricity solar heat power complementary air energy storage power station, a nuclear power air separation and energy storage power station, a ire coal combustion biomass power generation plane smoke separation and energy storage power station, a gas power generation smoke separation and energy storage power station and an industrial kiln smoke separation and energy storage power station.

Owner:江洪泽

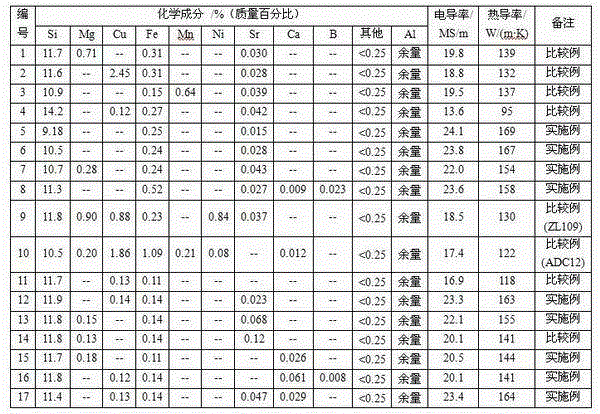

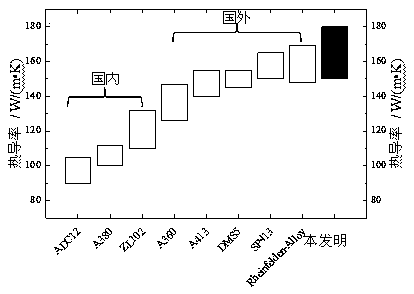

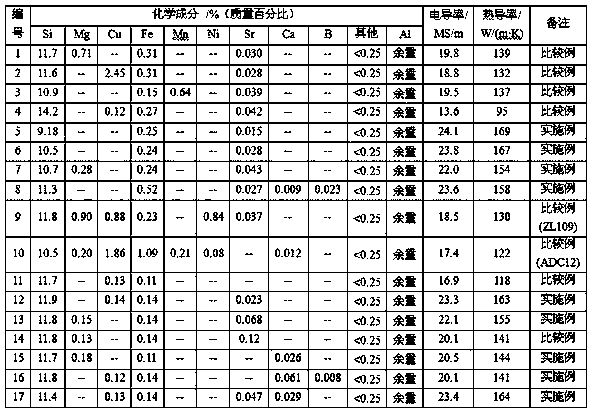

Near co-crystallizing type cast aluminum silicon alloy material with high heat conductivity and production method thereof

The invention relates to a near co-crystallizing type casting aluminum silicon alloy material with high heat conductivity and a production method thereof. The alloy comprises the main components including Al and Si, and is characterized by also comprising at least one of Sr, Ca and B. During casting production, the temperature of a melt is maintained within a range of 600-850 DEG C, and the alloy melt is cast into a casting mould so as to be cast into a casting; when the casting product is subjected to heat treatment, the temperature rising velocity of the heat treatment process is lower than 20 DEG C / min, and the temperature is maintained to be 100-450 DEG C and maintained for 0.5-10 hours, and then, the casting is cooled or air-cooled along with a furnace.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

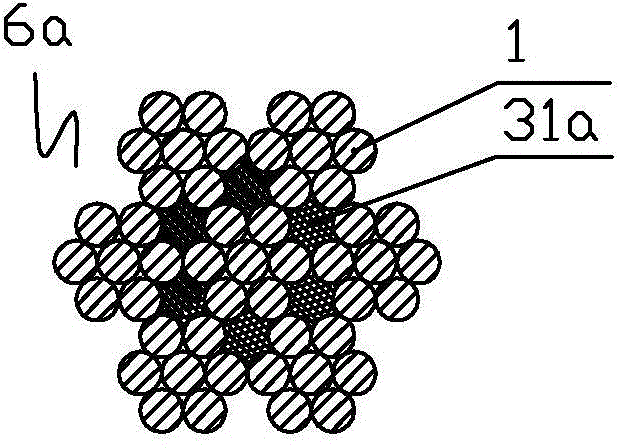

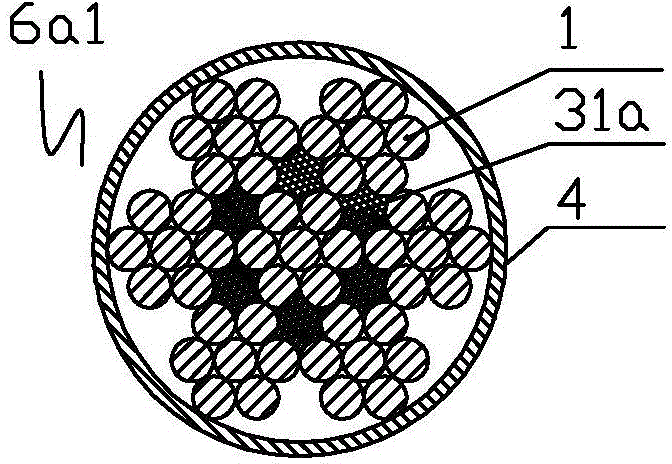

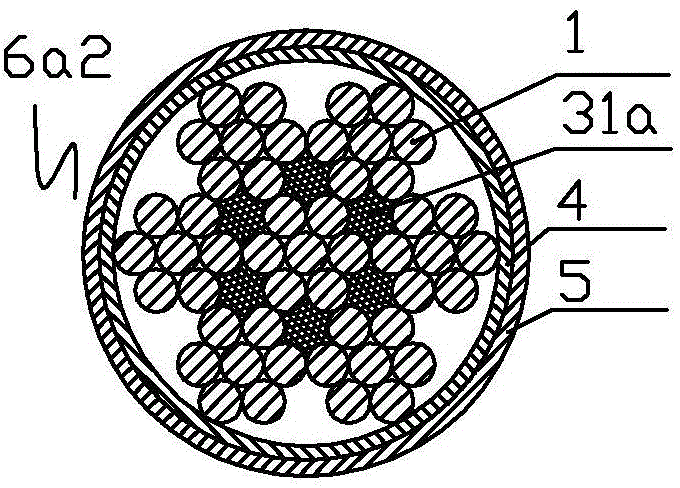

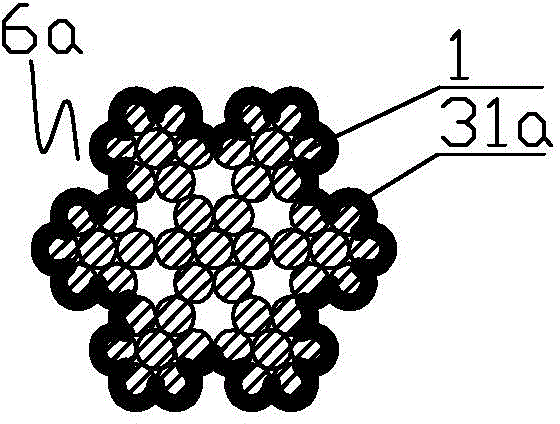

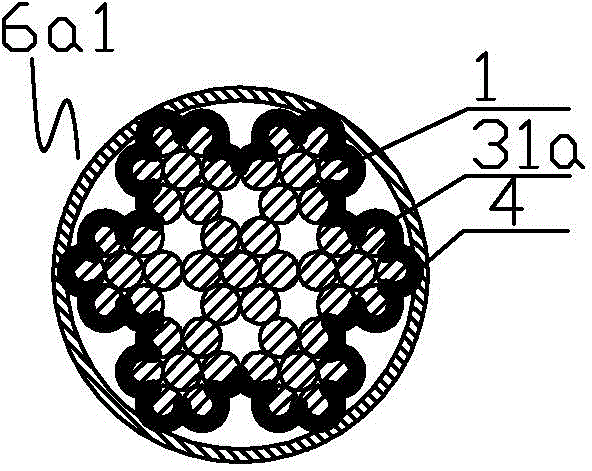

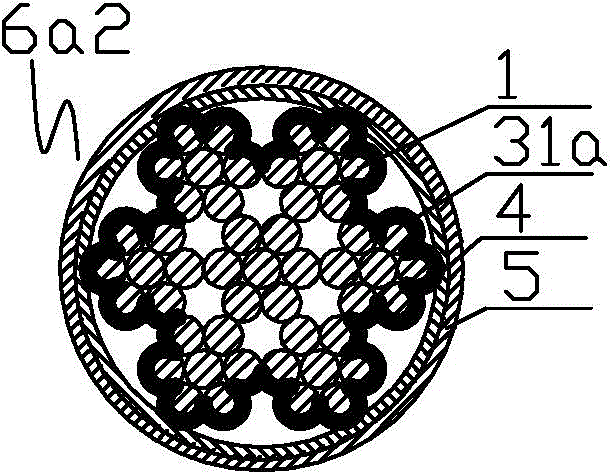

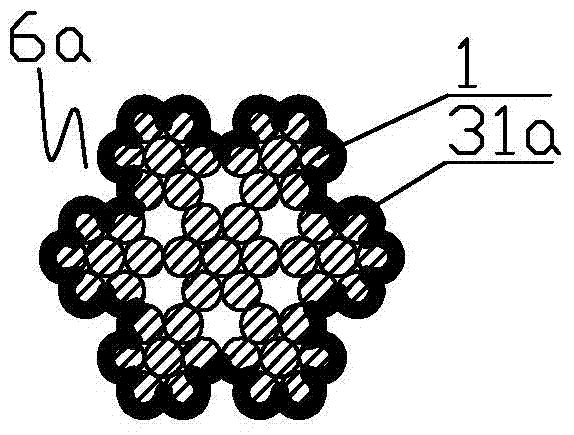

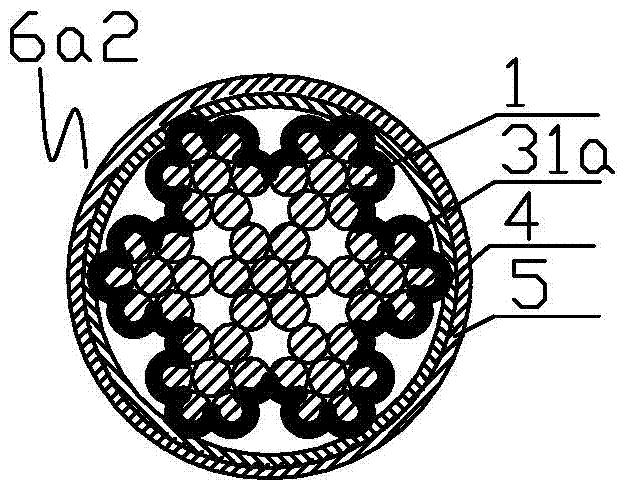

Steel strand inhaul cable filled or coated with polyurea protective material and manufacturing method of steel strand inhaul cable

InactiveCN105088949AImprove shock absorptionImprove skid resistanceBridge structural detailsTextile cablesEngineeringMechanical engineering

The invention relates to a steel strand inhaul cable filled or coated with a polyurea protective material. The steel strand inhaul cable comprises series steel strand inhaul cable bodies including the steel strand inhaul cable body Ia formed in a manner that gaps between n steel strands are filled with the polyurea protective material, the steel strand inhaul cable body Ib formed in a manner that the outer layer of the steel strand inhaul cable body Ia is coated with a polyurea protective coating and the like. A manufacturing method includes the steps that the n steel strands are pretreated, dried and filled with the polyurea protective material, a steel strand combination is molded through coalescence, and the steel strand inhaul cable body Ia filled or coated with the polyurea protective material is formed; and the series steel strand inhaul cable which has multiple protective functions is manufactured by the steel strand inhaul cable body Ia through one or more of the polyurea material coating process I, the wrapping and packaging process, the polyurea material coating process II and III, the extrusion molding process and the like. The method is simple and convenient; the manufactured steel strand inhaul cable is good in tension-resisting strength and flexibility, high in damping and good in ageing resistance, wear resistance and damping performance; the corrosion prevention capacity of the steel strand inhaul cable can be greatly improved, and the service life of the steel strand inhaul cable can be prolonged; and the n is larger than or equal to 1.

Owner:LIUZHOU OVM MASCH CO LTD

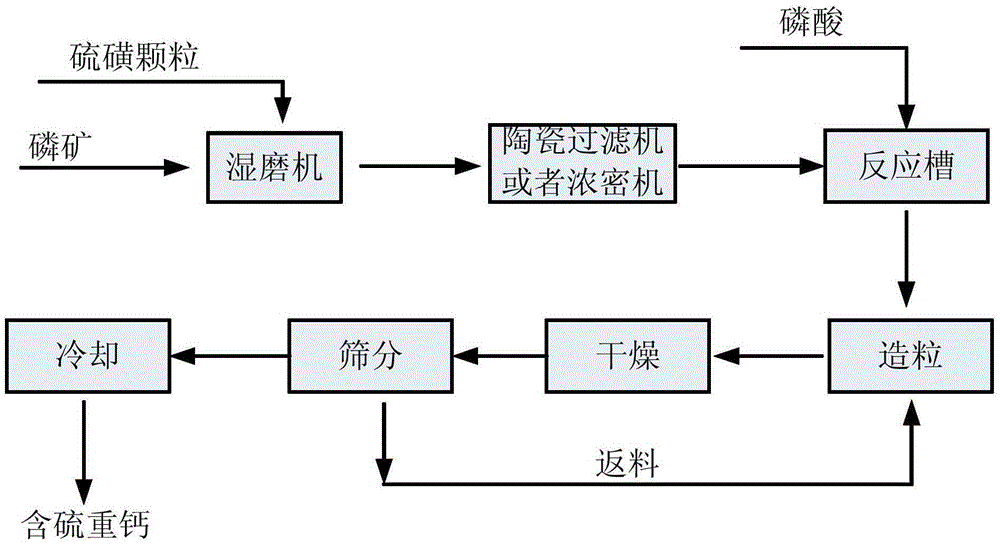

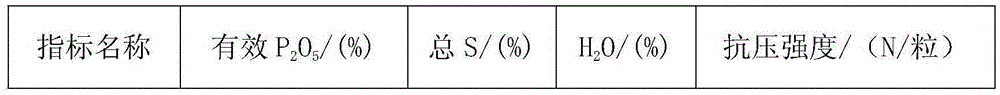

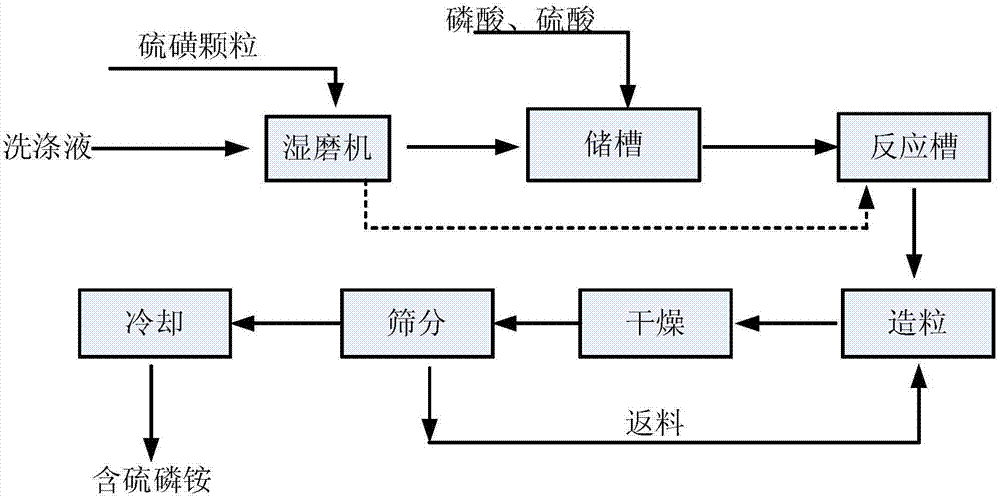

Preparation method of sulfur-containing heavy calcium

ActiveCN105254341AOvercome the disadvantage of uneven mixingImprove economySuperphosphatesPhosphatePhosphor

The invention discloses a preparation method of sulfur-containing heavy calcium. The preparation method comprises carrying out wet grinding on phosphate rock and elemental sulfur particles, conveying the ground product into a ceramic filter or a thickener, removing a part of water, conveying the materials into a slurry process-based heavy calcium production device, feeding phosphoric acid into the device, carrying out reaction preparation, carrying out granulation and carrying out drying to obtain a finished product. The preparation method utilizes the existing phosphate rock wet grinding device and the heavy calcium production device to produce fertilizer containing two or more nutrients such as phosphor and sulfur, does not change the original technology route and provides a low-cost product up-gradation method for the traditional device. The product contains uniform elemental sulfur, greatly reduces material returning frequency and reduces dust explosion possibility.

Owner:YUNNAN YUNTIANHUA

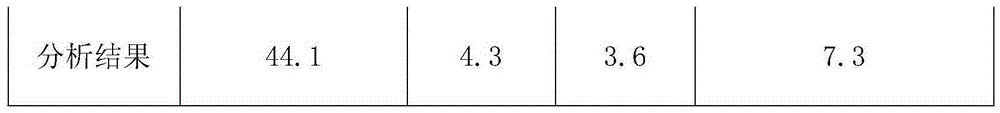

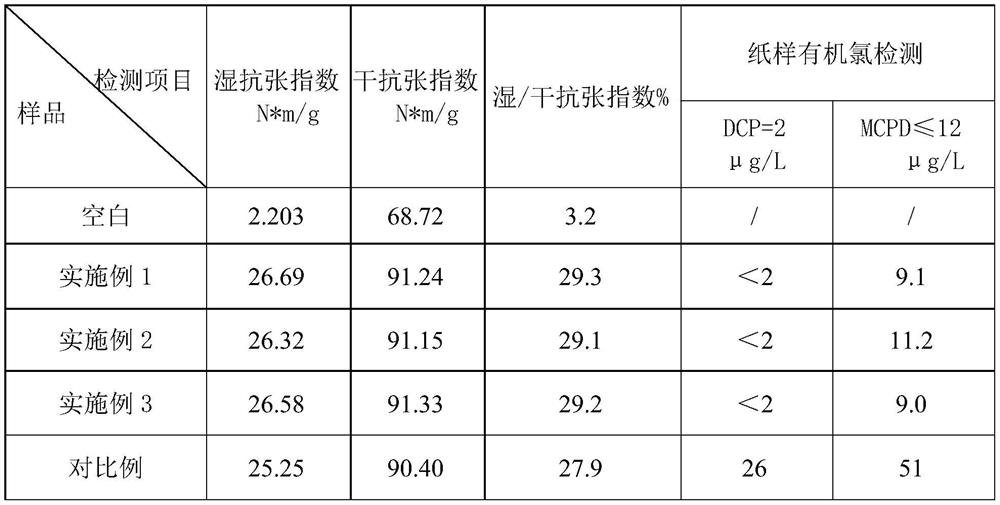

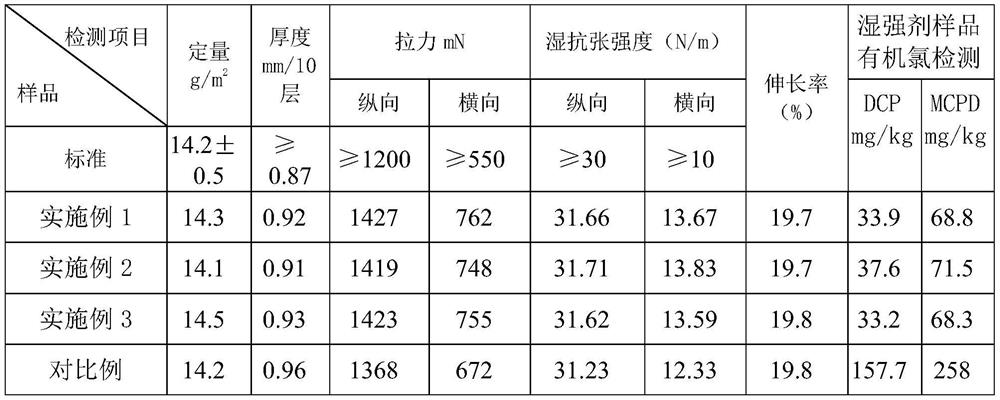

Low-chlorine wet strength agent and preparation method thereof, and application in living paper

PendingCN112626918AReduce organic chlorine contentLow technical transformation costReinforcing agents additionPaper/cardboardPolymer sciencePolyamide

The invention discloses a low-chlorine wet strength agent. The preparation method of the low-chlorine wet strength agent comprises the following steps: carrying out condensation polymerization on binary acid and diethylenediamine to synthesize a polyamide prepolymer, then slowly adding epoxy chloropropane, carrying out sufficient reaction, and after the reaction is finished, adding acid to terminate the reaction so as to obtain the low-chlorine wet strength agent. According to the invention, diethylenediamine with a six-membered ring structure is adopted to replace common chain structure polyethylene polyamine to react with binary acid to obtain a polyamide prepolymer, and then the polyamide prepolymer reacts with epoxy chloropropane to prepare the wet strength agent, so that the content of organochlorine in the wet strength agent can be remarkably reduced without other additional processes or adding a dechlorination reagent; and the wet strength agent is applied to living paper, and can meet the strict standard of high-quality living paper on residual organochlorine content.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

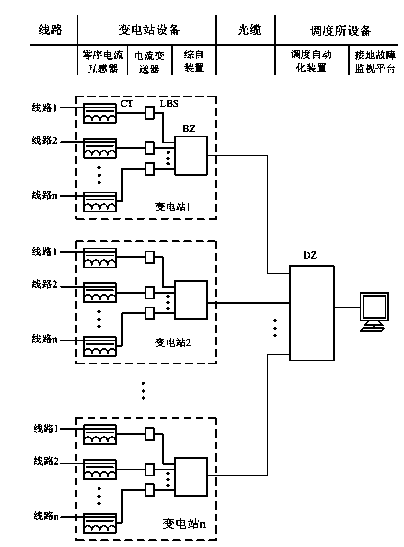

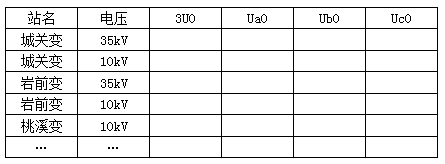

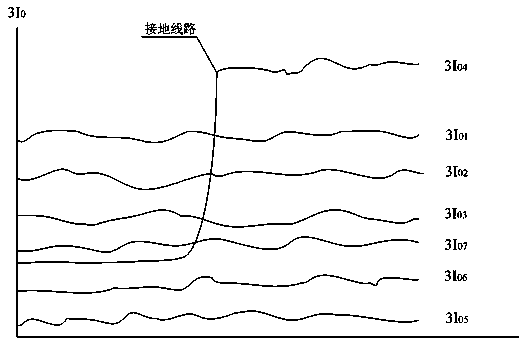

Low-current grounding fault manual discrimination line selection system of power system

InactiveCN103424671ALow technical transformation costHigh sensitivityFault locationTransformerElectric power system

The invention provides a low-current grounding fault manual discrimination line selection system of a power system and relates to a transformer substation outgoing line grounding fault searching method. The low-current grounding fault manual discrimination line selection system is characterized in that scheduling and monitoring personnel make a comparison according to grounding fault signals and zero-sequence current changing curves of incoming and outgoing lines in a monitoring interface and zero-sequence current value changes, and which incoming and outgoing lines have grounding fault is judged comprehensively through manual work. The method is suitable for county and municipal level power systems, wherein in the county and municipal level power systems, regulating and controlling integration systems are built, unattended operation of transformer substations is achieved, and all incoming and outgoing lines of the transformer substations can collect that 10-35kV neutral points of a zero-sequence current are not in ground connection and are connected with the ground through arc suppression coils and achieve high-resistance ground connection in a county and municipal level power system.

Owner:刘天明

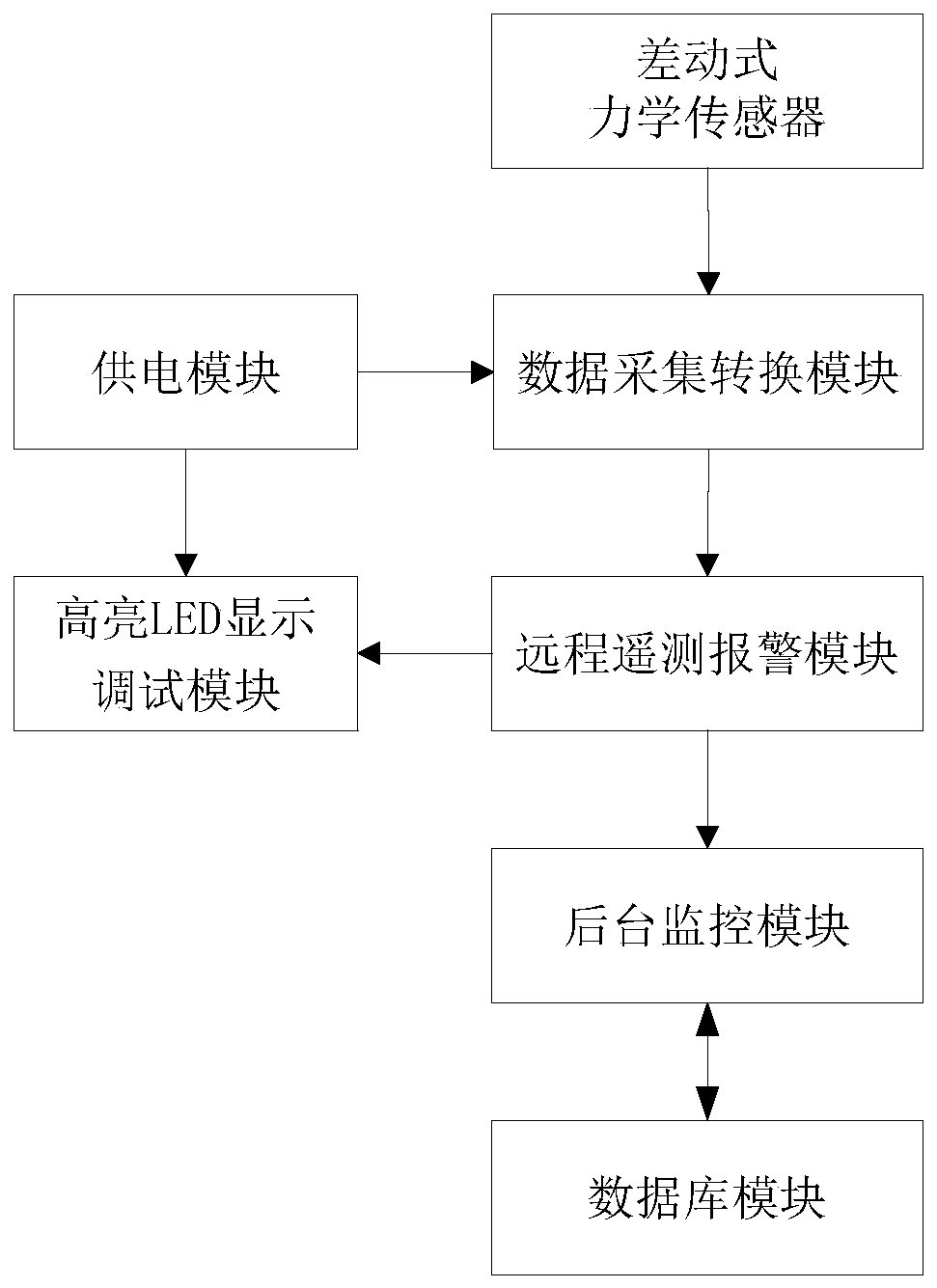

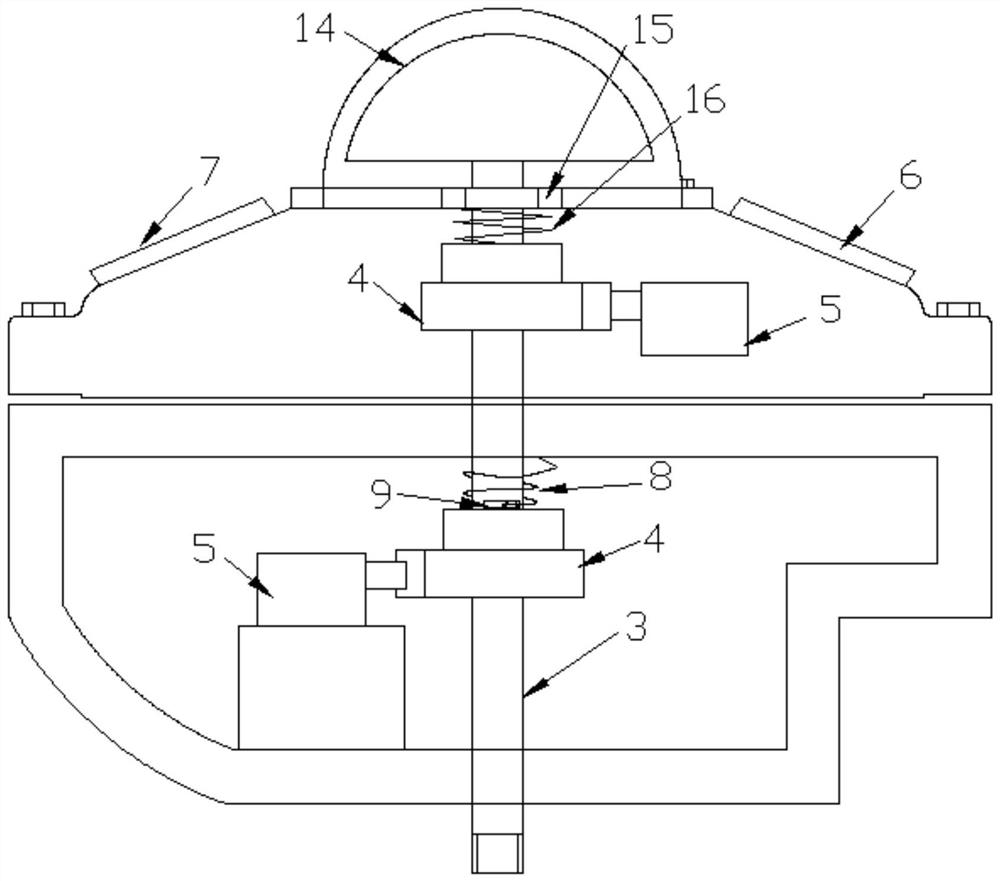

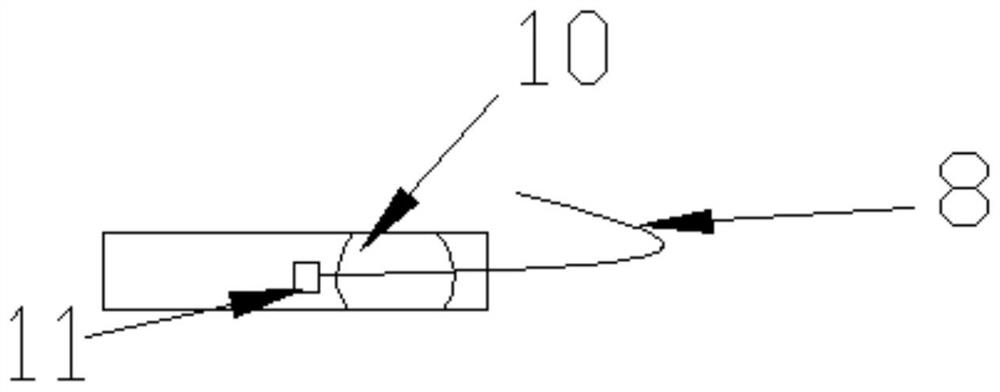

Breaker energy storage spring abnormal state assessment system

InactiveCN110752669AAvoid grid security incidentsLow technical transformation costCircuit arrangementsCircuit interrupters testingData transformationPower grid

The invention discloses a breaker energy storage spring abnormal state assessment system. The system comprises a mechanical sensor, a data collection module, a remote telemetry alarm module, a database module and a background monitoring module, wherein the mechanical sensor is used for measuring a stress value of an energy storage spring in real time; the data collection module is used for converting stress value data of the energy storage spring into analog signal data; the remote telemetry alarm module is used for generating an abnormal state early-warning signal according to the stress value data and a preset stress threshold and sending the stress value data and the abnormal state early-warning signal, which are obtained through conversion by the data collection module, to the background monitoring module through an equipment control system of a substation; the database module is used for storing the stress value data received by the background monitoring module; and the backgroundmonitoring module is used for assessing the residual life of the energy storage spring when the abnormal state early-warning frequency is greater than a preset frequency threshold. Through the system, an existing communication circuit can be fully utilized to achieve the monitoring alarm function on a site by a background, the fault identification rate of the energy storage spring is increased, and a risk caused by a breaker accident to power grid safety is avoided.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

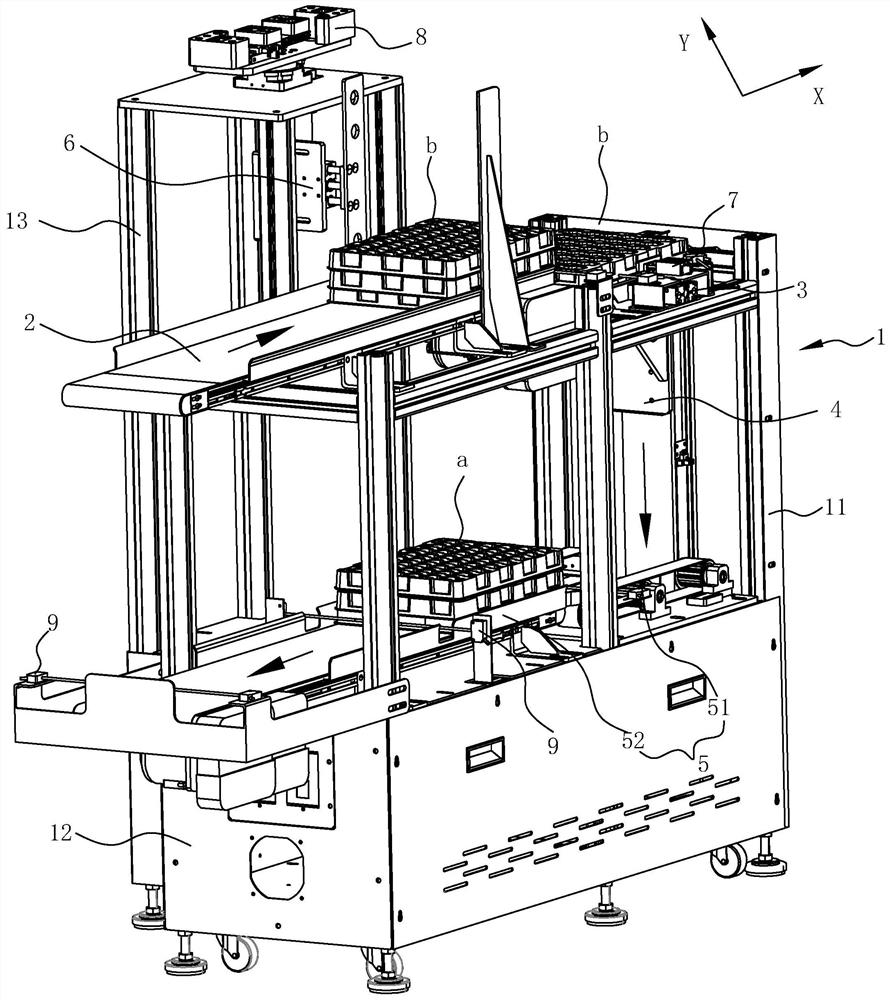

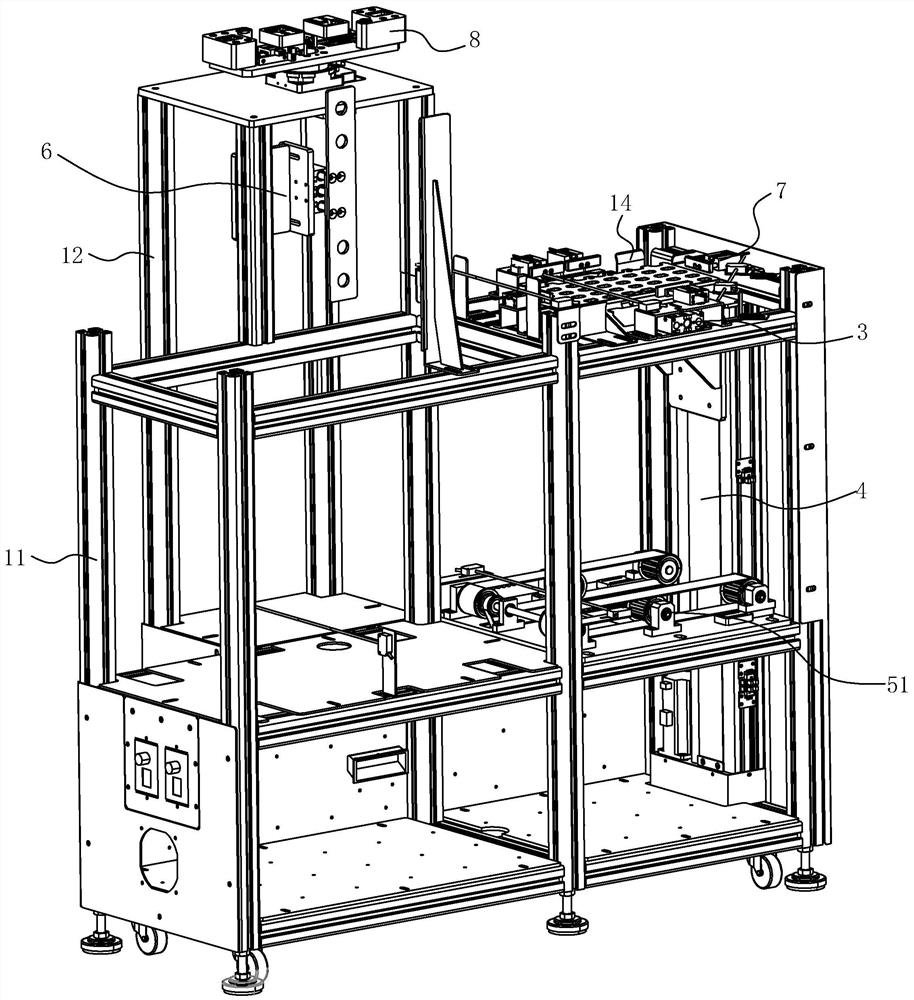

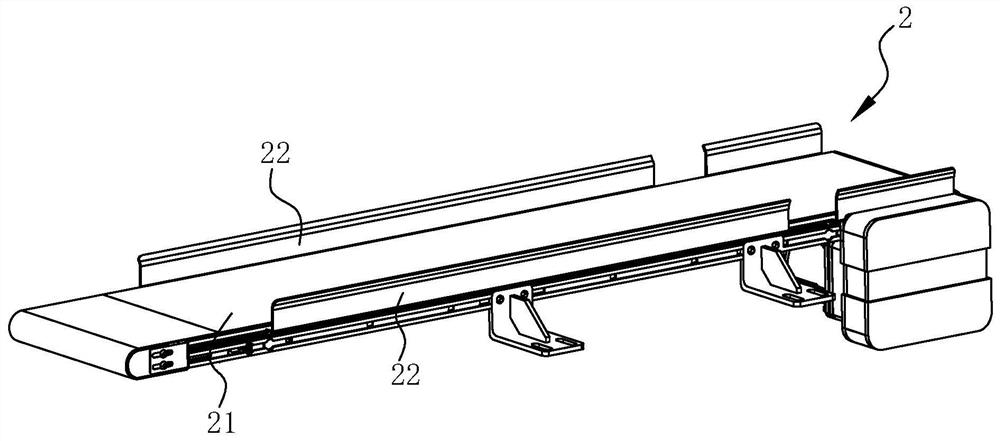

Automatic tray placing stock bin

PendingCN113086541AConvenient ArrangementImplement automatic importConveyor partsMechanical conveyorsEngineeringProcess engineering

The invention discloses an automatic tray placing stock bin. The automatic tray placing stock bin comprises a rack, and an empty tray feeding and conveying mechanism, a non-stop tray placing mechanism, a full tray carrying mechanism and a full tray transferring and discharging mechanism are arranged on the rack; the empty tray feeding and conveying mechanism is used for conveying the stacked empty trays to a feeding station; the non-stop tray placing mechanism is used for bearing single empty trays carried from the feeding station to a product tray placing station, so that tray placing is facilitated; and the non-stop tray placing mechanism is further used for releasing the full trays after the products are placed on the trays; and the full tray carrying mechanism is used for bearing the full trays released one by one by the non-stop tray placing mechanism and integrally carrying the full trays stacked to a preset number to a transferring station; and the full tray transferring and discharging mechanism is used for discharging and conveying the full trays at the transferring station. According to the automatic tray placing stock bin, and the problems that in the prior art, the number of stored trays is small, taking and placing are frequent, taking and placing are inconvenient, the working efficiency is low, and the technical improvement cost is high are solved.

Owner:GOERTEK INC

A kind of high thermal conductivity near-eutectic cast aluminum-silicon alloy material and production method

ActiveCN104674078BImprove thermal conductivityGood casting performanceSilicon alloyThermal conductivity

The invention relates to a near co-crystallizing type casting aluminum silicon alloy material with high heat conductivity and a production method thereof. The alloy comprises the main components including Al and Si, and is characterized by also comprising at least one of Sr, Ca and B. During casting production, the temperature of a melt is maintained within a range of 600-850 DEG C, and the alloy melt is cast into a casting mould so as to be cast into a casting; when the casting product is subjected to heat treatment, the temperature rising velocity of the heat treatment process is lower than 20 DEG C / min, and the temperature is maintained to be 100-450 DEG C and maintained for 0.5-10 hours, and then, the casting is cooled or air-cooled along with a furnace.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

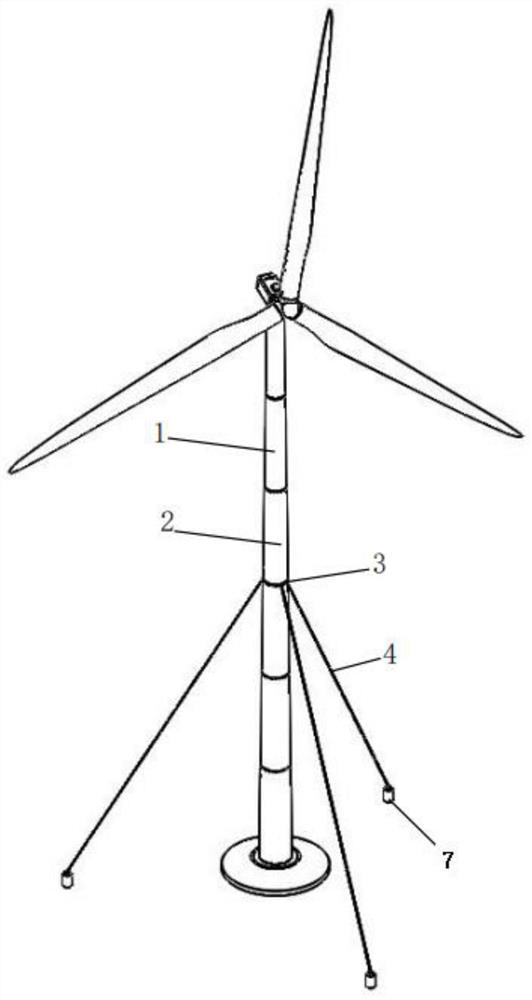

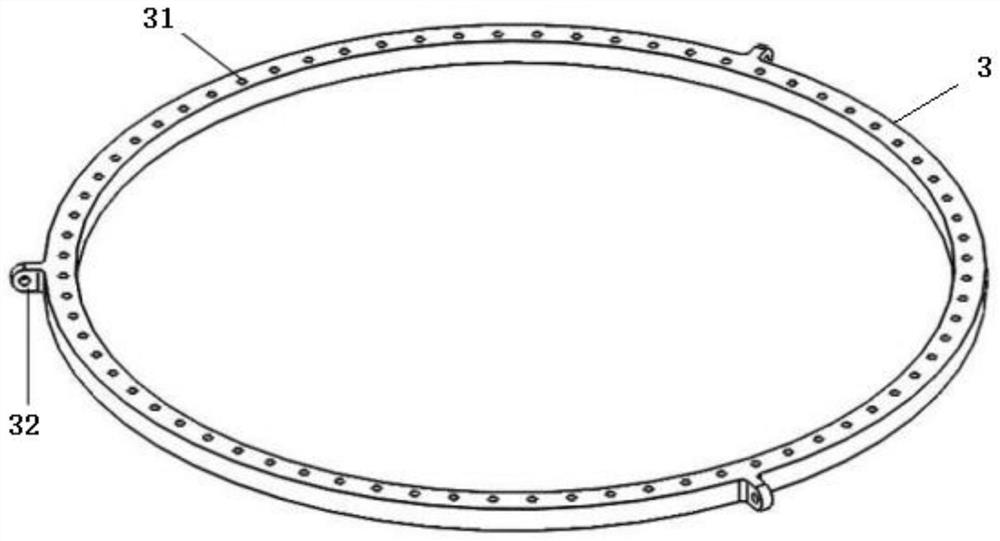

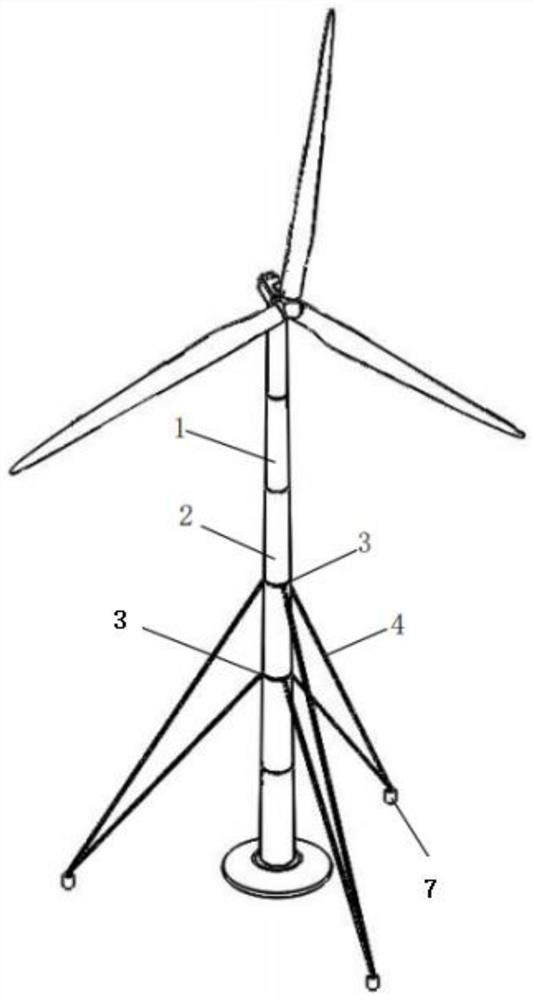

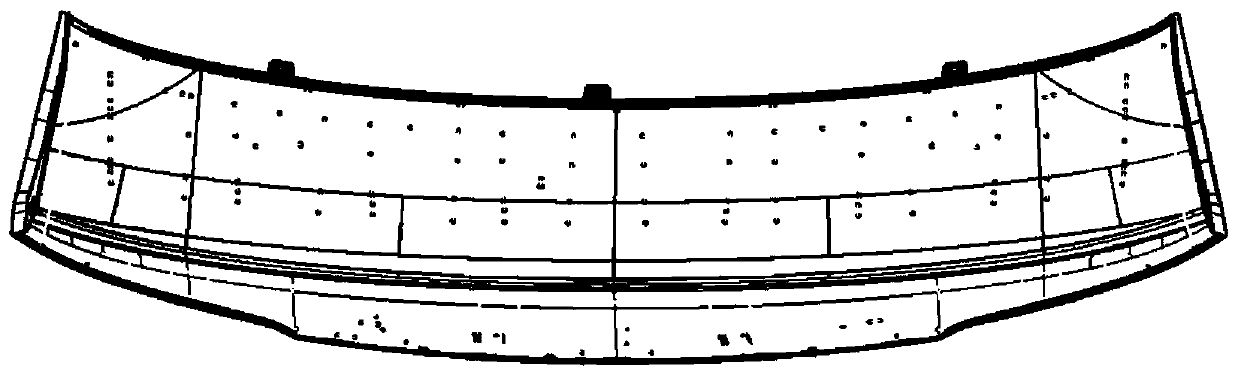

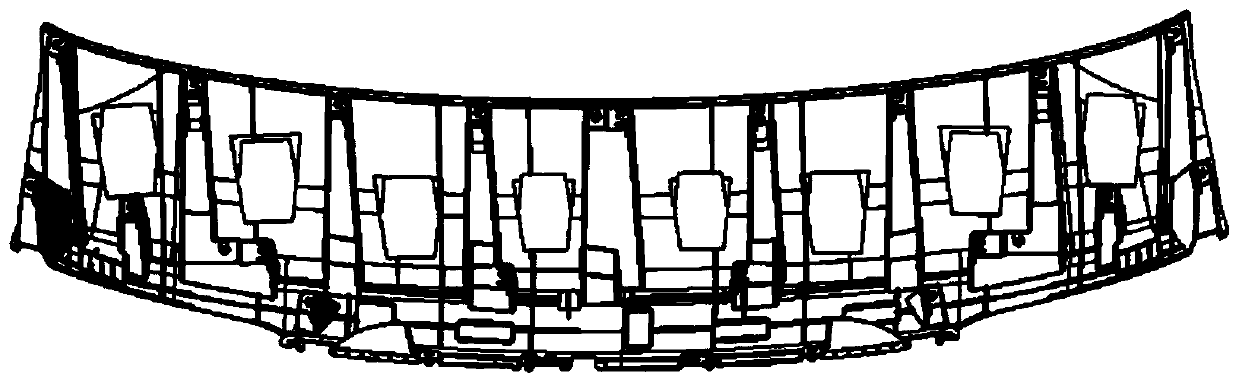

Wind generating set inhaul cable type steel cylinder tower and steel cylinder replacing method

PendingCN111608864AImprove carrying capacityImprove mechanical performanceWind motor supports/mountsMachines/enginesTowerMechanical engineering

The invention discloses a wind generating set inhaul cable type steel cylinder tower. The wind generating set inhaul cable type steel cylinder tower comprises a tower cylinder section, and is characterized by further comprising tower cylinder transition sections, an inhaul cable flange and an inhaul cable; tower cylinder transition section flanges are arranged at the two ends of each tower cylinder transition section, and flange bolt holes are formed in the tower cylinder transition section flanges; the inhaul cable flange is provided with an inhaul cable flange bolt hole, and the outer wall of the inhaul cable flange is provided with an inhaul cable flange lug plate; the inhaul cable flange is located between the two tower cylinder transition sections, and a flange connecting bolt penetrates through the flange bolt hole and the inhaul cable flange bolt hole to connect the two tower cylinder transition sections and the inhaul cable flange together; and the tower cylinder section is connected with the outer side ends of the two tower cylinder transition sections, one end of the inhaul cable is connected with the inhaul cable flange lug plate, and the other end of the inhaul cable isconnected with a ground anchoring point. The invention further discloses a steel cylinder replacing method of the wind generating set inhaul cable type steel cylinder tower. According to the wind generating set inhaul cable type steel cylinder tower and the steel cylinder replacing method, the stress path of the steel cylinder tower can be reasonably distributed, and the stress performance of thetower and joints is improved.

Owner:INNER MONGOLIA OF GIMHAE NEW ENERGY TECH +1

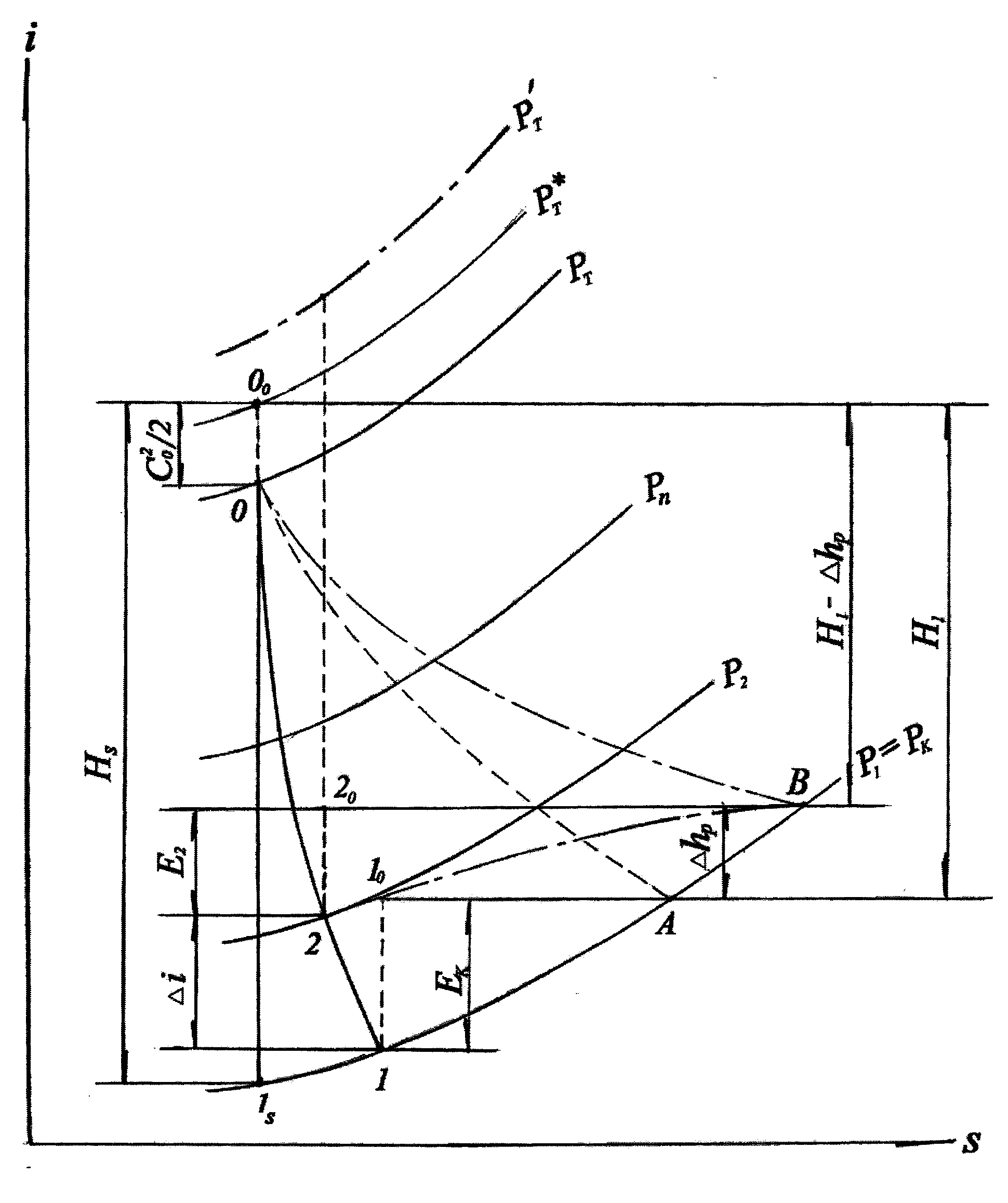

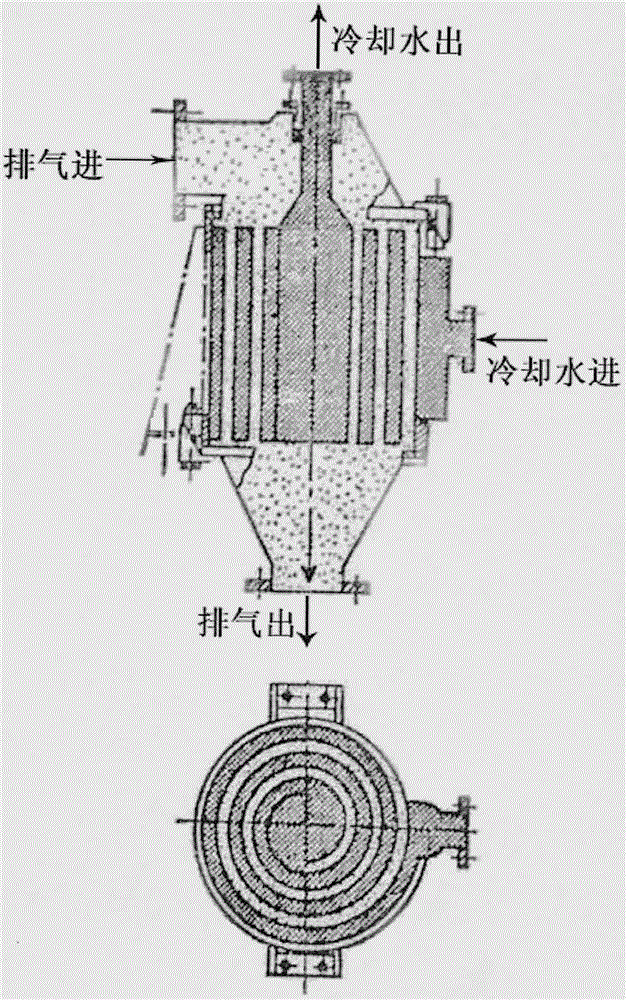

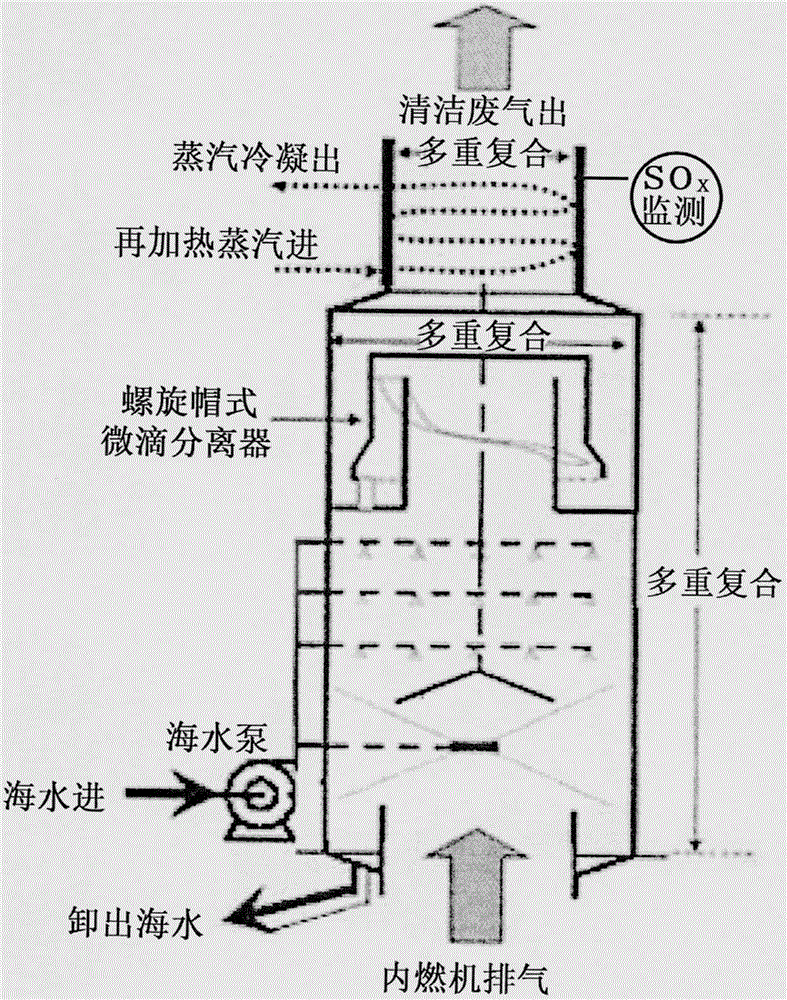

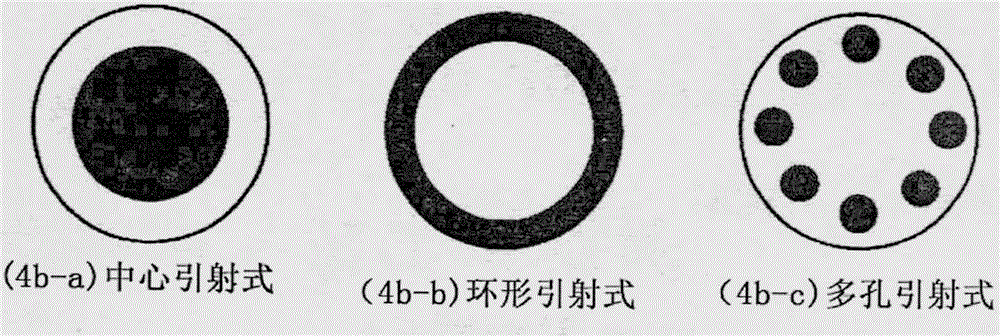

Exhaust by-pass valve for turbocharging system

InactiveCN103726928ASimple structureEasy to useInternal combustion piston enginesImpellerTurbine wheel

The invention discloses an exhaust by-pass valve for a turbocharging system wherein the exhaust by-pass valve is also a vortex forward pressure regulator / a turbine backpressure regulator. The exhaust by-pass valve for the turbocharging system is characterized in that a gas inject sucking device is mounted behind an exit of a turbine wheel of a turbocharger in a concatenation mode, the gas pressure(backpressure) of the exit of a turbine is caused to be reduced significantly, and therefore variable working condition performance of supercharging internal combustion engines can be improved greatly. The exhaust by-pass valve for the turbocharging system is strong in practicability, mature in technology, simple in structure, safe, reliable and convenient to use, obvious in energy-saving effect, low in cost of technical innovation, and worthy of wide popularization.

Owner:孙敏超 +1

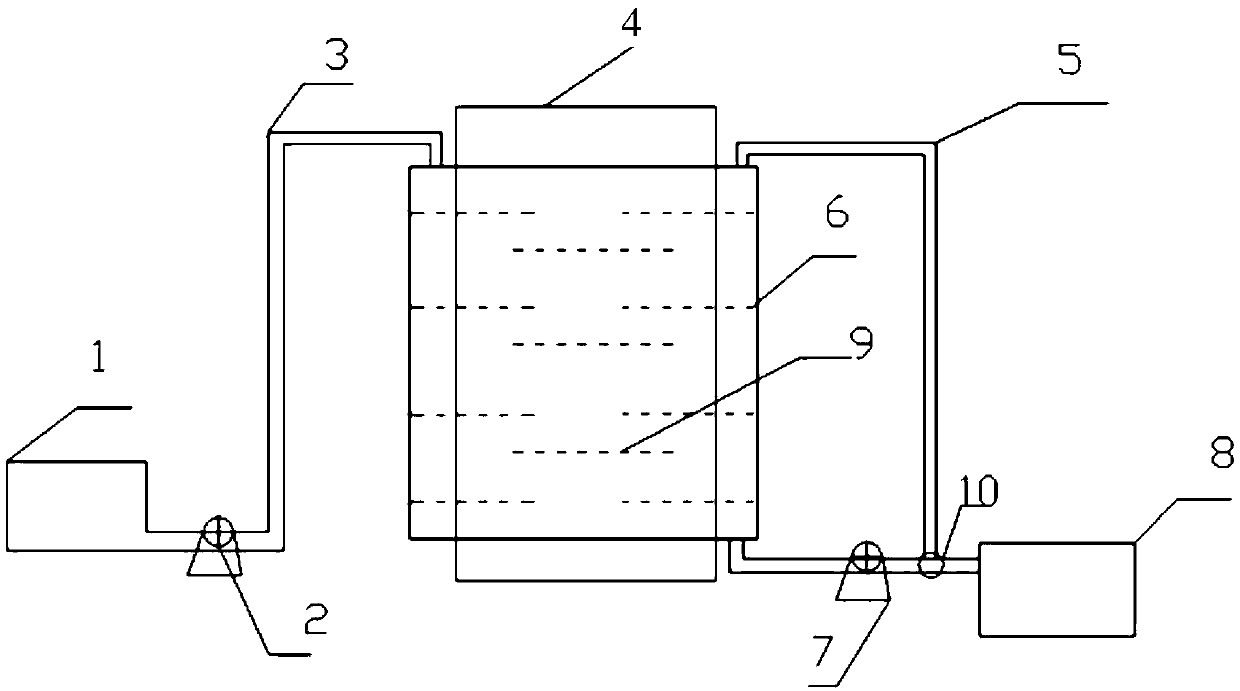

Adjustment device for reducing exhaust back pressure of internal combustion engine

The invention discloses an adjustment device for reducing exhaust back pressure of an internal combustion engine, which is suitable for being applied to various different forms of internal combustion engines in internal combustion engine classification. The core technology is that an adjustment device, which is formed by an ejector, a water ring vacuum pump and a water cooling box alone or in combination and used for reducing the exhaust back pressure of the internal combustion engine, is serially connected behind an outlet of an exhaust pipe of the internal combustion engine or at a turbine wheel combustion gas flow outlet in a supercharger of a turbocharged internal combustion engine, so that an exhaust back pressure value of the internal combustion engine can be greatly reduced and adjusted, and power, economic and exhaust performance indexes of an internal combustion engine device are effectively improved. The adjustment device disclosed by the invention has the advantages of mature technology, simple structure, safe and reliable use, great adjustment strength and good effect.

Owner:乌榴君 +1

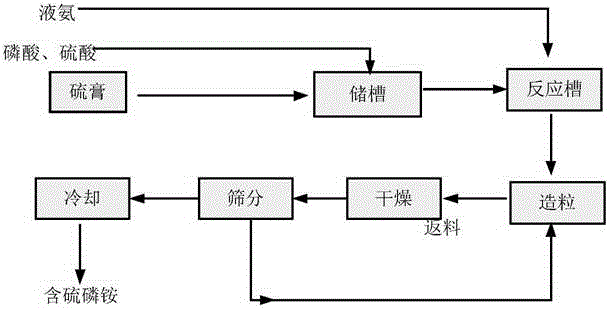

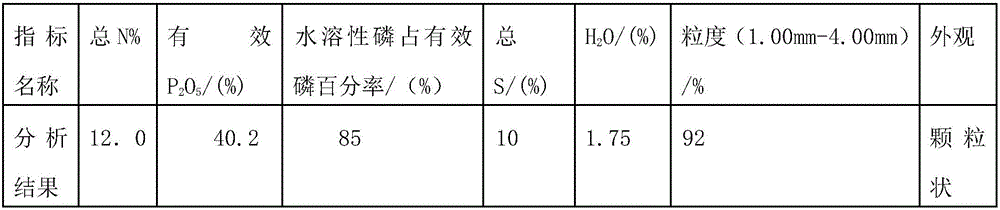

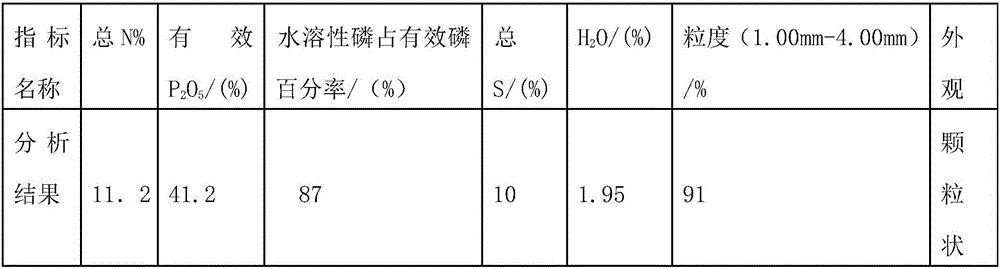

Method for producing sulfur-containing ammonium phosphates from industrial byproduct desulfuration paste

ActiveCN106316510AOvercome the disadvantage of uneven mixingImprove economyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidSulfur containing

The invention discloses a method for producing sulfur-containing ammonium phosphates. The method comprises the steps that firstly, byproduct sulfur paste of synthesis ammonia, coking coal and other factories is added into a phosphoric acid storage tank on the basis of the calculated amount and conveyed to a reactor after being stirred to be uniform, and pelleting and drying are performed to obtain the sulfur-containing ammonium phosphates. The byproduct sulfur paste and an existing ammonium phosphate device are used for producing fertilizer containing phosphorus, sulfur and other nutrient elements, an original technological path is not changed, and the low-cost product upgrading method is provided for a traditional device. The obtained product contains uniform elemental sulfur, the material returning frequency is greatly decreased, the dust explosion probability is lowered, and the byproduct sulfur paste is economically utilized.

Owner:云南云天化以化磷业研究技术有限公司

Method for treating DDNP waste water through technologically improved cement rotary kiln by adopting afterheat of cement rotary kiln

ActiveCN107144143AReduce generationLow technical transformation costWater contaminantsMultistage water/sewage treatmentBurn treatmentHot Temperature

The invention provides a method for treating DDNP waste water through a technologically improved cement rotary kiln by adopting afterheat of the cement rotary kiln. Through cooperating with surrounding existing cement enterprises, an existing cement rotary kiln is improved by using a low cost, and the afterheat, with a high temperature of nearly 1000 degrees, of the technologically improved cement rotary kiln is utilized to conduct evaporating treatment on the waste water; and after the waste water is treated to a certain concentration, the treated waste water is subjected to burning treatment. According to the method for treating the DDNP waste water through the technologically improved cement rotary kiln by adopting the afterheat of the cement rotary kiln, the environmental pollution is reduced, the difficulty of technological improvement can further be reduced, and the cost for treating the DDNP waste water is reduced.

Owner:FUJIAN CIVILIAN BLASTING CHEM

A high-strength cast aluminum-silicon alloy strengthened by cryogenic treatment and its preparation process

InactiveCN106498245BImprove solubilityAdvantages of mechanical propertiesSolubilitySolution treatment

Owner:NANJING LONGHAO NEW MATERIAL TECH CO LTD

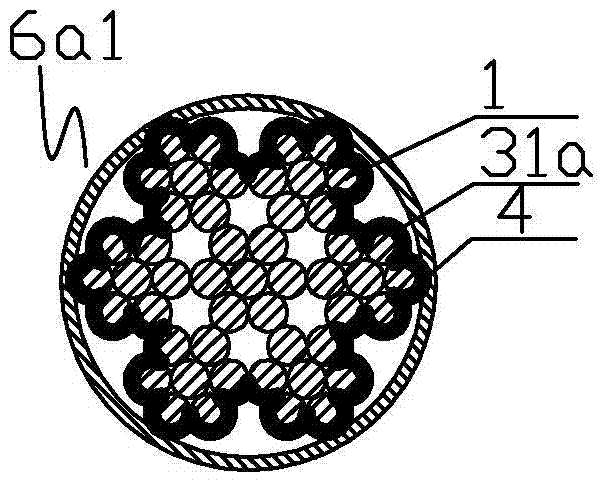

Steel strand inhaul cable with polyurea protective material on outer layer and manufacturing method of steel strand inhaul cable

ActiveCN105088950AImprove shock absorptionImprove skid resistanceRope making machinesBridge structural detailsWear resistancePolyurea

The invention relates to a steel strand inhaul cable with a polyurea protective material on an outer layer. The steel strand inhaul cable comprises a steel strand combination formed by n steel strands, the outer layer of the steel strand combination formed by the n steel strands is coated with a polyurea protective coating I to form a steel strand inhaul cable body Ia with the polyurea protective material, and the outer layer of a wrapping and packaging belt of the steel strand inhaul cable body Ia is coated with a polyurea protective coating II to form a steel strand inhaul cable body Ia0b. A manufacturing method of the steel strand inhaul cable includes the steps that a series steel strand inhaul cable which has multiple protective functions is manufactured through one or more of the polyurea material coating process I, the wrapping and packaging process, the polyurea material coating process II, the extrusion molding process, the polyurea material coating process III and the like of the steel strand combination obtained after the steps of pretreatment, drying and coalescence molding. The method is simple and convenient; the manufactured steel strand inhaul cable is good in tension-resisting strength and flexibility, high in damping and good in ageing resistance, wear resistance and damping performance; the corrosion prevention capacity of the steel strand inhaul cable can be greatly improved, and the service life of the steel strand inhaul cable can be prolonged; and the n is larger than or equal to 1.

Owner:LIUZHOU OVM MASCH CO LTD

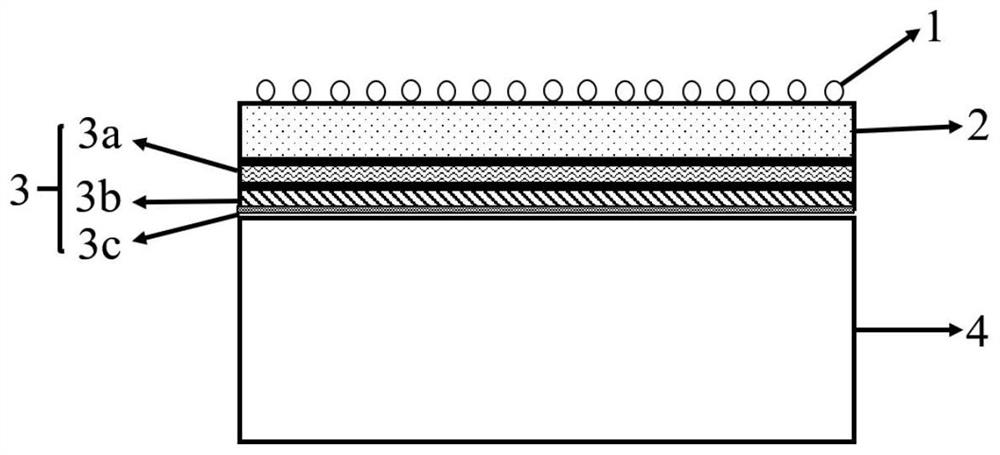

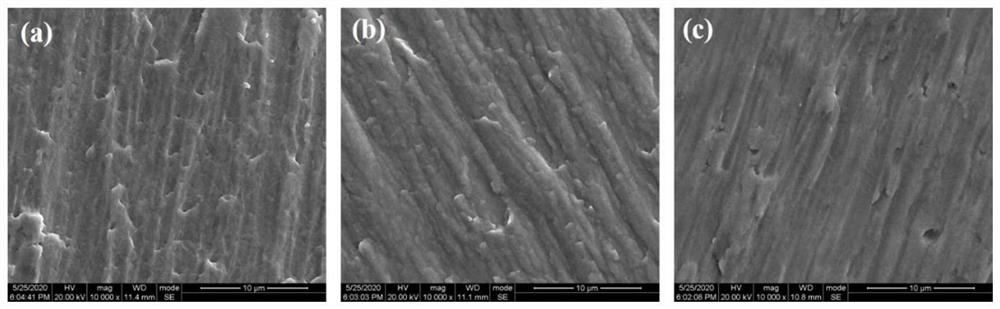

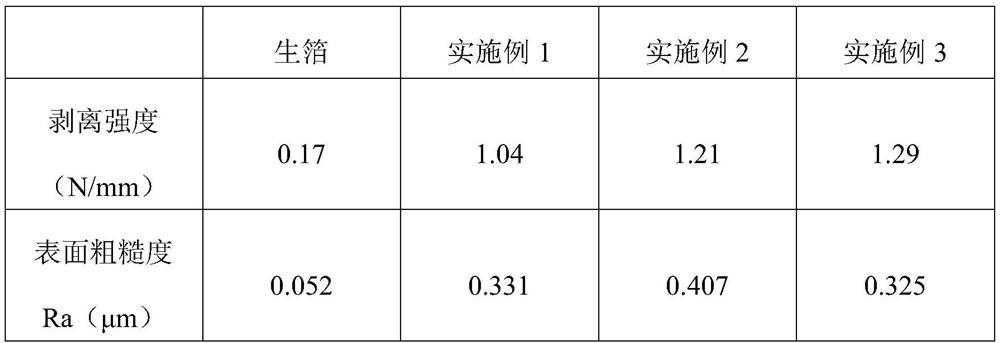

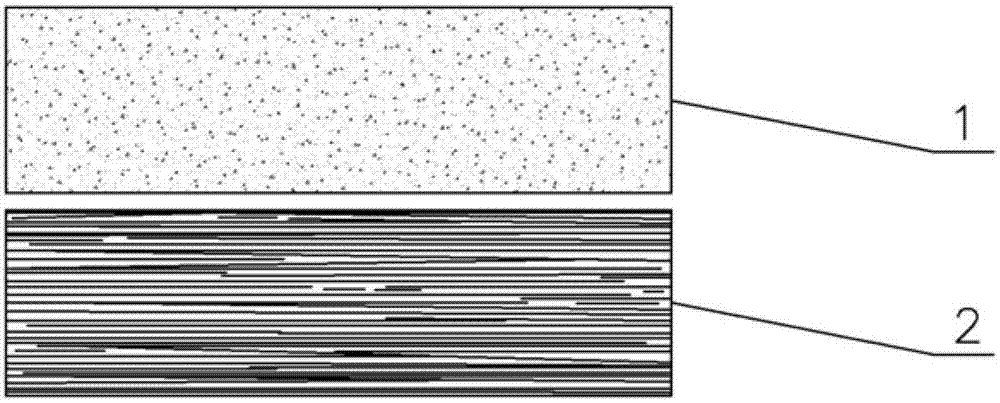

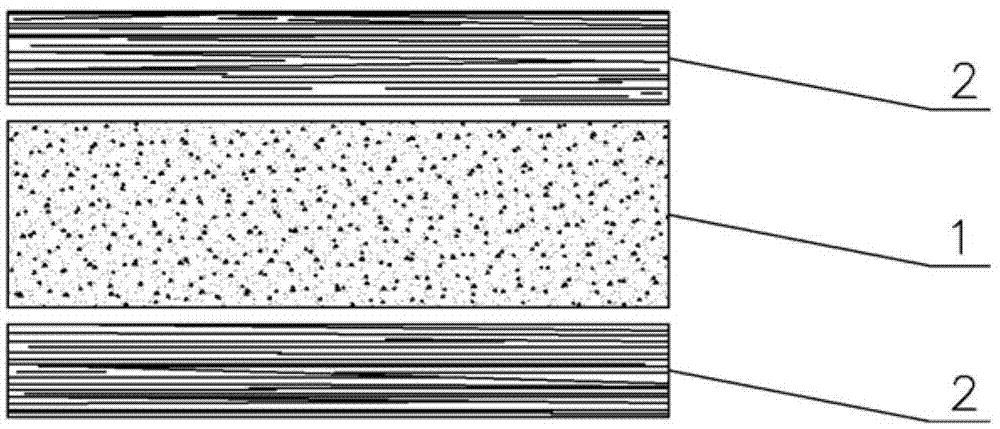

Preparation method of strippable ultrathin carrier copper foil

PendingCN114657610AEasy to peelSolve conductivity problemsCircuit precursor manufacturePhysical chemistryCopper foil

The invention relates to a preparation method of a strippable ultrathin carrier copper foil, and provides a key material for a 5G communication high-frequency and high-speed printed circuit board. According to the strippable ultrathin carrier copper foil, the 18-micron carrier copper foil, the dip-plated metal layer, the organic barrier layer, the stripping layer, the ultrathin copper foil layer and the coarsening layer are sequentially arranged, the dip-plated metal layer can reduce equipotential points of a copper surface, the binding force of the carrier copper foil and the organic layer is enhanced, and the requirement for anti-stripping strength is met; the organic layer and the metal layer are jointly used as a stripping layer, so that the problems that a single organic layer easily causes poor conductivity and non-uniform thickness during electro-deposition of an ultrathin copper foil layer and is easily separated from a carrier before use can be solved. The thickness of the ultrathin carrier copper foil prepared by the method is about 5 microns, the ultrathin carrier copper foil can be successfully stripped, and no copper powder or stripping layer is left on the surface of the ultrathin carrier copper foil.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

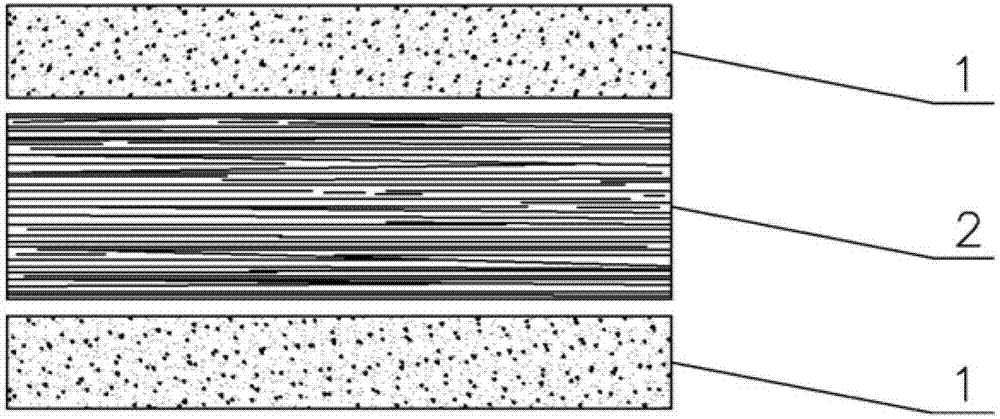

Composite structure plate of recombination bamboo wood and medium-density fiberboard and manufacture method thereof

InactiveCN102773886AUniform materialSmall difference in vertical and horizontal strengthWood veneer joiningAdhesive application devicesWeather resistanceMedium density fiberboard

The invention relates to a composite structure plate of recombination bamboo wood and a medium-density fiberboard and a manufacture method thereof. The composite structure plate is composed of at least one layer of recombination bamboo wood and at least one layer of medium density fiberboard, and the thickness of the composite structure plate is 7-90 mm. The manufacture method includes the following steps: coating weather resistance glue on the recombination bamboo wood and the medium-density fiberboard, and coating the weather resistant glue on a contact face or coating the weather resistance glue on one lateral surface of the contact face; assembling the recombination bamboo wood and the medium-density fiberboard with the weather resistance glue to obtain a plate blank; and cold pressing, maintaining pressure, relieving pressure and preserving the plate blank to obtain the composite structure plate of the recombination bamboo wood and the medium-density fiberboard. The composite structure plate has good structure performance and is capable of conducting continuous production, simple in process, high in production efficiency, stable and reliable in product performance, remarkable in cost advantage, energy-saving, environment-friendly and suitable for various use purposes.

Owner:INT CENT FOR BAMBOO & RATTAN

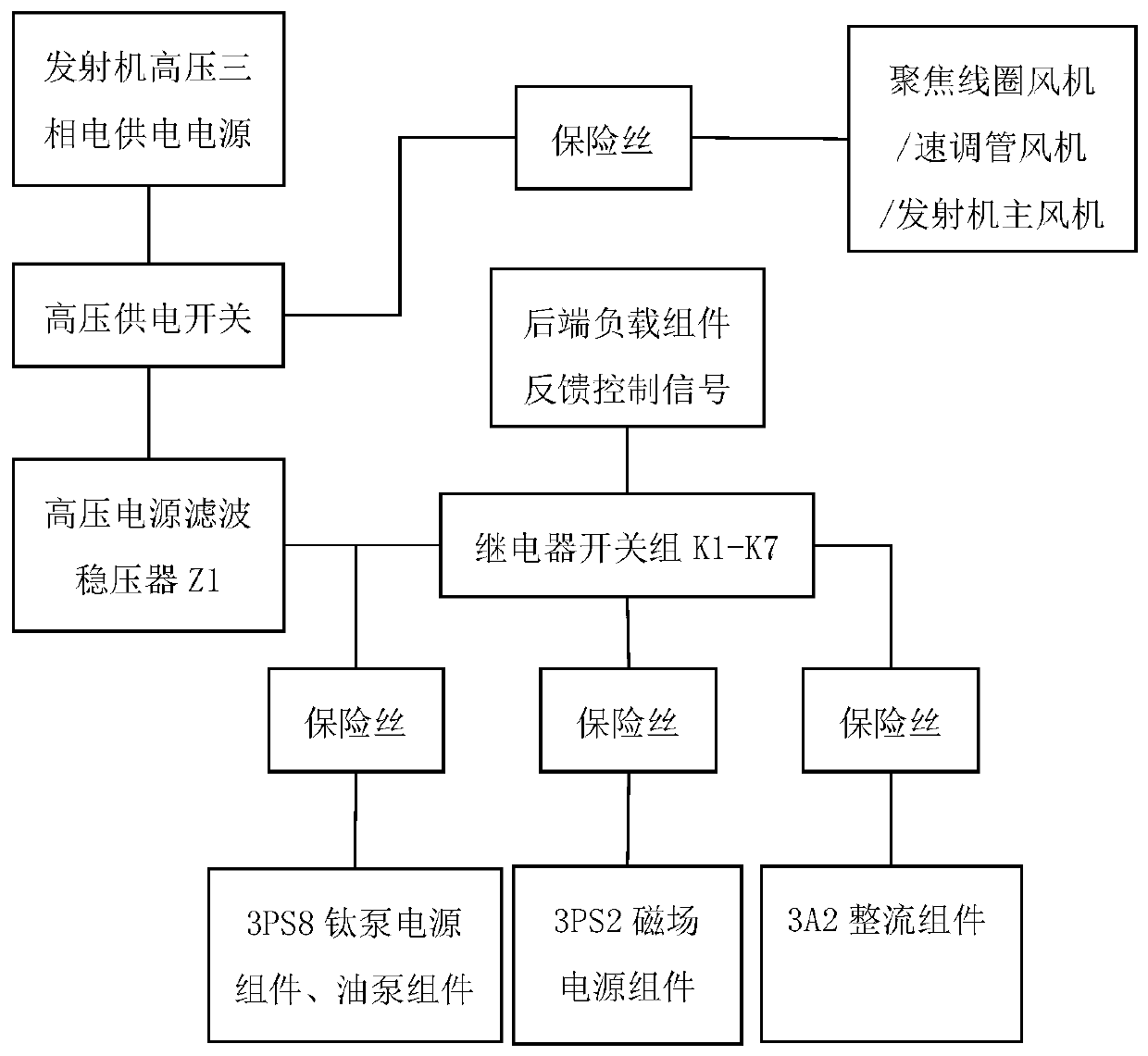

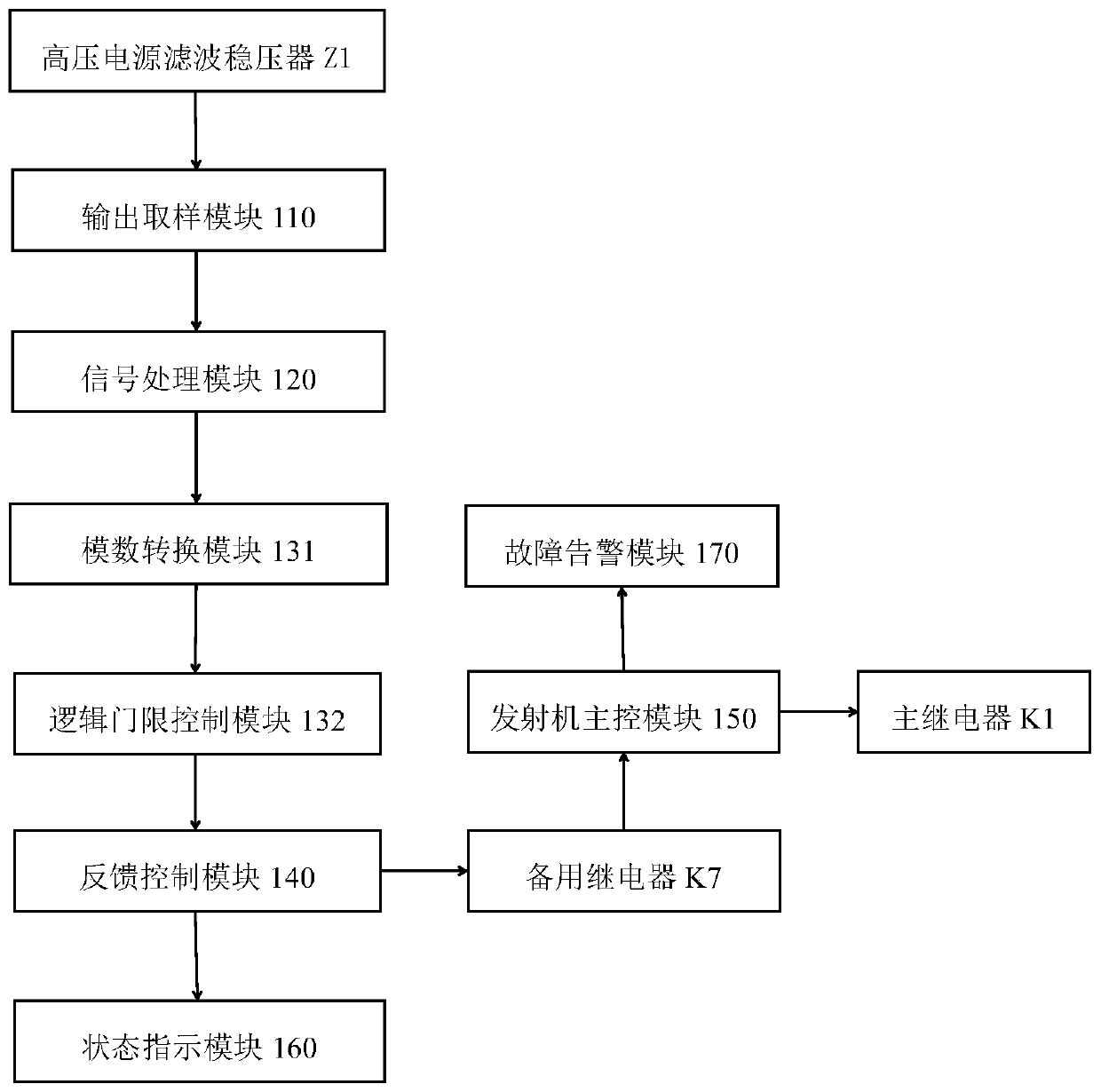

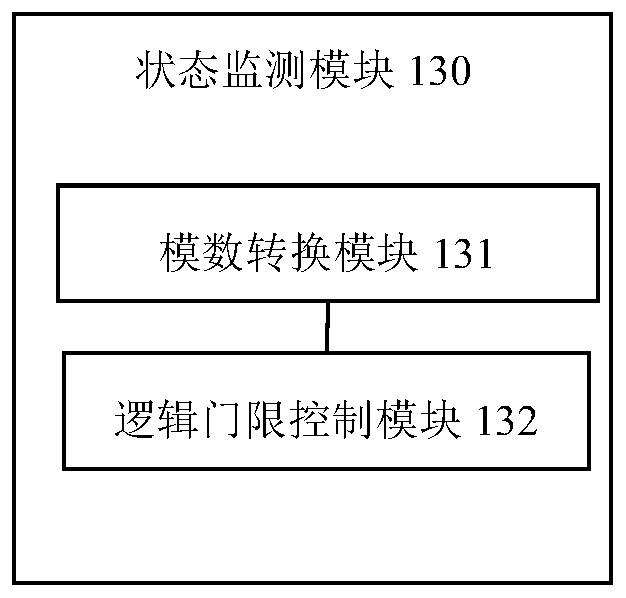

Meteorological radar transmitter fault detection system and method

ActiveCN110333493APrecise positioningRestoration and maintenance of normal operational observationsWave based measurement systemsWeather radarDetection diagnosis

The embodiment of the invention discloses a meteorological radar transmitter fault detection system and method. A high-voltage power supply filtering voltage stabilizer Z1 in a front-end high-voltagepower supply line of a transmitter is subjected to fault detection circuit design, so that an abnormal operation state of the high-voltage power supply filtering voltage stabilizer Z1 can be timely and effectively detected; when the high-voltage power supply filtering voltage stabilizer Z1 has a fault, a worker can be helped to rapidly and accurately position a fault unit and timely eliminate thefault, so as to improve the intelligent fault detection diagnosis capacity and the fault warning information positioning capacity of a meteorological radar transmitter system; and a standby K7 relay in an original relay switching group in the line is utilized to carry out operation state monitoring on the high-voltage power supply filtering voltage stabilizer Z1, so as to implement state monitoring on the high-voltage power supply filtering voltage stabilizer Z1 and linkage of control of the transmitter system, reduce improvement complexity on the front-end power supply line, improve improvement feasibility and greatly reduce technical transformation cost.

Owner:舒毅

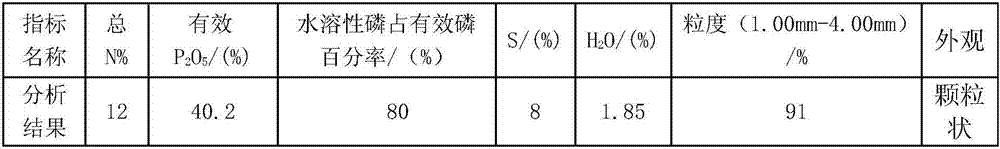

A kind of preparation method of sulfur-containing ammonium phosphate

ActiveCN105800574BOvercome the disadvantage of uneven mixingImprove economyPhosphatesSulfur granulesDiammonium phosphate

The invention discloses a preparation method of sulfur-containing ammonium phosphate. The preparation method comprises the steps that a diammonium phosphate device washing solution and elemental sulfur granules are together subjected to wet grinding, the size of the sulfur granules is controlled according to the production requirement, the sulfur granules are sieved and then conveyed to a reactor of an ammonium phosphate production device or conveyed to a storage tank to be mixed with wet process phosphoric acid and then conveyed to the reactor to react with liquid ammonia, and granulating and drying are performed to obtain sulfur-containing ammonium phosphate. According to the preparation method, the fertilizer containing more than two nutrient elements including phosphorus and sulfur is produced through the existing diammonium phosphate device washing solution, an original process route is not changed, and a low-cost product upgrading method is supplied to a traditional device. The obtained product contains uniform elemental sulfur, the returning frequency is significantly decreased, and the dust explosion possibility is reduced.

Owner:YUNNAN YUNTIANHUA

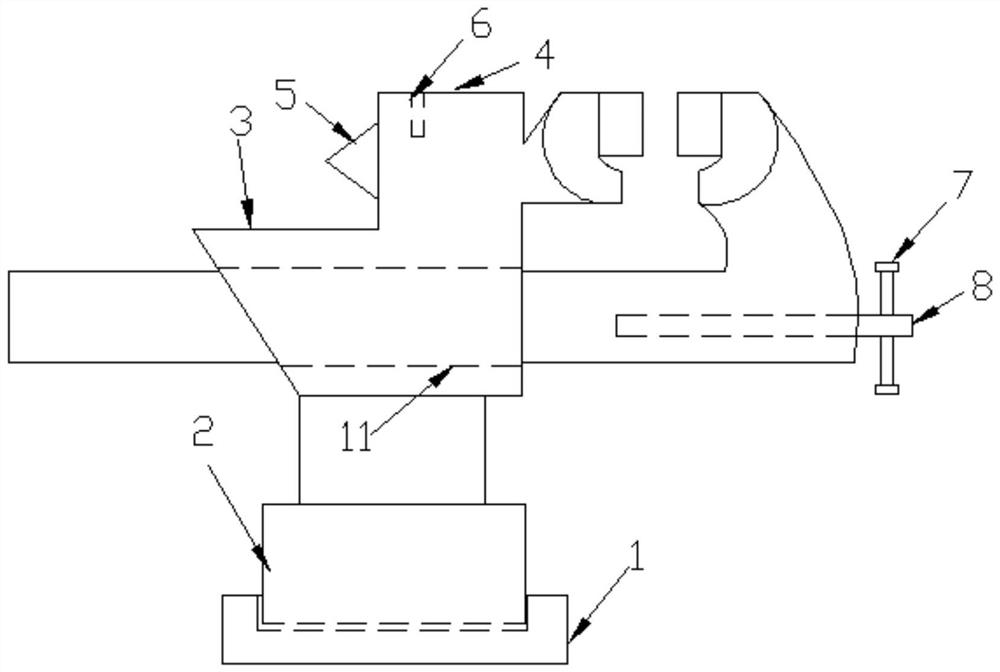

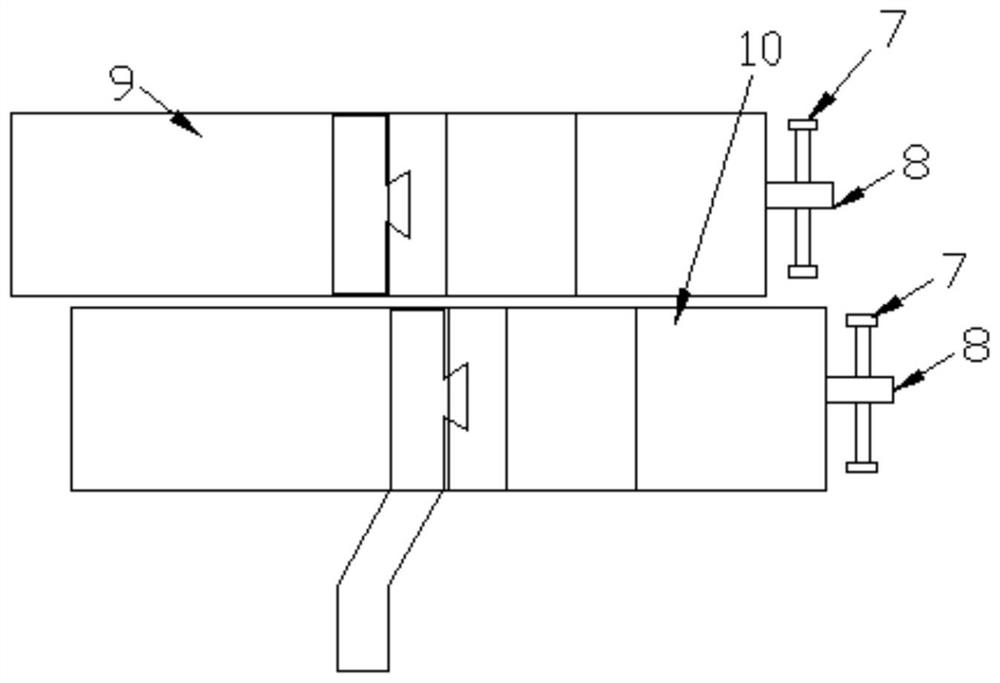

Bench vice

The bench vice comprises a bench vice base and a rotating base rotationally arranged on the base, a fixed vice body is fixedly arranged on the rotating base, a movable vice body driven by a slow clamping mechanism is arranged in the direction, right facing the fixed vice body, of the rotating base, and the movable vice body is arranged in a sliding mode relative to the fixed vice body. Compared with a quick clamping bench vice on the market, the quick clamping bench vice is simple in structure, the mode that the sliding vice body slides relative to the fixed vice body is directly adopted for idle stroke quick forward or quick backward, the handle is rotated after a workpiece to be machined is clamped, and the sliding vice body slowly, gradually and tightly clamps the workpiece through rotation of the lead screw; the technical improvement degree is small, the structure is simple and the technical improvement cost is low. The invention has the advantages of elegant appearance, light weight, large clamping force, long service life, accurate action and the like, is a high-grade and medium-grade product in the tool market, and is widely applicable to factory workshops, school teaching and maintenance departments and the like.

Owner:盐城嘉和五金制造有限公司

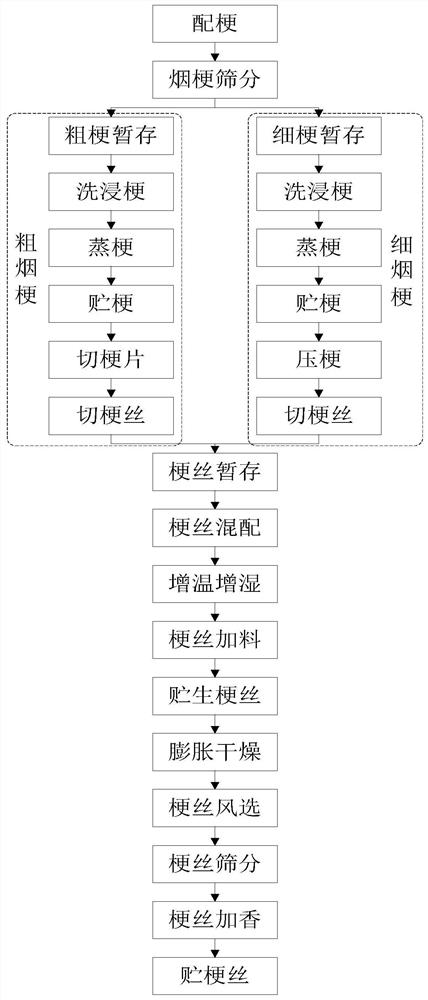

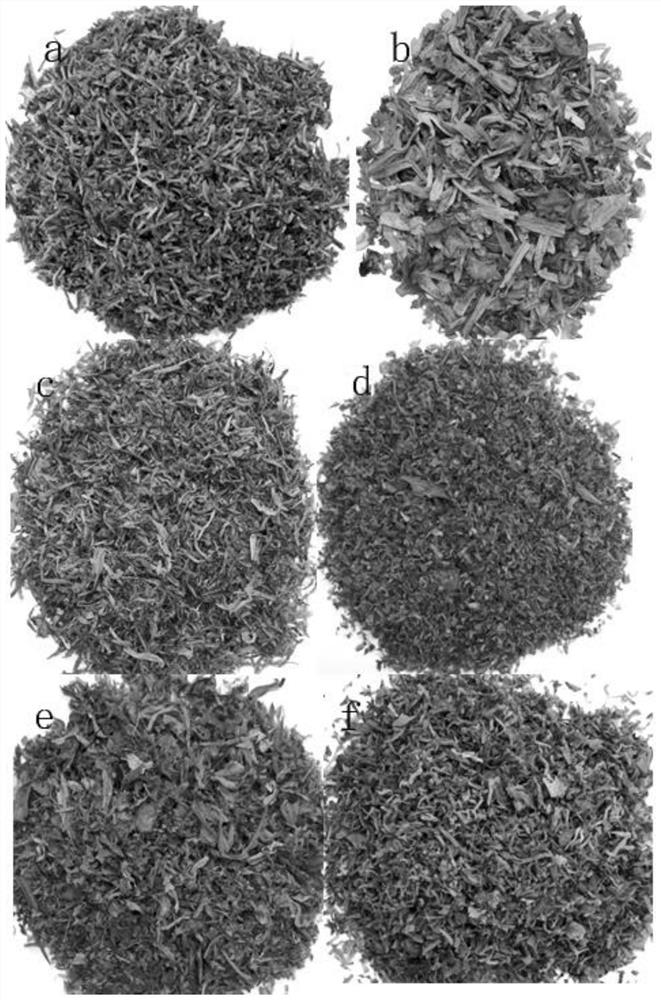

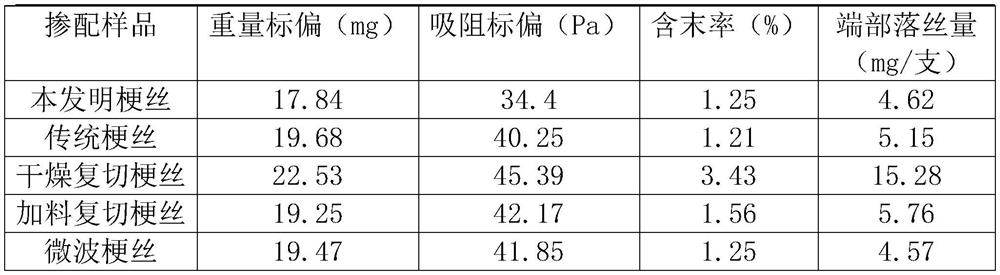

A processing technology of high crimp silky cut stems

ActiveCN108968127BGuaranteed lengthGuaranteed widthTobacco preparationTobacco treatmentBiotechnologyEngineering

The invention discloses a processing technology of high-curling-degree shredded cut stems. According to the technology, tobacco stems are screened into thin tobacco stems and thick tobacco stems for pre-treatment of different intensities after stem preparation, the thin tobacco stems are sequentially subjected to stem washing and soaking, stem steaming, stem storage, stem sheet pressing, stem cutting and cut stem temporary storage, and the stem pressing and stem cutting process is used, so that the crushing problem caused by re-cutting of the thin tobacco stems is avoided, and the utilizationrate of tobacco stem raw materials is effectively increased. The thick tobacco stems are sequentially subjected to stem washing and soaking, stem steaming, stem storage, stem sheet cutting, stem cutting and cut stem temporary storage, the thick cutting and thin cutting process is used, low-water-content stem cutting is carried out before feeding by using a cutting machine, the difference between cut stem sheets and traditional pressed stem sheets is small, the stem cutting machine stably operates for a long time, and the actual cut stem shredded effect is good. After pre-treatment, cut stem mixing and cut stem processing are carried out. The size and shape of the cut stems prepared through the method are highly similar to those of cut tobacco.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

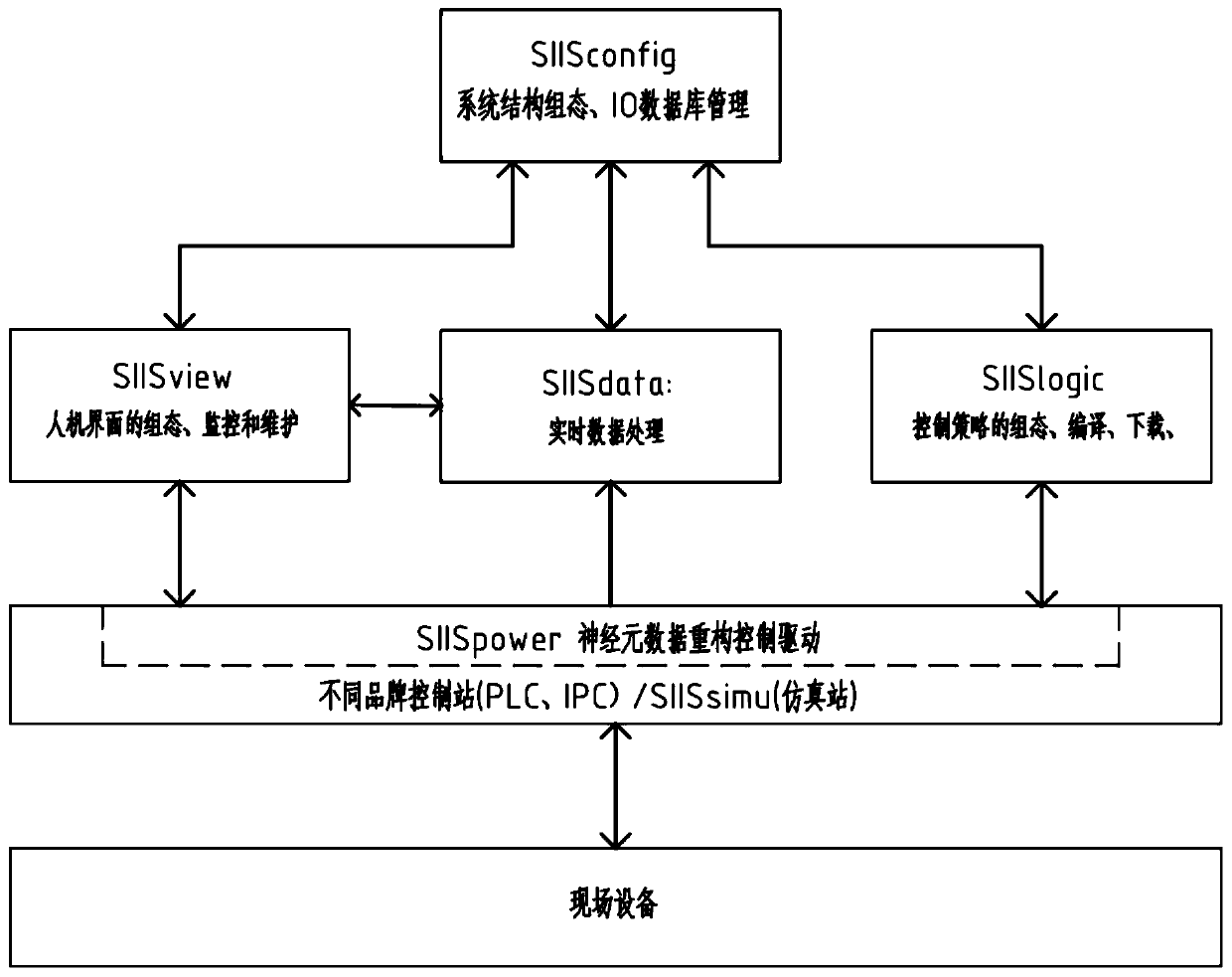

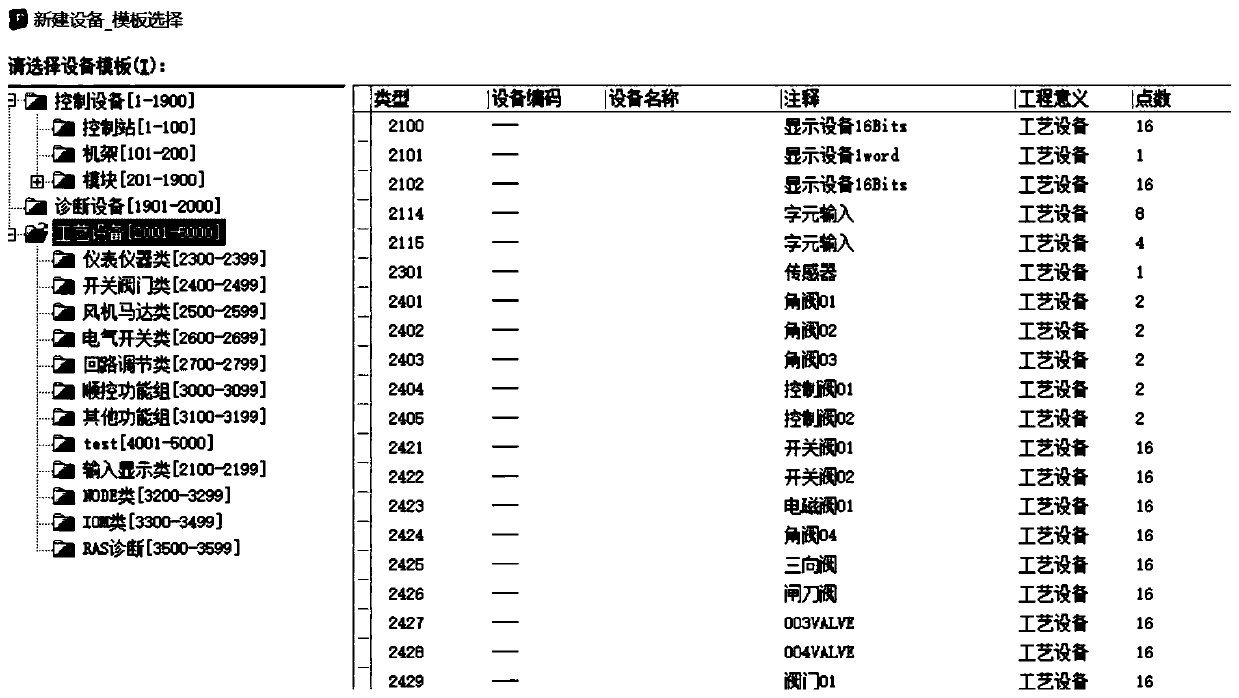

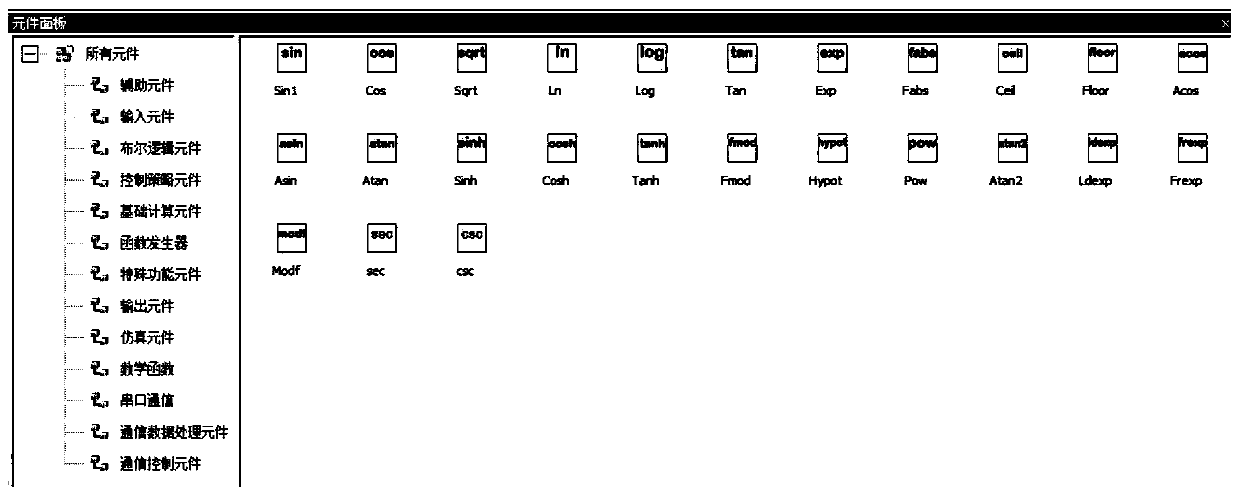

Isomorphic system and platform system of heterogeneous control system

InactiveCN111338299ALow technical transformation costSolve the problem of unified controlTotal factory controlProgramme total factory controlSystem structureProcess engineering

The invention discloses an isomorphic system and platform system of a heterogeneous control system. A system structure and an IO database module encapsulate different equipment models into configuration elements to form a standard element library so as to complete system structure configuration and IO database configuration; a control configuration module can package various different control algorithms into a control configuration element; core modules are installed on all control stations of the heterogeneous control system, operate control configuration elements, and unify the control systems of all the control stations to the same software platform; a man-machine interaction module provides a man-machine configuration element integrated with multiple control algorithms, and the development and application of a man-machine interaction interface are completed through parameter configuration. Various control systems are integrated on the same platform, standard control algorithm configuration is executed, stable transition of industrial equipment system upgrading can be achieved, the production and operation efficiency is improved, and the enterprise technical improvement cost isreduced.

Owner:中工慧科(北京)智能科技有限公司

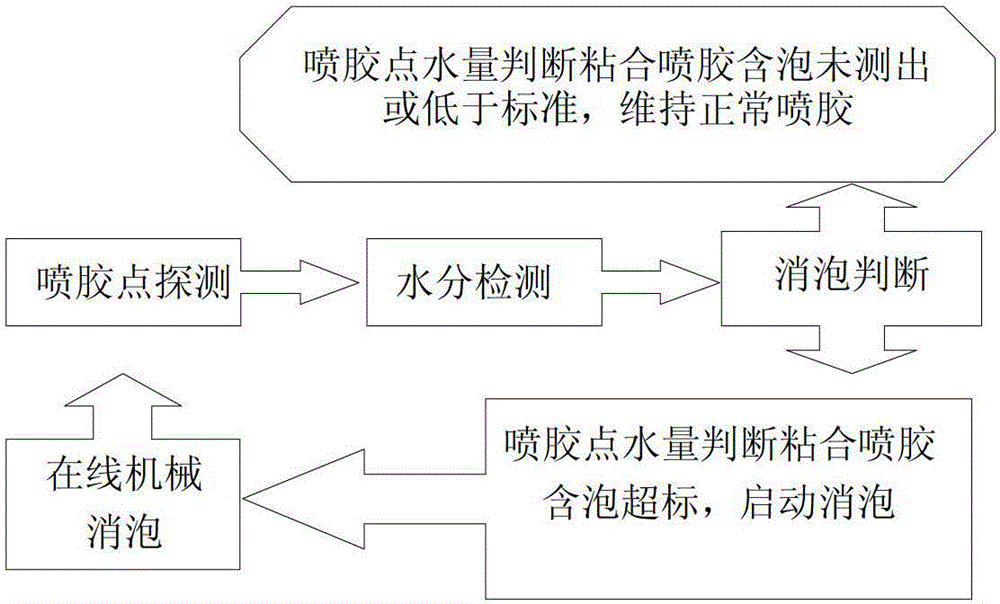

Online automatic detecting and defoaming method for bonding spray glue

ActiveCN103105481BReduce dependenceCompact processMaterial testing goodsFoam dispersion/preventionWater volumeBonding process

Owner:上海九星印刷包装有限公司

A method of treating ddnp wastewater by using the remaining heat of the cement rotary kiln

ActiveCN107144143BReduce generationLow technical transformation costWater contaminantsMultistage water/sewage treatmentCement rotary kilnEnvironmental protection

The invention provides a method for treating DDNP waste water through a technologically improved cement rotary kiln by adopting afterheat of the cement rotary kiln. Through cooperating with surrounding existing cement enterprises, an existing cement rotary kiln is improved by using a low cost, and the afterheat, with a high temperature of nearly 1000 degrees, of the technologically improved cement rotary kiln is utilized to conduct evaporating treatment on the waste water; and after the waste water is treated to a certain concentration, the treated waste water is subjected to burning treatment. According to the method for treating the DDNP waste water through the technologically improved cement rotary kiln by adopting the afterheat of the cement rotary kiln, the environmental pollution is reduced, the difficulty of technological improvement can further be reduced, and the cost for treating the DDNP waste water is reduced.

Owner:FUJIAN CIVILIAN BLASTING CHEM

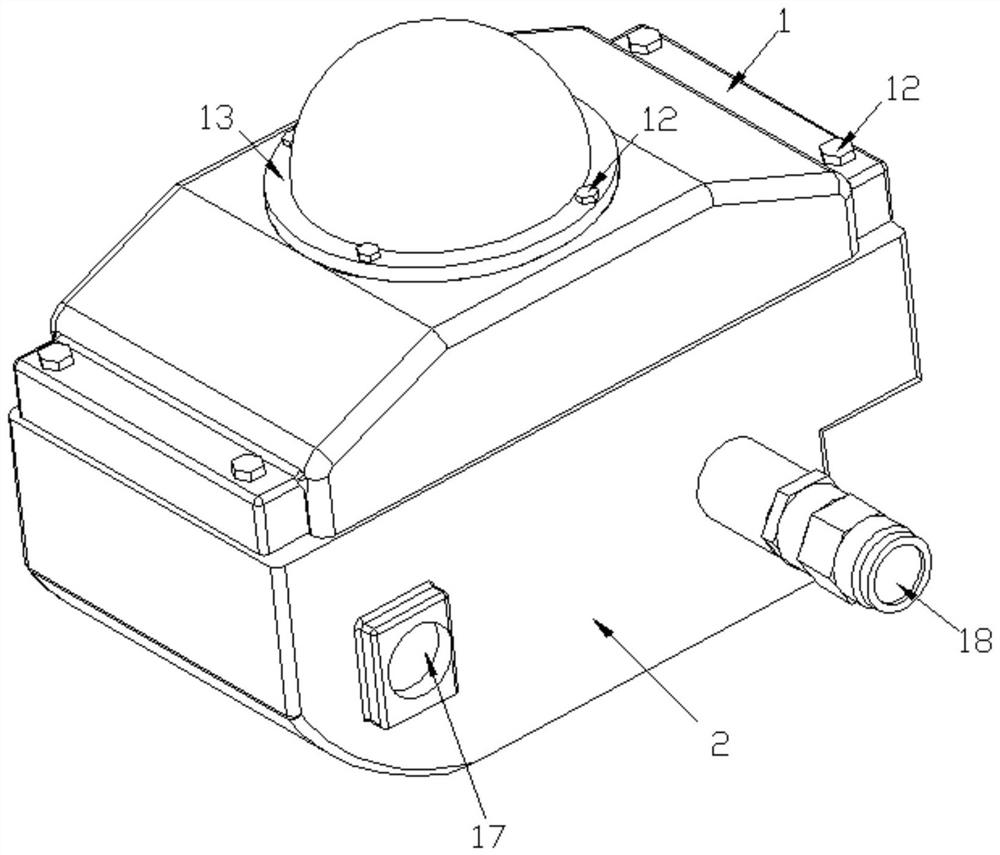

Valve limiting indication structure

InactiveCN114526311AAvoid destructionAvoid the problem that switching will be unstableOperating means/releasing devices for valvesVibration suppression adjustmentsCamTorsion spring

The valve limiting indication structure comprises an upper cover and a main body connected with the upper cover, a driving rod is arranged in the main body, the lower end of the driving rod penetrates through the lower end of the main body, an upper cam and a lower cam are fixedly arranged on the driving rod, and the arrangement positions of the cams correspond to two microswitches on the main body; the driving rod is connected with a torsion spring structure which is used for preventing impact force generated by quick action from possibly damaging the switch. Through the arrangement of the torsion spring structure, the switch can be prevented from being damaged by impact force generated by quick action, the problem that switching of contacts is unstable when the operation speed is extremely low can also be avoided, the technical improvement degree is low, the technical improvement cost is low, two needed functions are achieved through one technical improvement point, and the design is ingenious.

Owner:盐城志驰机械有限公司

Steel strand cable with polyurea protective material on outer layer and manufacturing method thereof

ActiveCN105088950BImprove shock absorptionImprove skid resistanceRope making machinesBridge structural detailsEngineeringUltimate tensile strength

A steel strand cable with a polyurea protective material on the outer layer, comprising a steel strand assembly composed of n steel strands, and a polyurea protective coating I is coated on the outer layer of the n steel strand assembly A steel strand cable Ia with a polyurea protective material on the outer layer is formed, and a steel strand cable Ia0b composed of a polyurea protective coating II is coated on the outer layer of the wrapping tape of the steel strand cable Ia. The production method is to pass the steel strand assembly after pretreatment, drying, and forming steps through polyurea material coating process I, wrapping process, polyurea material coating process II, extrusion molding, and polyurea material coating process. One or more steps in the coating process III and other processes to make a series of steel strand cables with multiple protections. The production method of the invention is simple; the produced steel strand cable has good tensile strength, flexibility, high damping, aging resistance, wear resistance, and good vibration damping performance; it can greatly improve the anticorrosion ability of the steel strand cable and extend the The service life of twisted cable, 1≤n≤1000.

Owner:LIUZHOU OVM MASCH CO LTD

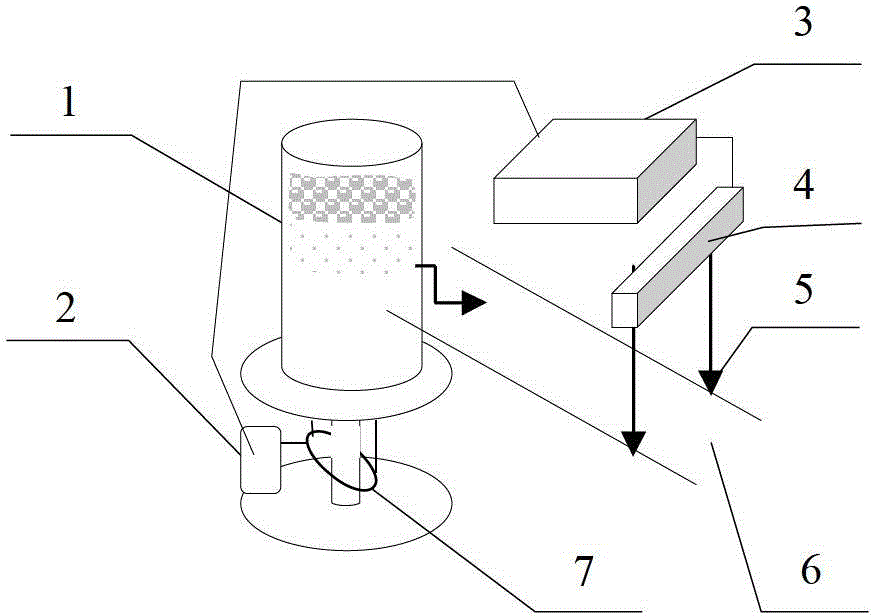

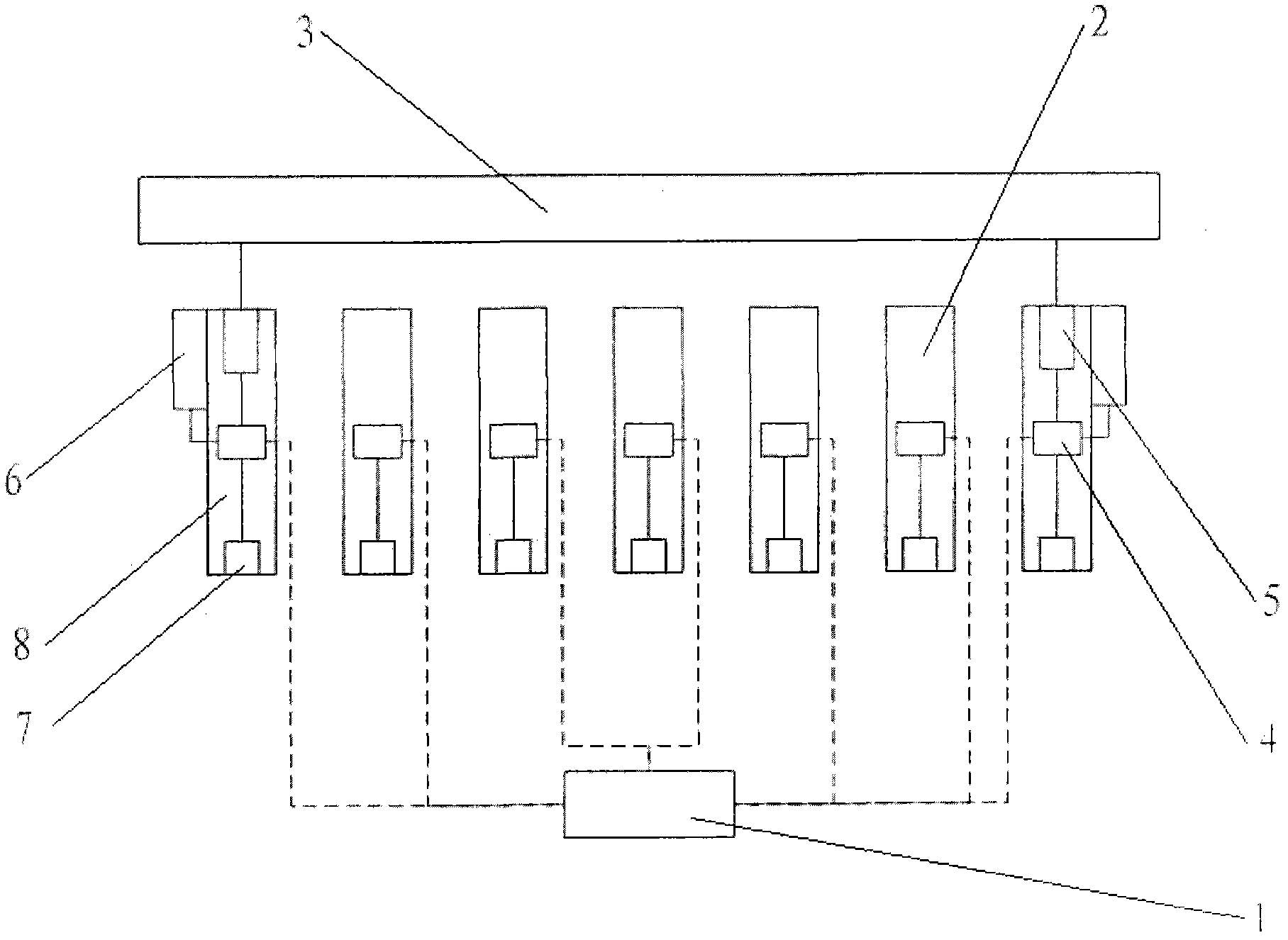

Automatic coal caving system on top coal caving working face and coal caving method thereof

ActiveCN102493827BRealize automatic coal dischargeNo human intervention requiredMine roof supportsSpelunkingControl system

The invention relates to an automatic coal caving system on a top coal caving working face and a coal caving method thereof. The automatic coal caving system comprises a monitoring host, support controllers, inclination angle sensors, distance measuring instruments and data acquisition devices, wherein the distance measuring instruments and the data acquisition devices are mounted on end hydraulic supports in top coal caving supports, and the data acquisition devices are connected with a scraper conveyor of the top coal caving working face; the support controllers are in the same number with the top coal caving supports, and each top coal caving support is provided with the support controller; the inclination angle sensors are in the same number with the top coal caving supports, and the inclination sensor is arranged on a tail beam of each top coal caving support; the monitoring host is mounted in an underground road and in wireless connection with all the support controllers; each distance measuring distance and the corresponding data acquisition device are electrically connected with the support controller on the same top coal caving support; and each inclination angle sensor is electrically connected with the support controller on the same top coal caving support through a connector.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

Automobile tail gate assembly and process technology thereof

PendingCN110103688AReduce the difficulty of selectionReduce weightSuperstructure connectionsDoorsStructural engineeringInjection moulding

The invention discloses an automobile tail gate assembly which comprises an integrated injection molding tail gate plate. A locking structure is arranged on the inner wall of the tail gate, wherein the locking structure is connected with a tail gate lock of a automobile body rear end plate, the locking structure is arranged close to the free end of the tail gate plate, and a hinge shaft hinged tothe rear end of the automobile roof is fixedly arranged on the inner wall of the tail gate plate; and a taillight box is arranged on the tail gate plate in a clamping mode. The invention further discloses a processing technology of the tail gate, a metal material is changed into plastics, so that the weight is reduced, the stamping difficulty is reduced, and molding is diversified; stamping is changed into an injection molding technology; compared with the metal material, plasticity of the plastics is higher; and the purpose that the tail gates are closed more tightly when automobiles are driving on bad roads is achieved.

Owner:江阴名鸿车顶系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com