Patents

Literature

31 results about "Sulfur granules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In severe cases, they may penetrate the surrounding bone and muscle to the skin, where they break open and leak large amounts of pus, which often contains characteristic granules (sulfur granules) filled with progeny bacteria. These granules are named due to their appearance, but are not actually composed of sulfur.

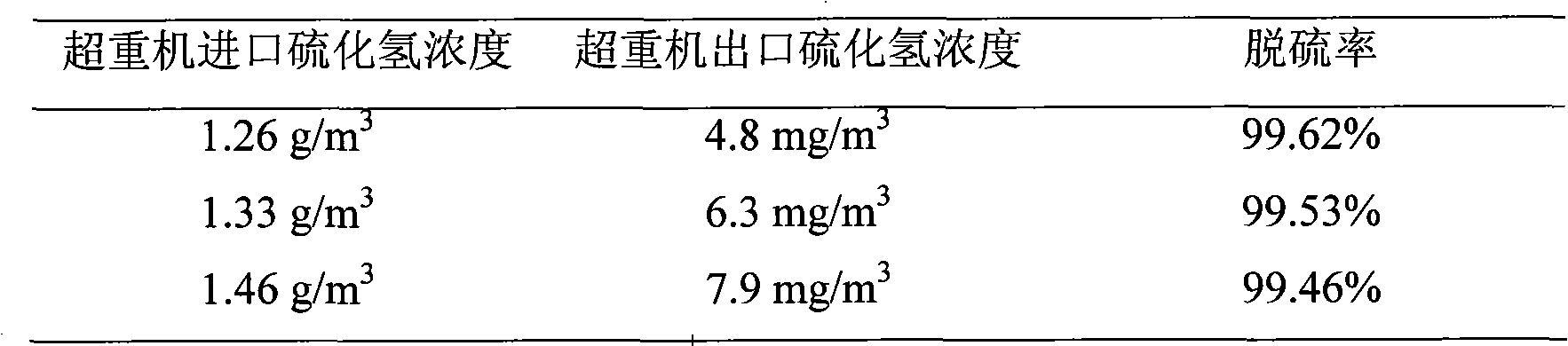

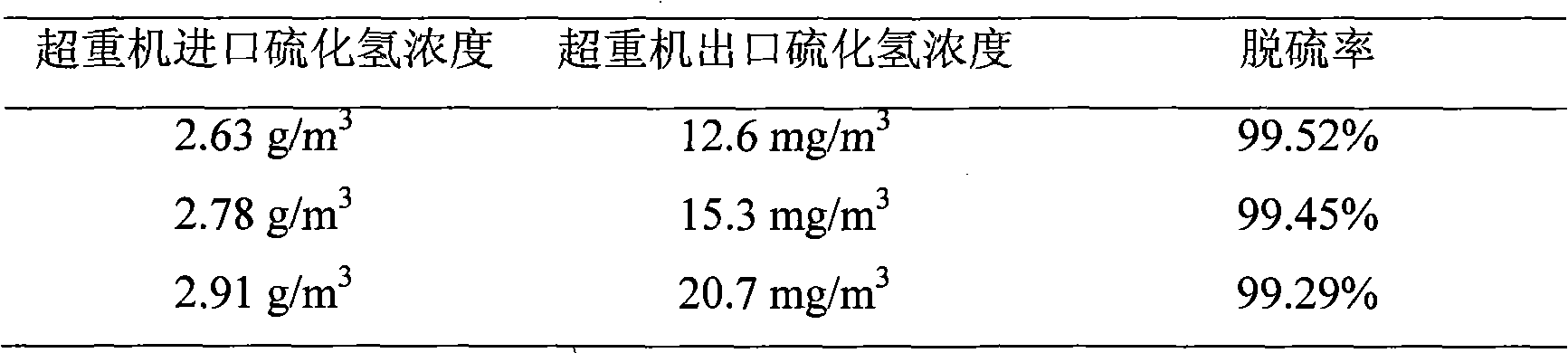

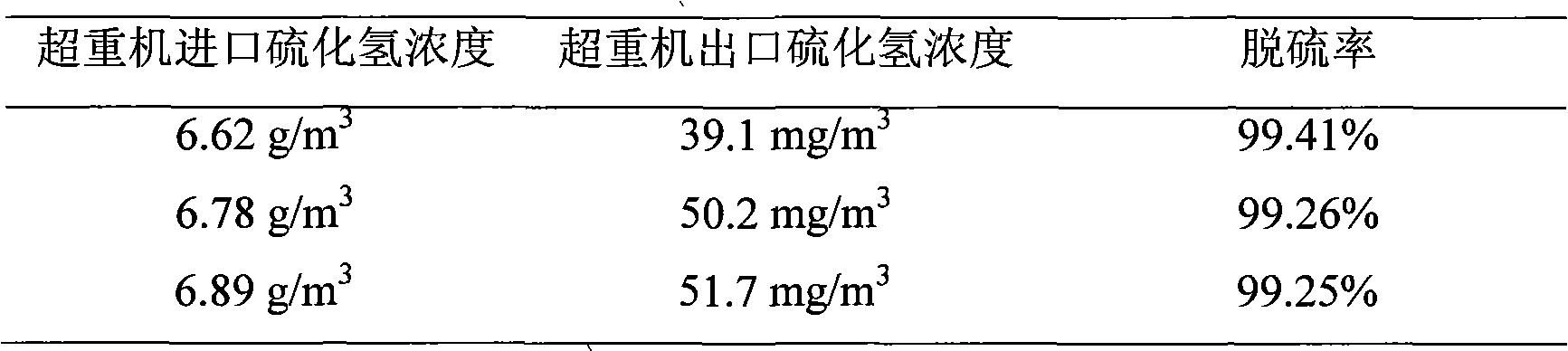

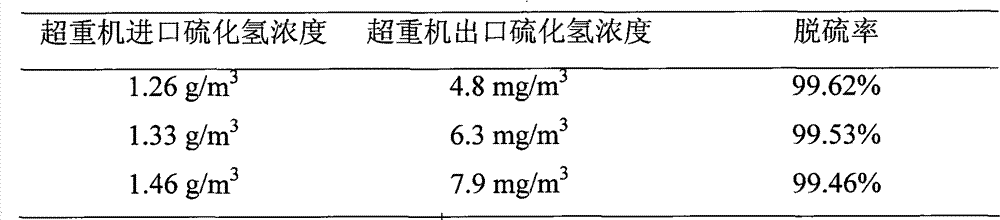

Iron complex desulfurizer suitable for super-gravity desulfurization

ActiveCN101874968AReduce corrosionReduce corrosion rateDispersed particle separationSulfur granulesIron salts

The invention belongs to the technical field of gas purification, and in particular relates to an iron complex desulfurizer suitable for super-gravity desulfurization. The active ingredients of the iron complex desulfurizer are the following components: a soluble iron salt, an iron salt complexing agent, hydrosulfide absorbants comprising alkaline matters and alcamines, and additives comprising astabilizing agent, a synergist, a sulfur granule settling agent and a corrosion inhibitor. The iron complex desulfurizer has the advantages of large accumulative saturation sulfur capacity (reaching 0.60g / L), high absorption speed, high efficiency, stable solution performance without degradation, easy recovery of sulfur, less side reactions, low running cost and the like; and the accumulative saturation sulfur capacity and the absorption speed are obviously improved, so the iron complex desulfurizer is suitable for the characteristics of small liquid circulating volume and short retention time of the super-gravity desulfurization, fully takes the obvious advantages of the super-gravity technology in the wet desulphurization, and is a high-efficiency, economic, practical and environment-friendly iron complex desulfurizer.

Owner:ZHONGBEI UNIV

Production technique of organic fertilizer

InactiveCN101200390ASimple production processSimple processBio-organic fraction processingAlkali orthophosphate fertiliserAutomatic controlSulfur granules

The invention provides a production process of organic fertilizer; firstly the train liquid is prepared by aerobic actinomycosis; the train liquid is sprayed into the uniform crushed material of straw, Chinese medicine residue, grass coal, wood coal and livestock dung according to the proportion, and then the material is stacked, the temperature rises to 60 DEG C to 80 DEG C automatically, and the temperature is kept for 7 to 14 days and then is dropped to 40 DEGC automatically, after that, the moisture is dried to less than 20 percent; afterwards the material is added with the lemery salt of 10 percent to 15 percent, phosphoric acid amine of 8 percent to 10 percent and amino acid of 1 percent to 2.5 percent, and when is mixed equably, thereby the organic fertilizer is generated. The production of the organic fertilizer has the advantages of simple production process, short production cycle, less strain consumption and low cost. The organic matter content of the fertilizer is greater than 30 percent; the amino acid content is above 2.5 percent; the content of nitrogen, phosphorus and potassium is 8 percent to 12 percent; and the fertilizer efficiency is high; while increasing the crop yield, the crop quality is improved, furthermore, the invention is conductive to environmental protection. Thereby the invention is suitable for the crops of foodstuff, tobacco leaf, vegetable and fruit.

Owner:李珍发

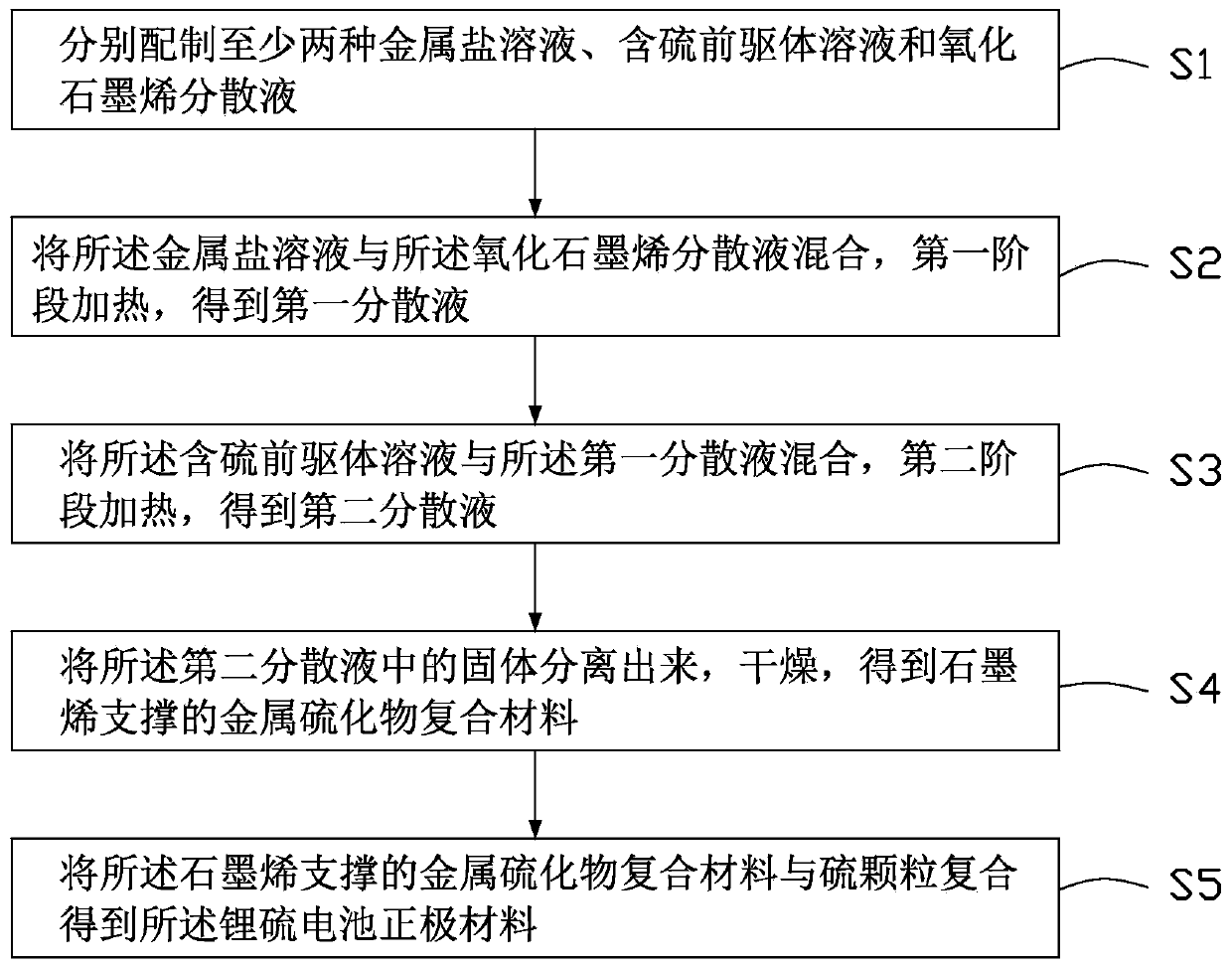

Lithium-sulfur battery anode material, preparation method thereof, anode piece and lithium-sulfur battery

ActiveCN109742359AHigh reactivityAchieve polar dopingMaterial nanotechnologyCell electrodesSulfur granulesLithium–sulfur battery

The invention discloses a lithium-sulfur battery anode material, which comprises graphene, metal sulfide and sulfur granules, wherein the metal sulfide comprises at least two transition metal sulfides, and the metal sulfides and the sulfur granules are jointly loaded to the surface of the graphene. The invention also provides a method for preparing the lithium-sulfur battery anode material, the anode sheet comprising the lithium-sulfur battery anode material and a lithium-sulfur battery. The lithium-sulfur battery anode material provided by the invention has a structure that at least two metalsulfides are tightly embedded in the surface of the graphene to form an electric-conduction network structure, a channel is provided for the quick transmission of electrons and ions, the polarity characteristics of the metal sulfides and the characteristic that an edge is rich in active sites can be used for accelerating polysulfide to be converted into lithium persulfide and lithium sulfide in alithium-sulfur battery anode reaction process, the use ratio of active substances in the lithium-sulfur battery is improved, and finally, the lithium-sulfur battery is accelerated to be practical.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

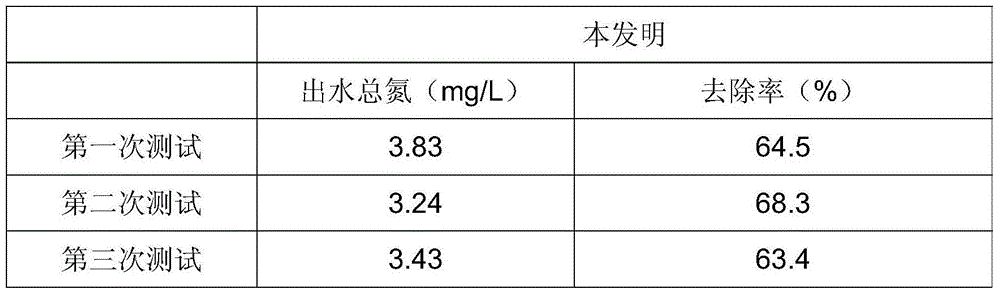

Denitrifying filler, preparation method of denitrifying filler and application of denitrifying filler to denitrification of water body

InactiveCN104925944AImprove adaptabilityShort breeding timeTreatment with aerobic and anaerobic processesSulfur granulesDenitrifying bacteria

The invention provides a denitrifying filler, a preparation method of the denitrifying filler and application of the denitrifying filler to denitrification of a water body. On the first aspect, a surface modifier is coated on the surface of sulfur granules, and the adsorptivity of the surface modifier and the positive charge on the surface modifier facilitates a microbial flora with negative charge to be grown on the surface of the sulfur granules in an attaching way; on the second aspect, heterotrophic denitrifying bacteria are increased in a conventional autotrophic denitrification microbic system to form a mixotrophic denitrification system, so that the breeding time is short, the antijamming capability is strong, the hydraulic retention time is relatively shortened, and the stability of the system and the adaptability of the system to external conditions are also improved; on the third part, the defects that secondary pollution is easily caused by overhigh sulfate ion content in effluent of a sulfur-based autotrophic denitrification system, land salinization is caused, and reusing of the effluent is not benefited are also greatly reduced by the denitrifying filler, and the denitrification performance is improved.

Owner:HUBEI UNIV

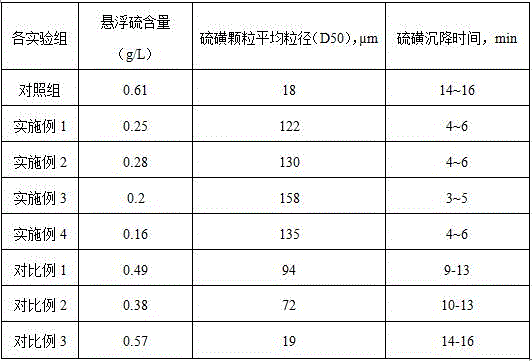

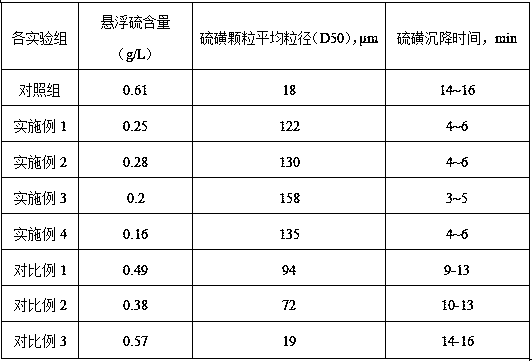

Sulfur granule modifying agent for complexing iron desulphurization liquid and use method thereof

ActiveCN106139837AQuick wetAccelerated settlementDispersed particle separationSulfur preparation/purificationSulfur granulesMicrometer

The invention provides a sulfur granule modifying agent for complexing iron desulphurization liquid and a use method thereof. The modifying agent is prepared from the following ingredients in percentage by weight: 10 to 30 percent of nonionic surfactants, 0.1 to 0.2 percent of flocculating agents, 5 to 15 percent of wetting agents, 2 to 20ppm of antifoaming agents and the balance of water, wherein the flocculating agents are sodium polystyrene sulfonate, and has the molecular weight being 50 to 200 thousand. A preparation method of the sulfur granule modifying agent comprises the steps of mixing, stirring and dissolving each raw material. In the use process, the materials are added into the complexing iron desulphurization liquid, and the addition is 30 to 100ppm. The sulfur granule modifying agent for complexing iron desulphurization liquid can fast moisturize sulfur; the flocculating effect in the alkaline complexing iron desulphurization liquid is good; the average granule diameter of the sulfur can be increased to a value greater than 120 micrometers from several micrometers; the sulfur can easily settle; the sulfur settling time is reduced; the suspended sulfur content is reduced; a sulfur foam layer in the desulphurization liquid can be eliminated in time; the settling and separation effect of sulfur granules is improved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Process for Making a Composite Granule With Rock Phosphate, Sulfur, and Humic Acid

ActiveUS20200270183A1Phosphatic fertiliser granulation/pelletisationOrganic fertilisersSulfur granulesPhosphate

A potassium humate, rock phosphorous, sulfur granule: a fully soluble potassium humate component comprising about 3% of the composite granule; a sulfur component comprising about 15% of the composite granule; and a rock phosphate powder component comprising about 82% of the composite granule. The composite granule is semi-soluble and has a pH of 2.5 to about 12.

Owner:HUMIC GROWTH SOLUTIONS LLC

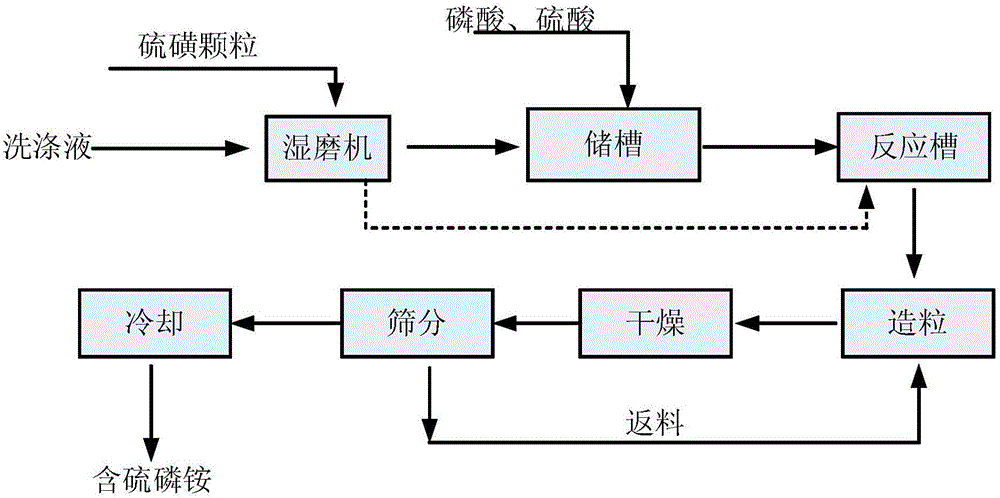

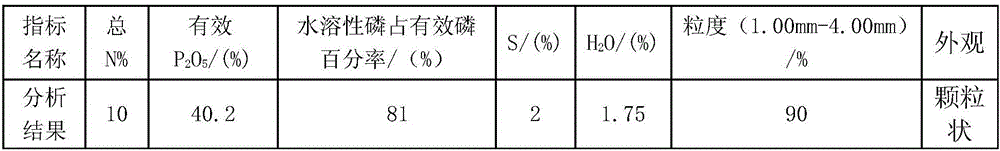

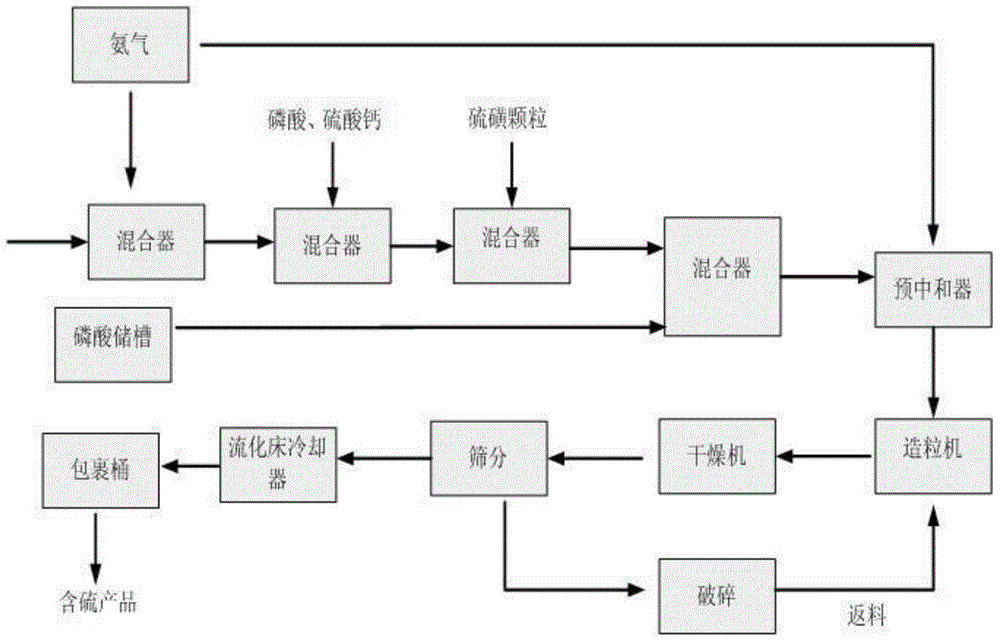

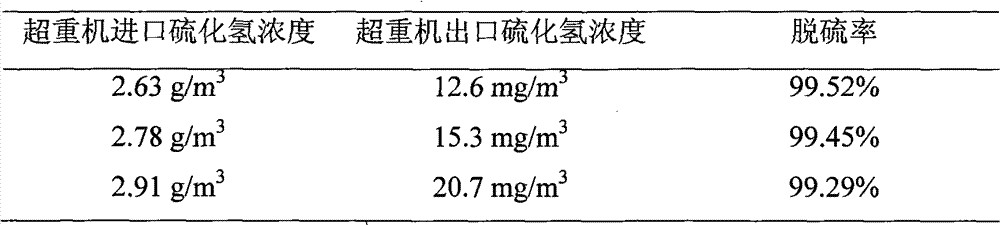

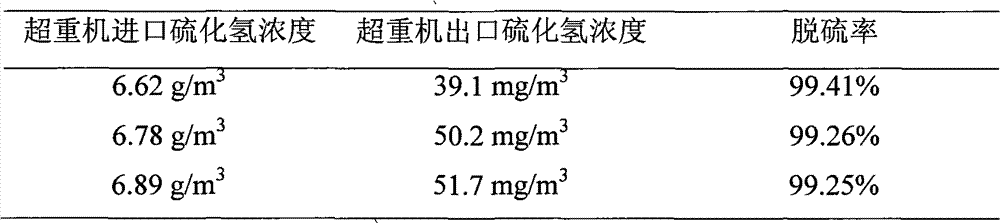

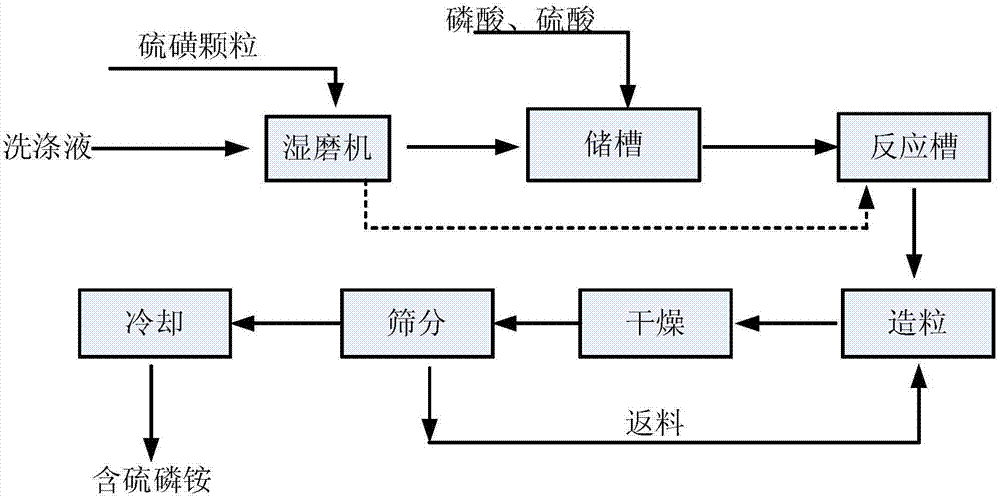

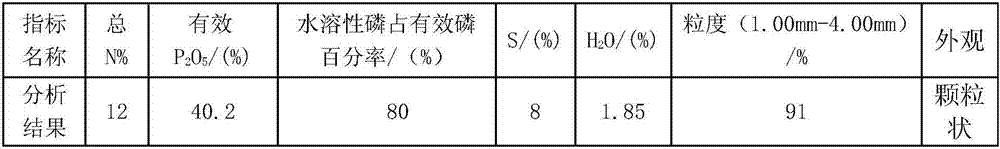

Preparation method of sulfur-containing ammonium phosphate

ActiveCN105800574AOvercome the disadvantage of uneven mixingImprove economyPhosphatesSulfur granulesDiammonium phosphate

The invention discloses a preparation method of sulfur-containing ammonium phosphate. The preparation method comprises the steps that a diammonium phosphate device washing solution and elemental sulfur granules are together subjected to wet grinding, the size of the sulfur granules is controlled according to the production requirement, the sulfur granules are sieved and then conveyed to a reactor of an ammonium phosphate production device or conveyed to a storage tank to be mixed with wet process phosphoric acid and then conveyed to the reactor to react with liquid ammonia, and granulating and drying are performed to obtain sulfur-containing ammonium phosphate. According to the preparation method, the fertilizer containing more than two nutrient elements including phosphorus and sulfur is produced through the existing diammonium phosphate device washing solution, an original process route is not changed, and a low-cost product upgrading method is supplied to a traditional device. The obtained product contains uniform elemental sulfur, the returning frequency is significantly decreased, and the dust explosion possibility is reduced.

Owner:YUNNAN YUNTIANHUA

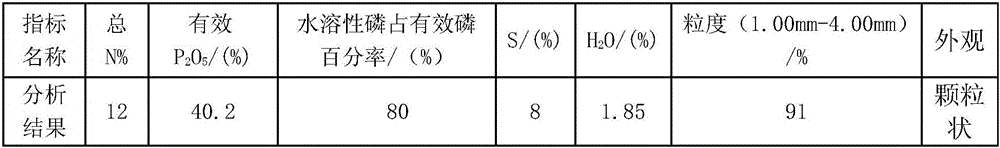

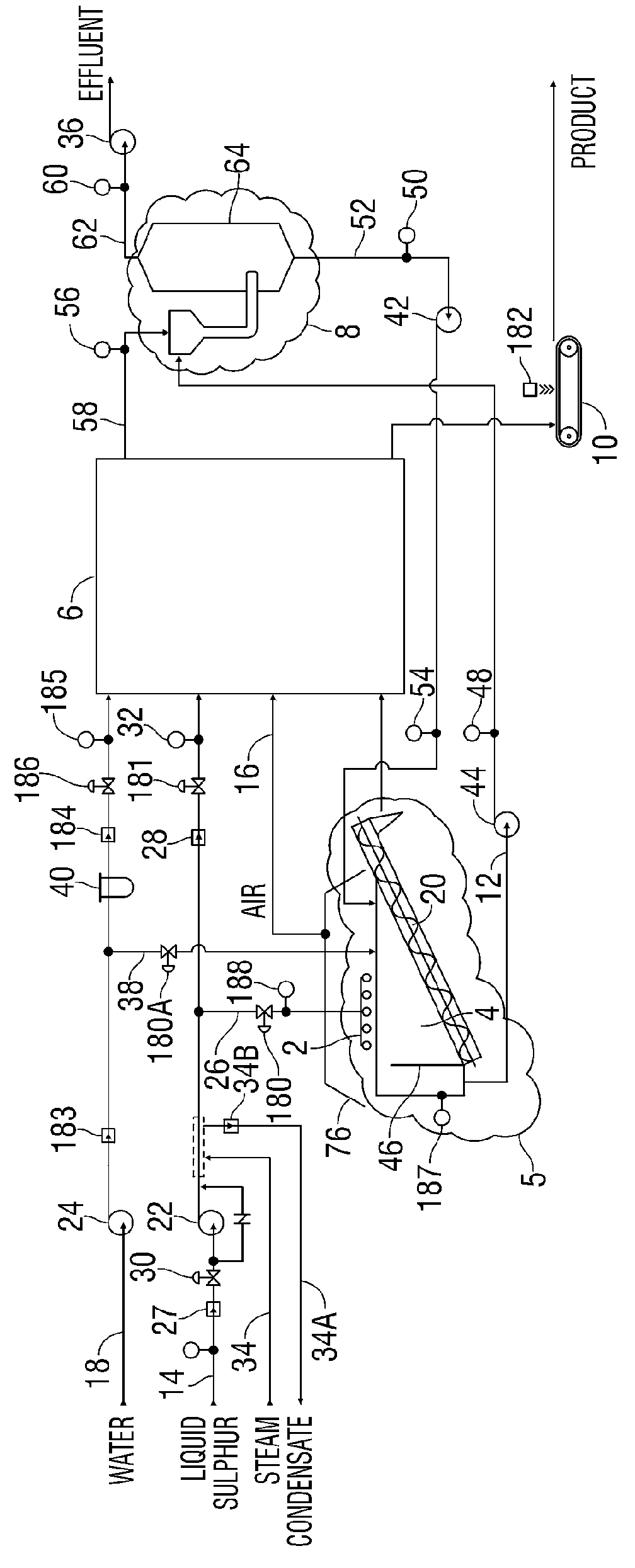

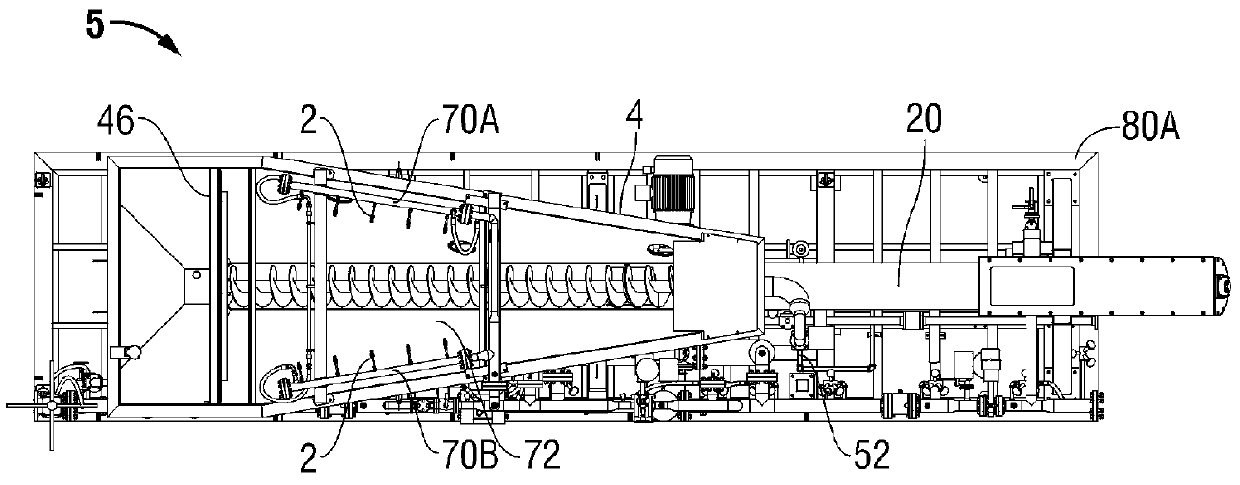

Method and system for generating sulfur seeds and granules

ActiveUS20120126439A1Faster rateIncrease and decrease its productionLiquid surface applicatorsGranulation in rotating drumsSulfurLiquid state

Sulfur (or sulphur) spray nozzles disposed with a cooling tank spray liquid molten sulfur into the cooling liquid in the tank. Solid sulfur seeds are formed in the cooling liquid and settle in the tank. The cooling tank may be a spiral dewaterer tank that has a screw conveyor at the bottom of the tank that moves the seeds to a granulating drum for enlargement into sulfur granules. The cooling tank may also be used to capture and remove sulfur dust from a slurry of sulfur dust and water recycled from the granulating drum. The sulfur dust in the cooling tank may be captured by contact with molten sulfur droplets streaming down the cooling liquid column such that the dust particles become incorporated into the droplet, thereby being converted to seed. The granulating drum may be equipped with two or more sets of segmented lifting flights. The sets of flights may not be in alignment. The flights may be spaced apart from the inside surface of the drum with segmented rib members. The rib members may allow for the movement of sulfur seeds and granules between the flights and the inside surface of the drum as the drum rotates.

Owner:IPCO US LLC

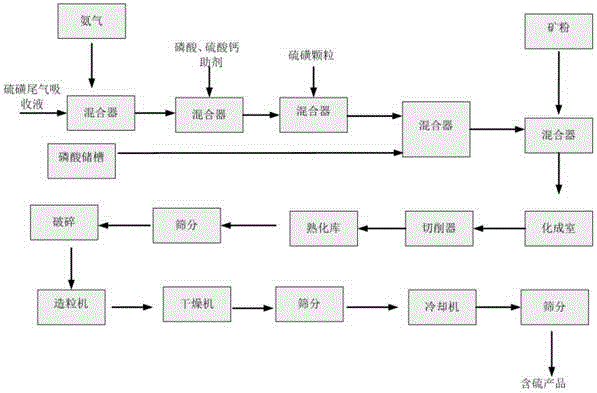

Preparation method for sulfur-containing phosphate fertilizer

The invention discloses a preparation method for a sulfur-containing phosphate fertilizer. The method includes: firstly adding additives into an absorption liquid of sulfuric acid tail gas, endowing the absorption liquid with dispersibility to sulfur granules, performing mixing, then adding the mixture into phosphoric acid, using an existing phosphate fertilizer production device, and carrying out reaction, granulation and drying, thus obtaining the product. The method provided by uses sulfuric acid plant tail gas absorption liquid cyclically, utilizes existing ammonium phosphate, triple superphosphate plant and other traditional phosphate fertilizer devices to prepare the fertilizer containing over two nutrient elements of nitrogen, phosphorus, potassium and sulfur, and provides a low cost product upgrading method for traditional device.

Owner:YUNNAN YUNTIANHUA

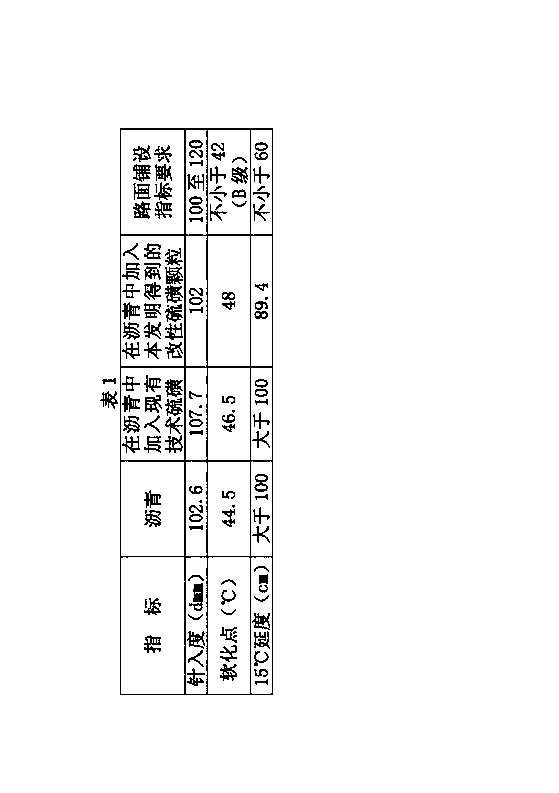

Modified sulfur granules and preparation method and application thereof

InactiveCN103275498AEnhanced inhibitory effectRaw materials are easy to getBuilding insulationsSulfur granulesPhysical chemistry

The invention relates to the technical field of sulfur, and in particular relates to modified sulfur granules and a preparation method and application thereof. The modified sulfur granules comprise the following raw materials in parts by weight: 80-100 parts of sulfur and 1-10 parts of hydrogen sulfide inhibitor. The modified sulfur granules are prepared by the following steps of: adding the sulfur and hydrogen sulfide inhibitor of the required amount into a reaction container and uniformly mixing; heating the uniformly mixed sulfur and hydrogen sulfide inhibitor in an oil bath at 130-140 DEG C; and after the sulfur and hydrogen sulfide inhibitor are molten, reacting for 25-35 minutes until the product has a bright ash black color. According to the sulfur granules provided by the invention, after the heating reaction of the sulfur and hydrogen sulfide inhibitor in the oil bath, the mixture after the reaction is poured into cold water and then filtered to obtain the modified sulfur granules. The sulfur granules provided by the invention have the characteristics that the raw materials are easily available, the physical and chemical properties are stable, the sulfur granules are convenient to store and transport, and the hydrogen sulfide inhibition effect is good in combination with asphalt; and moreover, the production cost is reduced, and the production efficiency is improved.

Owner:XINJIANG UNIVERSITY

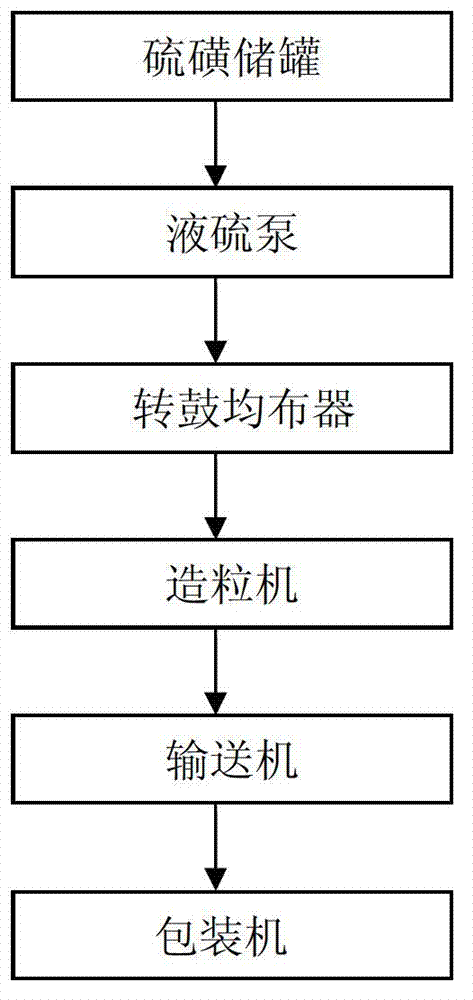

Sulfur forming device and working method

InactiveCN102897719AImprove product quality stabilityEasy to operateSulfur preparation/purificationSulfur granulesSulfur

The invention discloses a sulfur forming device and a sulfur forming working method. The sulfur forming device comprises a sulfur storage tank, a liquid sulfur pump, a drum distributor, a granulator, a conveyer and a packing machine. The sulfur forming working method comprises the following steps of: (a), conveying liquid sulfur from the sulfur storage tank to the drum distributor through the liquid sulfur pump, and spraying the liquid sulfur onto the granulator in a droplet shape through the drum distributor with pores; (b), quickly cooling and solidifying the liquid sulfur on a steel strip of a drum machine; and (c), directly conveying the formed sulfur granules to the packing machine through the conveyer and packing a finished product. On the principle that the conventional sulfur components are not changed, the conventional sulfur forming device with defects and weaknesses is improved and strengthened; and by optimizing the recovery process of the conventional device, the quality stability of a product and the operability are improved, and the process flow is shortened.

Owner:杨佳瑶

Process for making a composite granule with rock phosphate, sulfur, and humic acid

ActiveUS11136275B2Phosphatic fertiliser granulation/pelletisationOrganic fertilisersSulfur granulesPhosphate

Owner:HUMIC GROWTH SOLUTIONS LLC

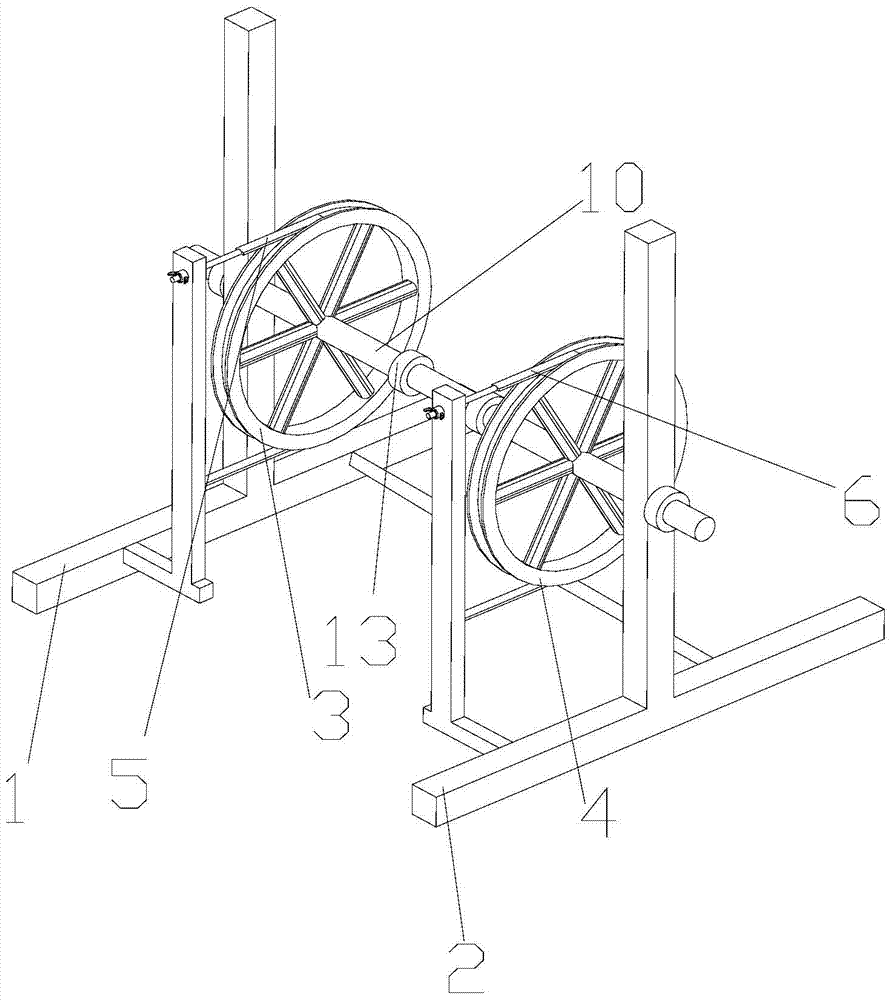

pay-off

The invention discloses a wire pay-off, which comprises a first support base, a second support base, a first runner, a second runner, a pay-off shaft, and a The first speed limiting member and the second speed limiting member installed on the second runner, one end of the pay-off shaft passes through the first runner and the first support seat in turn, and the other end passes through the second runner in turn. The runner and the second support seat, the two ends of the first speed limiting member are fixedly connected to the first support seat respectively, and are set on the outer circumference of the first runner, and the second speed limiter The two ends of the speed piece are respectively fixed on the second support seat, and are sleeved on the outer circumference of the second runner. The pay-off shaft includes a plurality of connecting sections connected in sequence, and two adjacent The connecting sections are connected by a detachable connecting mechanism. This kind of wire pay-off can control the speed of taking and releasing the cable, and can better cooperate with the wire taking equipment to take the wire.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Ammonium phosphate slow-release fertilizer with high sulfur content and preparation method of ammonium phosphate slow-release fertilizer

InactiveCN105272576AImprove qualityReduce security risksFertilizer mixturesHydrophilizationSulfur granules

The invention relates to the technical field of sulfur containing slow-release fertilizers, in particular to an ammonium phosphate slow-release fertilizer with high sulfur content and a preparation method of the ammonium phosphate slow-release fertilizer. Water, a dispersing agent, a humidizer and a thickener are uniformly mixed, a mixed solution is obtained, the mixed solution and sulfur granules are mixed and ground in a wet type grinding machine, sulfur coating slurry is prepared, the adding quantity of the sulfur granules is limited to be 30%-70% of the quantity of the sulfur coating slurry, and accordingly, dust is not formed in the grinding process; the dispersing agent, the thickener and the humidizer are added for grinding, so that hydrophilization of the surfaces of the sulfur granules is realized, the prepared sulfur coating slurry becomes hydrophilic groups and sprayed in a coating machine to coat surfaces of ammonium phosphate granules, further, a finished product is prepared, the content of sulfur in the prepared finished product is 5%-20%, the content of nitrogen is 15%-16%, and the content of phosphorus is 41%-43%. The quality of the sulfur containing ammonium phosphate slow-release fertilizer is improved, the potential safety hazard of sulfur dust to the production environment is reduced, and the production cost is reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Sulfur-supported feedstuff addictive and preparation method thereof

InactiveCN1826944ASmall particlesNarrow particle size distributionAnimal feeding stuffAccessory food factorsHydrotalciteHigh surface

The invention discloses feed addictive carrying sulfur and the method for preparing the same, with hydrotalcite carrying sulfur, and the sulfur content in hydrotalcite is 1-10% by weight percent. The invention takes hydrotalcite as micro-reactor and reduces SO32- with S2- to sulfur. The invention makes use of the nanometer channel structure of hydrotalcite as reactor, so the sulfur granule is small, and the dissipation is uniform and stable. The product is characterized by high sterilizing and disinfection effect and the hydrotalcite can release sulfur slowly because of the features it possesses: bio-availability, compatibility to gastrointestinal tract mucosa, commutativity between layers, high surface activity and large specific surface area. The product can effectively inhibit the propagation of enteric pathogenic bacteria and improve animal production capability.

Owner:ZHEJIANG UNIV

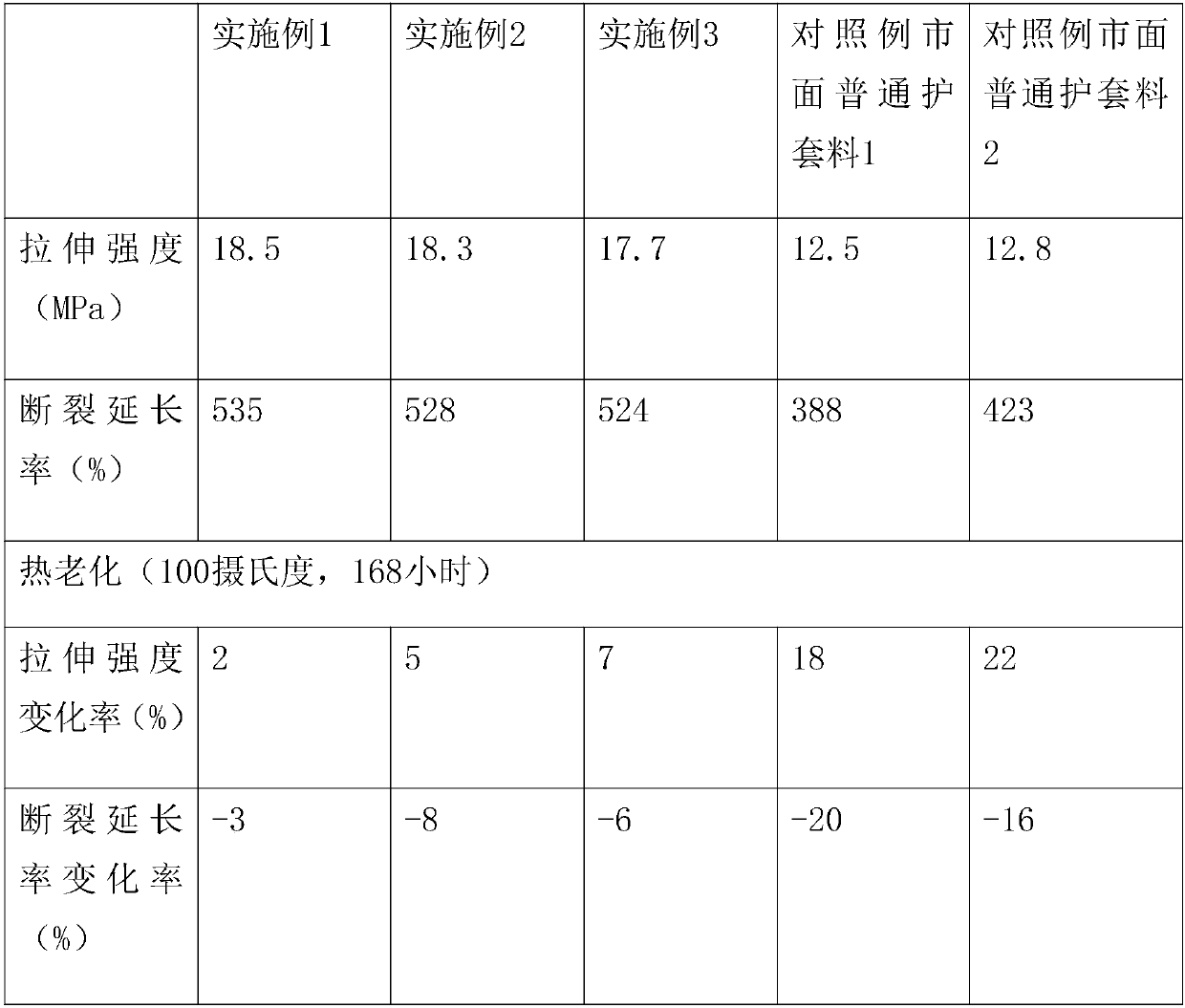

Electric vehicle age-proof wiper rubber strip

The invention discloses an electric vehicle age-proof wiper rubber strip. The electric vehicle age-proof wiper rubber strip comprises the following components in parts by weight: 50-80 parts of nitrile rubber, 30-50 parts of butadiene rubber, 15-20 parts of silica gel, 10-15 parts of polyphenyl ether, 2-5 parts of powdered steatile, 4-10 parts of acridine, 10-15 parts of sulfur granules, 10-12 parts of stearic acid, 5-8 parts of benzoic acid ethylester, 6-12 parts of phenyl silicone oil, 1-2 parts of pyridazine, 5-8 parts of emulsified paraffin, 3-6 parts of active biogum, 0.5-2 parts of methyl silsesquioxane, 1-3 parts of quinoxaline, 5-12 parts of graphite, 5-15 parts of a modified filling material, 1-3 parts of an anti-light aging agent, and 1-2 parts of a heat-aging resisting agent. The electric vehicle age-proof wiper rubber strip has the advantages of good toughness, strong corrosion resistance, and good flexibility, can effectively scrape the glass, is difficult to be aged, andhas long usage life.

Owner:ANHUI BAODAO NEW ENERGY DEV

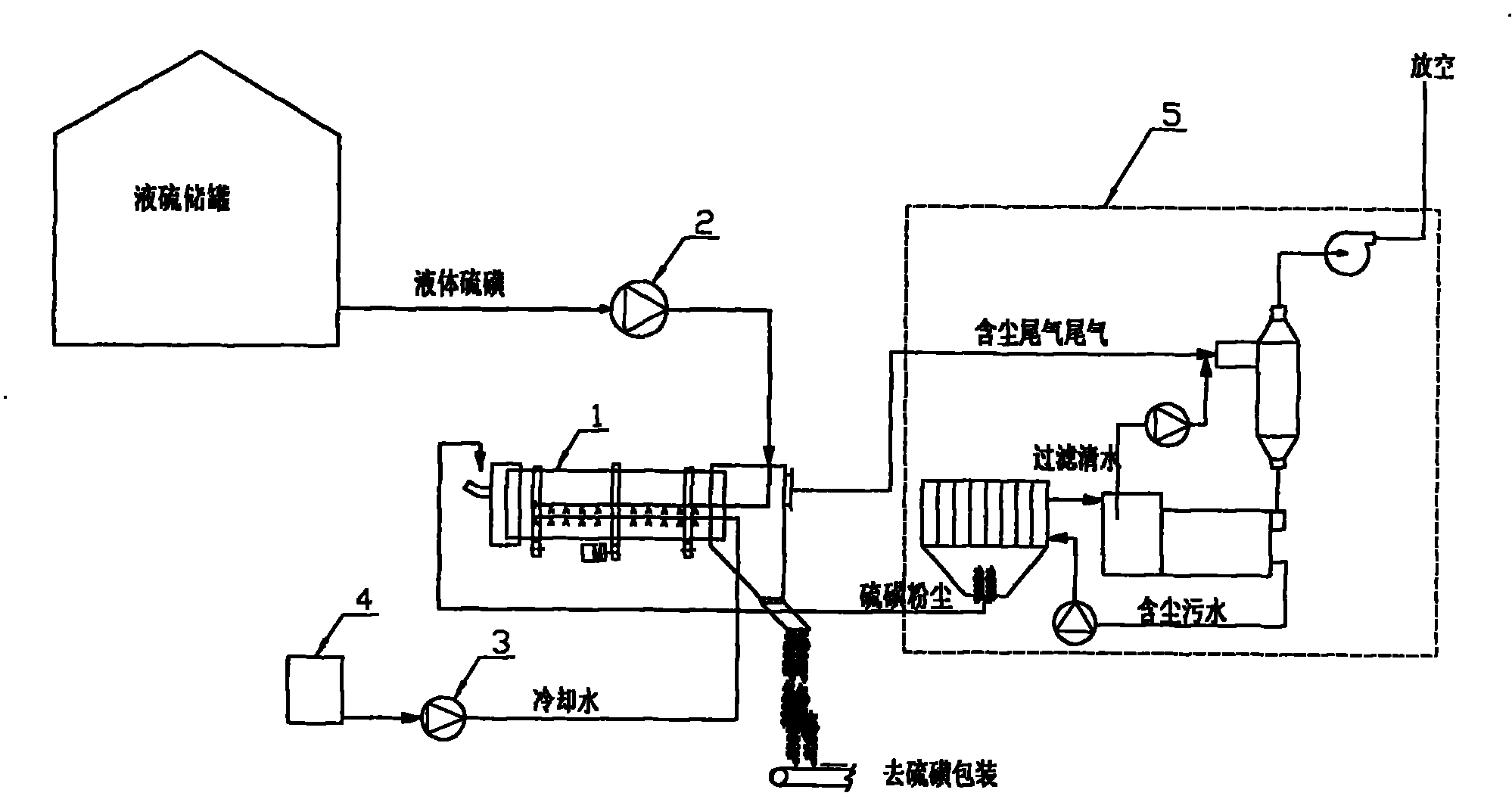

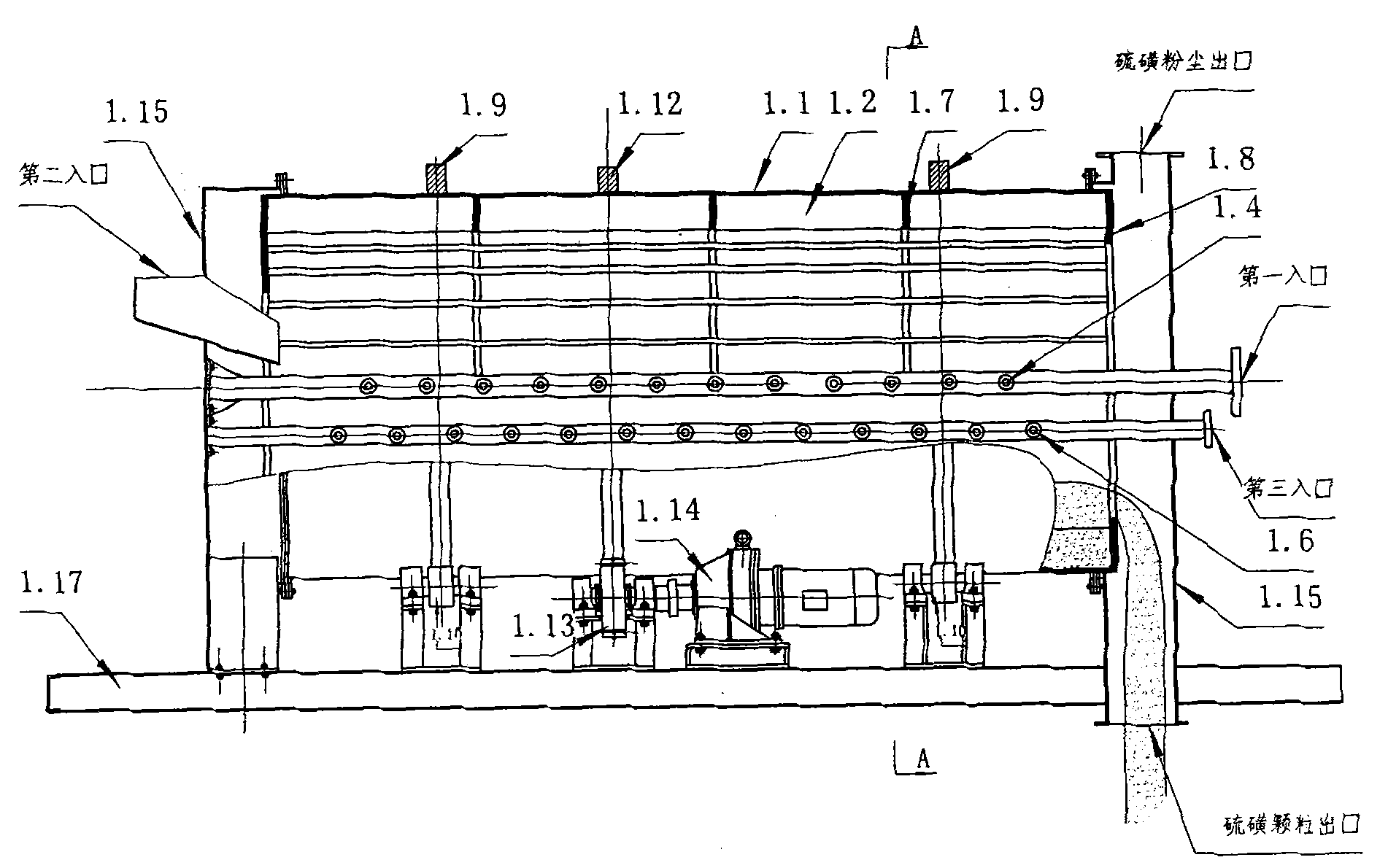

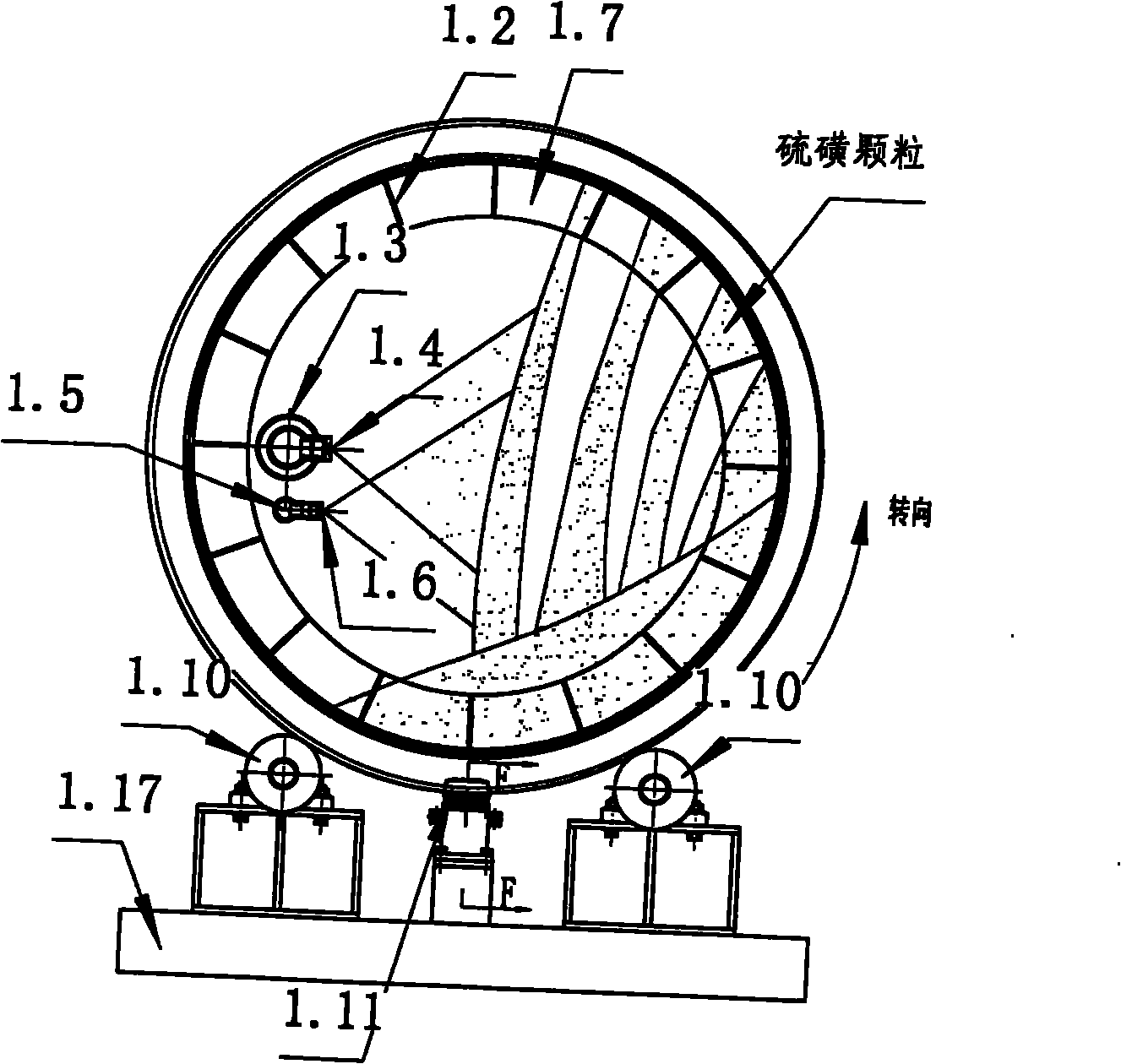

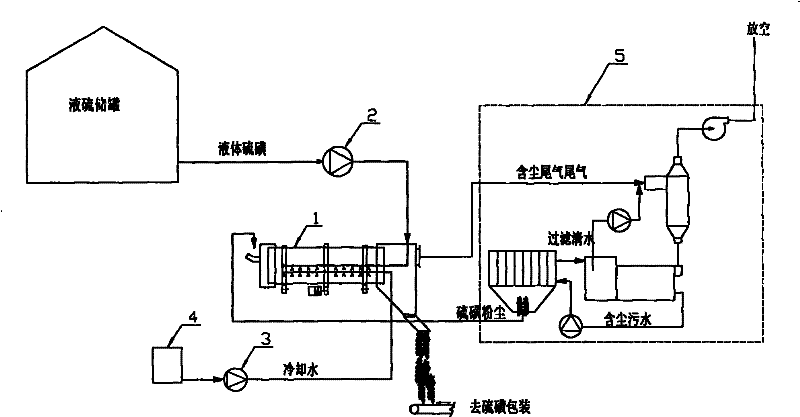

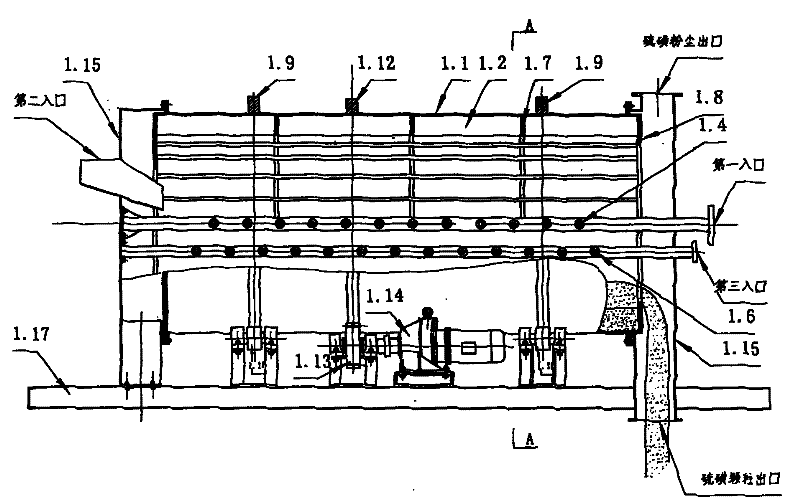

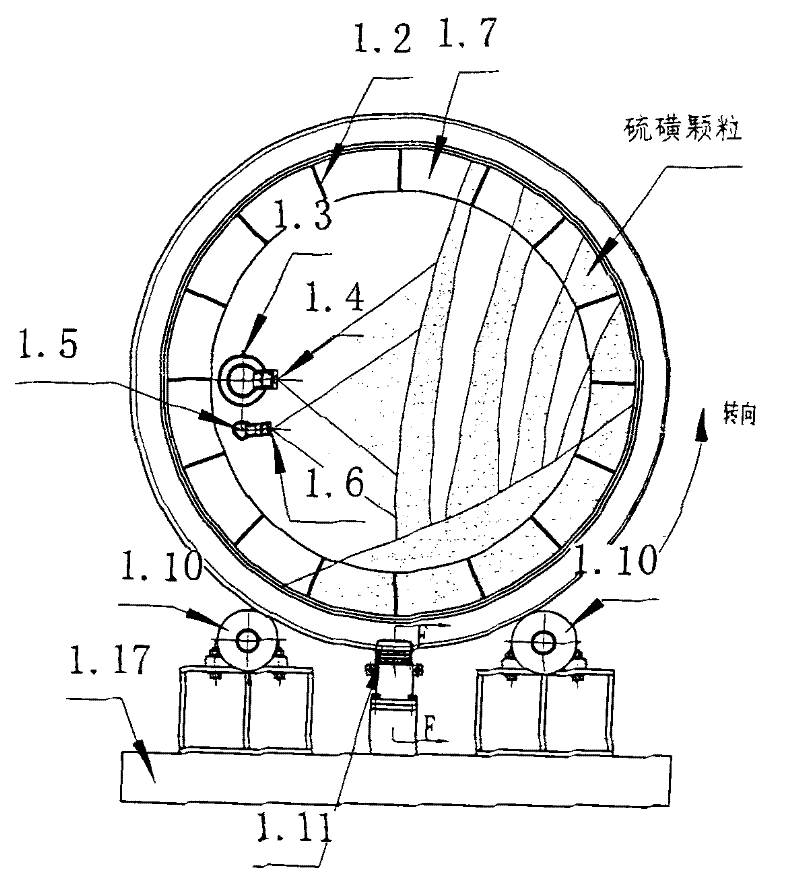

Manufacturing equipment and manufacturing process for spherical sulfur granules

ActiveCN101830441ANo pollution in the processSmall footprintIon-exchange column/bed processesSulfur compoundsSulfur granulesSulfur

The invention discloses manufacturing equipment and a manufacturing process for spherical sulfur granules. The manufacturing process is characterized by comprising the following steps of: feeding liquid sulfur pumped by a liquid sulfur pump in a storage tank into a drum granulator through a jacket pipeline to perform granulation, compressing cooling water in a cooling water tank by a cooling water pump and then spraying the compressed cooling water into the drum granulator, and discharging the solidified sulfur granules into a product packing section from one end of the drum granulator; pumping sulfur dust into a water film dust remover by a draught fan in a water film dust removing unit to perform washing and dust removal; discharging the washed clean gas into the atmosphere; delivering the washed sewage containing the sulfur dust to a filter through a filter pump to perform filter treatment; circulating the filtered water to wash the sulfur dust; and delivering the filtered solid sulfur into the drum granulator to perform granulation so as to form large sulfur granules, and packing products. The manufacturing process has the advantages of solving the problem of sulfur dust reclamation during granulation, and preventing the sulfur dust from exploding and polluting the atmosphere. The manufacturing process has the characteristics of large production capacity, small floor area, saved investment, reduction of production cost and the like.

Owner:南京三普造粒装备有限公司

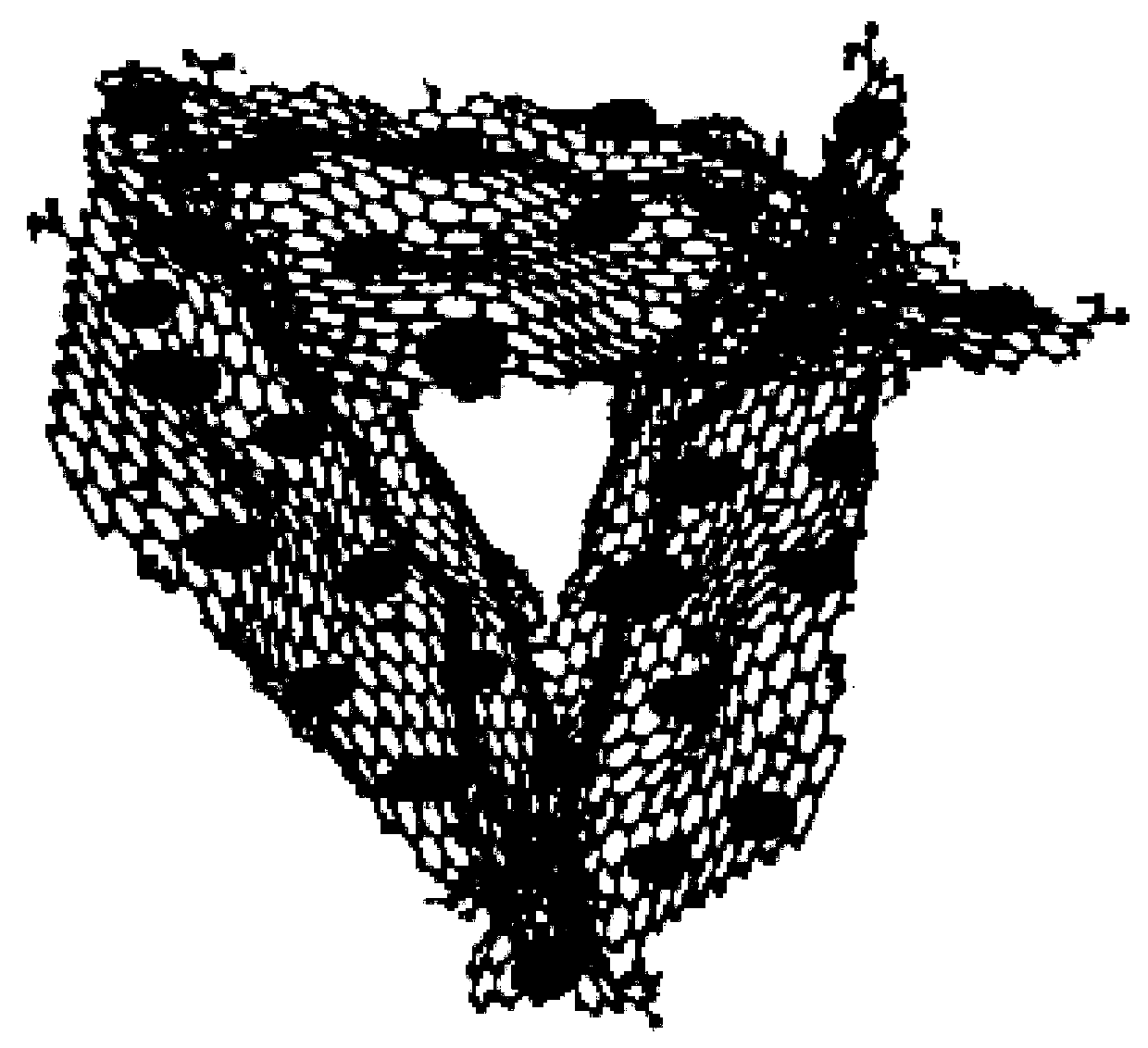

Three-dimensional tubular structured manganese dioxide sulfur supported composite material as well as preparation method, lithium-sulfur battery anode and lithium-sulfur battery

ActiveCN108511728AInhibit shuttleHigh specific capacityPositive electrodesLi-accumulatorsSulfur granulesManganese oxide

The invention provides a three-dimensional tubular structured manganese dioxide sulfur supported composite material as well as a preparation method, a lithium-sulfur battery anode and a lithium-sulfurbattery. Compared with the prior art, the manganese dioxide sulfur supported composite material is obtained by preparing a radiation zinc oxide three-dimensional nanorod with a hydrothermal method, growing manganese oxide on zinc oxide with the hydrothermal method, washing off the zinc oxide by hydrochloric acid, and finally supporting sulfur granules in a sulfur fumigation mode. The product is high in purity and can be applied to a lithium-sulfur battery anode material. By adopting the composite material, difficulties such as polysulfide shuttling can be effectively solved, a composite material preparation method which is simple in process and low in cost is provided, and the lithium-sulfur battery anode material which is good in circulation stability and high in specific capacity can beprepared.

Owner:ANHUI NORMAL UNIV

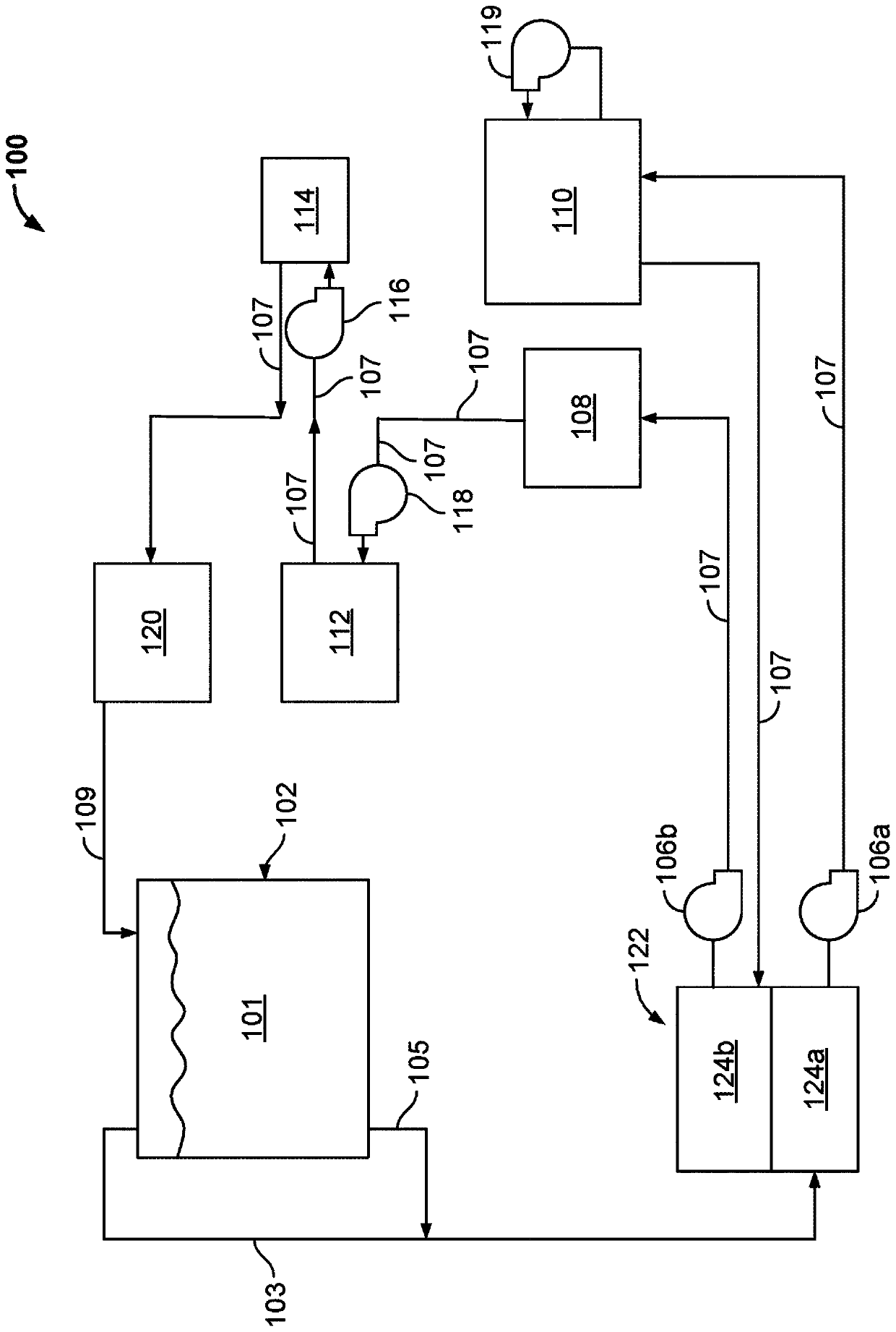

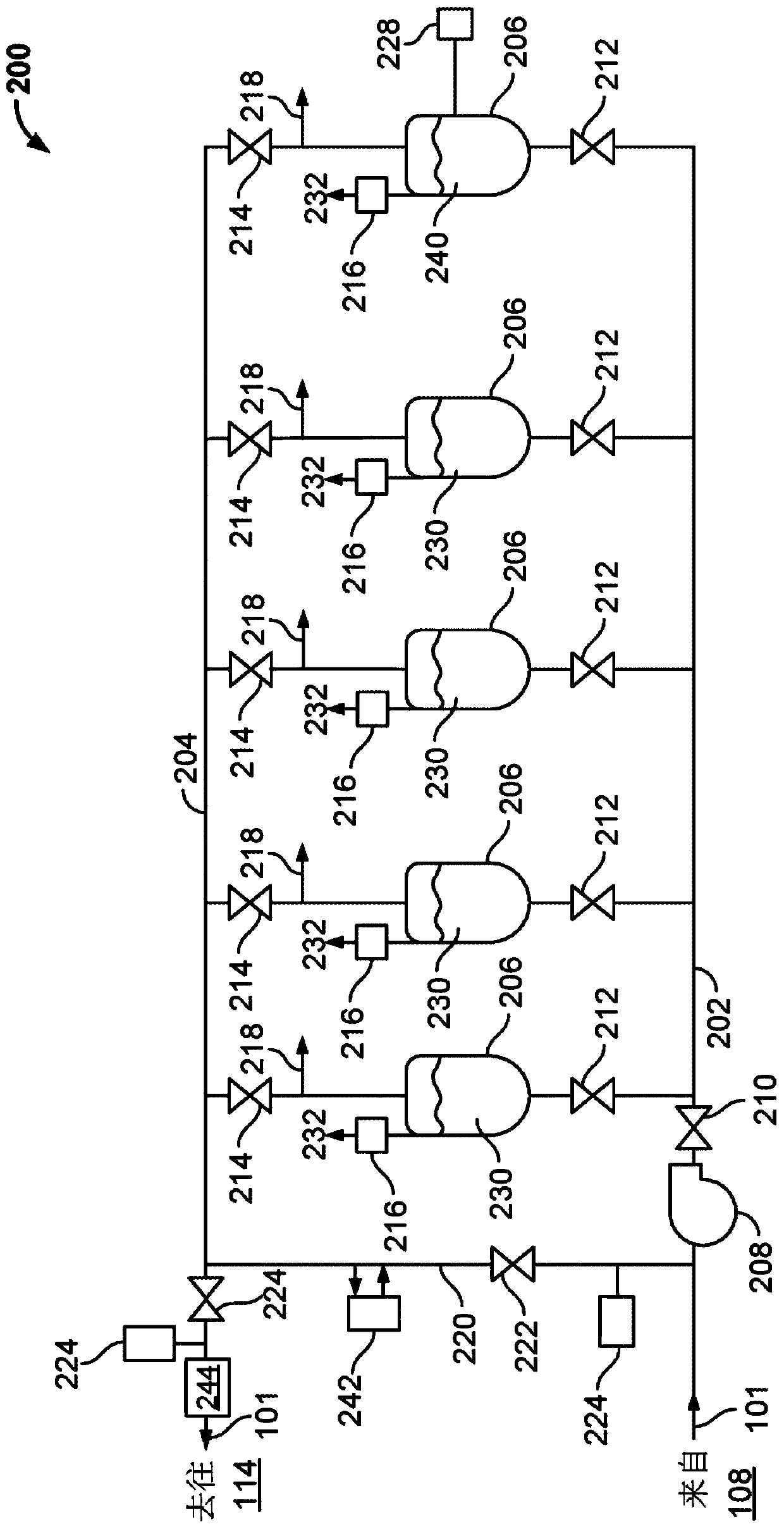

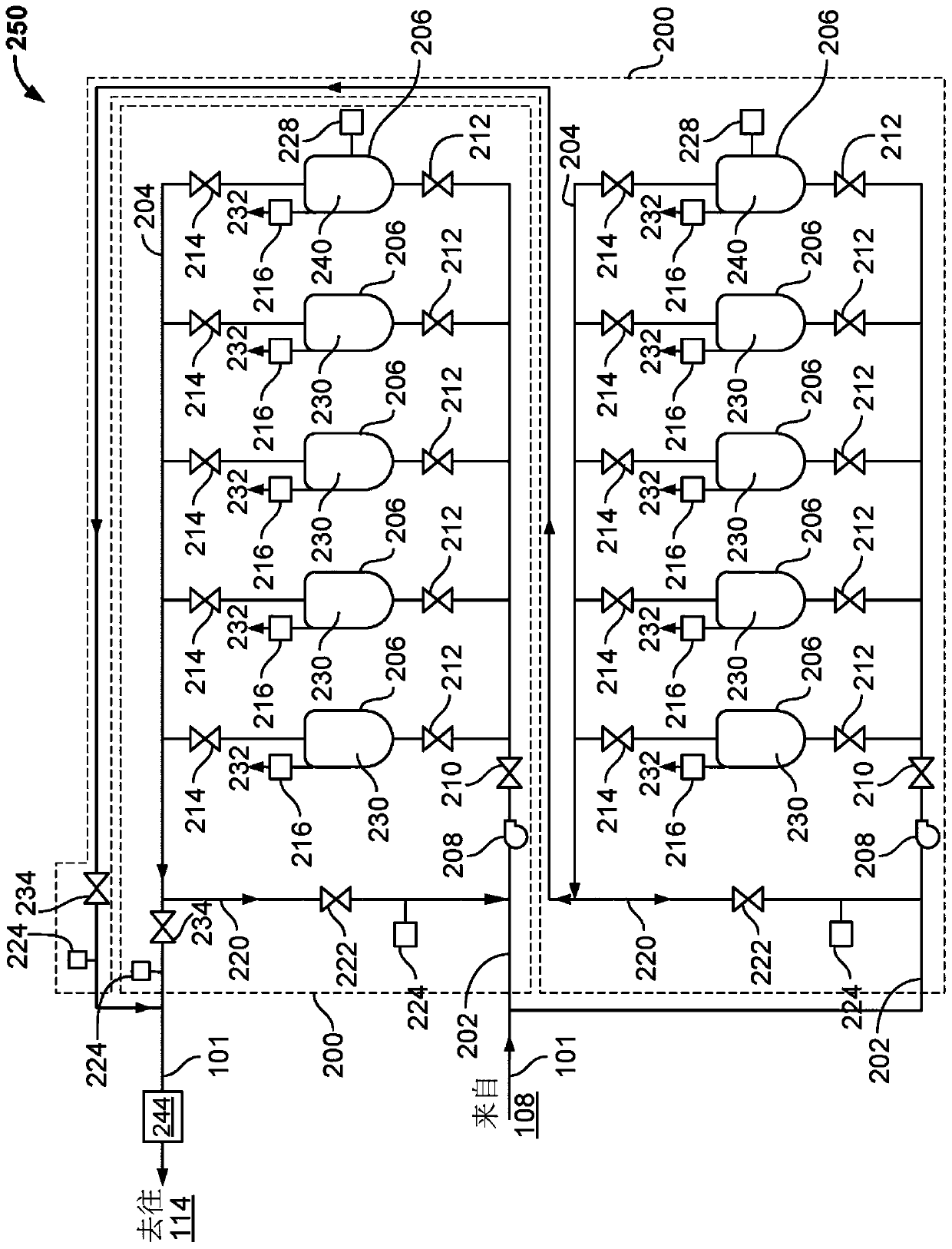

Removing nitrate from water

ActiveCN110234609ABiological treatment regulationWaste water treatment from animal husbandrySulfur granulesWater source

A sulphur de-nitrification system includes a liquid input fluidly coupled to a source of saltwater that includes nitrate; a liquid output fluidly coupled to the source of saltwater; a plurality of vertically-oriented tanks, at least one of the tanks including a liquid inlet that is fluidly coupled to the liquid input to receive a flow of the saltwater, a volume configured to enclose a plurality ofsulphur particles that support de-nitrification bacteria that biologically transform the nitrate into at least one of nitrous oxide or nitrogen gas, and a liquid outlet fluidly coupled to the liquidoutput and the liquid inlets of the tanks; and a circulation system configured to circulate a portion of the saltwater though the liquid input to the liquid inlets of the plurality of tanks, through the plurality of tanks, and from the liquid outlets of the tanks to the liquid output and the liquid inlets of the tanks.

Owner:GEORGIA AQUARIUM INC

Iron complex desulfurizer suitable for super-gravity desulfurization

ActiveCN101874968BIncreased saturated sulfur capacityHigh saturated sulfur capacityDispersed particle separationHigh absorptionSulfur granules

The invention belongs to the technical field of gas purification, and in particular relates to an iron complex desulfurizer suitable for super-gravity desulfurization. The active ingredients of the iron complex desulfurizer are the following components: a soluble iron salt, an iron salt complexing agent, hydrosulfide absorbants comprising alkaline matters and alcamines, and additives comprising astabilizing agent, a synergist, a sulfur granule settling agent and a corrosion inhibitor. The iron complex desulfurizer has the advantages of large accumulative saturation sulfur capacity (reaching 0.60g / L), high absorption speed, high efficiency, stable solution performance without degradation, easy recovery of sulfur, less side reactions, low running cost and the like; and the accumulative saturation sulfur capacity and the absorption speed are obviously improved, so the iron complex desulfurizer is suitable for the characteristics of small liquid circulating volume and short retention time of the super-gravity desulfurization, fully takes the obvious advantages of the super-gravity technology in the wet desulphurization, and is a high-efficiency, economic, practical and environment-friendly iron complex desulfurizer.

Owner:ZHONGBEI UNIV

Modified sulfur particles and its preparation method and application

InactiveCN103275498BEnhanced inhibitory effectRaw materials are easy to getBuilding insulationsSulfur granulesPhysical chemistry

The invention relates to the technical field of sulfur, and relates to a modified sulfur granule and its preparation method and application; the raw material of the modified sulfur granule contains 80 to 100 parts of sulfur and 1 to 10 parts of hydrogen sulfide inhibitor in parts by weight; The modified sulfur granules are obtained according to the following steps: in the first step, add the required amount of sulfur and hydrogen sulfide inhibitor into the reaction vessel and mix them uniformly, then place the uniformly mixed sulfur and hydrogen sulfide inhibitor at 130°C to Heating in an oil bath at 140°C, the sulfur and hydrogen sulfide inhibitors are melted and reacted for 25 to 35 minutes before turning into bright gray black. In the present invention, sulfur and hydrogen sulfide inhibitors are heated and reacted in an oil bath, and the reacted mixture is poured into cold water and filtered to obtain modified sulfur particles; the present invention has the advantages of easy-to-obtain raw materials, stable physical and chemical properties, convenient storage and transportation, and The combination of asphalt and hydrogen sulfide has a good suppression effect, which reduces the production cost and improves the production efficiency.

Owner:XINJIANG UNIVERSITY

A kind of preparation method of sulfur-containing ammonium phosphate

ActiveCN105800574BOvercome the disadvantage of uneven mixingImprove economyPhosphatesSulfur granulesDiammonium phosphate

The invention discloses a preparation method of sulfur-containing ammonium phosphate. The preparation method comprises the steps that a diammonium phosphate device washing solution and elemental sulfur granules are together subjected to wet grinding, the size of the sulfur granules is controlled according to the production requirement, the sulfur granules are sieved and then conveyed to a reactor of an ammonium phosphate production device or conveyed to a storage tank to be mixed with wet process phosphoric acid and then conveyed to the reactor to react with liquid ammonia, and granulating and drying are performed to obtain sulfur-containing ammonium phosphate. According to the preparation method, the fertilizer containing more than two nutrient elements including phosphorus and sulfur is produced through the existing diammonium phosphate device washing solution, an original process route is not changed, and a low-cost product upgrading method is supplied to a traditional device. The obtained product contains uniform elemental sulfur, the returning frequency is significantly decreased, and the dust explosion possibility is reduced.

Owner:YUNNAN YUNTIANHUA

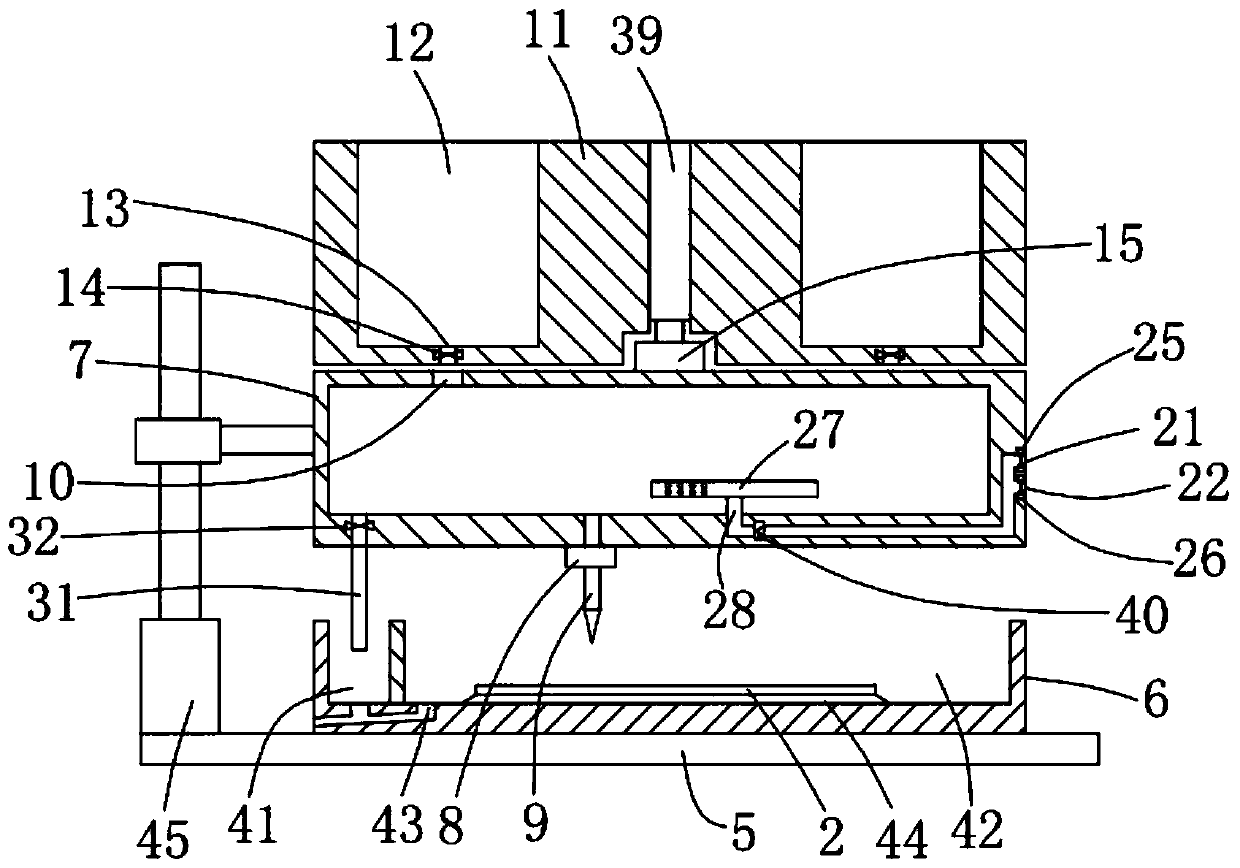

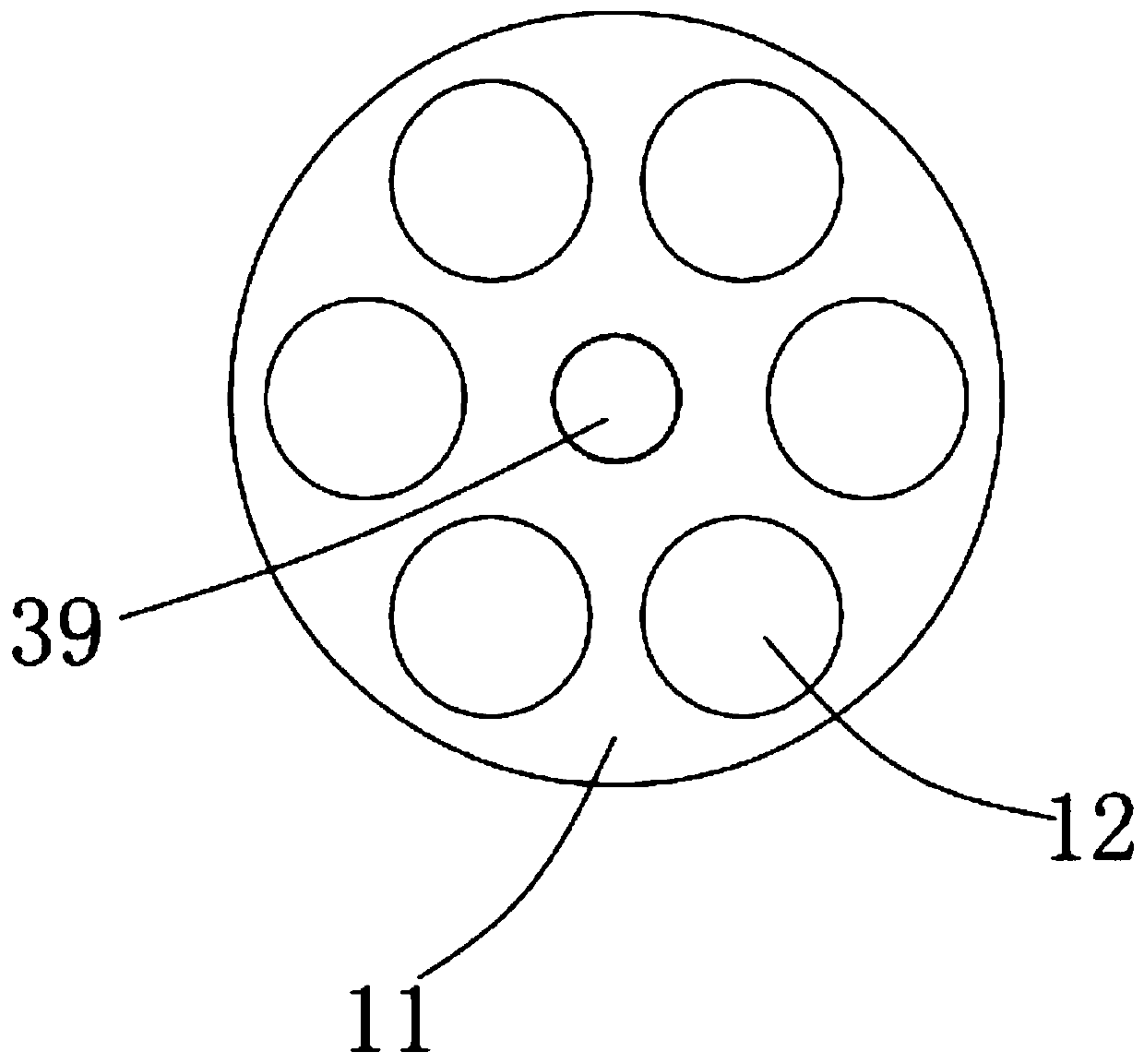

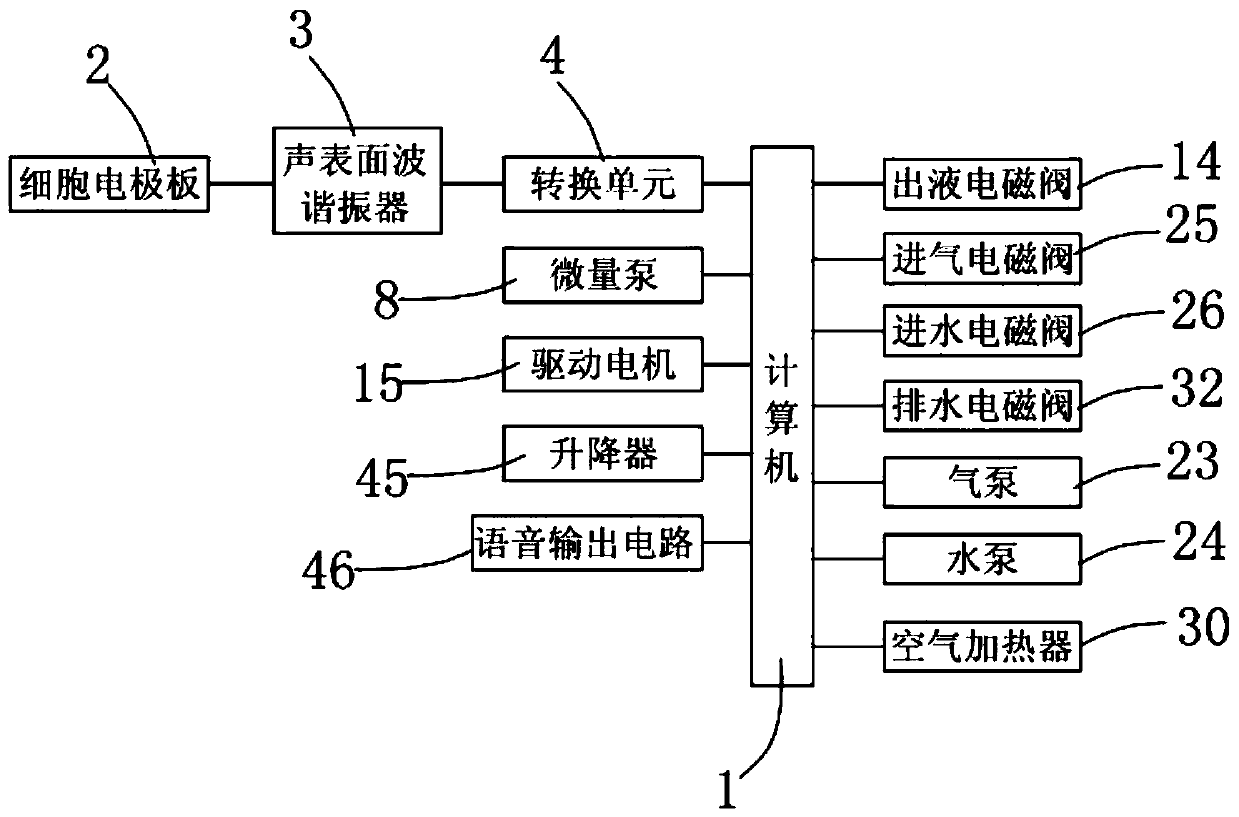

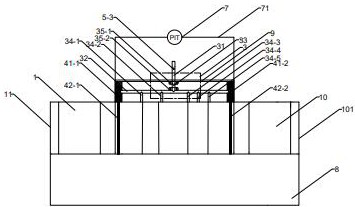

Device and method for detecting concentration of cycloheximide solution

InactiveCN105021666BWill not be disturbedSimple structureMaterial electrochemical variablesSulfur granulesSolenoid valve

The invention discloses a device and method for detecting the concentration of cycloheximide solution. The device includes a computer, an acquisition unit and an acquisition workbench, the acquisition unit includes a cell electrode plate, a surface acoustic wave resonator and a conversion unit, the acquisition workbench includes a base, a placement groove is arranged on the base, and a positioning base is arranged in the placement groove, A positioning groove is arranged on the positioning base, a dripping chamber is arranged above the placing groove, a micropump connected with the dripping chamber is arranged at the bottom of the dripping chamber, a dripping head connected with the micropump is arranged at the bottom of the micropump, and the dripping chamber There is a liquid inlet on the top, and a cleaning mechanism and a drainage mechanism in the drip chamber. There is a disc above the drip chamber, and several liquid storage chambers are arranged around the center of the circle on the disc. The bottom of the liquid storage chamber corresponds to the liquid inlet. A liquid outlet is provided at the position of the liquid outlet, a liquid solenoid valve is provided on the liquid outlet, and a drive motor for driving the rotation of the disc is provided on the top of the dripping chamber. The invention has simple structure and low cost, and can quickly and accurately detect the concentration of cycloheximide solution.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

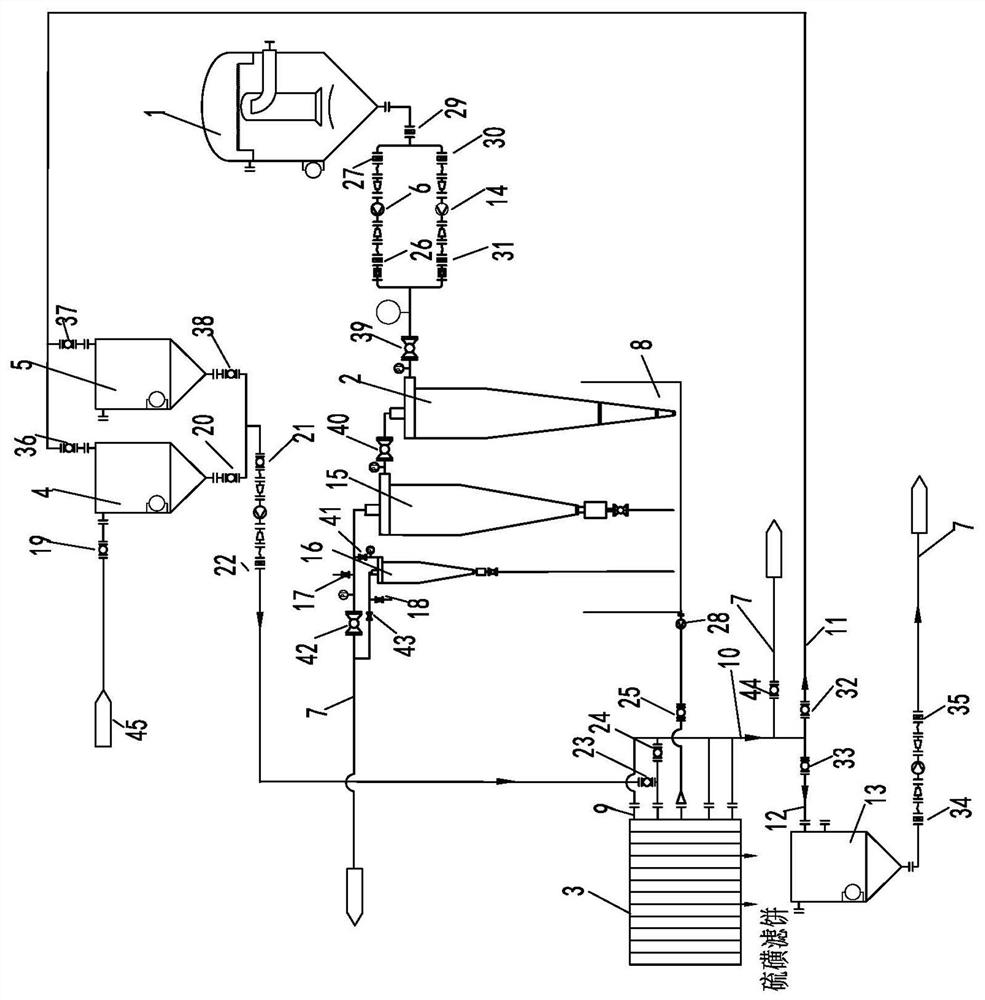

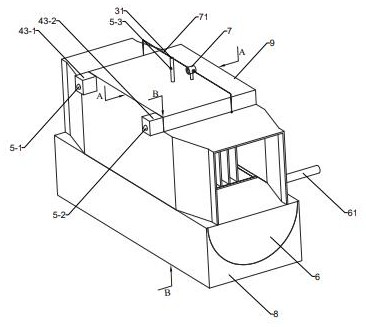

A kind of sulfur particle separation system and method

ActiveCN110075608BReduce the number of inputsEasy to detectSulfur compoundsDispersed particle separationSulfur granulesIndustrial engineering

The invention discloses a sulfur granule separation system and method and belongs to the technical field of waste gas purification treatment in viscose production. A sand removing device is additionally mounted and is mounted in a specific assembling mode, the technology process of the whole system is controlled through valves, the system and the method are combined and optimized with conventionalsulfur granule washing and recycling modes, the problems that in the prior art multiple plate frame type filter presses and conveying pumps need to be mounted, a large floor space is needed, the investment cost is high, the operation process is complex, and process control is obstructed can be solved, sulfur granules can be washed cleanly, the cost can be lowered, and process control can be facilitated.

Owner:YIBIN GRACE +1

A sulfur particle modifier for complex iron desulfurization liquid and its application method

ActiveCN106139837BQuick wetAccelerated settlementDispersed particle separationSulfur preparation/purificationSulfur granulesMicrometer

The invention provides a sulfur granule modifying agent for complexing iron desulphurization liquid and a use method thereof. The modifying agent is prepared from the following ingredients in percentage by weight: 10 to 30 percent of nonionic surfactants, 0.1 to 0.2 percent of flocculating agents, 5 to 15 percent of wetting agents, 2 to 20ppm of antifoaming agents and the balance of water, wherein the flocculating agents are sodium polystyrene sulfonate, and has the molecular weight being 50 to 200 thousand. A preparation method of the sulfur granule modifying agent comprises the steps of mixing, stirring and dissolving each raw material. In the use process, the materials are added into the complexing iron desulphurization liquid, and the addition is 30 to 100ppm. The sulfur granule modifying agent for complexing iron desulphurization liquid can fast moisturize sulfur; the flocculating effect in the alkaline complexing iron desulphurization liquid is good; the average granule diameter of the sulfur can be increased to a value greater than 120 micrometers from several micrometers; the sulfur can easily settle; the sulfur settling time is reduced; the suspended sulfur content is reduced; a sulfur foam layer in the desulphurization liquid can be eliminated in time; the settling and separation effect of sulfur granules is improved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

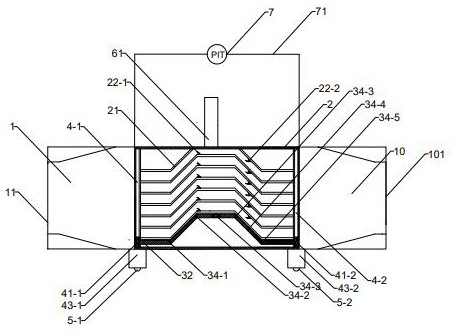

Separation device for sulfur particles and liquid drops in high-sulfur-content gas field

PendingCN114748942APrevent liquidExhausted completelyDispersed particle separationSulfur granulesEnvironmental engineering

The device comprises an inlet section, a folded plate section, an outlet section, a pollution discharge cavity, a washing system, a top plate and a base, the inlet section is connected with the folded plate section and then connected with the outlet section, an arc-shaped pollution discharge cavity is formed in the lower portion from the inlet section to the outlet section, and a pollution discharge pipe is located at the bottom of the pollution discharge cavity and transversely penetrates out of the base. The upper portions of the two ends of the folded plate section are provided with rails, an intelligent differential pressure sensor is arranged between the two ends of the folded plate section, a water collecting pipe moves in the rails through a sliding block under the action of a reciprocating driver, a partition plate is connected below the sliding block, a water inlet pipe is connected with a telescopic hose and then connected with the water collecting pipe, and a washing pipeline is connected below the water collecting pipe. And the intelligent differential pressure sensor transmits signals to control the water inlet pipe and the inductive switch on the reciprocating driver. According to the invention, sulfur particles and liquid drops in gas are separated, dead-corner-free automatic flushing is carried out under the condition of not stopping production, and secondary entrainment of the liquid drops by airflow during flushing is avoided at the same time.

Owner:SOUTHWEST PETROLEUM UNIV

Sulfur-supported feedstuff addictive and preparation method thereof

InactiveCN100475053CSmall particlesNarrow particle size distributionAnimal feeding stuffAccessory food factorsBiotechnologySulfur granules

The invention discloses feed addictive carrying sulfur and the method for preparing the same, with hydrotalcite carrying sulfur, and the sulfur content in hydrotalcite is 1-10% by weight percent. The invention takes hydrotalcite as micro-reactor and reduces SO32- with S2- to sulfur. The invention makes use of the nanometer channel structure of hydrotalcite as reactor, so the sulfur granule is small, and the dissipation is uniform and stable. The product is characterized by high sterilizing and disinfection effect and the hydrotalcite can release sulfur slowly because of the features it possesses: bio-availability, compatibility to gastrointestinal tract mucosa, commutativity between layers, high surface activity and large specific surface area. The product can effectively inhibit the propagation of enteric pathogenic bacteria and improve animal production capability.

Owner:ZHEJIANG UNIV

Manufacturing equipment and manufacturing process for spherical sulfur granules

ActiveCN101830441BNo pollution in the processSmall footprintIon-exchange column/bed processesSulfur compoundsSulfur granulesSulfur

Owner:南京三普造粒装备有限公司

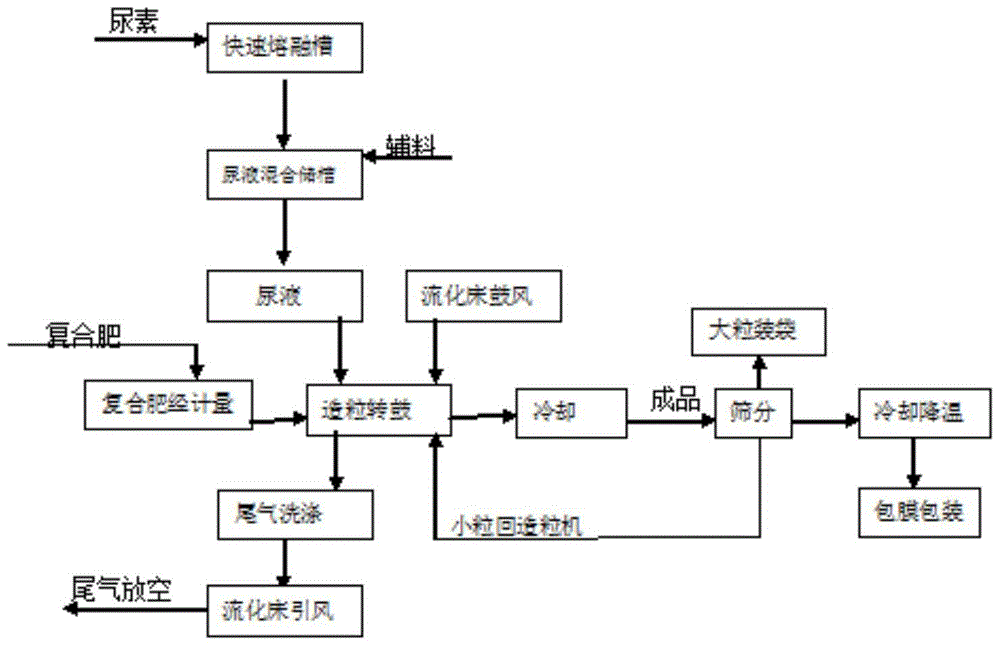

A production method for producing granule-integrated sulfur-based high-nitrogen compound fertilizer by using a drum

The invention discloses a production method for producing granule-integrated sulfur-based high-nitrogen compound fertilizer by means of a drum. The compound fertilizer particles enter the drum after heating up, and at the same time add trace elements to urine to form a mixed liquid, which is directly completed in the drum. The mixed liquid wraps the compound fertilizer to form a product compound fertilizer, which solves the problem of shelling after wrapping in the industry at present. By adjusting the temperature, air volume, pressure, coating time and other indicators of the granulation process, the surface of the compound fertilizer and The urine mixture can achieve the condition of combining with each other, so that the two can be fully fused together, and the problem of shelling of the finished product is solved.

Owner:山东聊城鲁西硝基复肥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com