Energy-saving environment-friendly feeding device for ink production

An energy-saving, environmental-friendly, and feeding device technology, which can be used in transportation and packaging, dissolving, mixers, etc., and can solve the problems of insufficient stirring, troublesome removal of raw materials, and insufficient sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

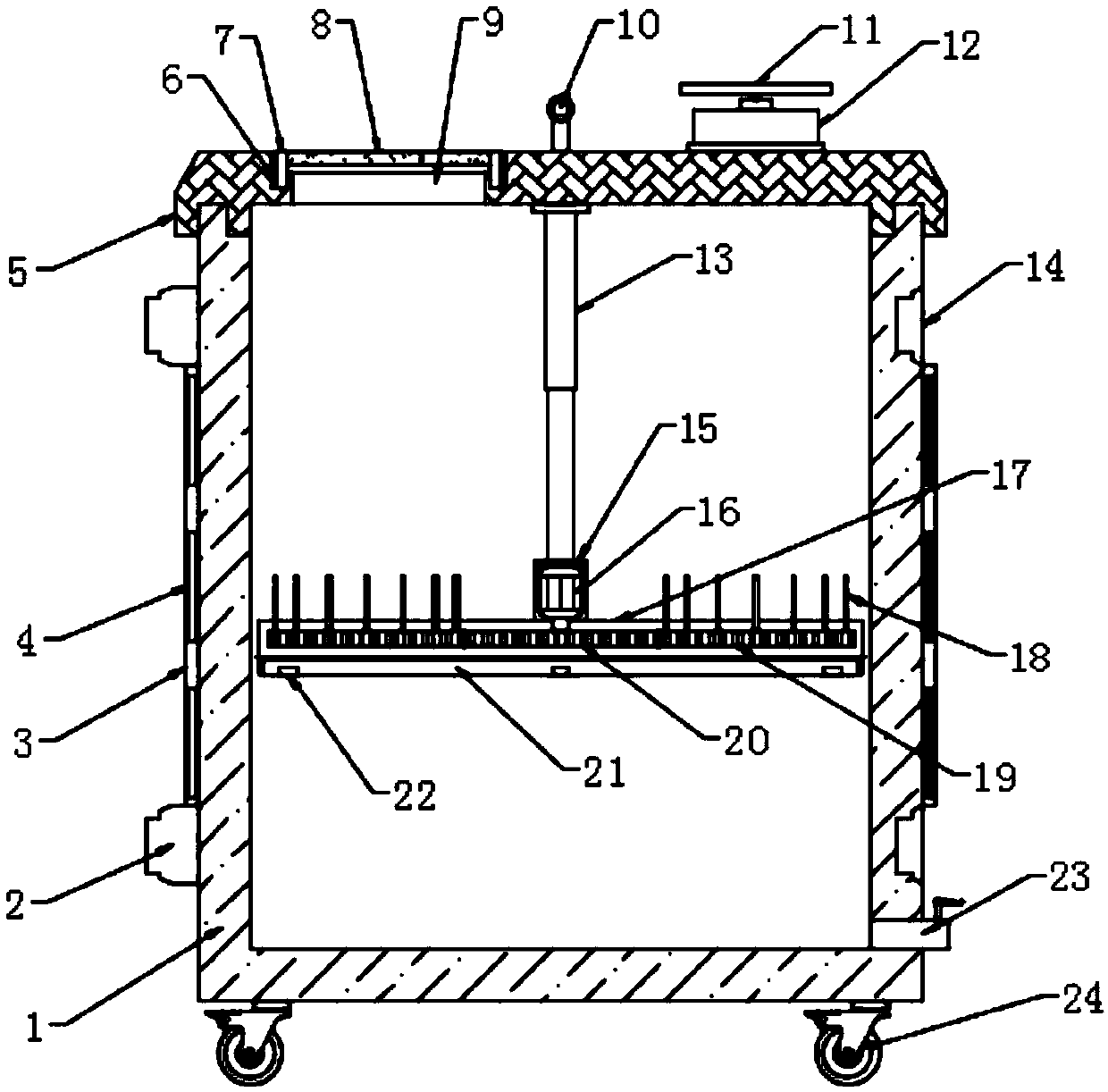

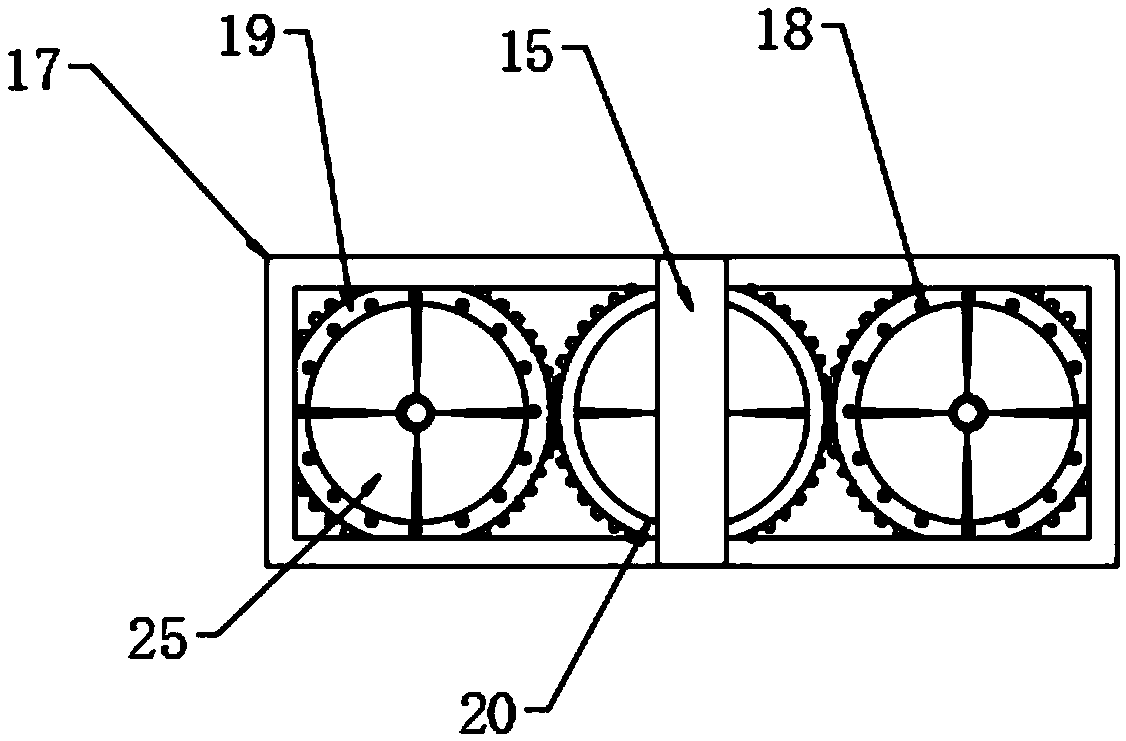

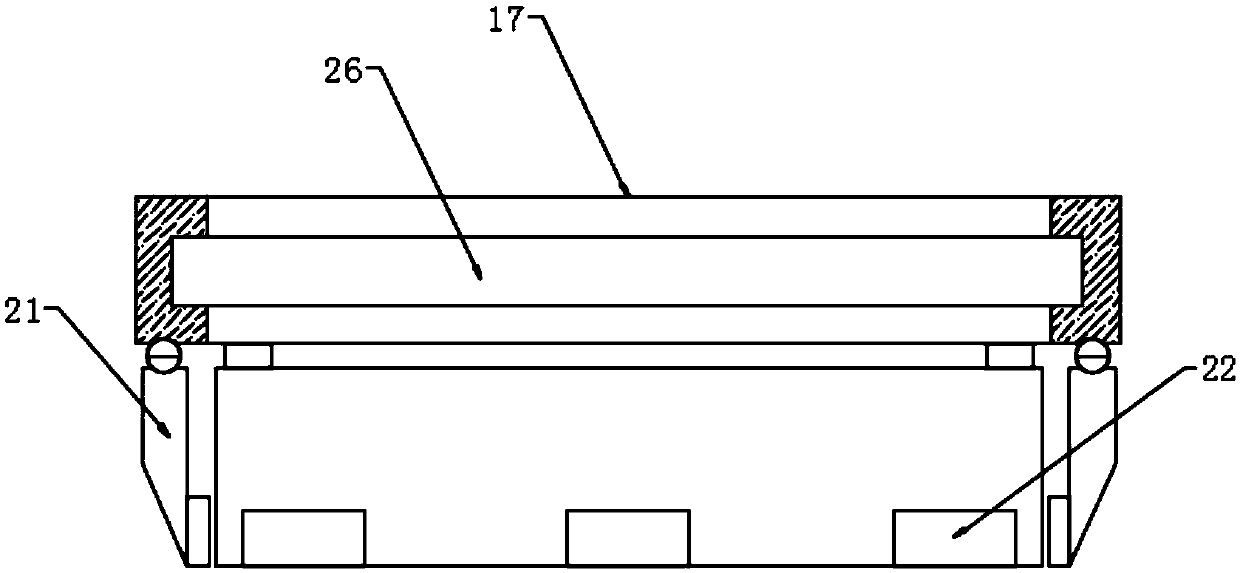

[0026] Embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Given, the present invention includes a box body 1, the upper and lower parts of one side of the box body 1 are glued with a positioning head 2, which is used to position and fix two identical devices, and the top of the box body 1 is fixed with a box body through a rubber pad. The cover 5 and the middle part of the top of the box cover 5 are provided with a feed inlet 9 to facilitate the entry of raw materials. The outer edge of the feed inlet 9 is provided with a sealing groove 6, and the inside of the sealing groove 6 is provided with a sealing door 7, which is located in the middle of the top of the sealing door 7. Inlaid with a glass observation window 8, it is convenient for the staff to observe the mixing of raw materials through the eyes. The other side of the top middle of the box cover 5 is fixedly installed with a battery 12 through the installation base. The top of t...

Embodiment 2

[0027] Embodiment two, on the basis of embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Given, universal runners 24 are fixedly installed at the four corners of the bottom of the box body 1, and the rotation of the universal runners 24 facilitates the transportation of the device.

Embodiment 3

[0028] Embodiment three, on the basis of embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Given, the upper and lower parts of the other side of the box body 1 are provided with positioning holes 14, and the positioning holes 14 are consistent with the vertical section size of the positioning head 2. This design is convenient for multiple devices to be positioned and fixed, and is convenient for the neat placement of the devices and deposit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com