Separation device for sulfur particles and liquid drops in high-sulfur-content gas field

A separation device and technology of sulfur particles, applied in the direction of dispersed particle separation, separation method, chemical instrument and method, etc., can solve the problems of flushing dead angle, gas carrying liquid, and flushing and air intake can not be carried out at the same time, so as to avoid gas carrying liquid , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

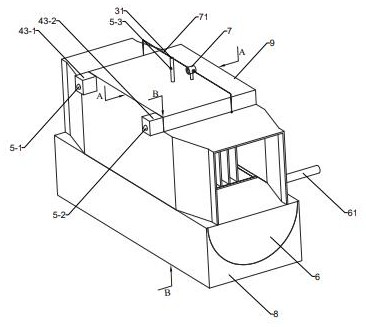

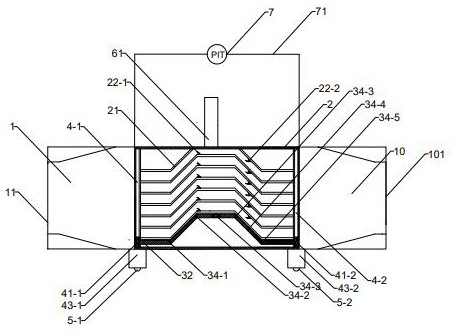

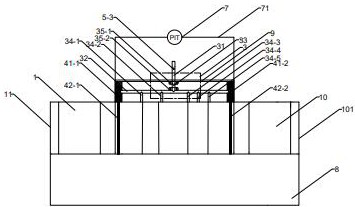

[0027] like Figure 1-3 As shown, an embodiment of the present invention provides a separation device for sulfur particles and liquid droplets in a high-sulfur gas field, comprising an inlet section (1), a folded plate section (2), an outlet section (10), and a blowdown chamber (6) , the water washing system (3), the top plate (9) and the base (8), the inlet section (1) is gradually expanding, the inlet section (1) is connected to the folded plate section (2), and each folded plate section (2) Two arc baffles (22.1-2) are arranged in the flow channel, a water washing system (3) is arranged above the folded plate section (2), and the water washing system (3) consists of a water inlet pipe (31), a telescopic hose (33) , water collecting pipe (32) and water washing pipe (34.1-5), the water inlet pipe (31) is fixed through the top plate (9) through the pipe clamp (35-1) and connected to the telescopic hose (33), above the top plate (9) The water inlet pipe (31) is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com