Electric vehicle age-proof wiper rubber strip

An anti-aging technology for electric vehicles, applied in the field of electric vehicle parts, can solve the problems that the wipers cannot remove rainwater and clean well, the weather resistance of natural rubber materials is poor, and noise is generated, so as to achieve long service life, not easy to age, good softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

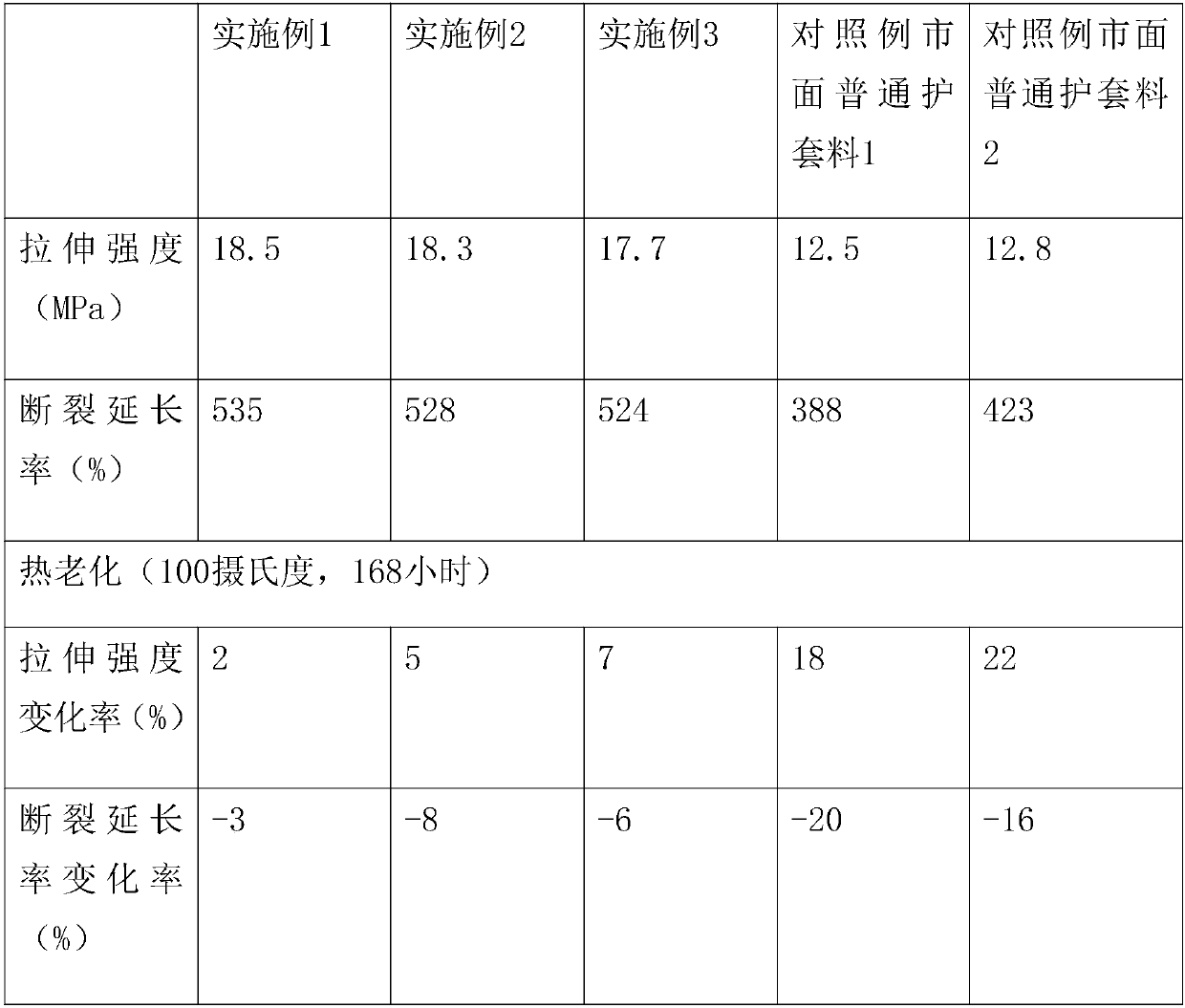

Embodiment 1

[0027] An anti-aging wiper rubber strip for an electric vehicle, prepared from the following components in parts by weight: 70 parts of nitrile rubber, 40 parts of butadiene rubber, 18 parts of silica gel, 12 parts of polyphenylene ether, 5 parts of talcum powder, 5 parts of acridine, 12 parts of granular sulfur, 12 parts of stearic acid, 6 parts of ethyl benzoate, 8 parts of phenyl silicone oil, 2 parts of o-diazepine, 5 parts of emulsified paraffin, 5 parts of active biological glue, methyl 0.8 parts of silsesquioxane, 2 parts of quinoxaline, 8 parts of graphite, 12 parts of modified filler, 2 parts of anti-light aging agent, and 1 part of anti-heat aging agent.

[0028] Further, the modified filler is prepared from the following raw materials in parts by weight: 10 parts of bentonite, 2 parts of calcium sulfate whisker powder, 3 parts of thousand-mesh talc powder, 6 parts of sodium lauryl sulfate, dibutyl 2 parts of tin dioctoate, 1 part of aluminized glass microspheres, 8 ...

Embodiment 2

[0044] An anti-aging wiper rubber strip for an electric vehicle, prepared from the following components in parts by weight: 80 parts of nitrile rubber, 30 parts of butadiene rubber, 18 parts of silica gel, 15 parts of polyphenylene ether, 3 parts of talcum powder, 5 parts of acridine, 12 parts of granular sulfur, 11 parts of stearic acid, 5 parts of ethyl benzoate, 8 parts of phenyl silicone oil, 2 parts of o-diazepine, 8 parts of emulsified paraffin, 6 parts of active biological glue, methyl 2 parts of silsesquioxane, 3 parts of quinoxaline, 7 parts of graphite, 7 parts of modified filler, 2 parts of anti-light aging agent, and 1 part of anti-heat aging agent.

[0045] Further, the modified filler is prepared from the following raw materials in parts by weight: 10 parts of bentonite, 2 parts of calcium sulfate whisker powder, 3 parts of thousand-mesh talc powder, 6 parts of sodium lauryl sulfate, dibutyl 2 parts of tin dioctoate, 1 part of aluminized glass microspheres, 8 par...

Embodiment 3

[0061] An anti-aging wiper rubber strip for an electric vehicle, prepared from the following components in parts by weight: 55 parts of nitrile rubber, 45 parts of butadiene rubber, 20 parts of silica gel, 12 parts of polyphenylene ether, 3 parts of talcum powder, 5 parts of acridine, 11 parts of granular sulfur, 11 parts of stearic acid, 6 parts of ethyl benzoate, 7 parts of phenyl silicone oil, 1 part of o-diazepine, 6 parts of emulsified paraffin, 4 parts of active biological glue, methyl 1.5 parts of silsesquioxane, 1.5 parts of quinoxaline, 8 parts of graphite, 8 parts of modified filler, 3 parts of anti-light aging agent, 2 parts of anti-heat aging agent.

[0062] Further, the modified filler is prepared from the following raw materials in parts by weight: 10 parts of bentonite, 2 parts of calcium sulfate whisker powder, 3 parts of thousand-mesh talc powder, 6 parts of sodium lauryl sulfate, dibutyl 2 parts of tin dioctoate, 1 part of aluminized glass microspheres, 8 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com