Patents

Literature

134 results about "Lanthanum hexaboride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum hexaboride (LaB₆, also called lanthanum boride and LaB) is an inorganic chemical, a boride of lanthanum. It is a refractory ceramic material that has a melting point of 2210 °C, and is insoluble in water and hydrochloric acid. It has a low work function and one of the highest electron emissivities known, and is stable in vacuum. Stoichiometric samples are colored intense purple-violet, while boron-rich ones (above LaB6.07) are blue. Ion bombardment changes its color from purple to emerald green.

Solar control laminate

InactiveUS20070048519A1Synthetic resin layered productsCellulosic plastic layered productsControl layerNanoparticle

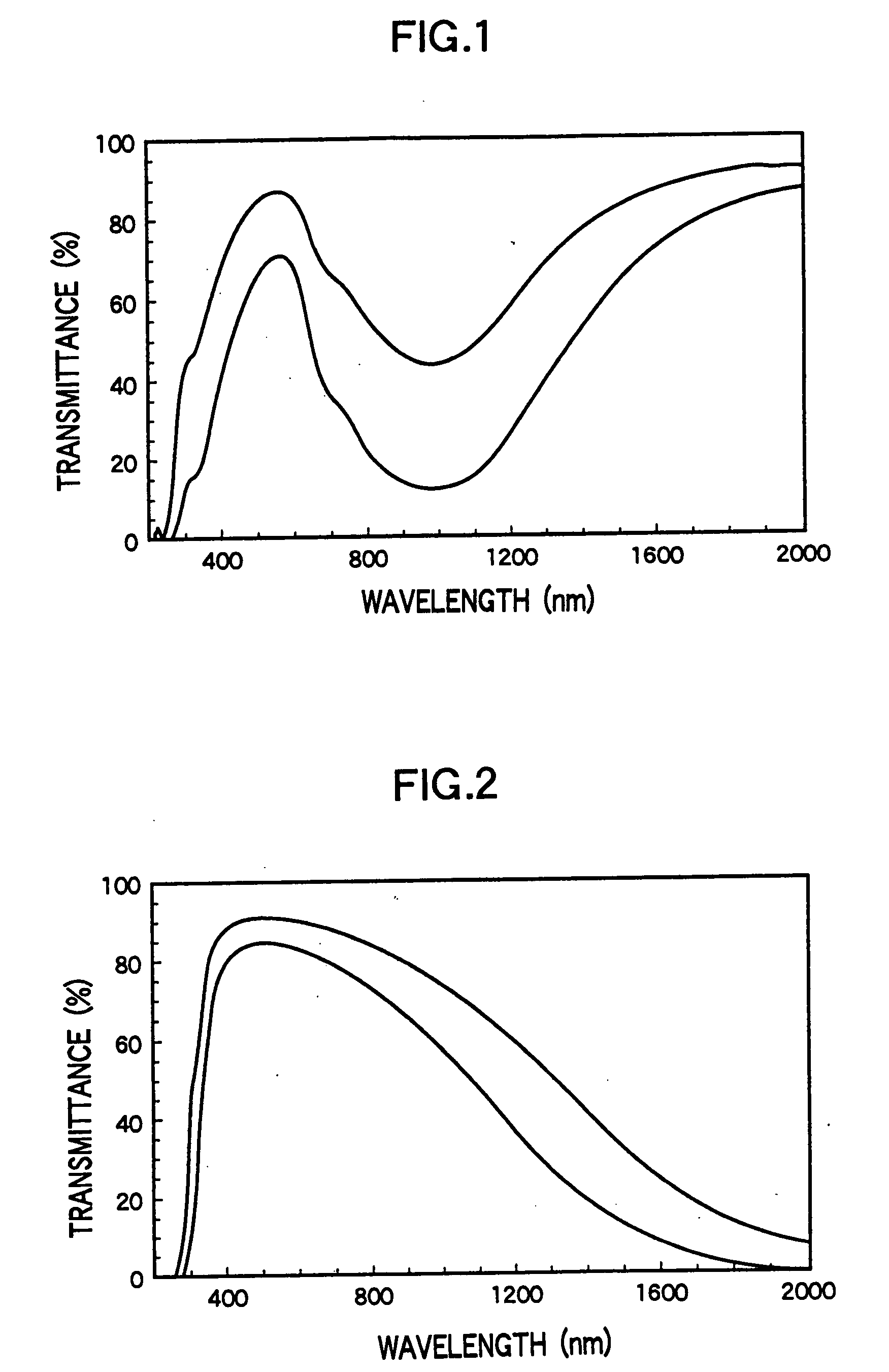

Provided are solar control laminates comprising a solar control film and a polymeric sheet. The solar control film comprises a polymeric film coated with a coating comprising inorganic infrared absorbing nanoparticles. Preferably, inorganic infrared absorbing nanoparticles comprise nanoparticles of antimony tin oxide (ATO), indium tin oxide (ITO), lanthanum hexaboride (LaB6) or mixtures thereof. Optionally, the solar control laminate also comprises a rigid sheet, such as a glass sheet.

Owner:KURARAY AMERICA INC

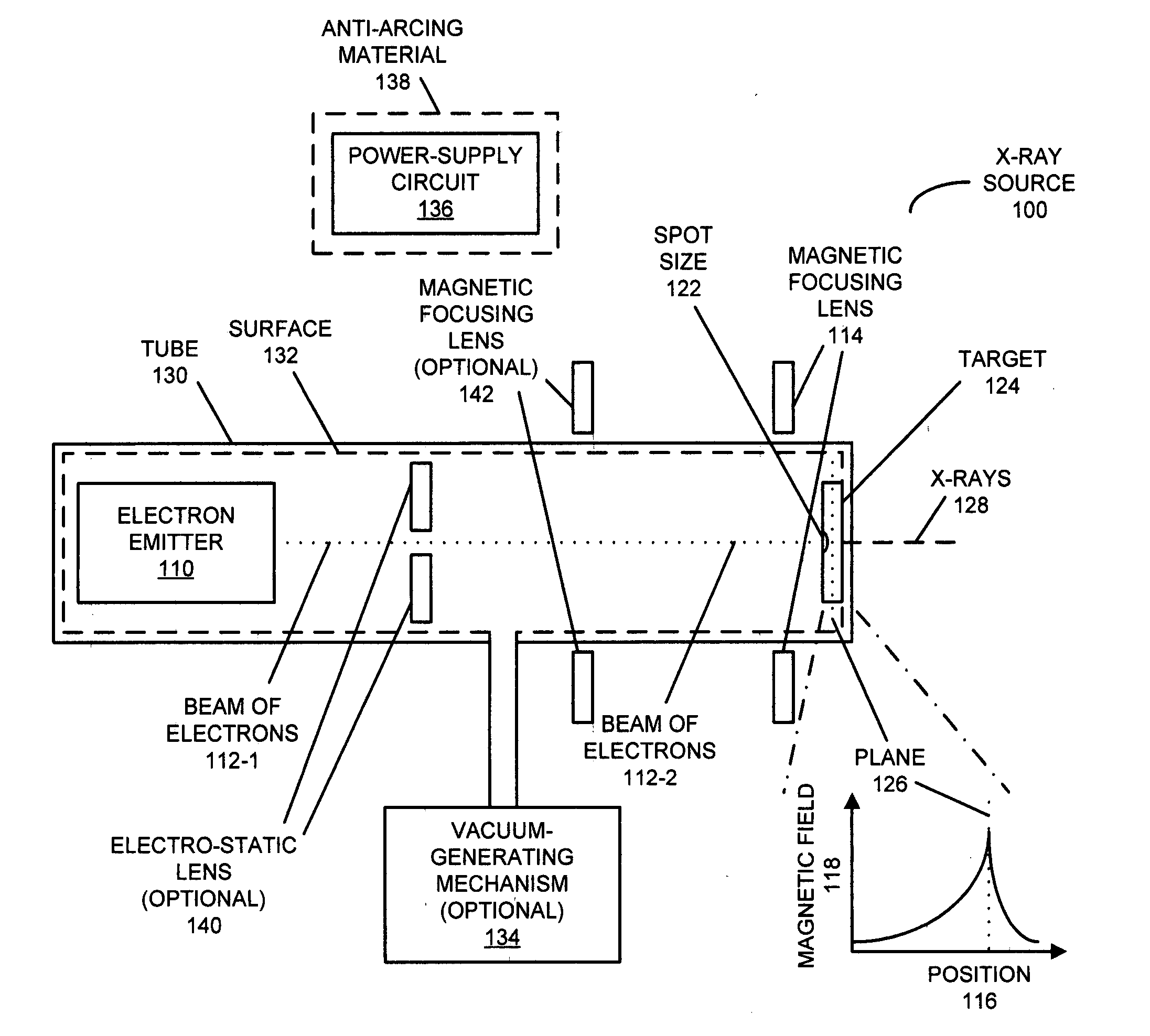

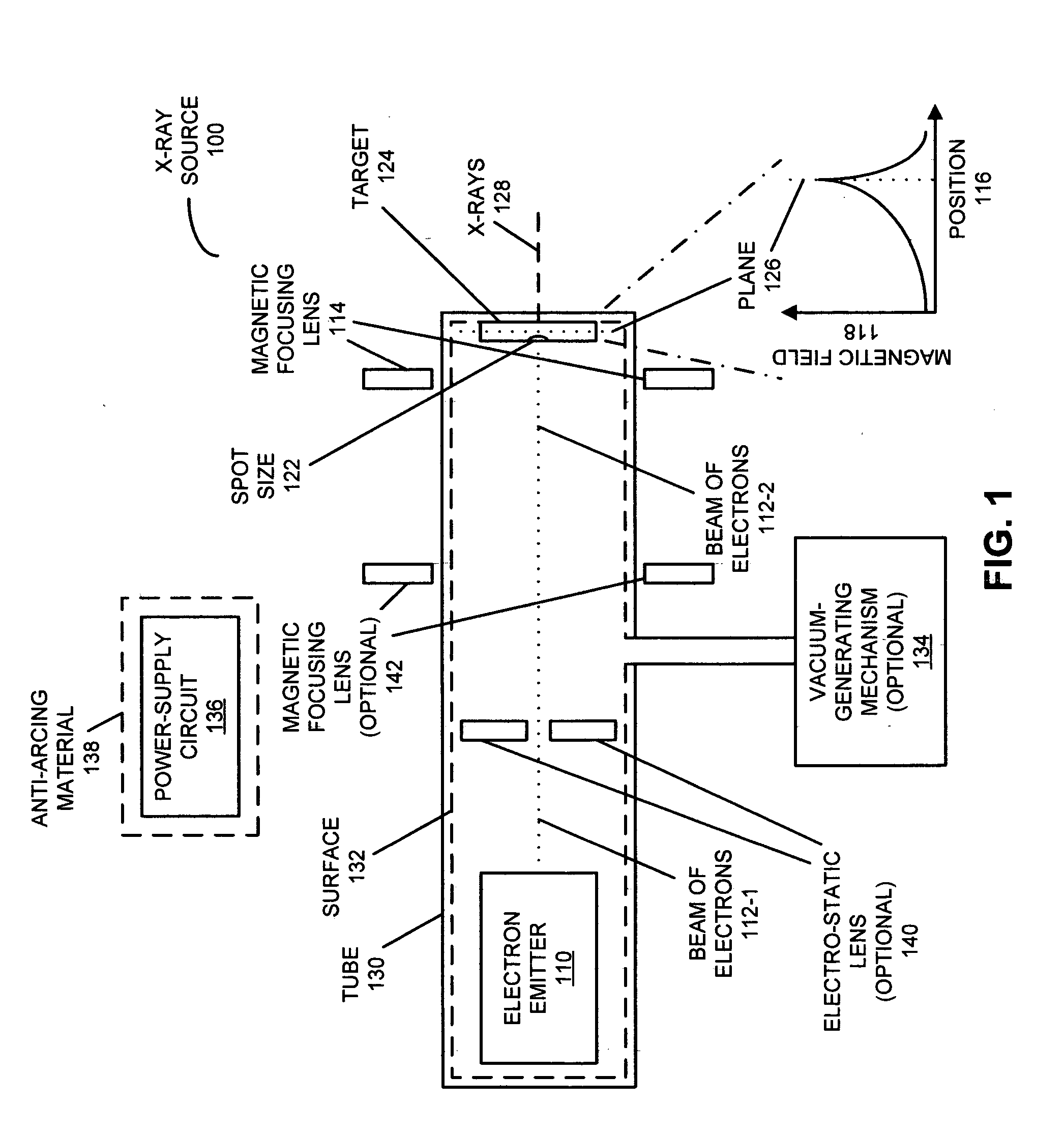

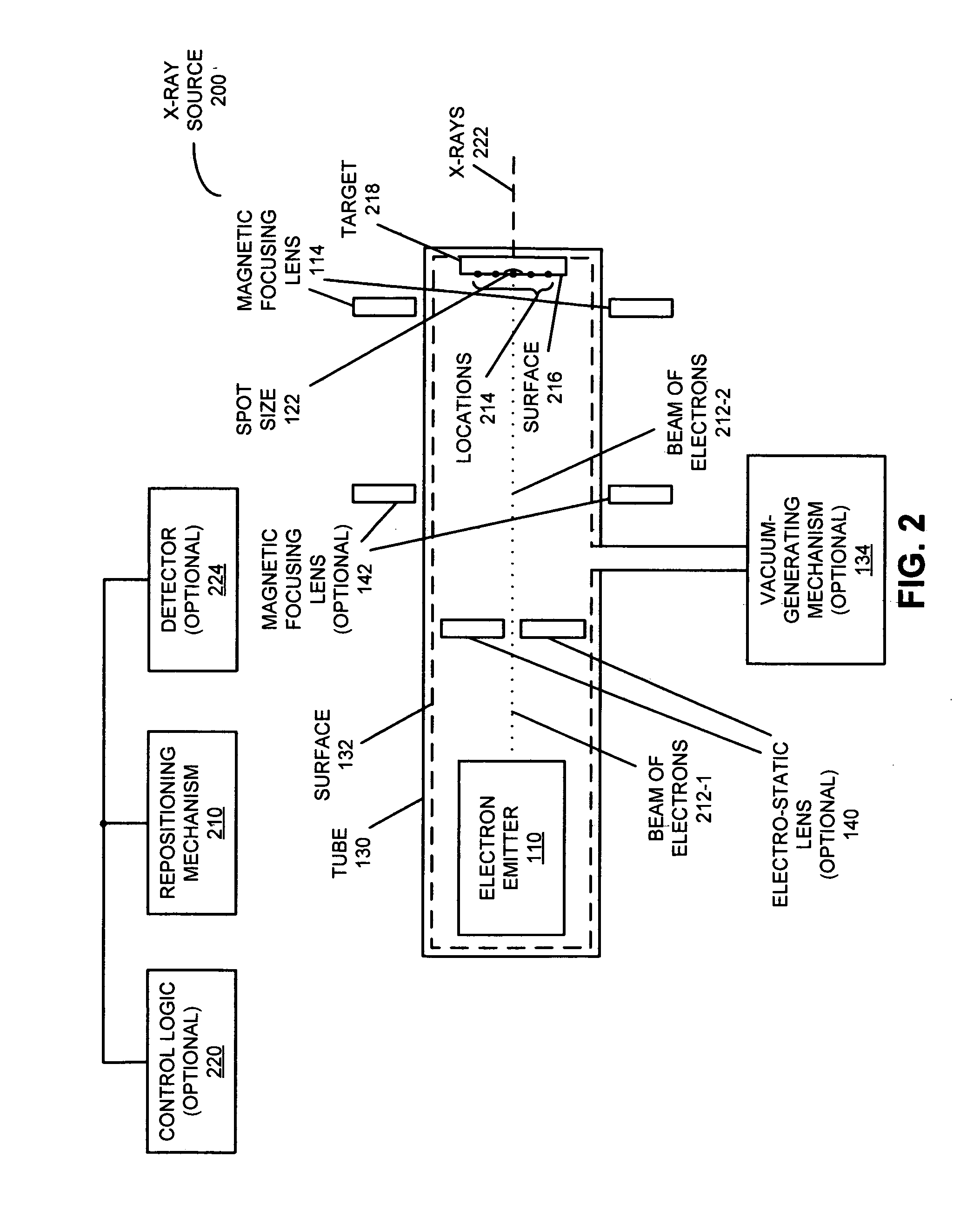

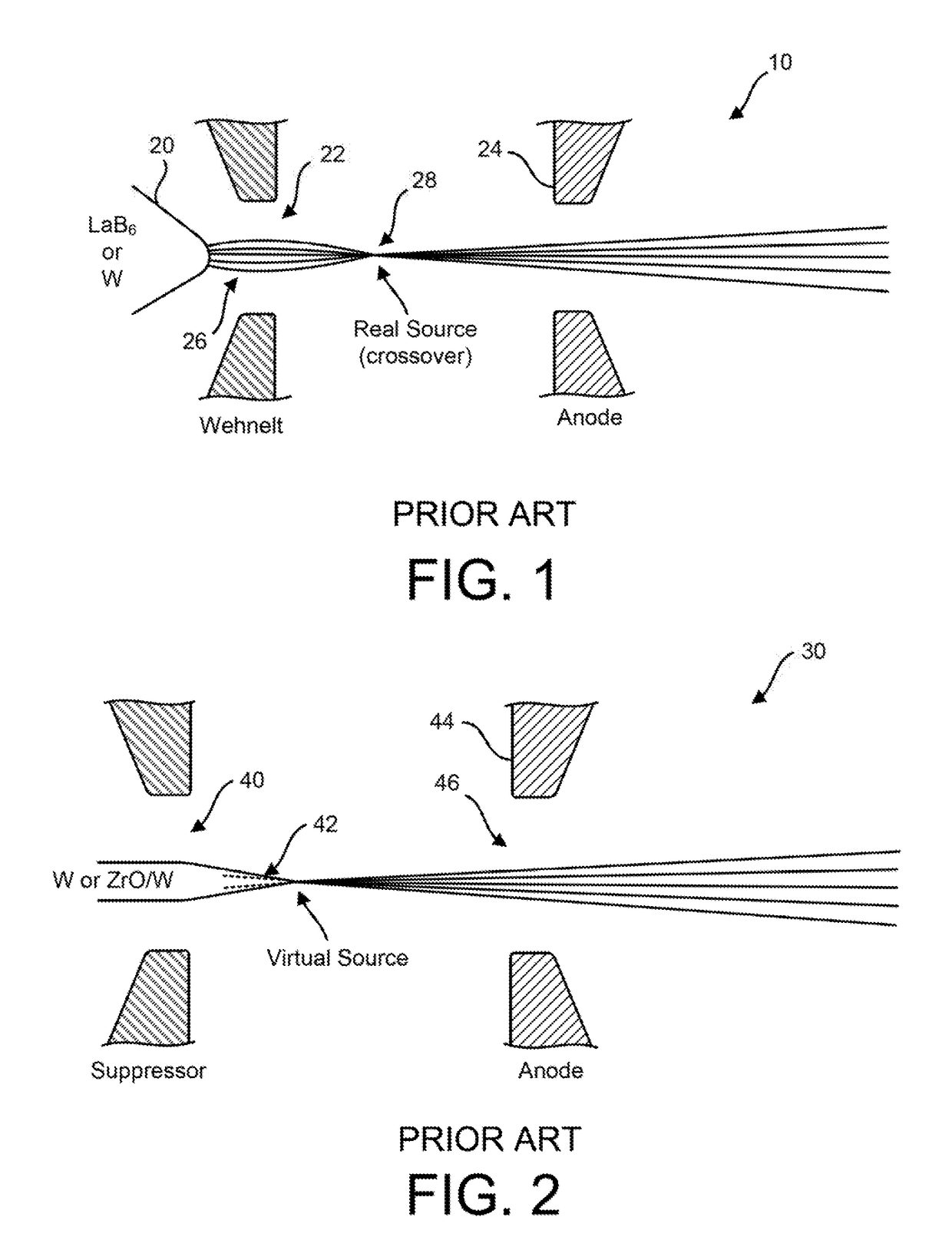

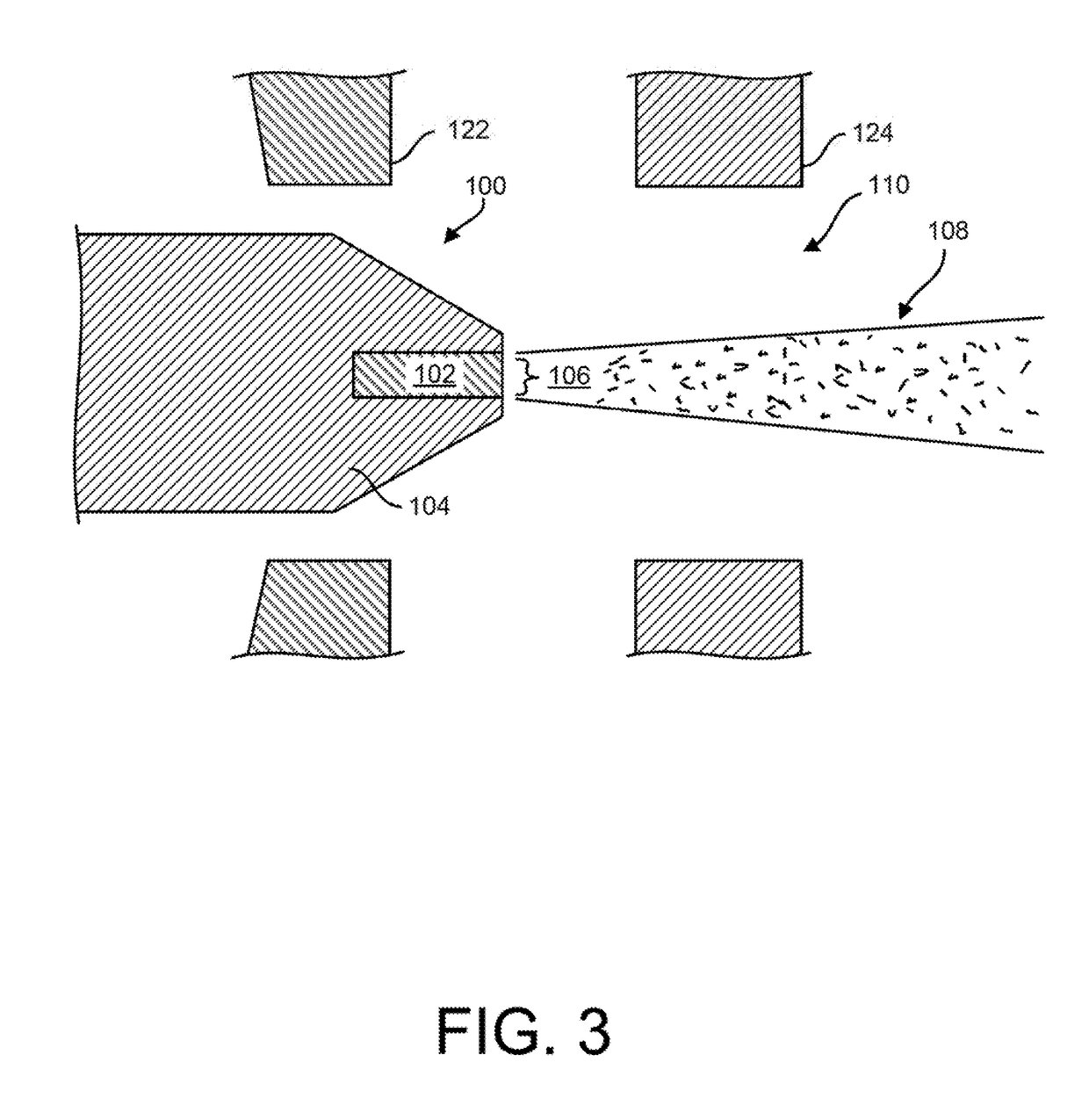

X-ray source with high-temperature electron emitter

InactiveUS20120269326A1X-ray tube electrodesCathode ray concentrating/focusing/directingElectron sourceX-ray

An x-ray source is described. This x-ray source includes an electron source with a refractory binary compound having a melting temperature greater than that of tungsten. For example, the refractory binary compound may include: hafnium carbide, zirconium carbide, tantalum carbide, lanthanum hexaboride and / or compounds that include two or more of these elements.

Owner:ADLER DAVID L +1

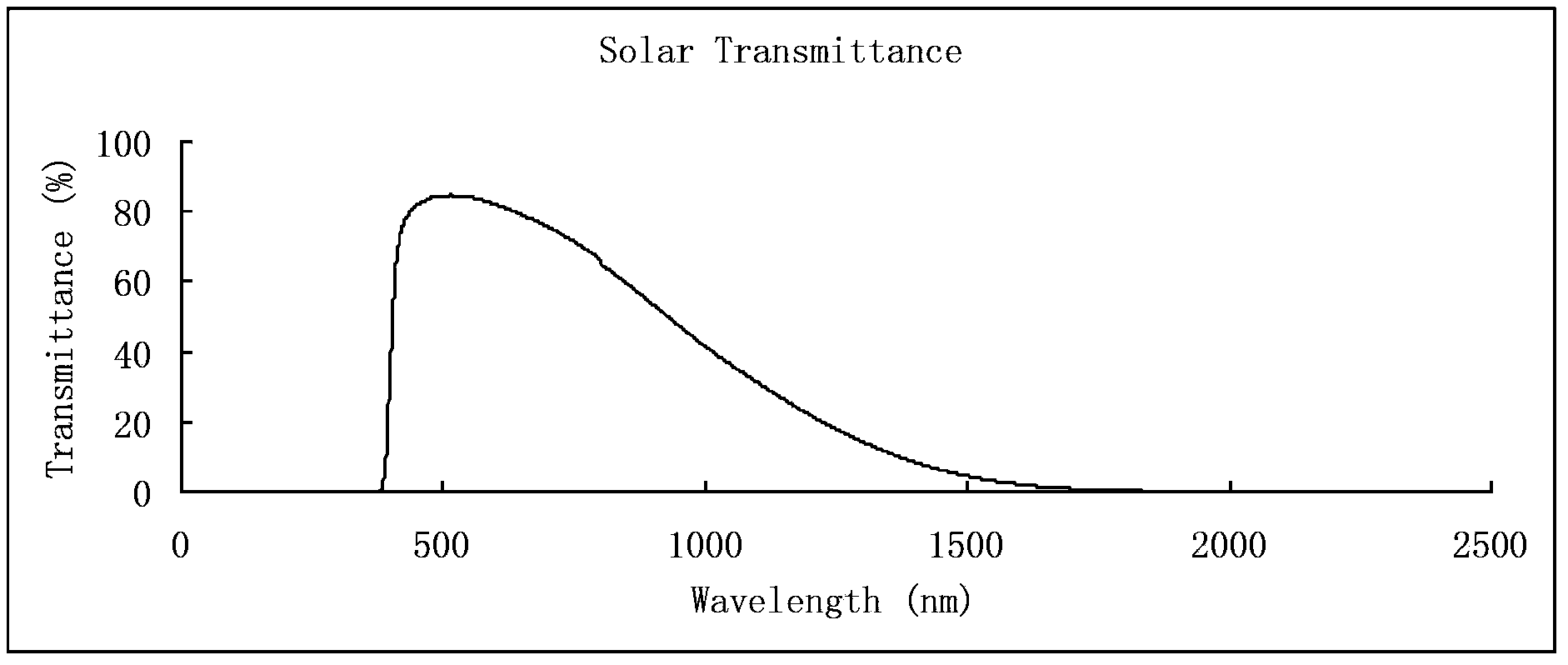

Transparent heat insulation coating material, preparation method and application thereof

InactiveCN101550307AImprove adhesionGood infrared blocking performancePolyurea/polyurethane coatingsPolyester coatingsDispersion stabilityPolyester

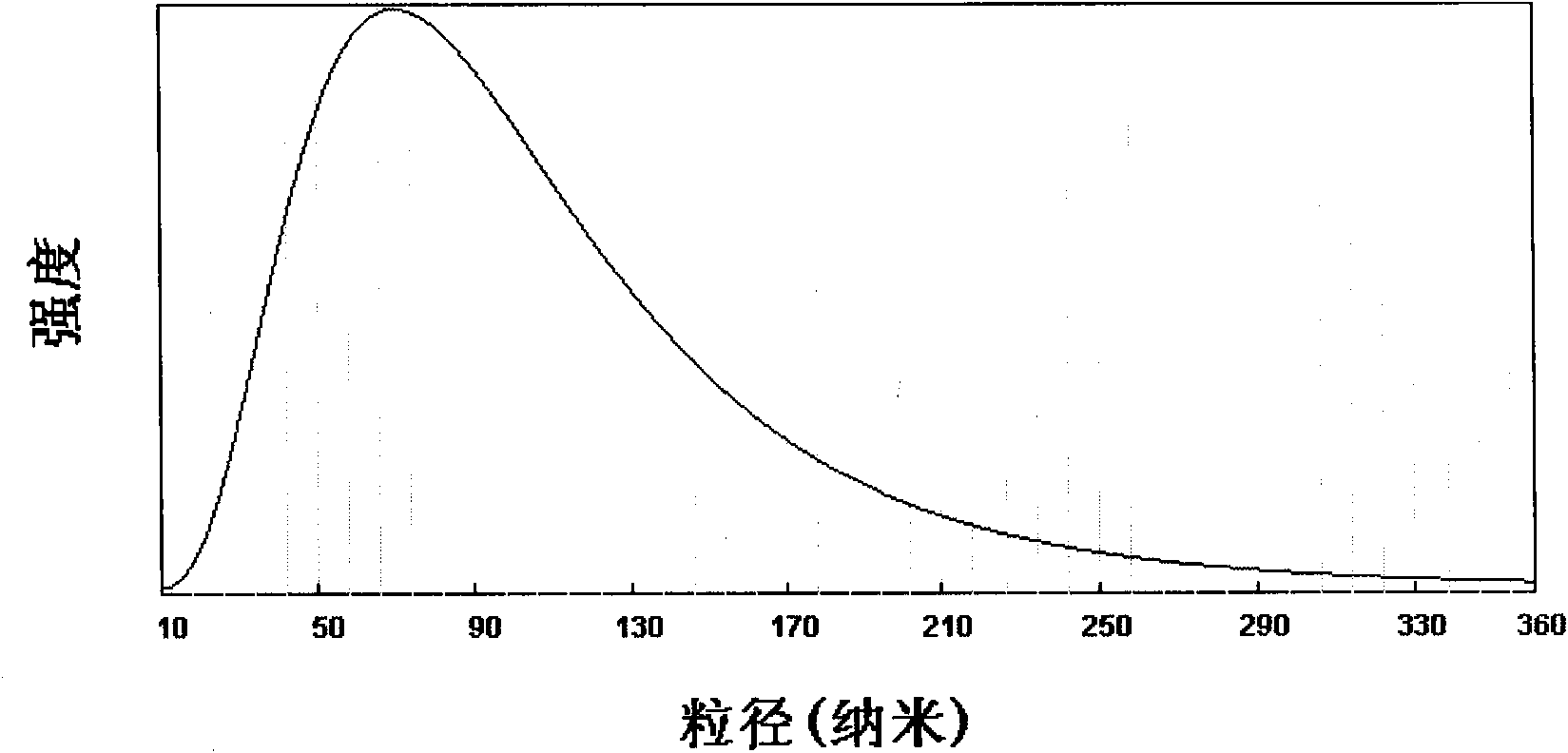

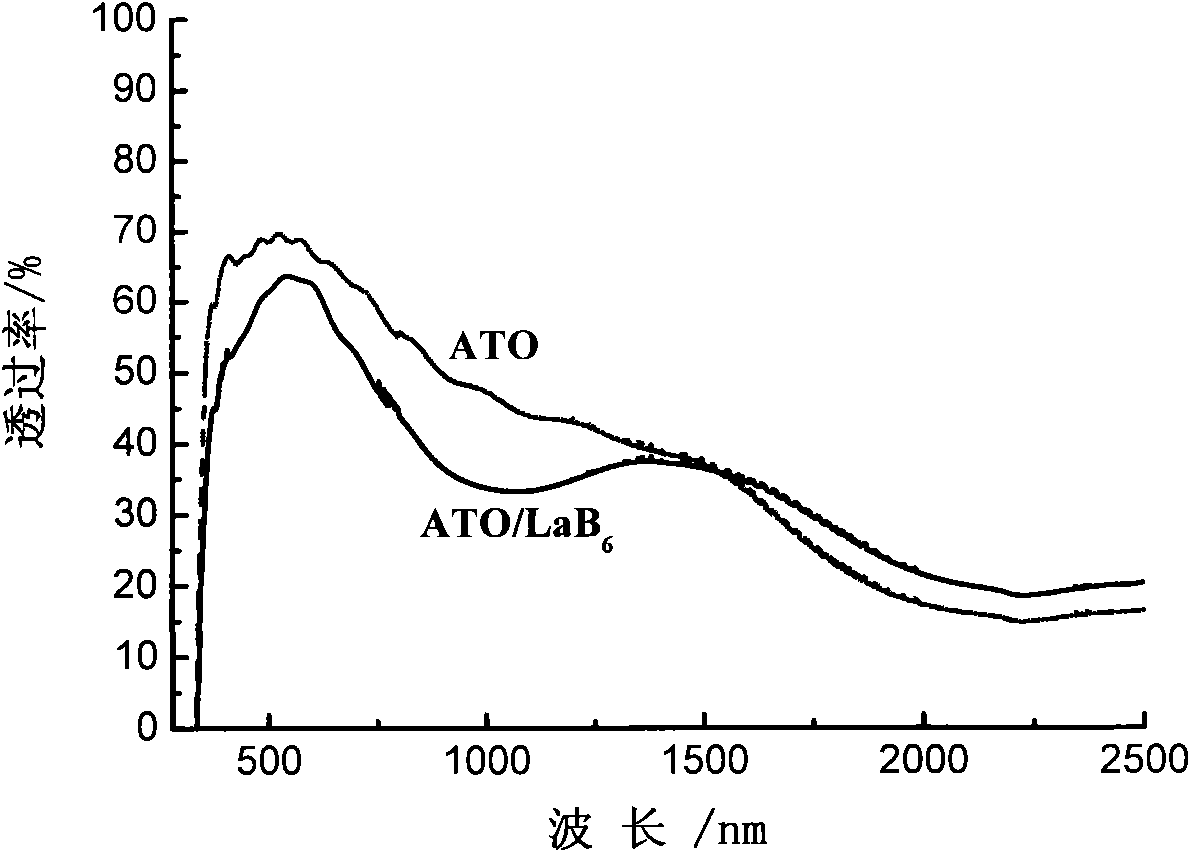

The invention relates to a transparent heat insulation coating material, the preparation method and the application thereof. The material is made from the raw material of lanthanum hexaboride / tin indium oxide or lanthanum hexaboride / tin antimony oxide, by the steps of pretreating by ultrasonic dispersion, and grinding to prepare nanometer slurry with heat insulation function, wherein the nanometer slurry has particle sizes mainly between 10nm and 200nm, the average particle size between 50nm and 120nm, and superior dispersion stability; mixing the nanometer slurry with film forming substance, auxiliary agent and solvent, to obtain the transparent heat insulation coating material. The coating material can obstruct more than 80% of infrared light, has a visible light transmittance above 60%, achieves excellent transparency and sunshine energy shielding effect; can be directly coated on transparent glass, polycarbonate, synthetic glass and polyester; and achieves the aims of energy conservation and heat insulation.

Owner:FUDAN UNIV +1

Powder metallurgy titanium alloy and preparation method thereof

InactiveCN101962721AImprove mechanical propertiesImprove performanceCompression moldingLanthanum hexaboride

The invention provides powder metallurgy titanium alloy and a preparation method thereof. The powder metallurgy titanium alloy comprises the following components in percentage by mass: 2 to 7 percent of Al, 2 to 8 percent of Mo, 2 to 6 percent of V, 2 to 10 percent of Ag, 0.1 to 3.0 percent of LaB6 and the balance of titanium and inevitable impurities. The method comprises the following steps of: weighing titanium powder, aluminum powder, molybdenum powder, aluminum-vanadium intermediate alloy powder, silver powder and lanthanum hexaboride powder with certain particle size according to the mass percentage of the components; uniformly mixing the powder by a mixing method; preparing a green compact with a certain shape by a compression molding process; placing the green compact in a vacuum hot pressing sintering furnace to sinter; and cooling the green compact along with the furnace to obtain silver and titanium boride particle-containing powder metallurgy titanium alloy. The technological process is simple; the silver powder is added during the mixing of the materials to improve the molding property of the green compact; the lanthanum hexaboride powder is added to perform reaction in situ so as to generate titanium boride dispersion enhanced matrix alloy; the compactness of the sinter compact is further improved by hot pressing sintering; and thus the novel powder metallurgy titanium alloy with high compactness and high strength is obtained.

Owner:CENT SOUTH UNIV

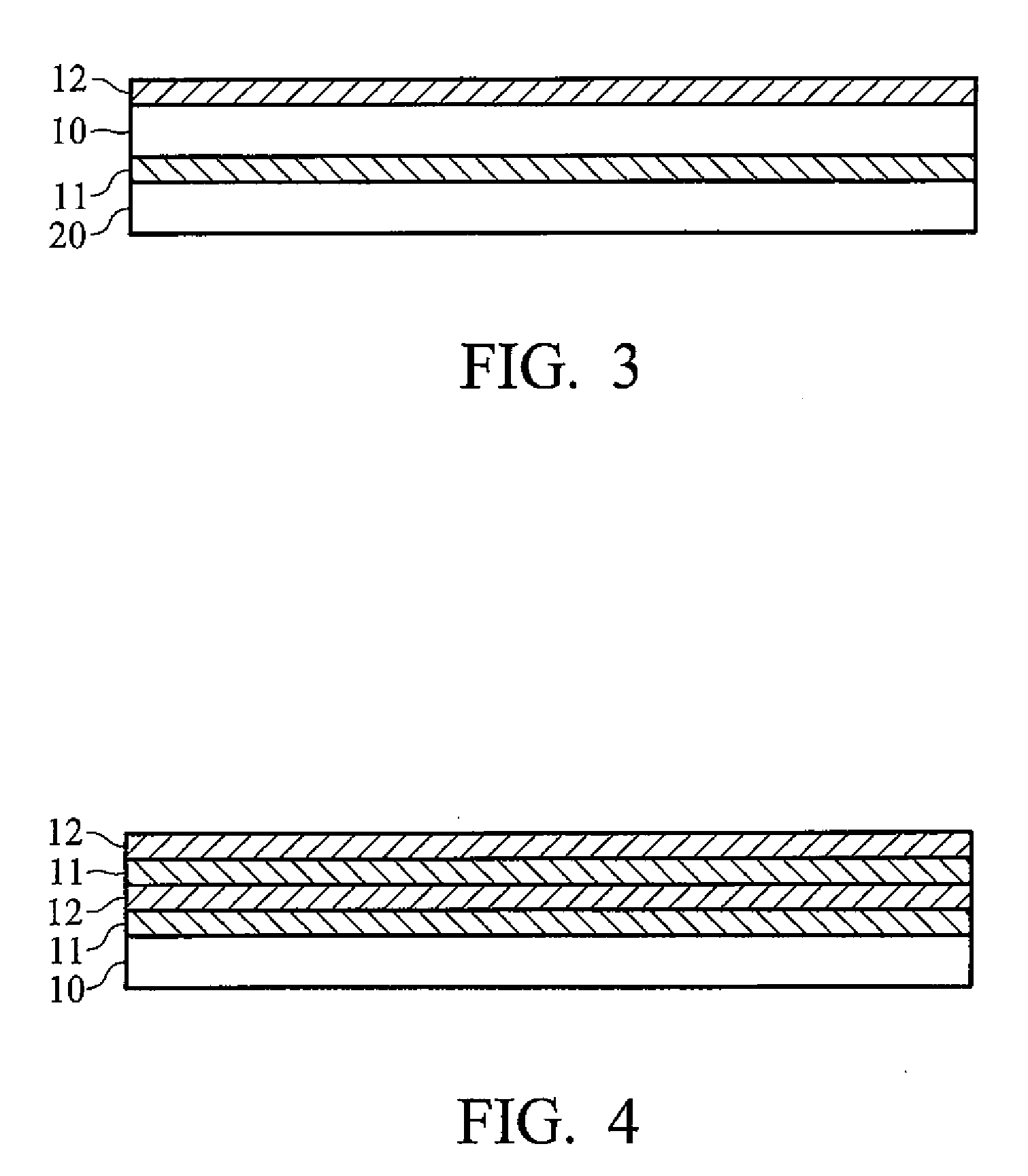

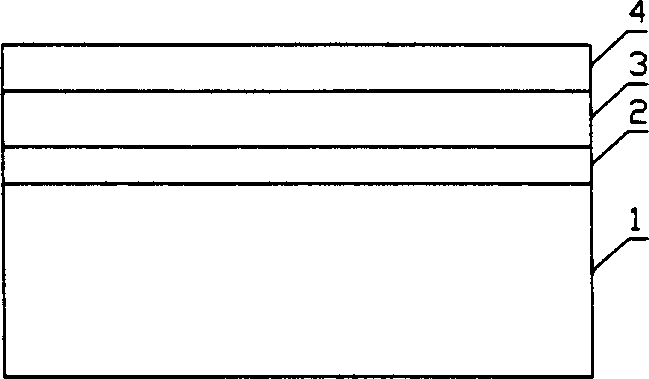

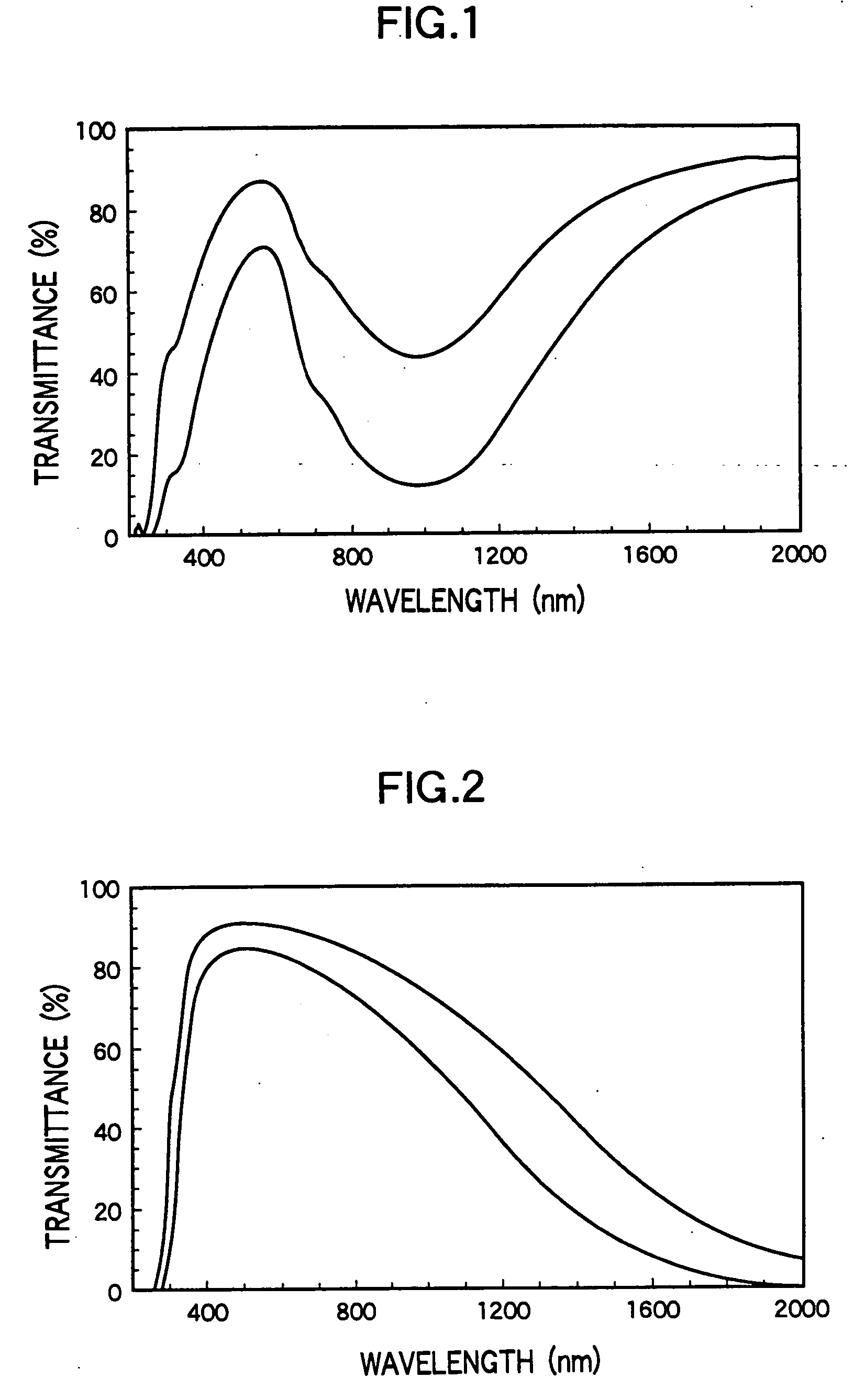

Transparent heat shielding multilayer structure

InactiveUS20090291295A1Low hazeImprove insulation performanceLayered productsCoatingsNanoparticleIndium tin oxide

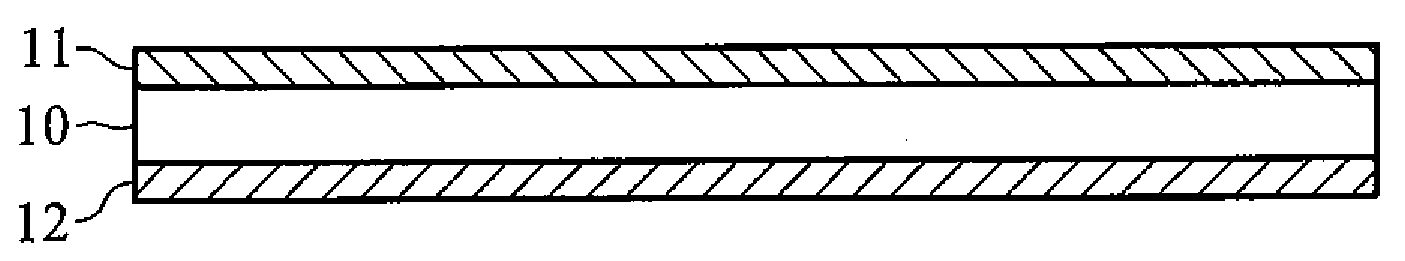

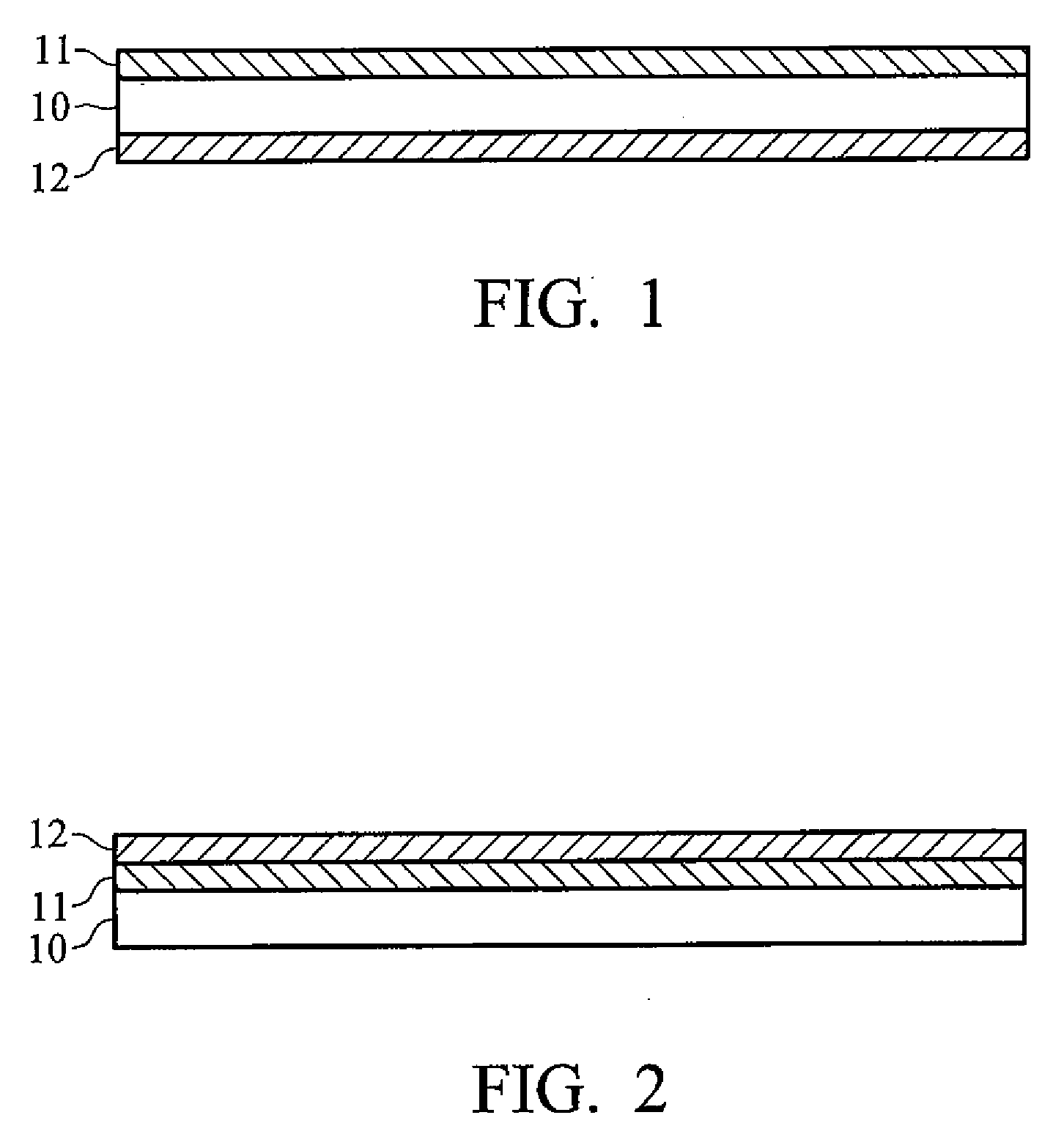

A transparent heat shielding multilayer structure is disclosed. The multilayer structure includes: a transparent base film; a first transparent heat shielding layer with lanthanum hexaboride (LaB6) nanoparticles dispersed therein; and a second heat shielding layer with ATO (antimony doped tin oxide), ITO (indium tin oxide), or metal doped tungsten oxide nanoparticles dispersed therein. The first and second transparent heat shielding layers may be disposed on the same side or opposite sides of the transparent base film.

Owner:IND TECH RES INST

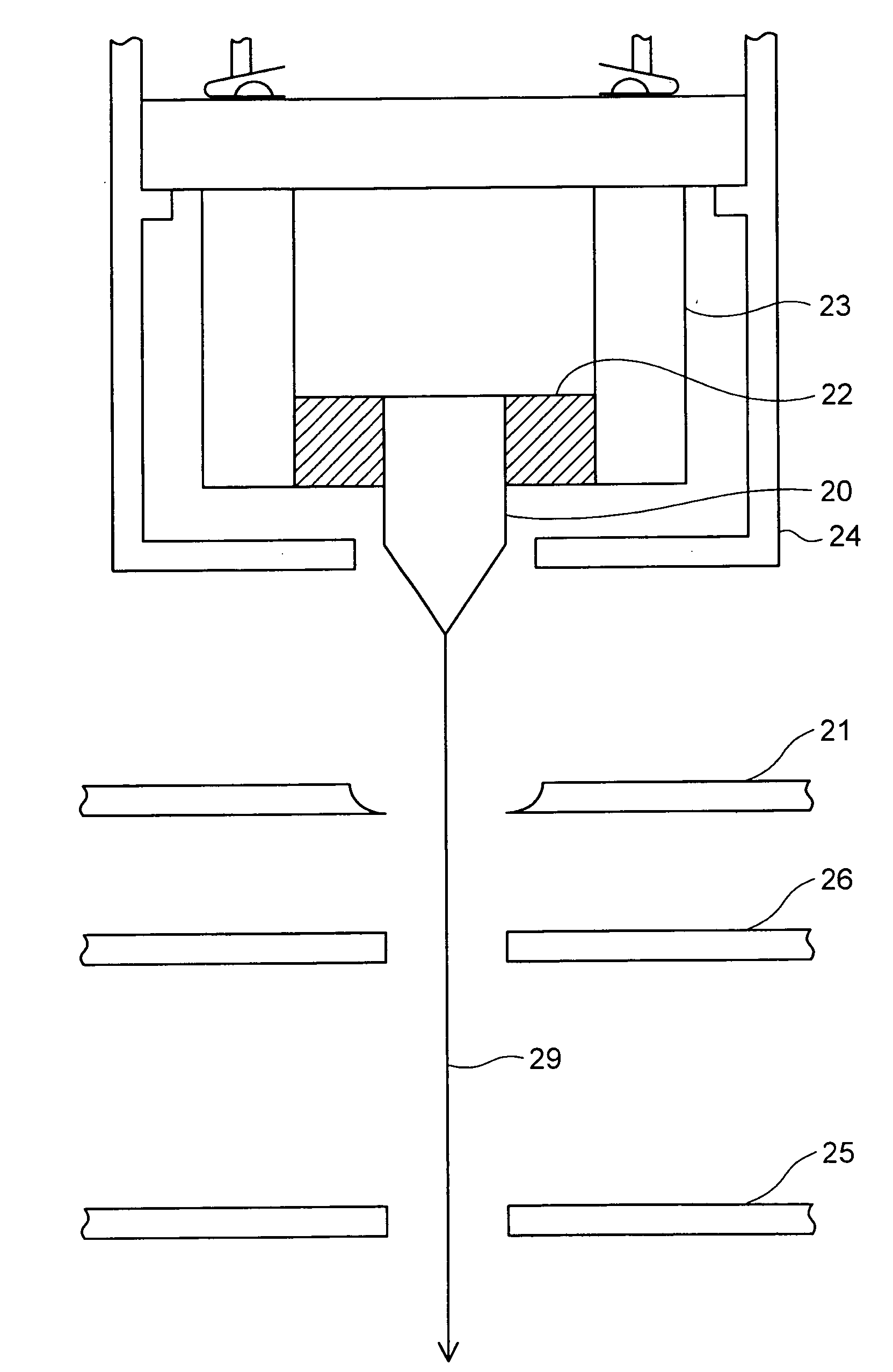

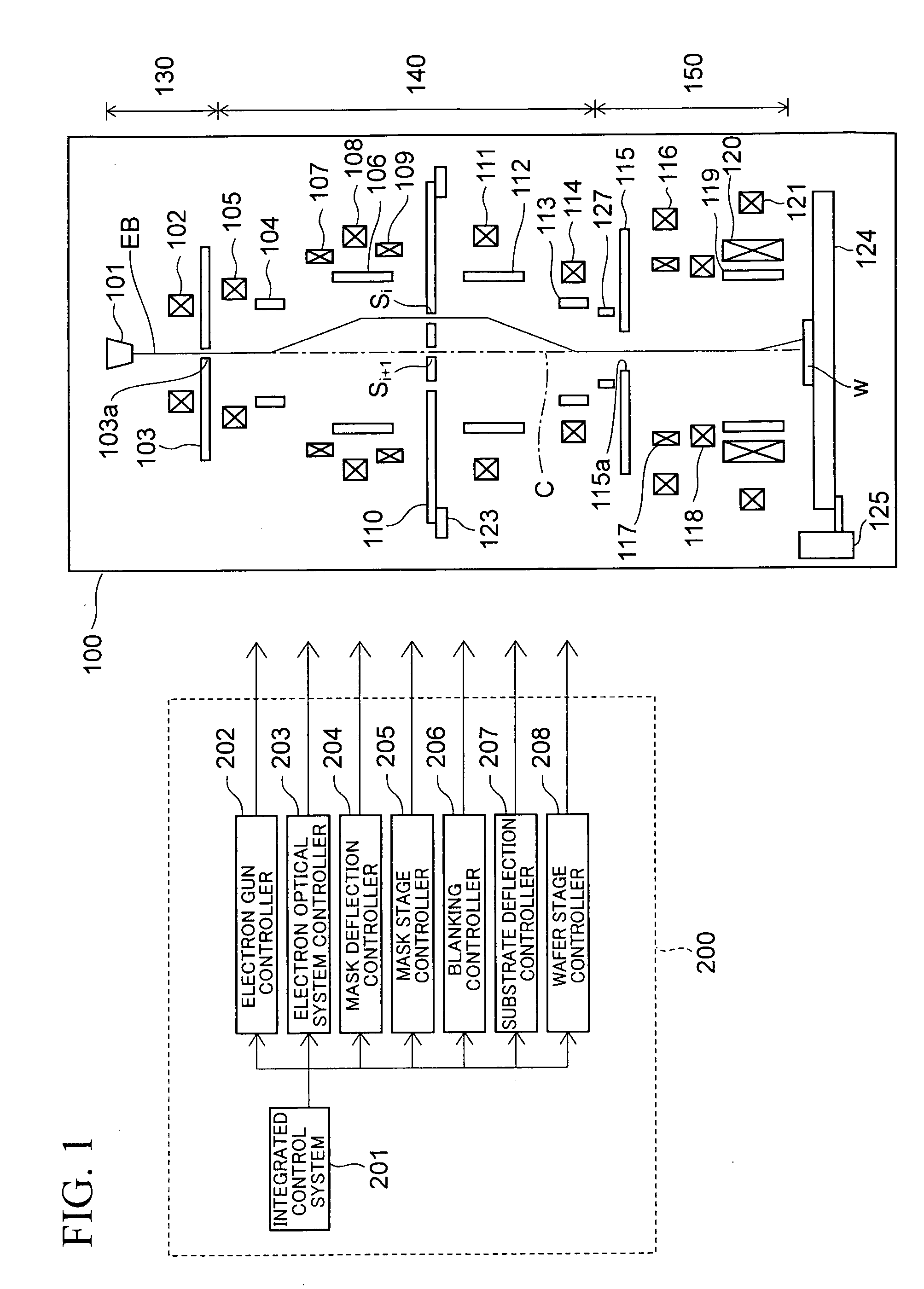

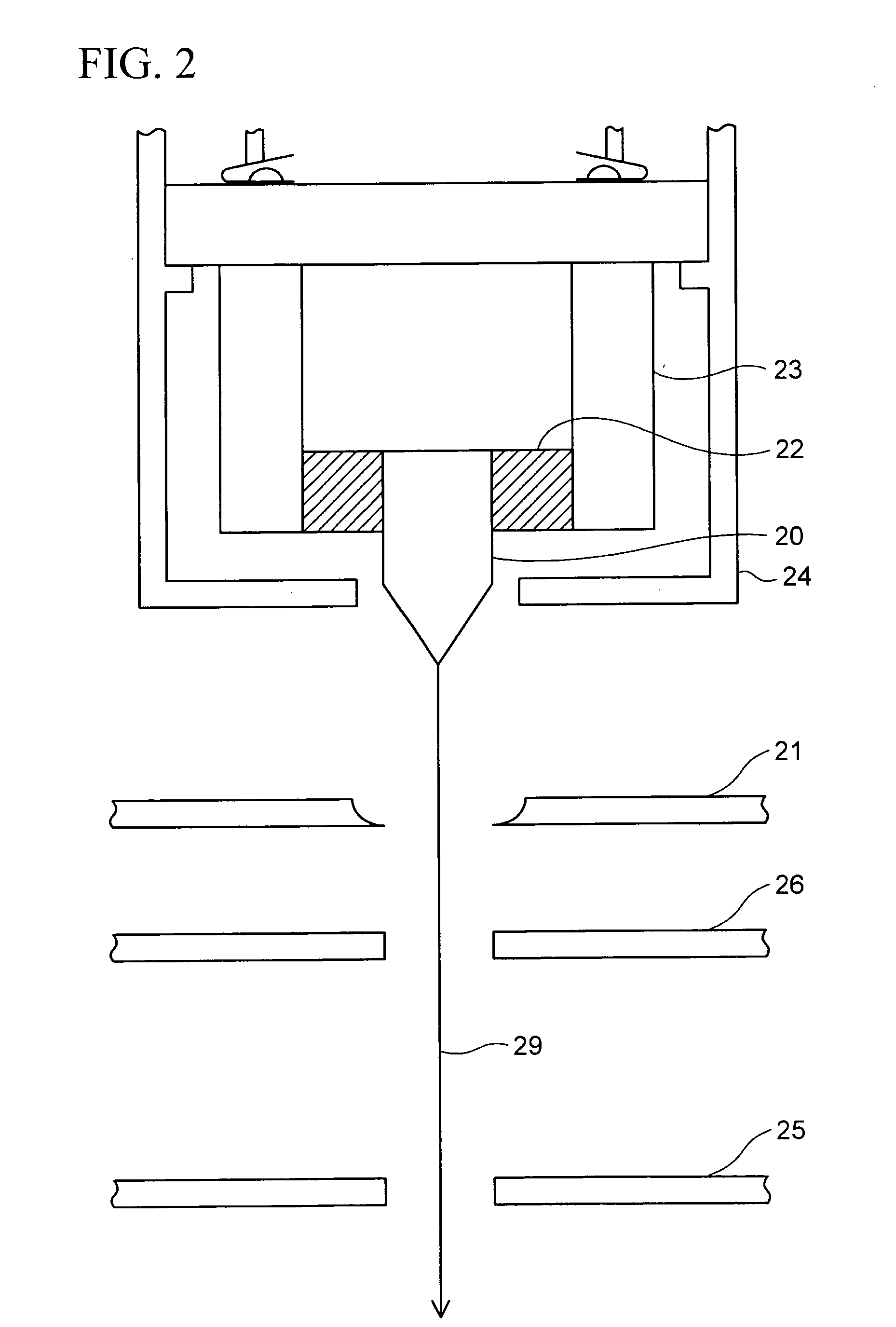

Electron gun, electron beam exposure apparatus, and exposure method

ActiveUS20080315089A1Reduce in quantityEasy to useMaterial analysis using wave/particle radiationElectrode and associated part arrangementsElectron sourceLanthanum hexaboride

An electron gun includes an electron source configured to emit electrons. The electron source includes an electron emission region configured to emit the electrons and an electron emission restrictive region configured to restrict emission of the electrons. The electron emission restrictive region is located on a side surface of the electron source except an electron emission surface on a tip of the electron source and is covered with a different material from the electron source. The electron gun emits thermal field-emitted electrons by applying an electric field to the tip while maintaining a sufficiently low temperature to avoid sublimation of a material of the electron source. The material of the electron source may be lanthanum hexaboride (LaB6) or cerium hexaboride (CeB6). The electron emission restrictive region may be covered with carbon.

Owner:ADVANTEST CORP +1

Water glass transparent reflecting heat-insulation coating material and preparation method thereof

InactiveCN106167657AAchieve a closed effectImprove lighting effectsPolyurea/polyurethane coatingsReflecting/signal paintsVanadium dioxideSlurry

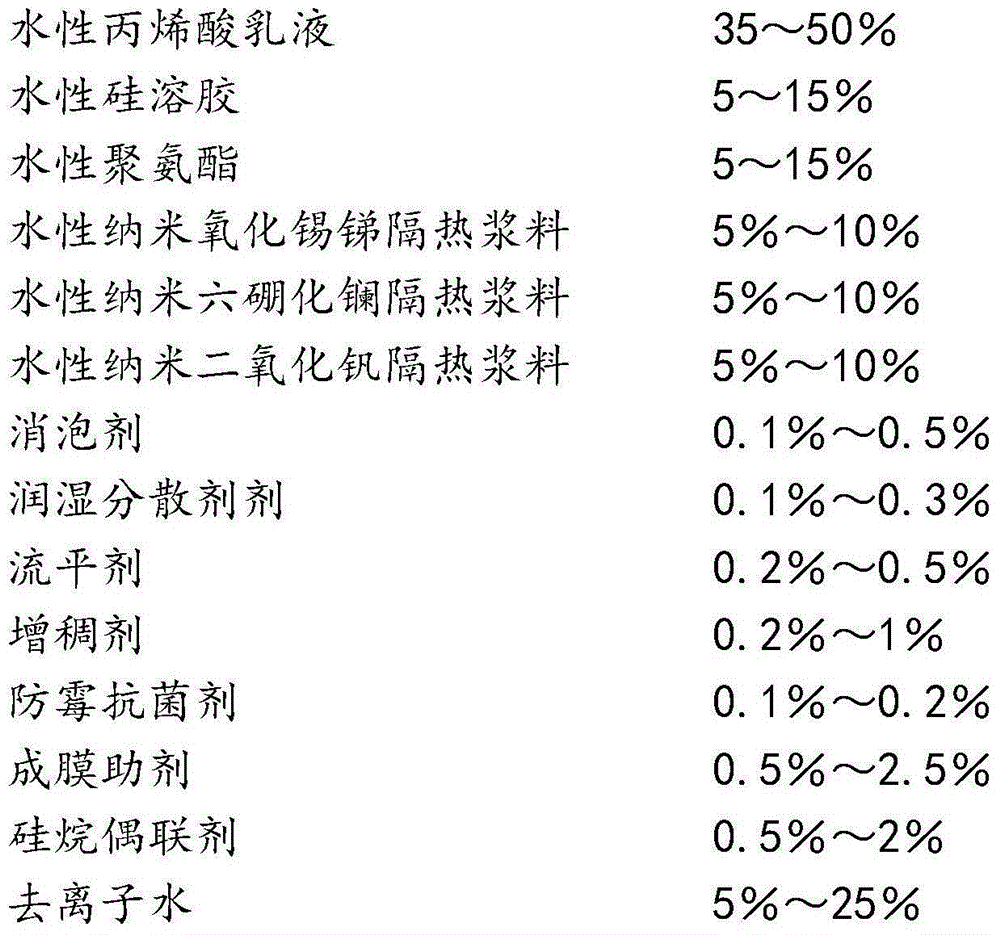

The invention discloses a water glass transparent reflecting heat-insulation coating material and a preparation method thereof, wherein the water glass transparent reflecting heat-insulation coating material comprises, by mass, 35-50% of an aqueous acrylic emulsion, 5-15% of an aqueous silica sol, 5-15% of an aqueous polyurethane, 5-10% of an aqueous nanometer antimony tin oxide heat-insulation slurry, 5-10% of an aqueous nanometer lanthanum hexaboride heat-insulation slurry, 5-10% of an aqueous nanometer vanadium dioxide heat-insulation slurry, 0.1-0.5% of an anti-foaming agent, 0.1-0.3% of a wetting dispersing agent, 0.2-0.5% of a leveling agent, 0.2-1% of a thickening agent, 0.1-0.2% of an anti-mildew antibacterial agent, 0.5-2.5% of a film forming auxiliary agent, 0.5-2% of a silane coupling agent, and 5-25% of deionized water.

Owner:刘生金

Security inks containing infrared absorbing metal compounds

ActiveUS8157905B2Easy to detectNot easy to detectNon-fibrous pulp additionLayered productsNeodymium chlorideLanthanum hexaboride

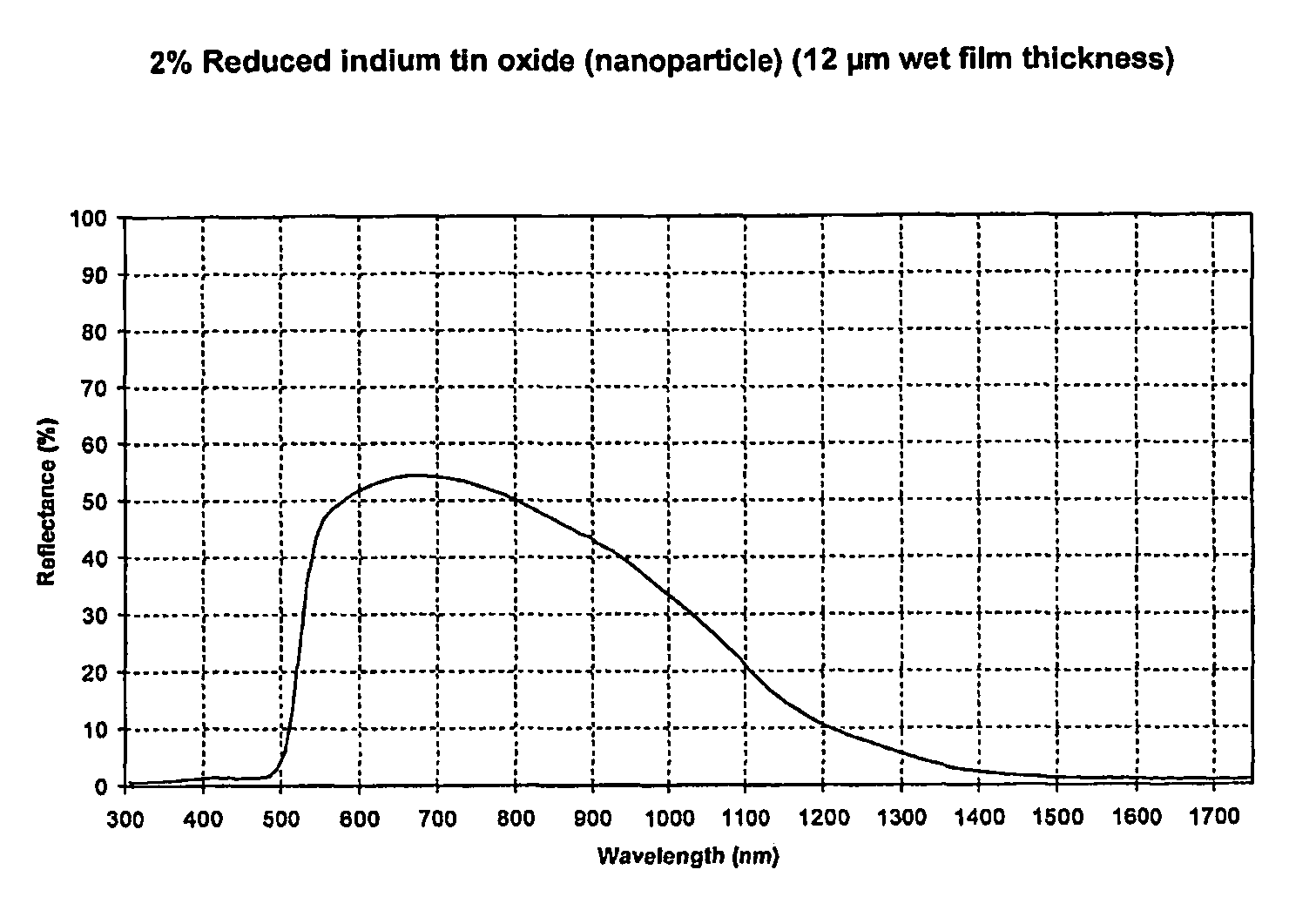

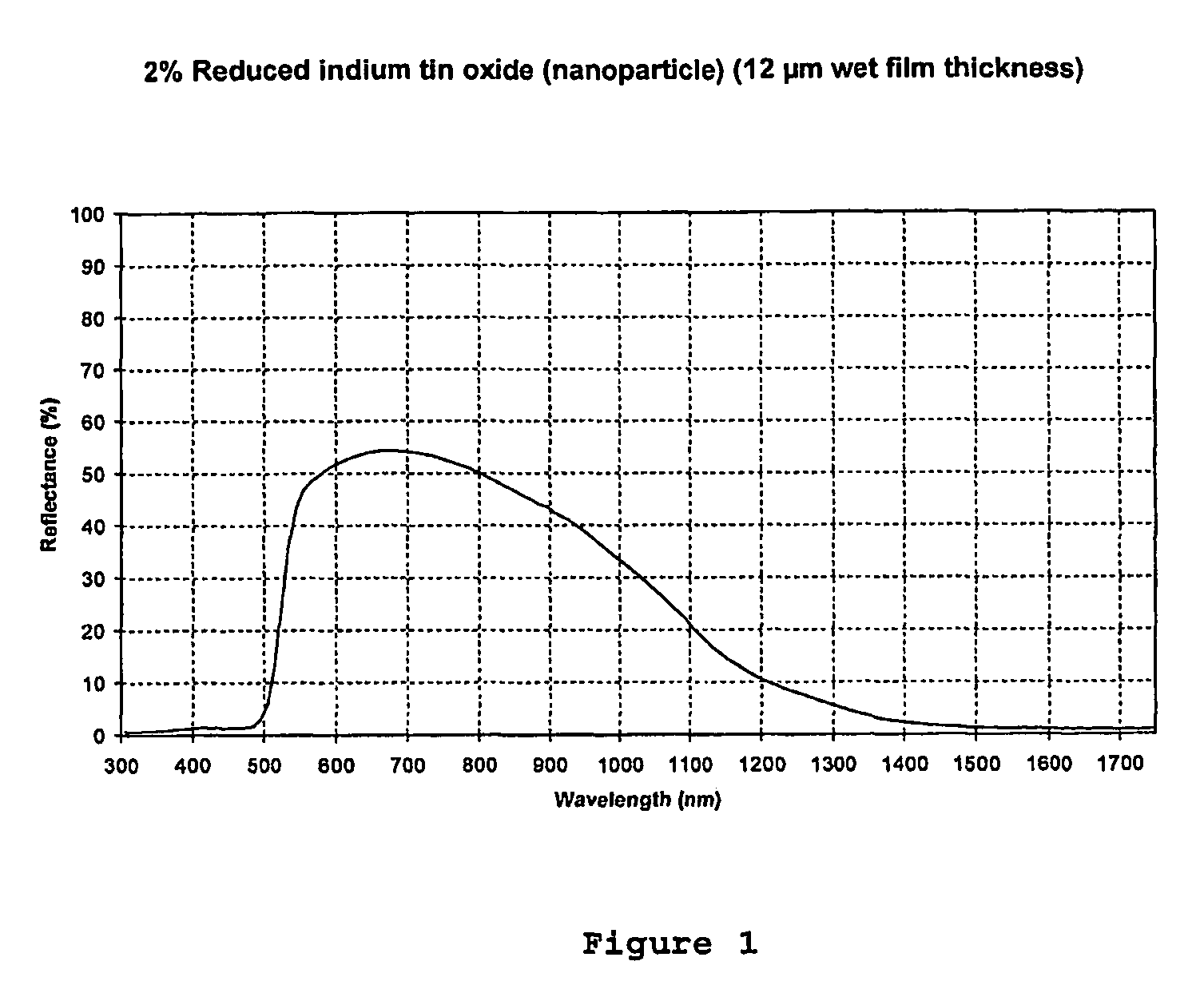

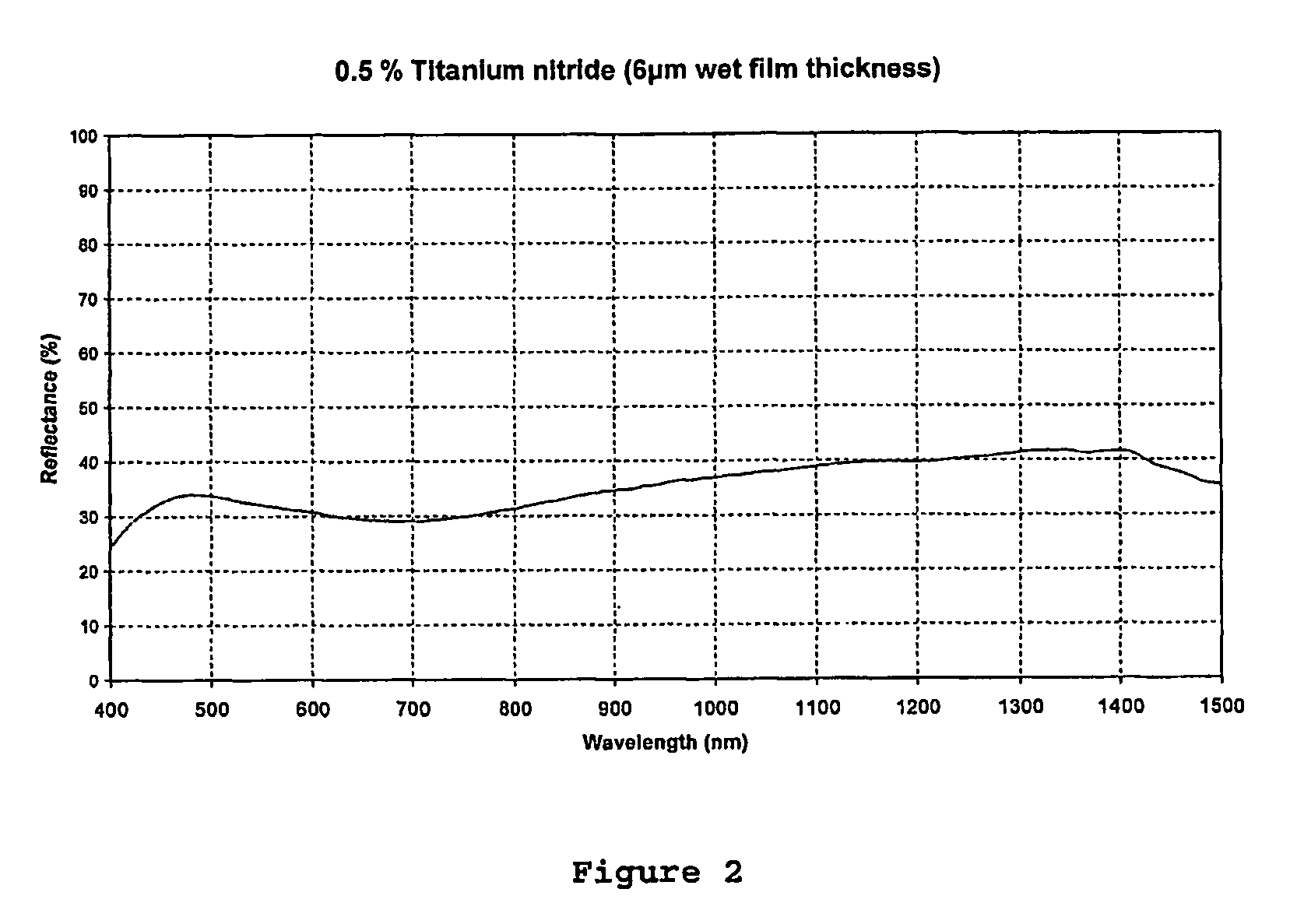

Composition including an oleophilic base ink composition having dispersed therein particles of an infrared-absorbing material wherein the infrared-absorbing material is selected from reduced indium tin oxide, titanium nitride, zirconium nitride, molybdenum metal, copper chromate, lanthanum hexaboride, neodymium oxide, neodymium chloride, dysprosium oxide and praseodymium oxide.

Owner:INOVINK

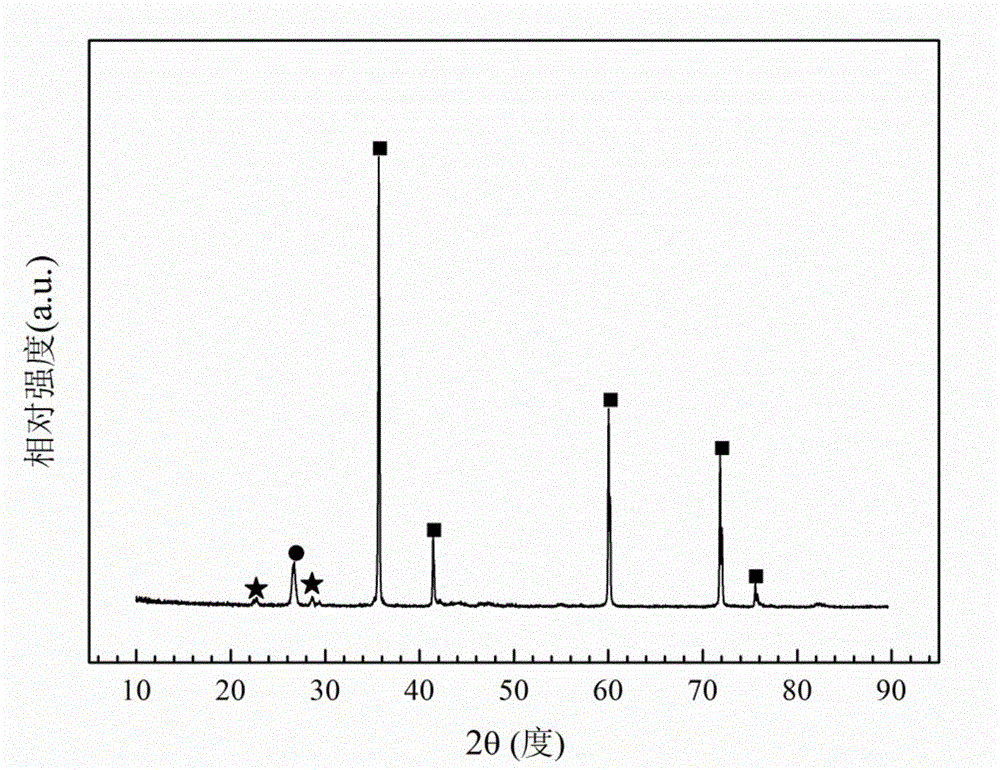

Preparing method of Si-B-C-N ceramic with laminated BN(C) grains toughened

InactiveCN106518075APromote in situ growthImprove fracture toughnessCeramic compositeArgon atmosphere

The invention provides a preparing method of Si-B-C-N ceramic with laminated BN(C) grains toughened and belongs to the technical field of preparing methods of Si-B-C-N ceramic. The method comprises the steps that 1, cubic silica powder, hexagonal boron nitride powder, graphite powder and lanthanum hexaboride powder are weighed according to the molar ratio and the mass ratio to be served as raw materials for standby application; 2, the raw materials weighed in the step 1 are put into a ball-milling tank, and high-energy ball milling is carried out under the protection of argon atmosphere, so that Si-B-C-N ceramic composite powder containing LaB6 is obtained; the ball material mass ratio is (10-90):1, the ball-milling diameter is 5-9 mm, and ball-milling time is 10-60 h; and 3, the ceramic composite powder obtained in the step 2 is subjected to spark plasma sintering to obtain a Si-B-C-N ceramic material with the laminated BN(C) grains toughened. The Si-B-C-N ceramic material obtained through the preparing method has high breaking tenacity, and the possibility of catastrophic fracture of the ceramic is reduced. The added rare earth compound LaB6 contributes to in-situ growth of the laminated BN(C) grains.

Owner:HARBIN INST OF TECH

Nanoparticulate solar control compositions

ActiveUS7759414B2Reduce transmissionHigh strengthSynthetic resin layered productsVehicle componentsLanthanum hexaborideAntimony tin oxide

Provided are compositions comprising infrared absorptive inorganic nanoparticles and an ethylene copolymer, and methods to produce the compositions. The infrared absorptive inorganic nanoparticles preferably include antimony tin oxide (ATO), indium tin oxide (ITO), lanthanum hexaboride (LaB6), or mixtures thereof. Also provided are polymer blends, polymeric films and sheets, solar control laminates, and processes to produce the polymer blends, polymeric films and sheets and solar control laminates.

Owner:KURARAY EURO GMBH

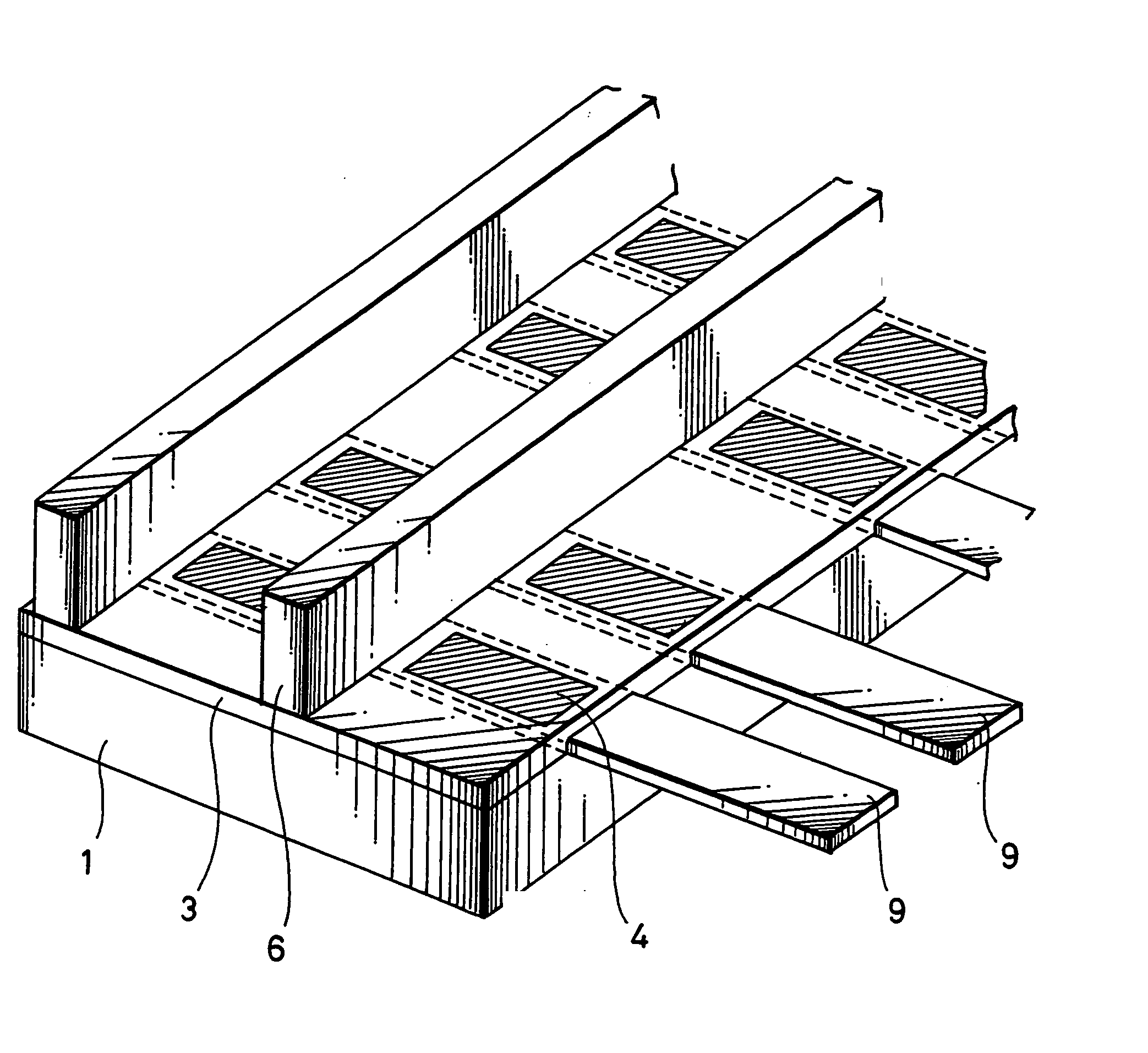

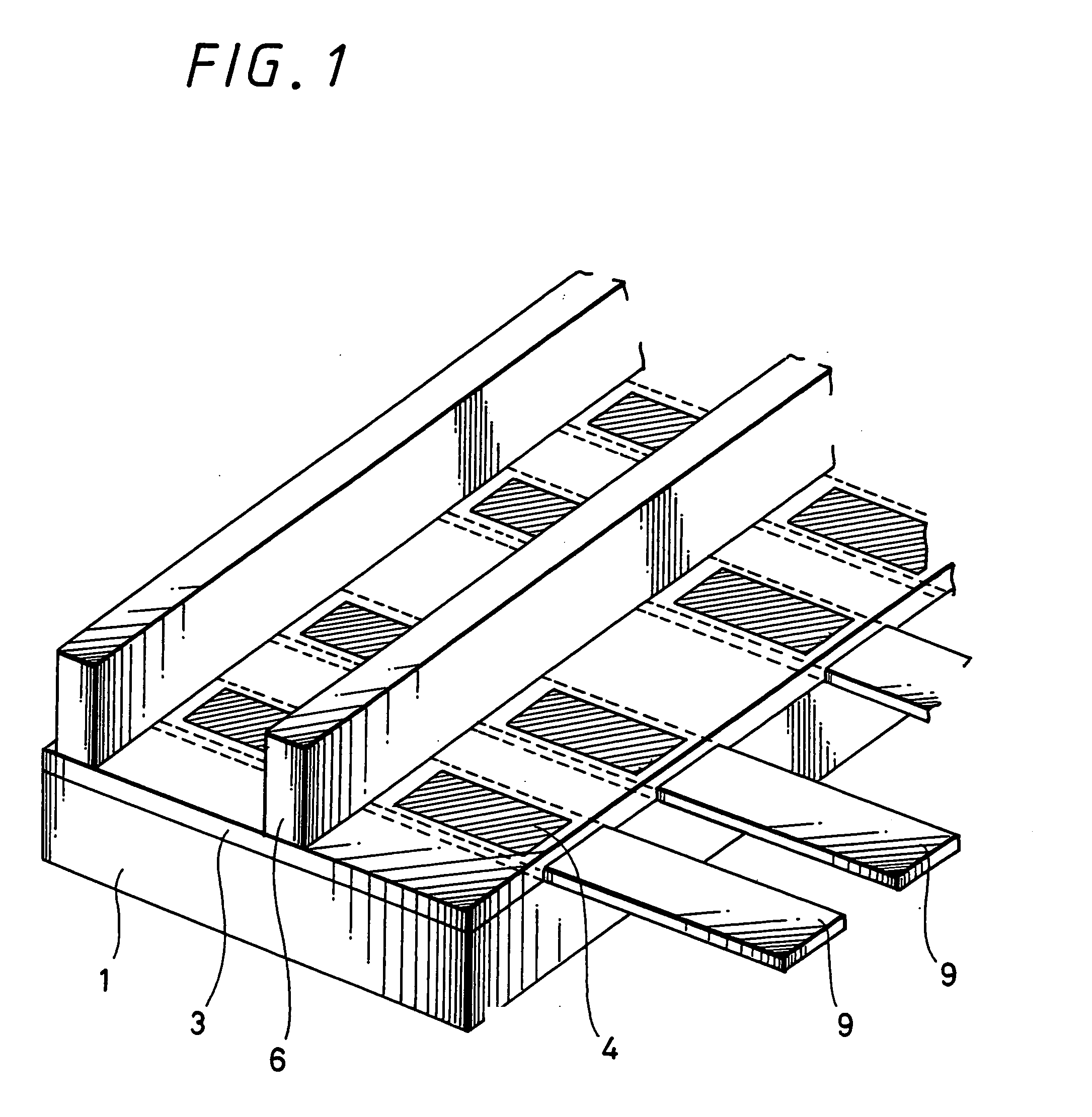

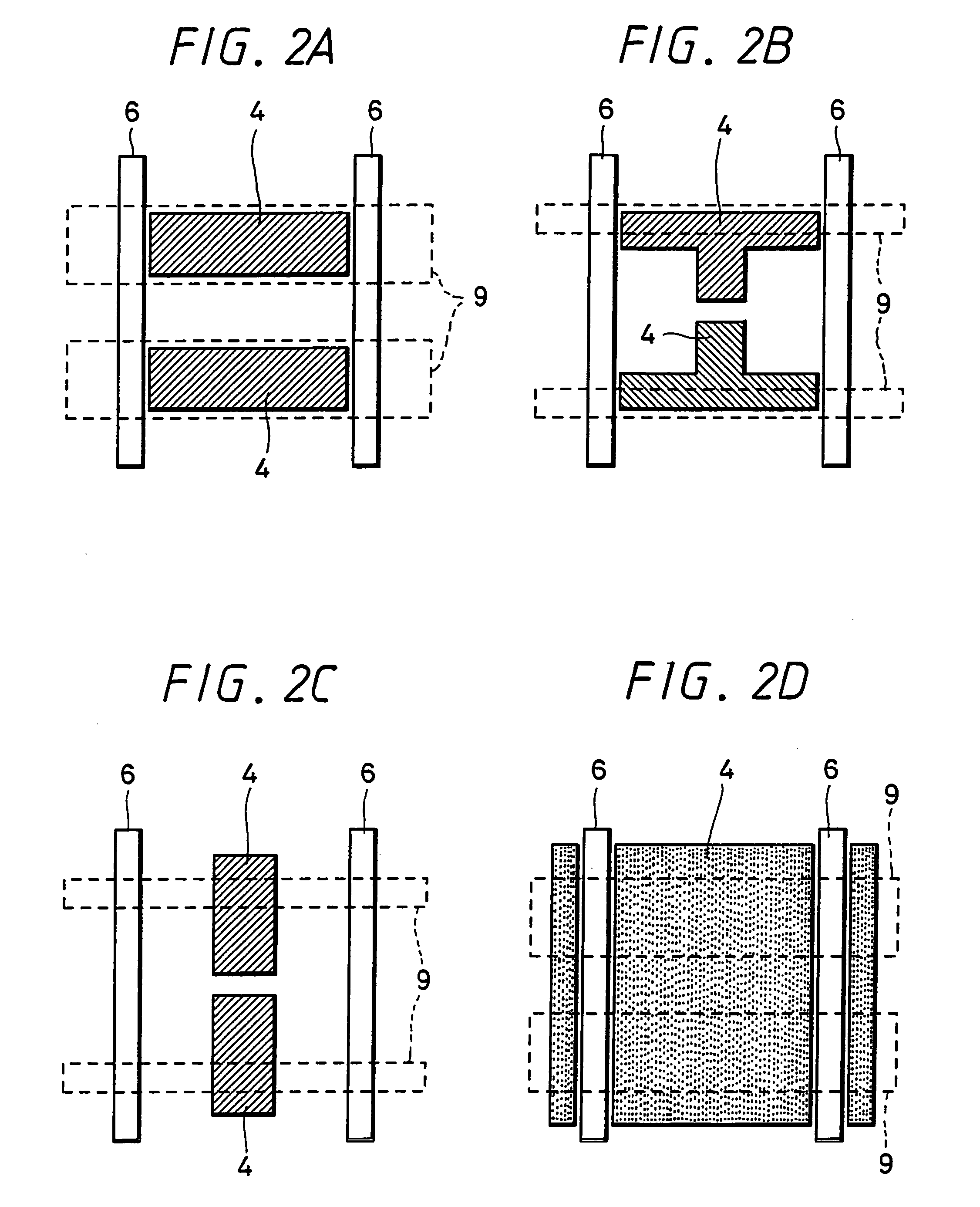

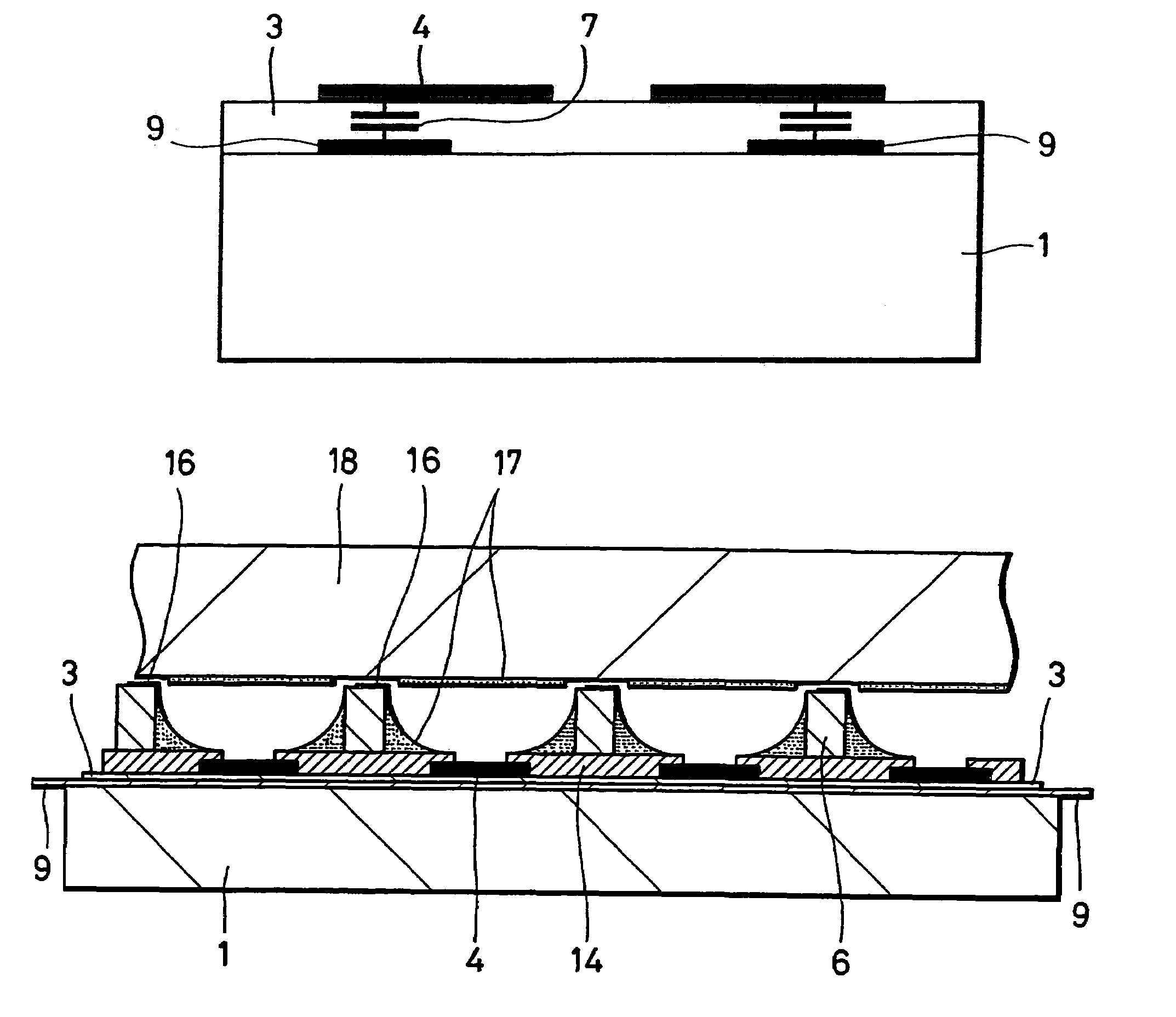

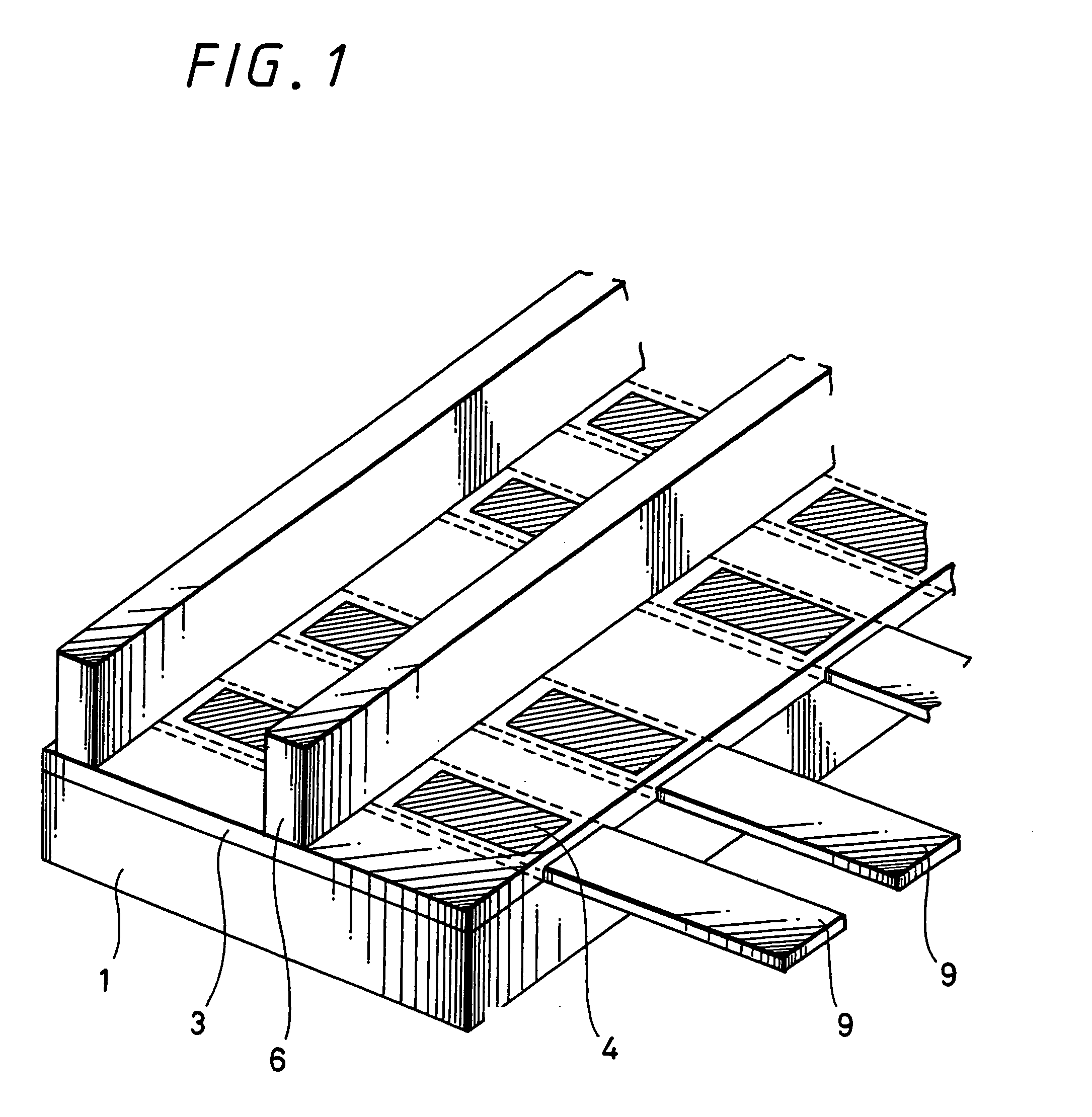

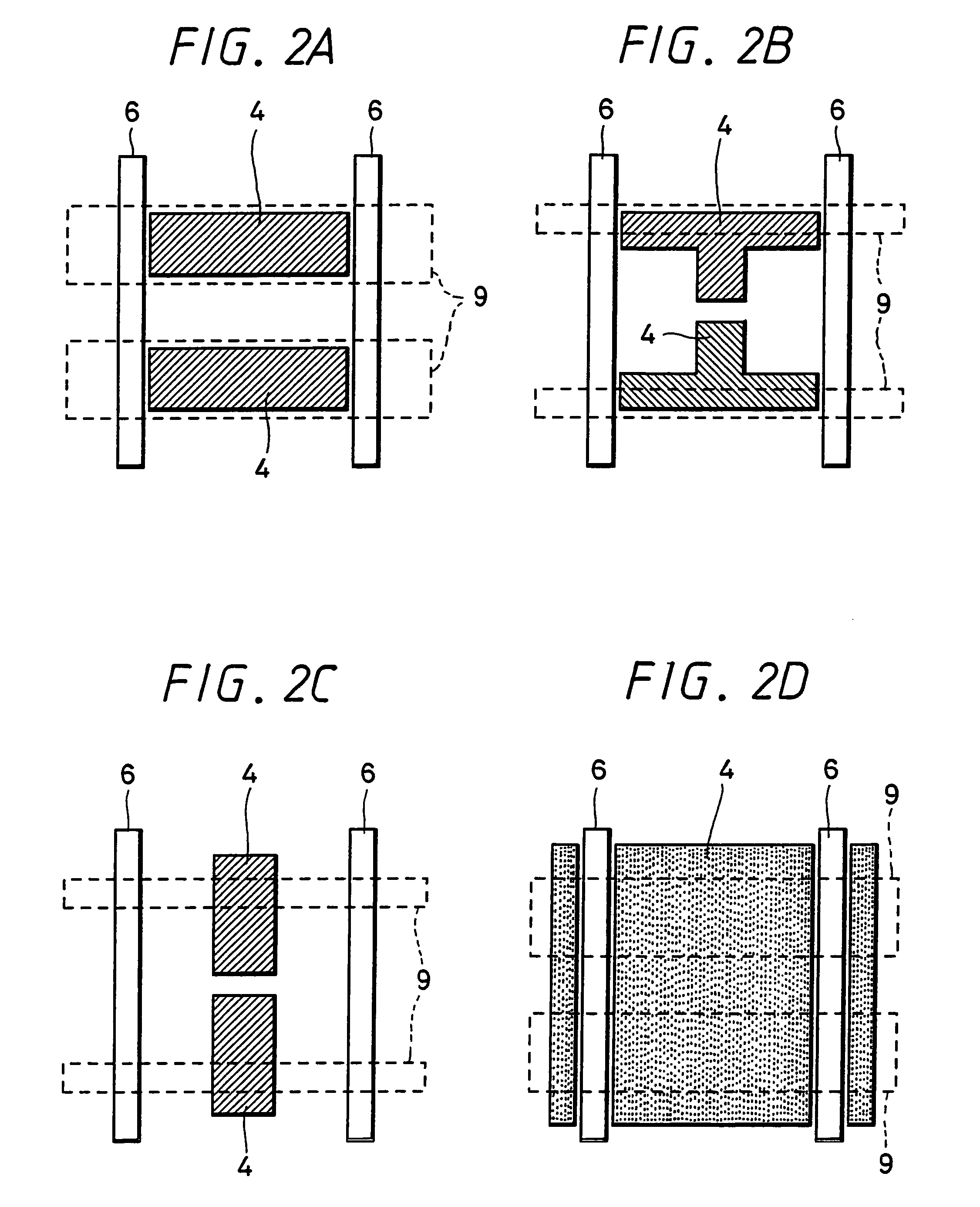

Structure of ac type pdp

InactiveUS20050127838A1Well formedEasy to processAddress electrodesSustain/scan electrodesConductive materialsSecondary electrons

Almost only choice by a secondary electron emission layer / protection layer covering the dielectric layer of an AC type PDP has been magnesium oxide (MgO) that is unstable during the production process and difficult to form, thus posing a serious production problem. An AC type PDP constructed such that, instead of covering the surface of a dielectric layer (3) with a dielectric material such as MgO, an insular electrode (4) is made by forming a conductive material such as nickel, aluminum, magnesium and lanthanum hexaboride into an insular shape, and the insular electrode (4) is allowed to capacity-couple with a lower-layer bus electrode (9) by means of an electrostatic capacity formed by a dielectric layer (3) to operate the insular electrode (4) as a sustained electrode.

Owner:TECHNOLOGY TRADE AND TRANSFER CORP

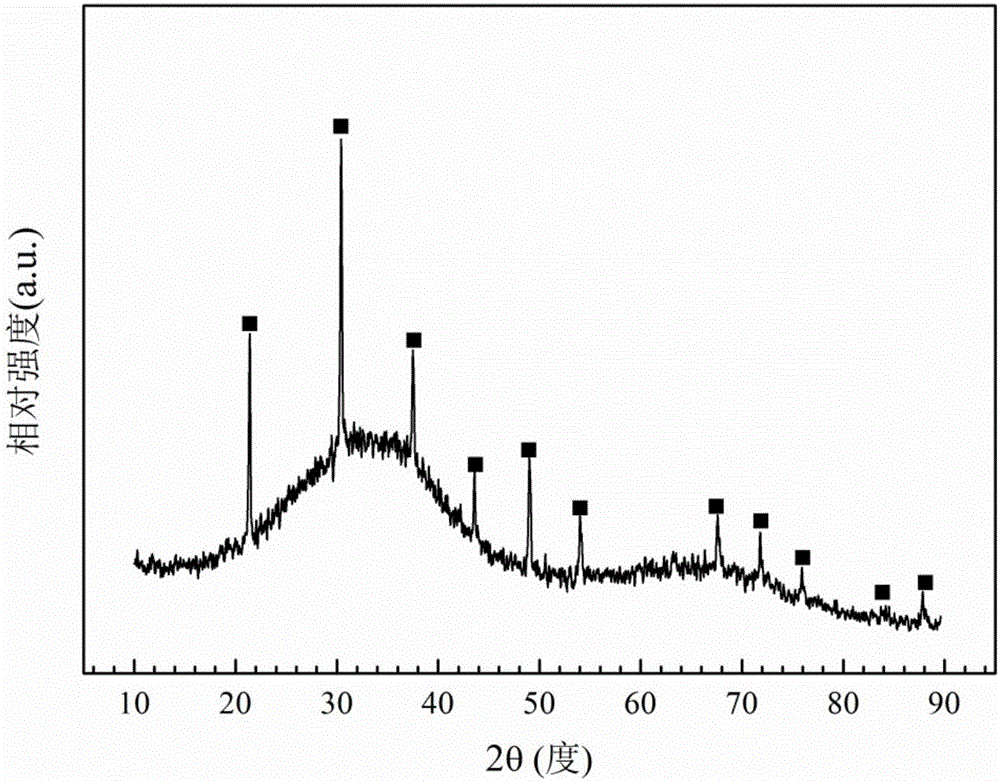

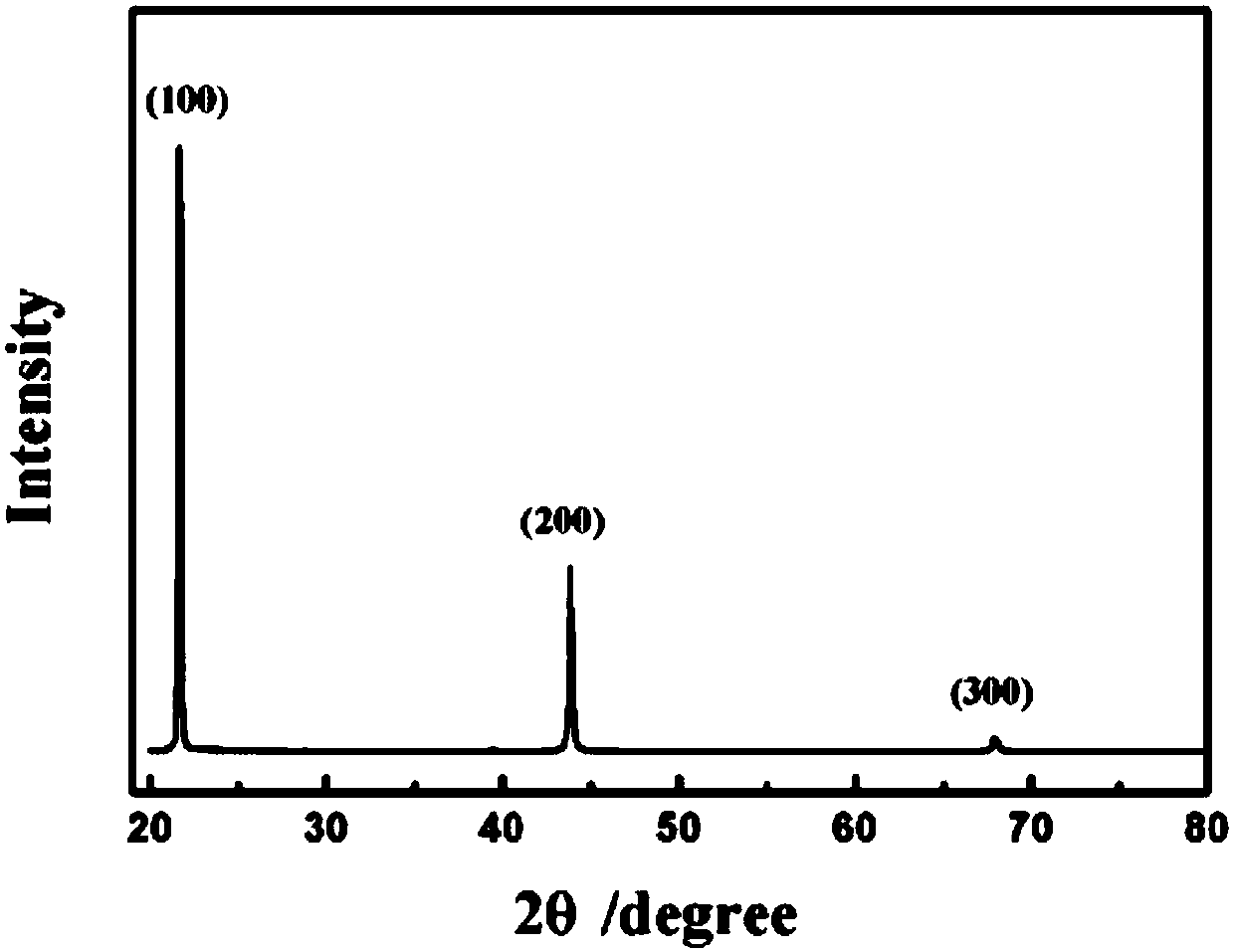

Preparation method of large-size and high-performance lanthanum hexaboride single crystals

ActiveCN108048907AQuality improvementImprove performancePolycrystalline material growthBy zone-melting liquidsZone meltingLanthanum hexaboride

The invention discloses a preparation method of large-size and high-performance lanthanum hexaboride single crystals. A discharge plasma sintering technology and an optical region smelting technologyare combined, firstly, a zone melting polycrystal is prepared at a higher growth rate, the lanthanum hexaboride single crystals with uniform diameter and size larger than or equal to 10 mm are prepared at a lower growth rate on the basis of the single crystals as seed crystals. The prepared lanthanum hexaboride single crystals have the diameter larger than that reported in all existing literaturesand have high quality and good performance, and a foundation for further engineering application of the single crystals is laid.

Owner:安徽尚欣晶工新材料科技有限公司

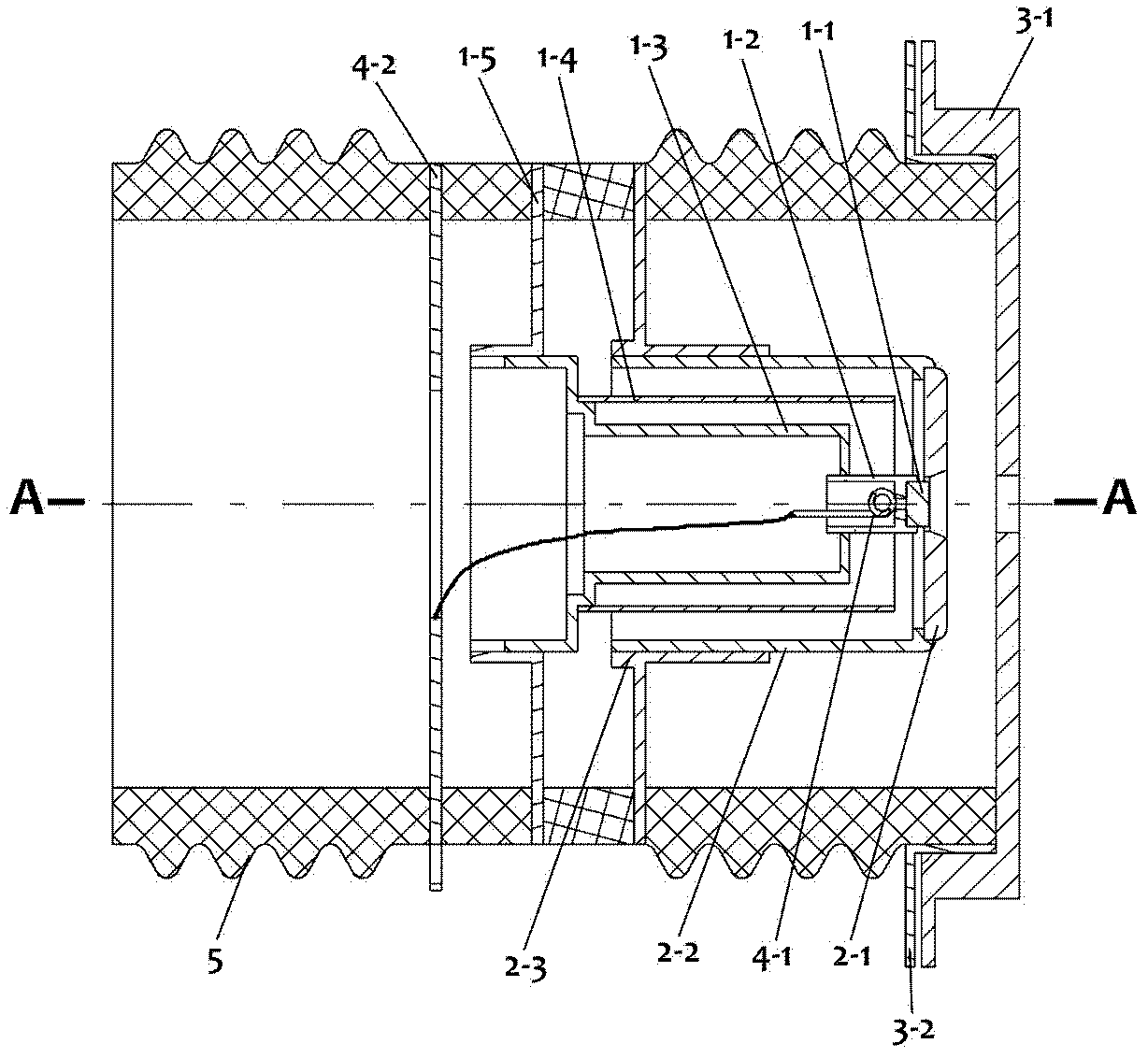

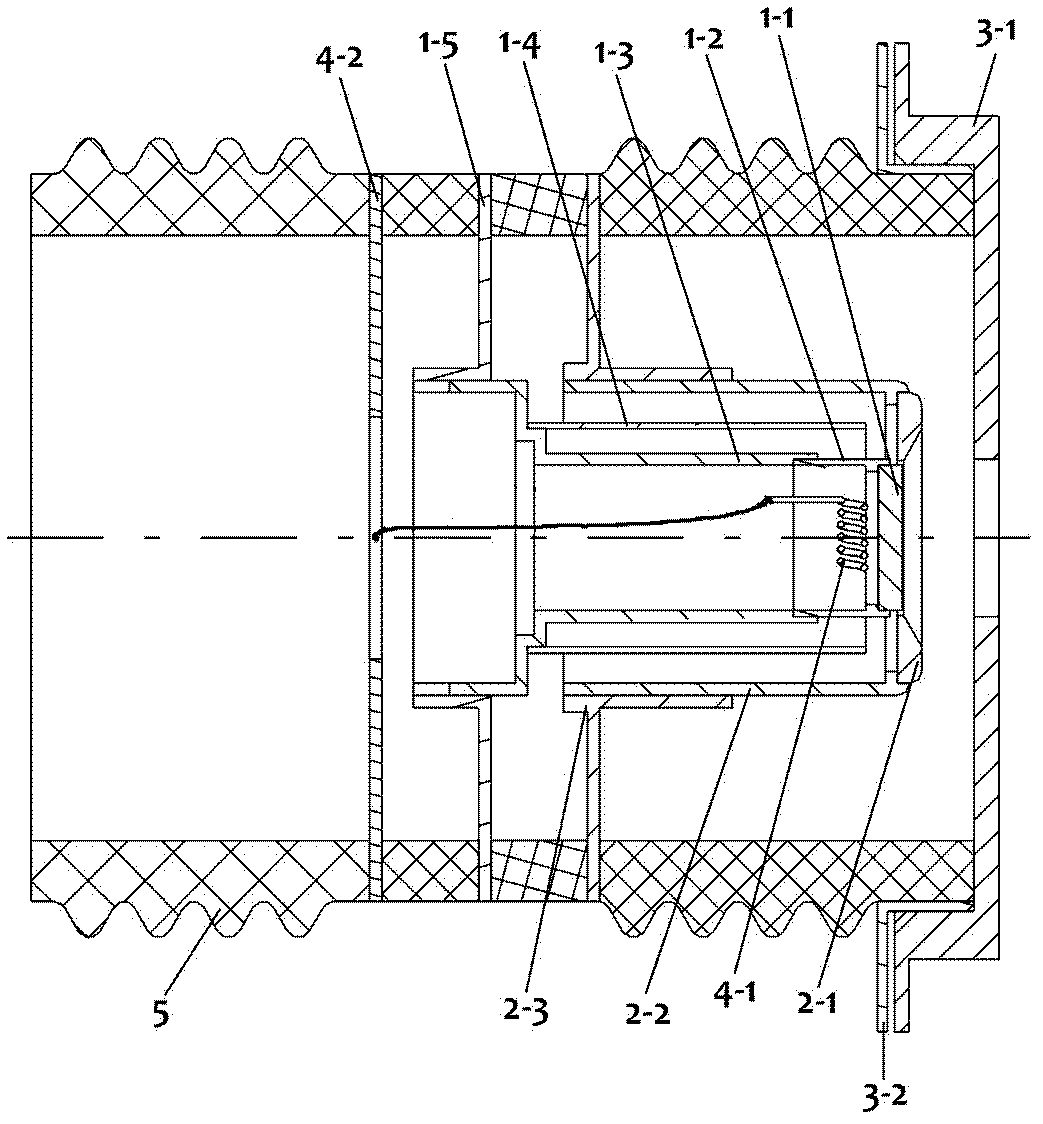

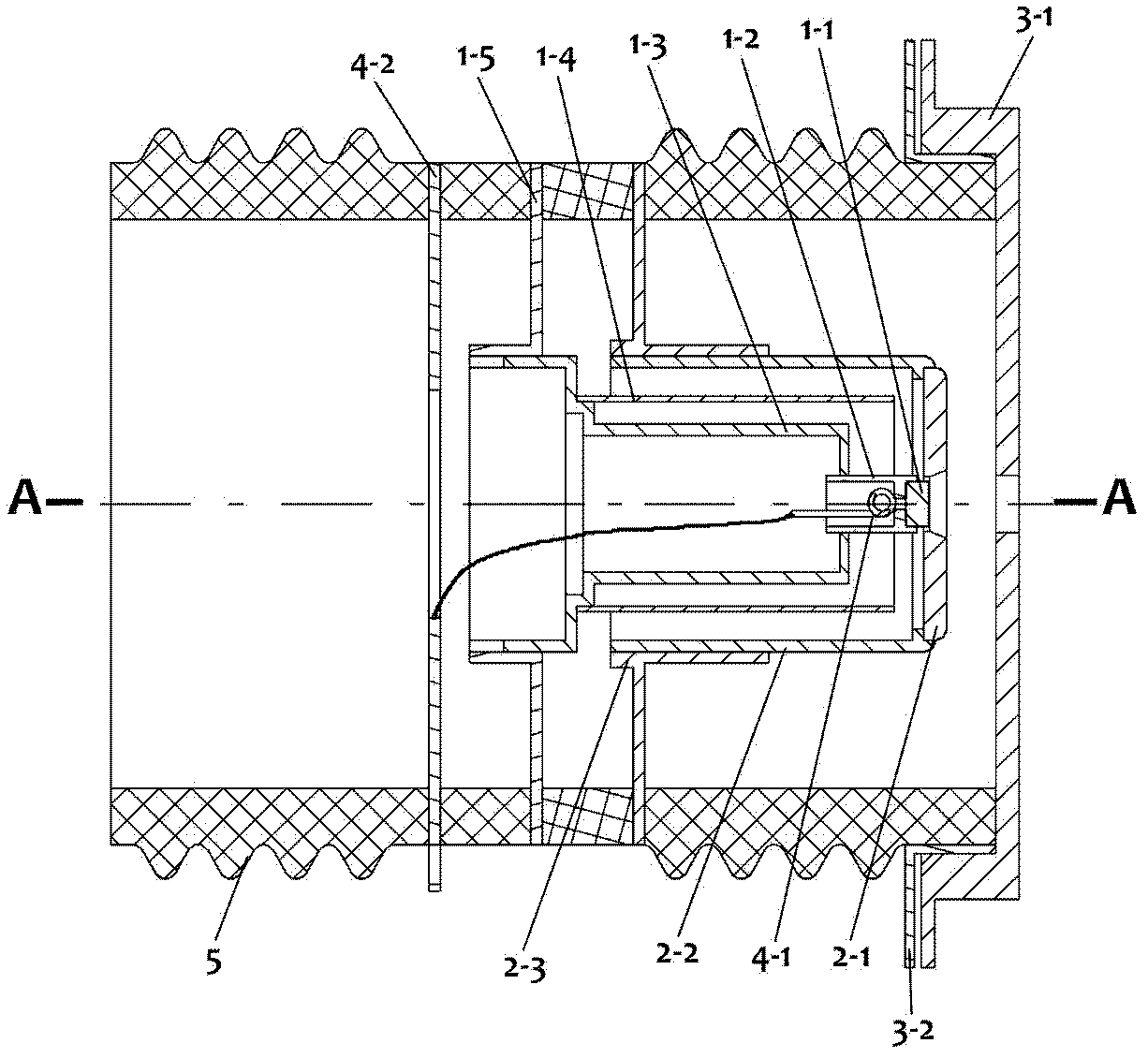

Oval sheet beam electron gun

InactiveCN102522298AMiniaturizationIncrease current densityTransit-tube electron/ion gunsTransit-tube focussing arrangementsBand shapeLanthanum hexaboride

The invention belongs to an oval sheet beam electron gun, which is used with a travelling wave tube, a backward wave tube and the like. The oval sheet beam electron gun comprises a shell, an electric heating wire in the shell, a cathode component, a focusing electrode component and an anode, wherein an emitting surface of a cathode head of the cathode component is a plane, the focusing electrode component comprises a pyramidal focusing hole, and the anode is positioned at an output port of the shell and provided with an anode hole which is a cylindroid hole. The cathode head is made of lanthanum hexaboride, the emitting surface of the cathode head is modified into a plane, a pyramidal hole with a rectangular axial section is used as the focusing hole, and the cylindroid hole is used as the anode hole, so that the oval sheet beam electron gun has the advantages that the oval sheet beam electron gun is simple in structure and convenient in processing, the precision is easy to be guaranteed, devices are easy to be miniaturized, the production cost is low, current emitted by the cathode head is high in density, operation frequency of the devices and current density of electron beams can be improved effectively, the electron gun is high in output efficiency and long in service life, and the like. The defects of complex structure, low current density and unevenness of the electron beams, high evaporativity and short service life of the cathode in operation at high temperature, and the like in the prior art can be overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

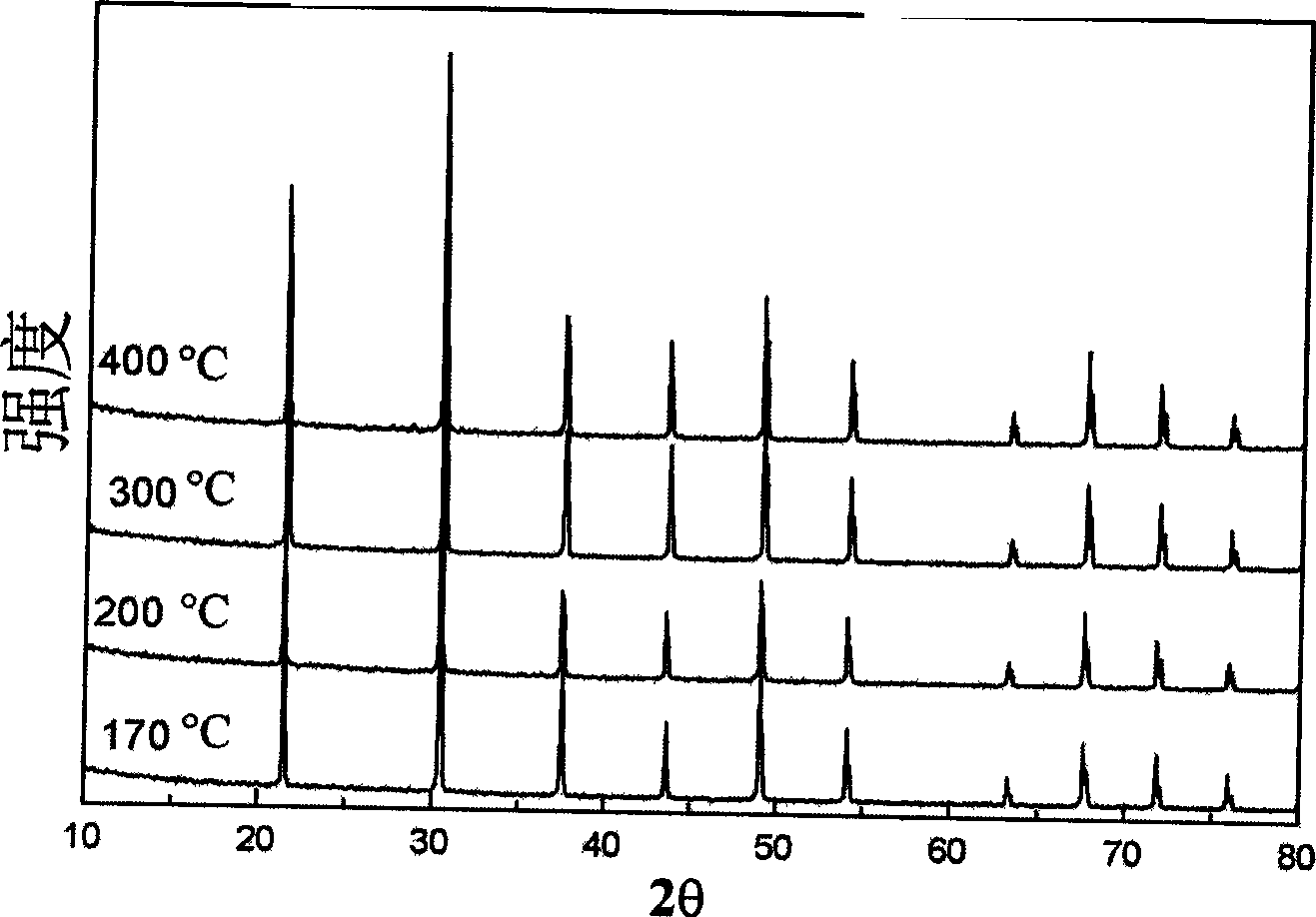

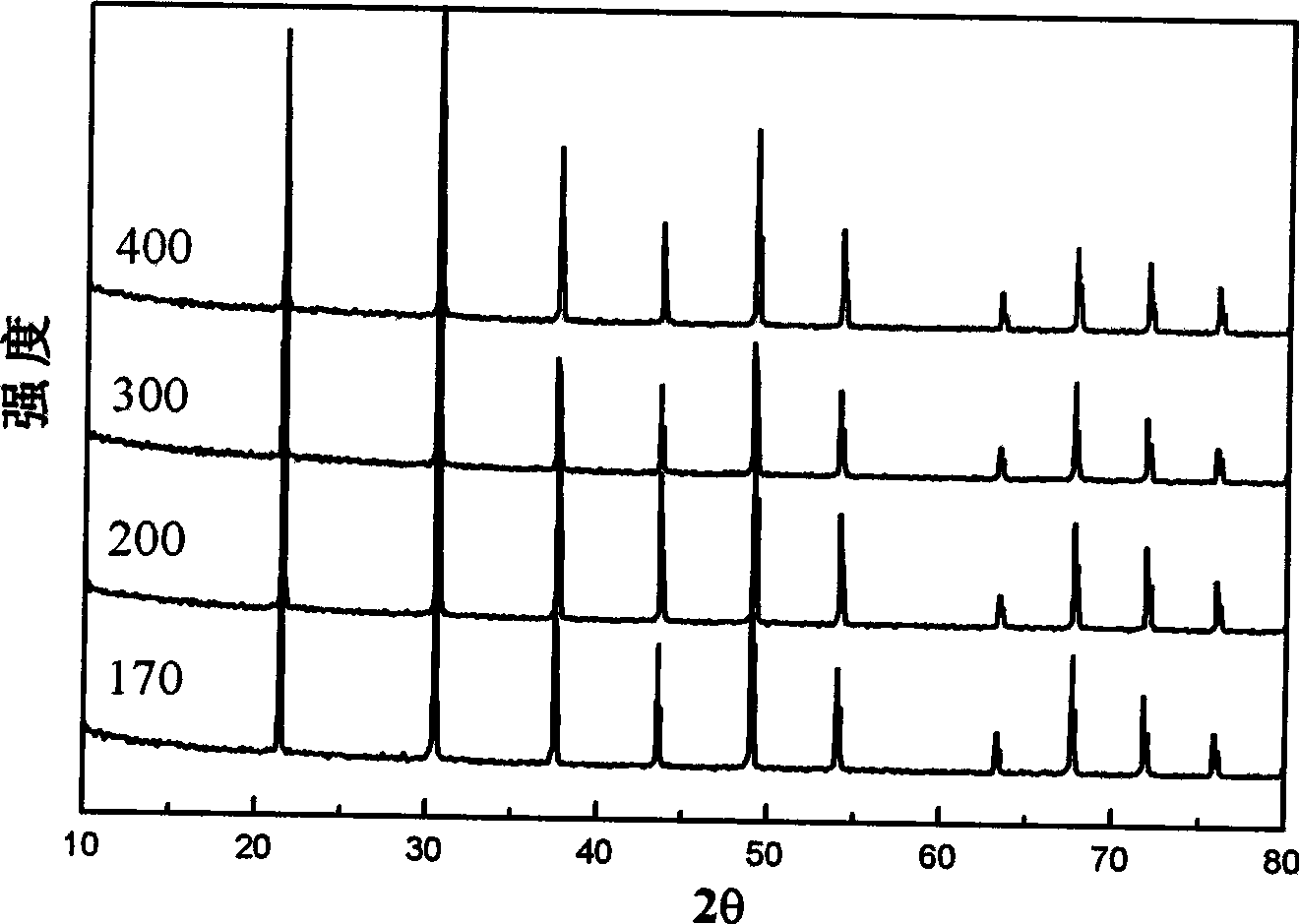

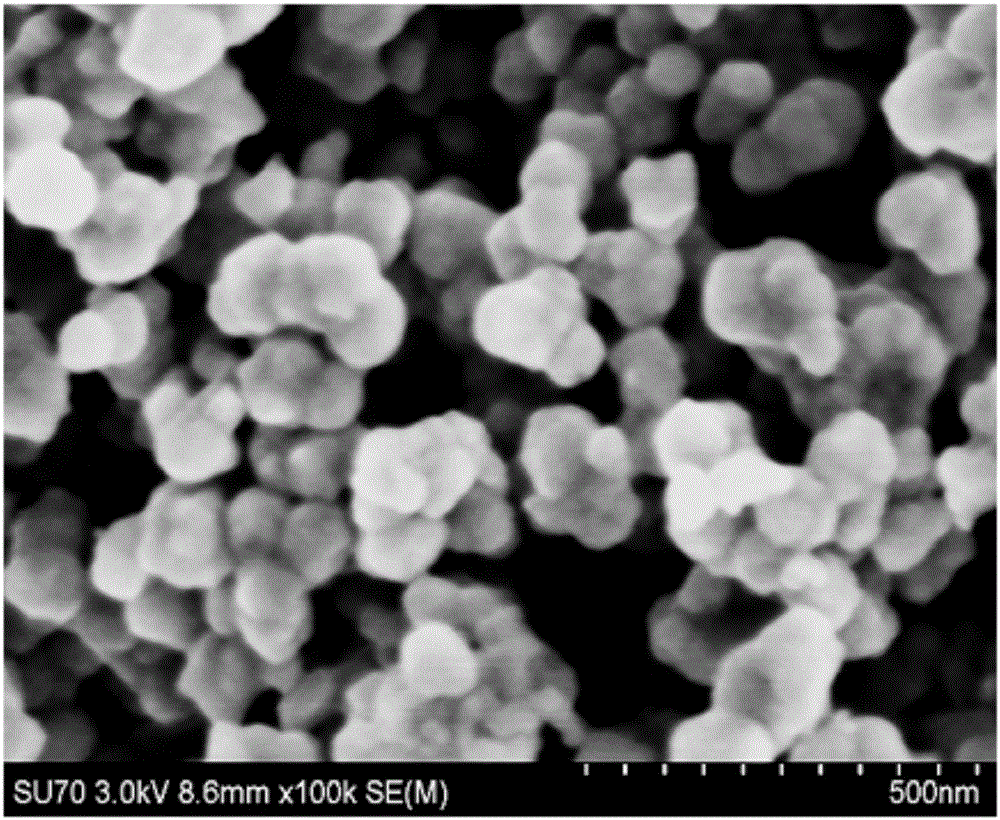

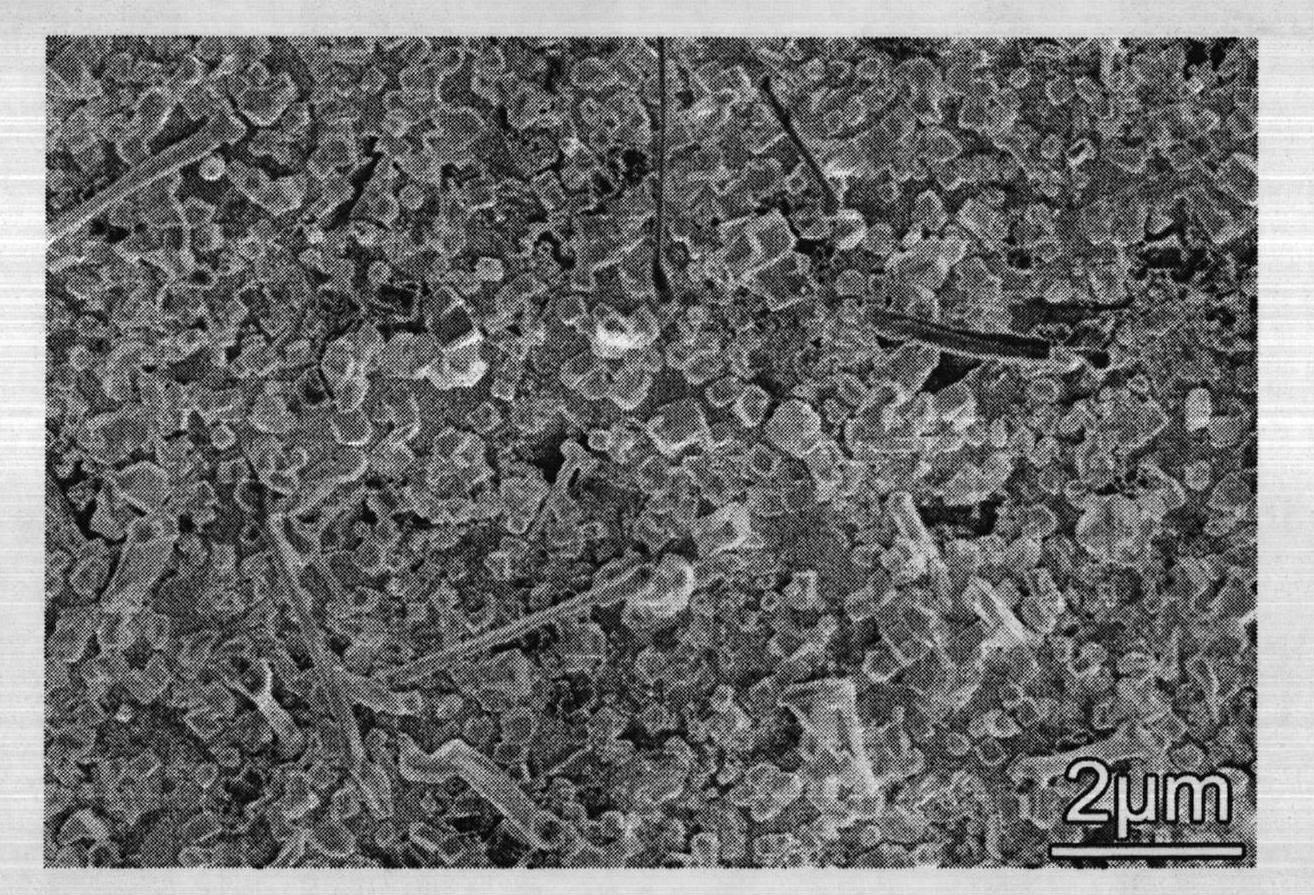

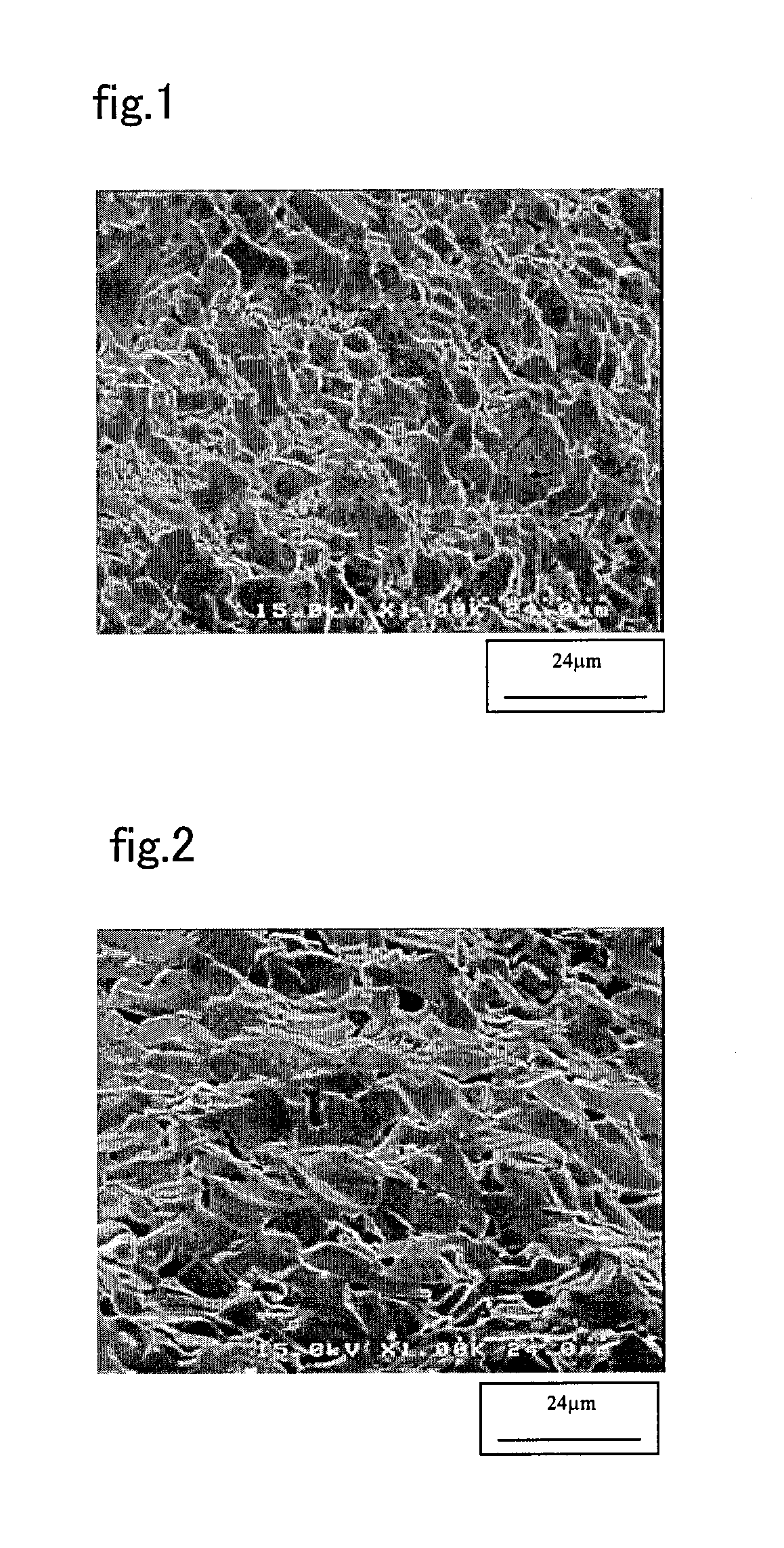

Method for synthesizing lanthanum hexaboride nano powder by solid-phase reaction under low temperature

InactiveCN101503198AGood lookingLow reaction temperatureMetal boridesSolid reactionReaction temperature

The invention relates to a method for preparing lanthanum hexaboride nano-powder by solid phase reaction at low temperature. The method comprises: lanthanum source, metallic reducing agent, halogenating agent and boron source are sealed in a high-pressure autoclave for reaction at the temperature of 170-500 DEG C for 30 minutes-3 days; the head product is treated by acid to remove impurity, and then is filtered and dried, so that pure phase lanthanum hexaboride powder is obtained and has the particle size within the range of 100-1500nm. Compared with the existing boron thermal, carbon thermal, boron carbide technologies and the like, the method has low reaction temperature as well as simple and easy control process, the obtained product has better appearance, and the material is low in price, so that the method is convenient for commercial process.

Owner:SHANDONG UNIV

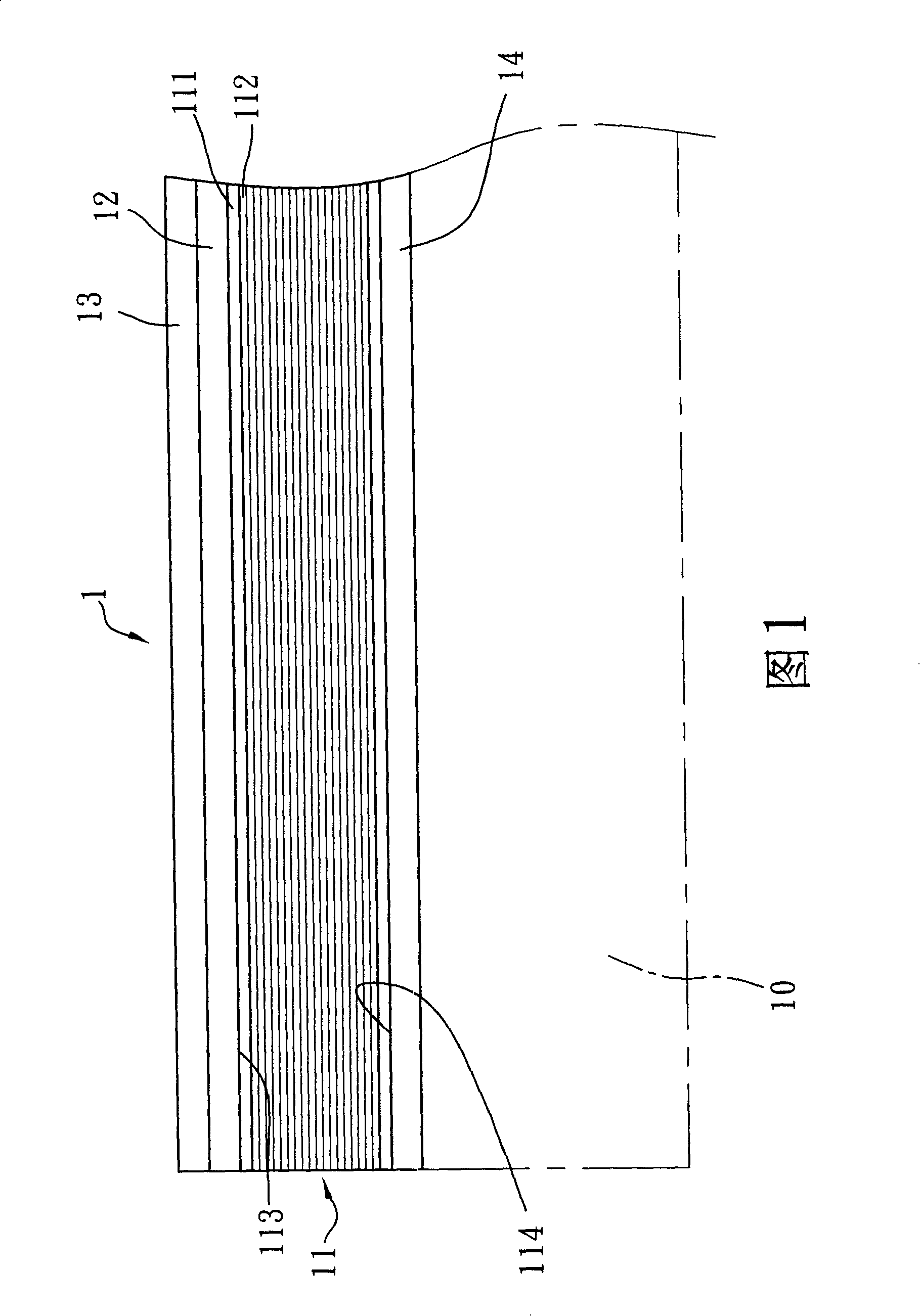

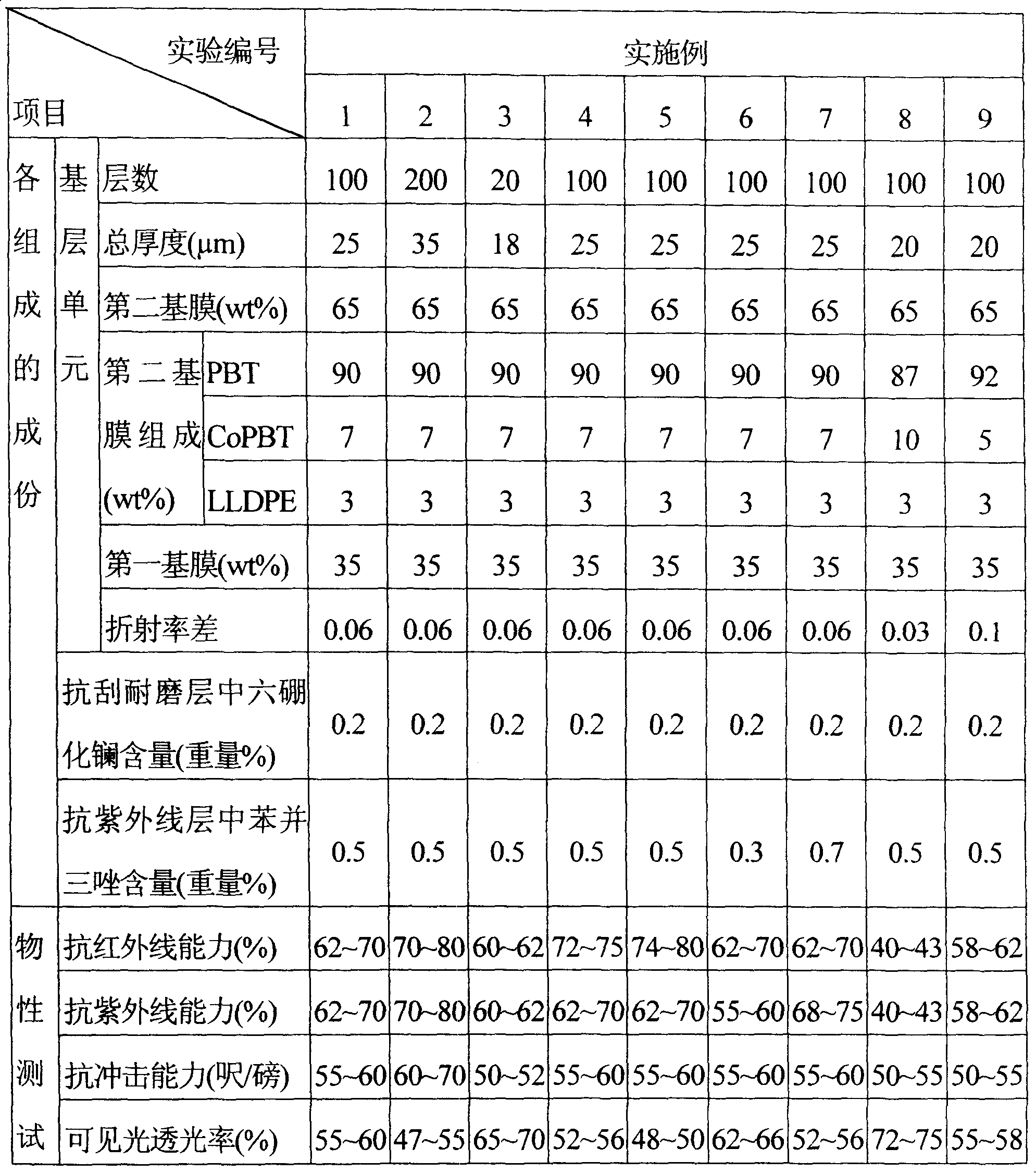

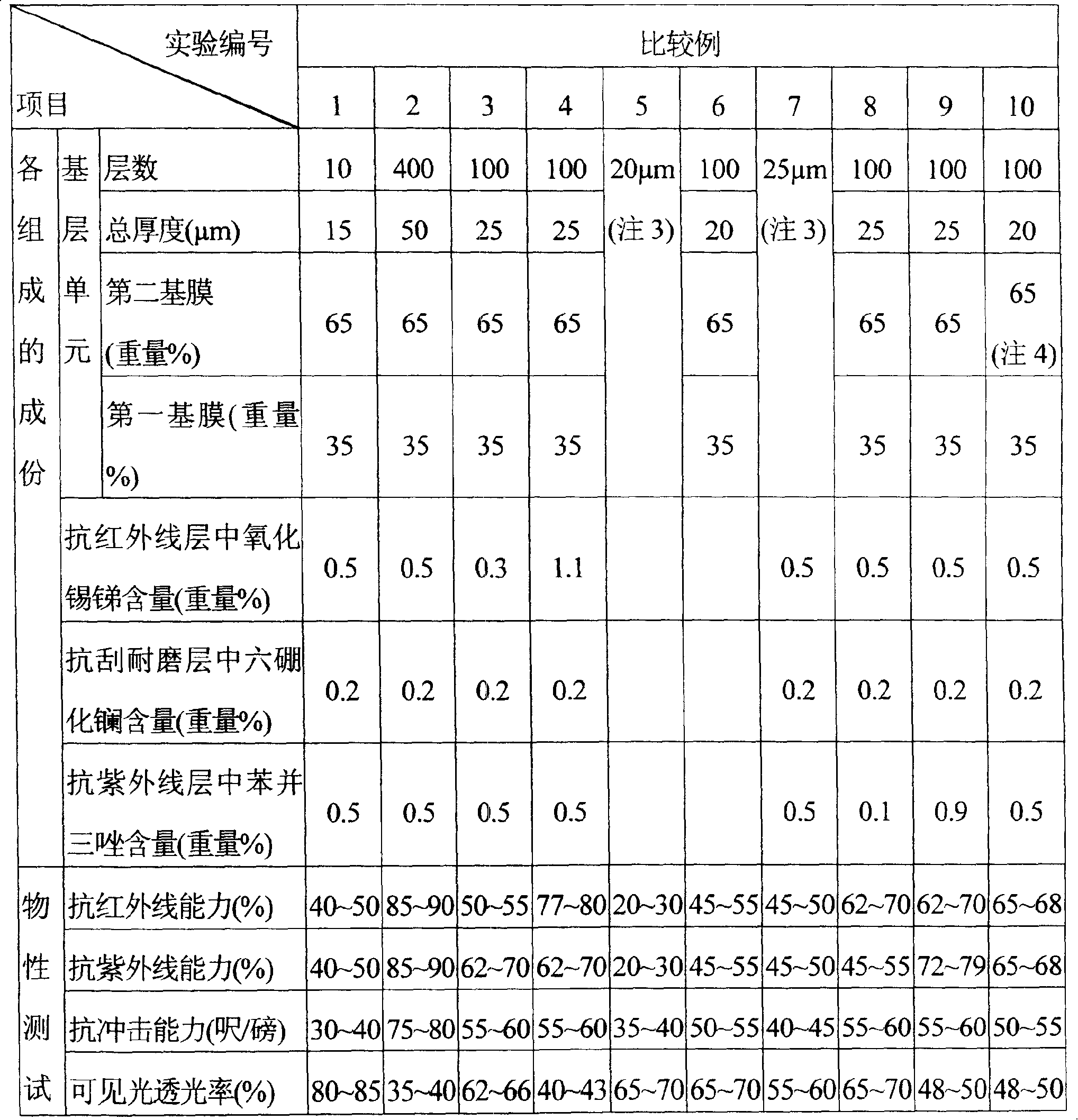

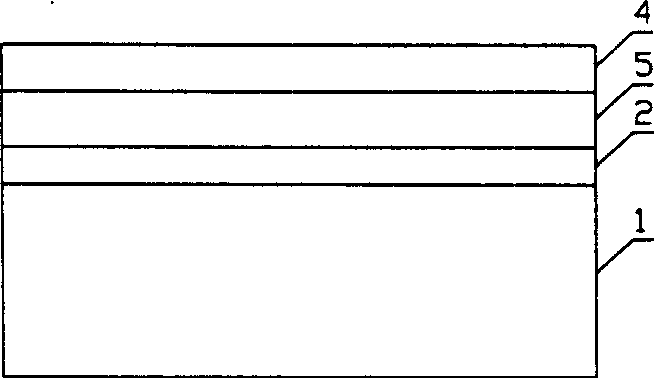

Multi-layer heat-insulating membrana paster

ActiveCN101231350AAvoid damageAvoid scratchesSynthetic resin layered productsOptical elementsPolyesterInfrared

The invention discloses a multilayer heat insulating membrane patch for insulating heat from sunshine, comprising a base layer unit stacked by 20-200 layers basal membrane and an infrared ray resistant layer, a scratch-resistant and wearing-proof layer and an ultraviolet ray resistant layer that are directly or indirectly combined with the basal membrane. The thickness of the basal membrane of the base layer unit is within the visible wavelength range and made from two different materials, the infrared ray resistant layer is prepared by adding 0.5-1.0 wt% infrared ray resistant nanometer particles in a matrix, the ultraviolet ray resistant layer is made of resin containing 0.3-0.7 wt% benzotriazole, and the scratch-resistant and wearing-proof layer is made of polyester compound containing 0.2 wt% lanthanum hexaboride. By the combination of the above layers, the patch has proper light transmittance and better effects of ultraviolet ray resistant, infrared ray resistant, scratch-resistant and wearing-proof.

Owner:RIHE IND CO LTD

Lanthanum-hexaboride-reinforced aluminum-silicon-base composite material and preparation method thereof

The invention belongs to the field of metal materials, and relates to a lanthanum-hexaboride-reinforced aluminum-silicon-base composite material and a preparation method thereof. The composite material is composed of a matrix alloy and a reinforcing phase. The invention is characterized in that the matrix alloy contains a lanthanum hexaboride reinforcing phase which is dispersively distributed; and the composite material comprises the following components in percentage by mass: 5.00-20.00% of silicon, 0.68-6.82% of lanthanum, 0.32-3.18% of boron and the balance of aluminum. The preparation method comprises the following steps: melting technically pure aluminum, industrial crystalline silicon and aluminum-boron alloy in a smelting furnace according to certain mass ratio, heating to 800-1200 DEG C, keeping the temperature for 5-10 minutes, adding a proper amount of technically pure lanthanum into the melt, carrying out in-situ reaction for 10-15 minutes, refining, and casting, thereby obtaining the lanthanum-hexaboride-particle-reinforced aluminum-silicon-base composite material. The invention can be implemented by a common smelting technique under atmospheric conditions, has the advantages of no pollution, low cost, simple technique and high production efficiency, and is suitable for large-scale production and application.

Owner:SHANDONG UNIV

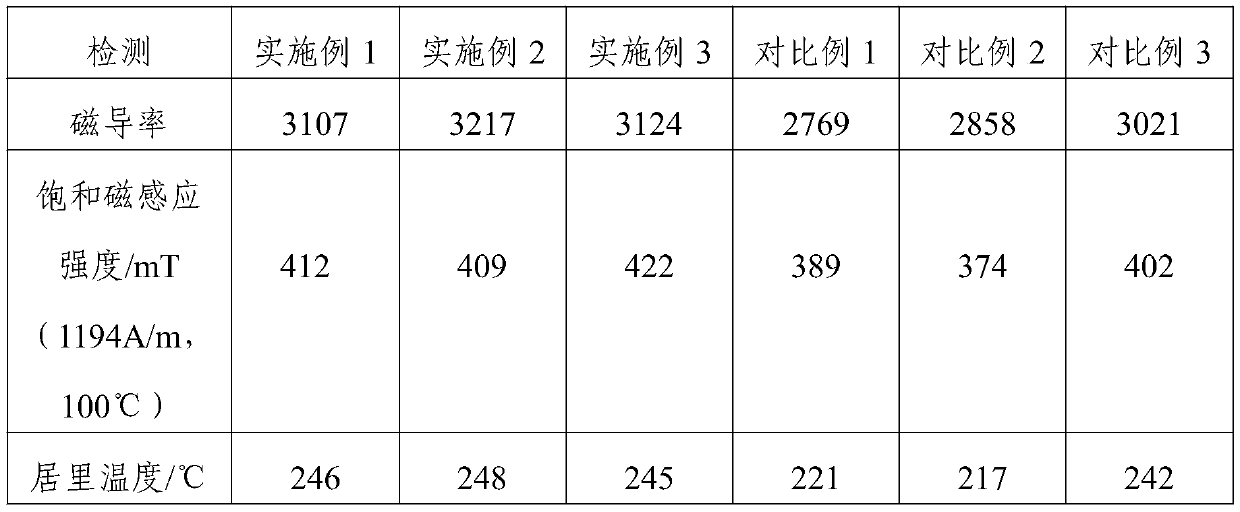

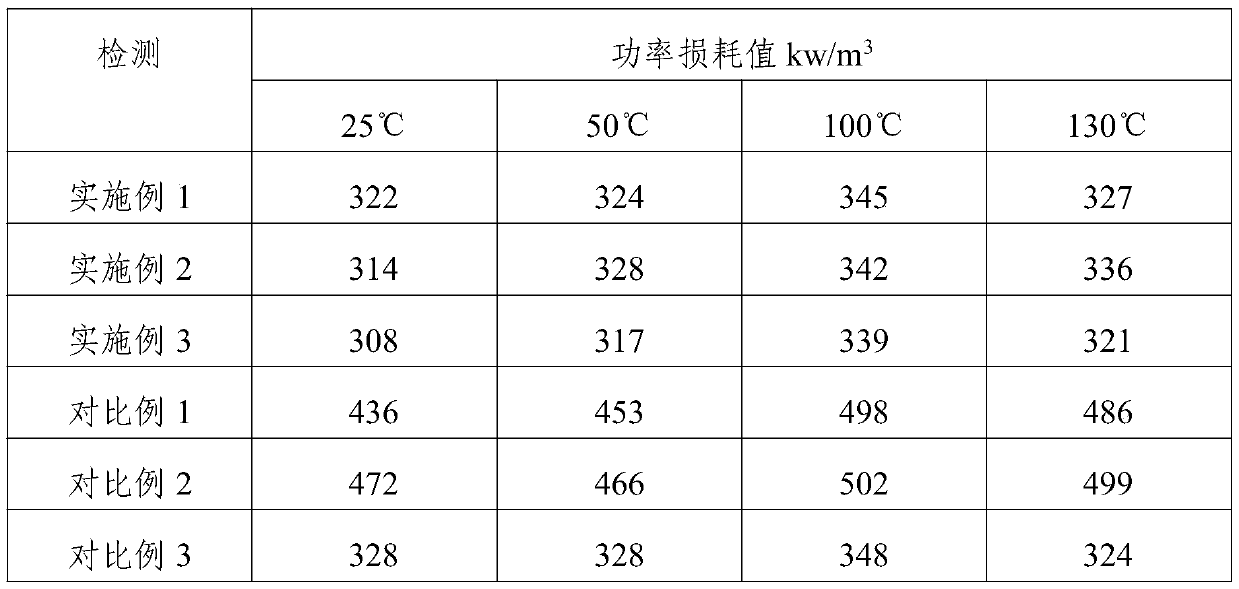

Wide-temperature-range low-loss ferrite and preparation method thereof

InactiveCN111039667AHigh initial permeabilityReduce magnetic lossInorganic material magnetismTungstateCerium

The invention provides wide-temperature-range low-loss ferrite and a preparation method thereof, and relates to the technical field of ferrite processing. The wide-temperature-range low-loss ferrite is prepared from the following raw materials in parts by weight: 90-100 parts of ferric oxide, 12-18 parts of nano titanium dioxide, 18-22 parts of magnesium oxide, 6-12 parts of barium oxide, 52-60 parts of manganese dioxide, 6-8 parts of a first mixture and 0.8-1.2 parts of a second mixture, wherein the first mixture is a mixture of chromium sesquioxide, tungsten trioxide, copper oxide and zinc oxide in a mass ratio of 3: 1: 4: 12, and the second mixture is a mixture of lanthanum hexaboride, cerium oxide and ammonium tungstate in a mass ratio of 2: 1: 1. The preparation method overcomes the defects of the prior art, effectively solves the problem of high loss of the traditional ferrite under the conditions of wide temperature and high frequency, effectively saves energy, and is suitable for various environments and fields.

Owner:天长市华磁磁电有限公司

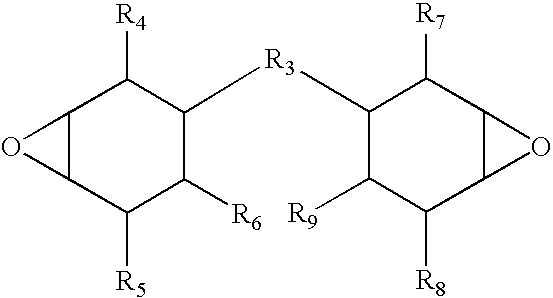

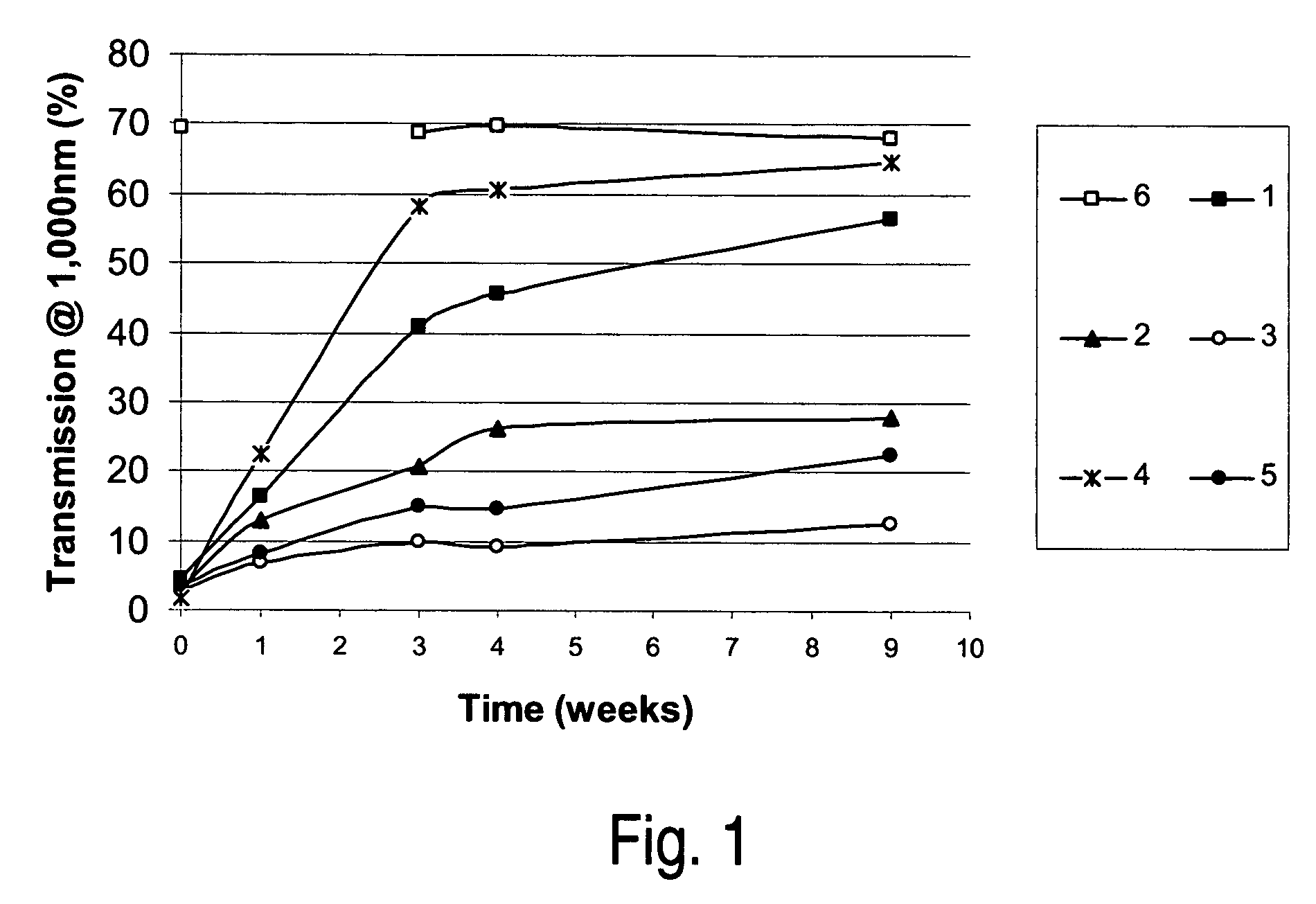

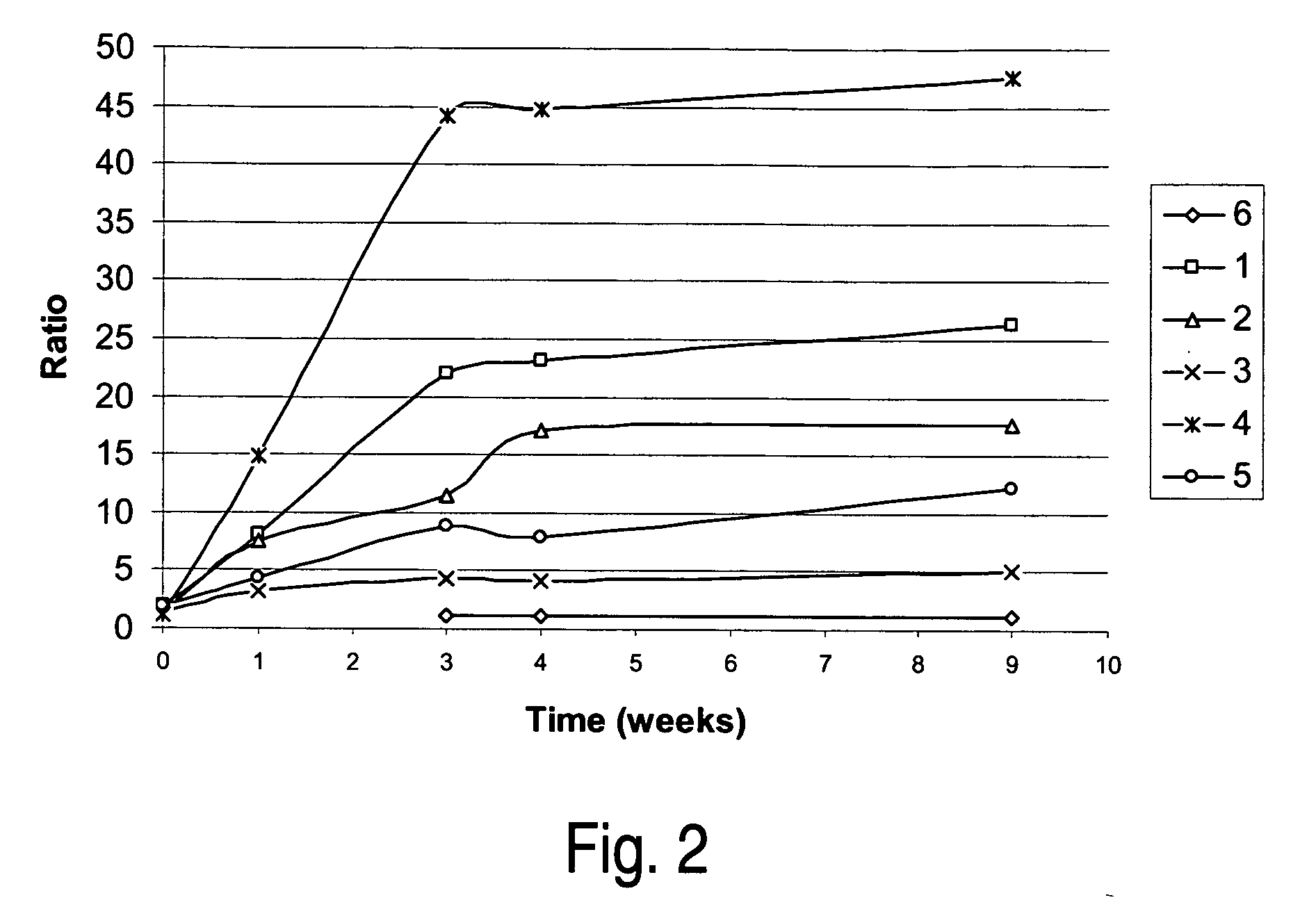

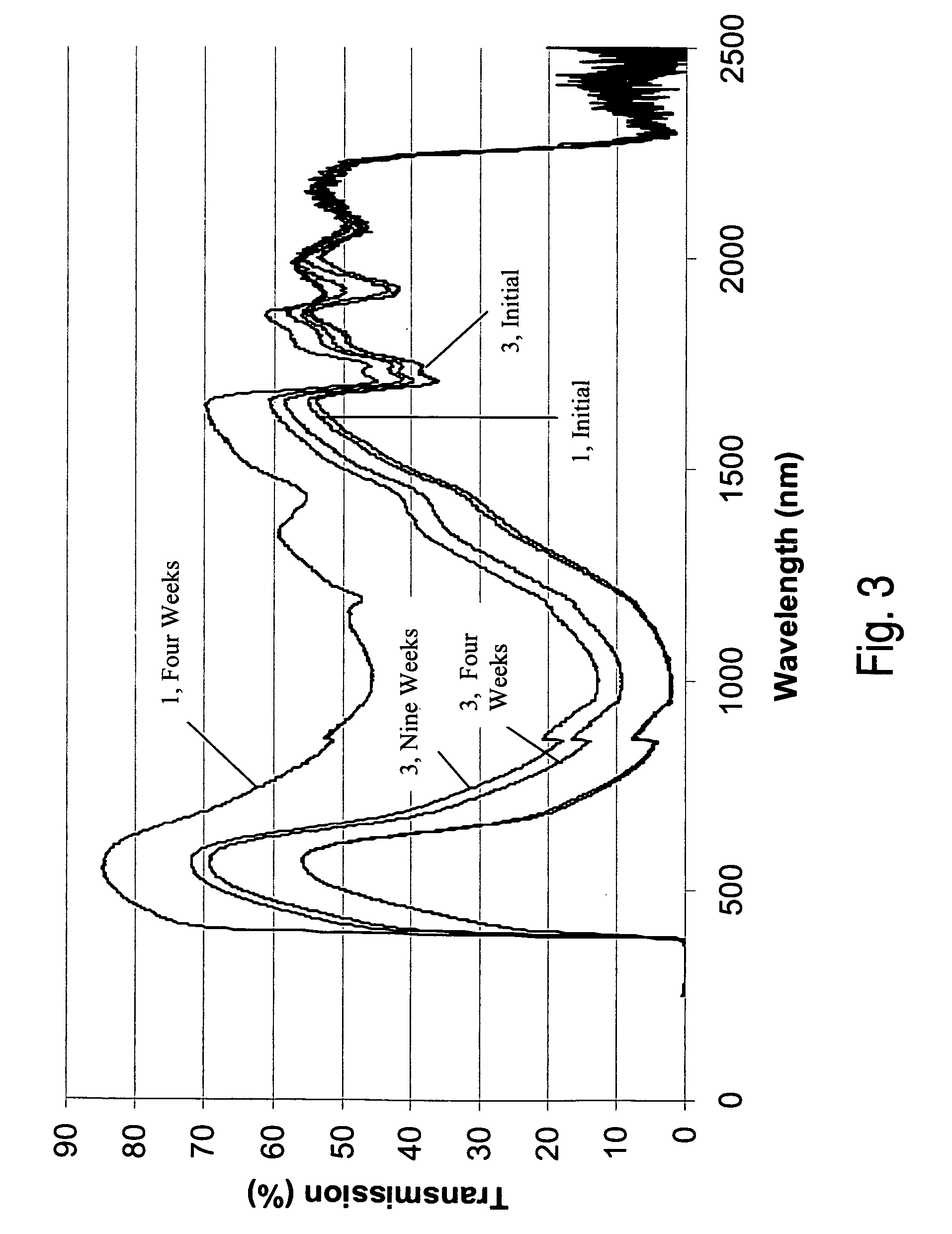

Polymer films comprising stabilized infrared absorbing agents

The present invention includes polymer films that comprise lanthanum hexaboride and an epoxy agent. The lanthanum hexaboride and epoxy agent can be incorporated into or onto a polymer film in any suitable manner. The addition of an epoxy agent surprisingly provides a stabilization effect to the lanthanum hexaboride, which allows for the production of polymer films that advantageously absorb infrared radiation and resist environmental degradation. Polymer films thus produced have a significant number of applications, for example, but not limited to, display devices, protective coverings, and glazing film applications.

Owner:SOLUTIA INC

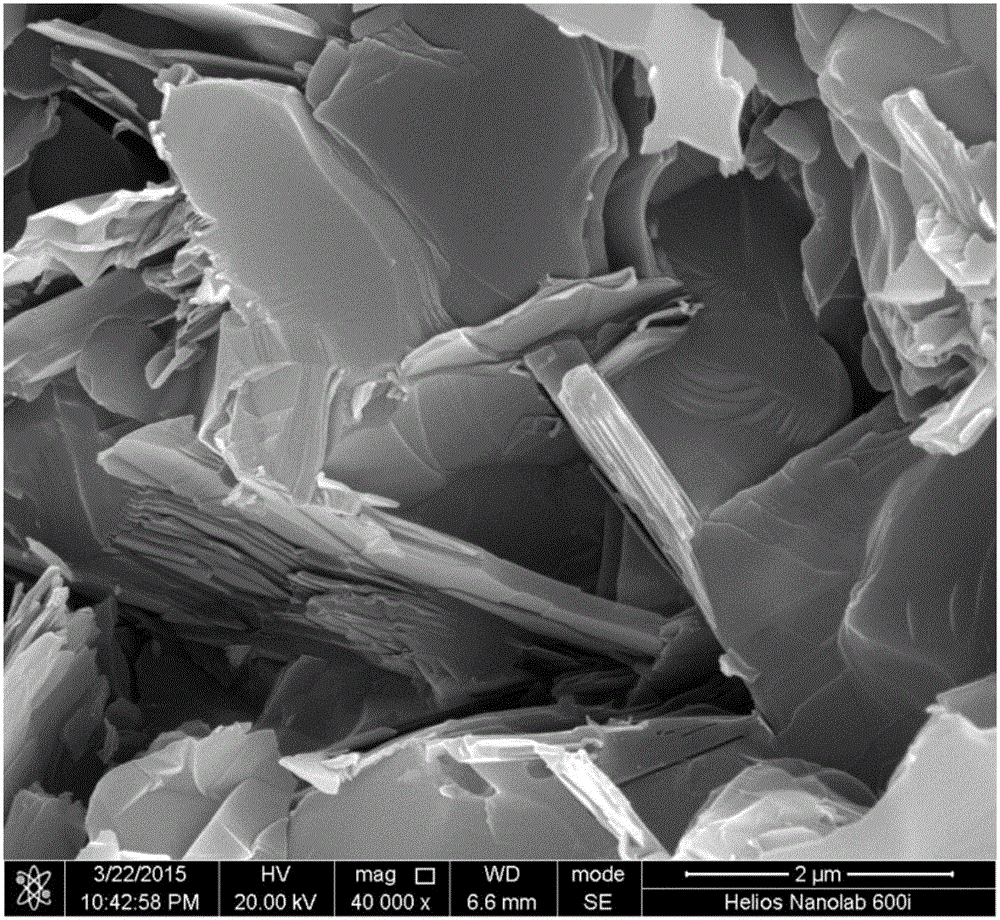

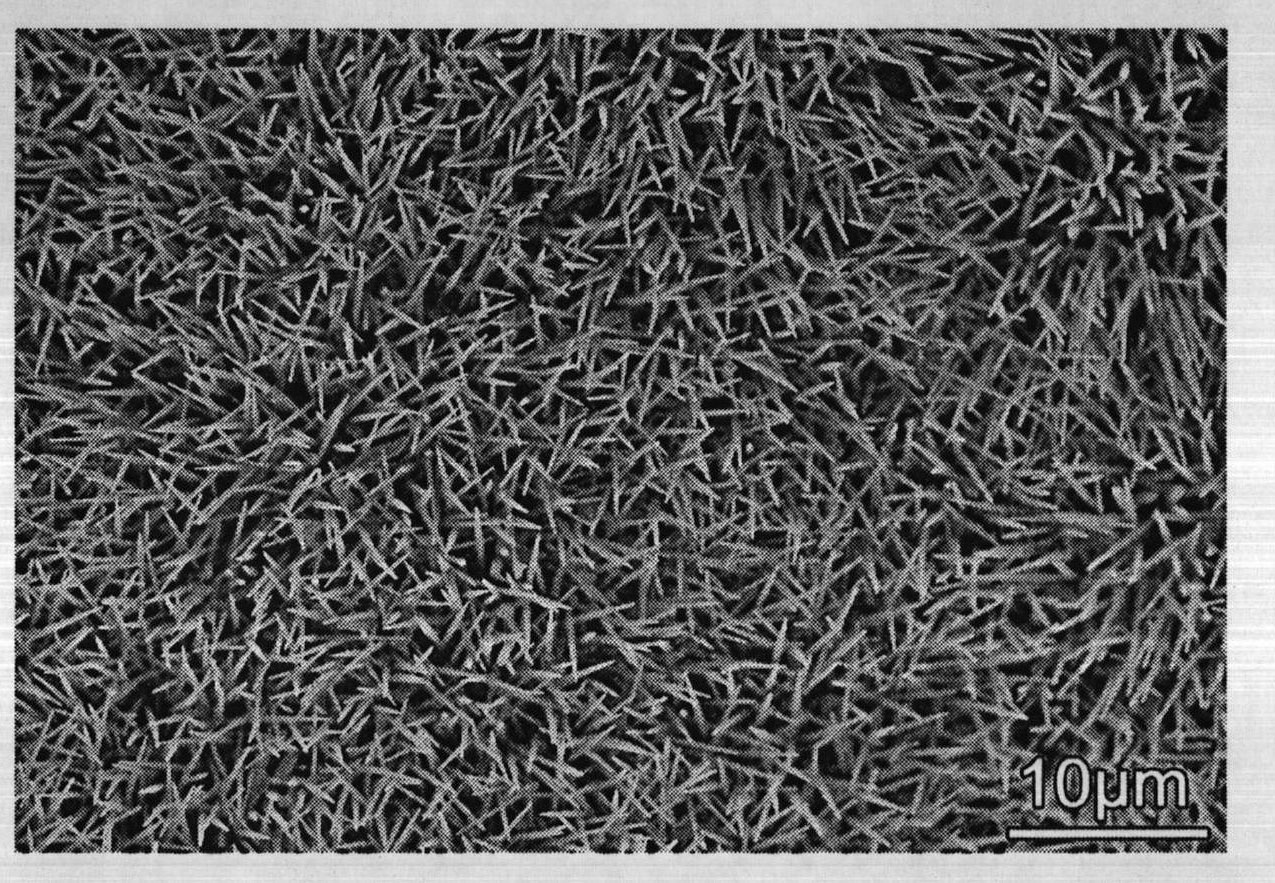

Preparation of nano single crystal lanthanum hexaboride and application of nano single crystal lanthanum hexaboride in electron microscope filament preparation

InactiveCN105197952ASynthesis temperature is lowImprove the consistency of single crystal grain sizeMetal boridesNanotechnologySingle crystalLanthanum hexaboride

The invention relates to the field of field emission materials, and aims at providing the preparation of nano single crystal lanthanum hexaboride and the application of the nano single crystal lanthanum hexaboride in the electron microscope filament preparation. The preparation comprises the following steps: weighing lanthanum compounds and alkali metal boron hydride powder, and performing ball-milling to obtain a mechanical mixture; placing the mechanical mixture into a reactor, heating up to 300 to 700 DEG C from the room temperature at the heating rate of 2 DEG C per minute, then performing heat preservation for 2 hours and releasing hydrogen; then cooling, washing, separating and performing vacuum drying at the temperature of 80 DEG C to obtain the nano single crystal lanthanum hexaboride. According to the preparation, the synthesis temperature of lanthanum hexaboride is greatly decreased, the quality management during the industrial production of the lanthanum hexaboride is facilitated, the single crystal particle size consistency of the lanthanum hexaboride is improved, and the quality management of large-scale production is facilitated. The raw material cost is low, the energy consumption is low, and the preparation process is easy and simple. When the nano single crystal lanthanum hexaboride is used for preparing an electron microscope filament, low work function, low volatility and low resistance are realized; the mechanical strength is high, and the chemical stability is good, so that an electron microscope image is more clear, the cost is lower and the service life is prolonged greatly.

Owner:ZHEJIANG UNIV

Structure of AC type PDP

InactiveUS7245077B2Well formedEasy to processAddress electrodesSustain/scan electrodesCapacitanceConductive materials

Almost only choice by a secondary electron emission layer / protection layer covering the dielectric layer of an AC type PDP has been magnesium oxide (MgO) that is unstable during the production process and difficult to form, thus posing a serious production problem. An AC type PDP constructed such that, instead of covering the surface of a dielectric layer with a dielectric material such as MgO, an insular electrode is made by forming a conductive material such as nickel, aluminum, magnesium and lanthanum hexaboride into an insular shape, and the insular electrode is allowed to capacity-couple with a lower-layer bus electrode by means of an electrostatic capacity formed by a dielectric layer to operate the insular electrode as a sustained electrode.

Owner:TECHNOLOGY TRADE AND TRANSFER CORP

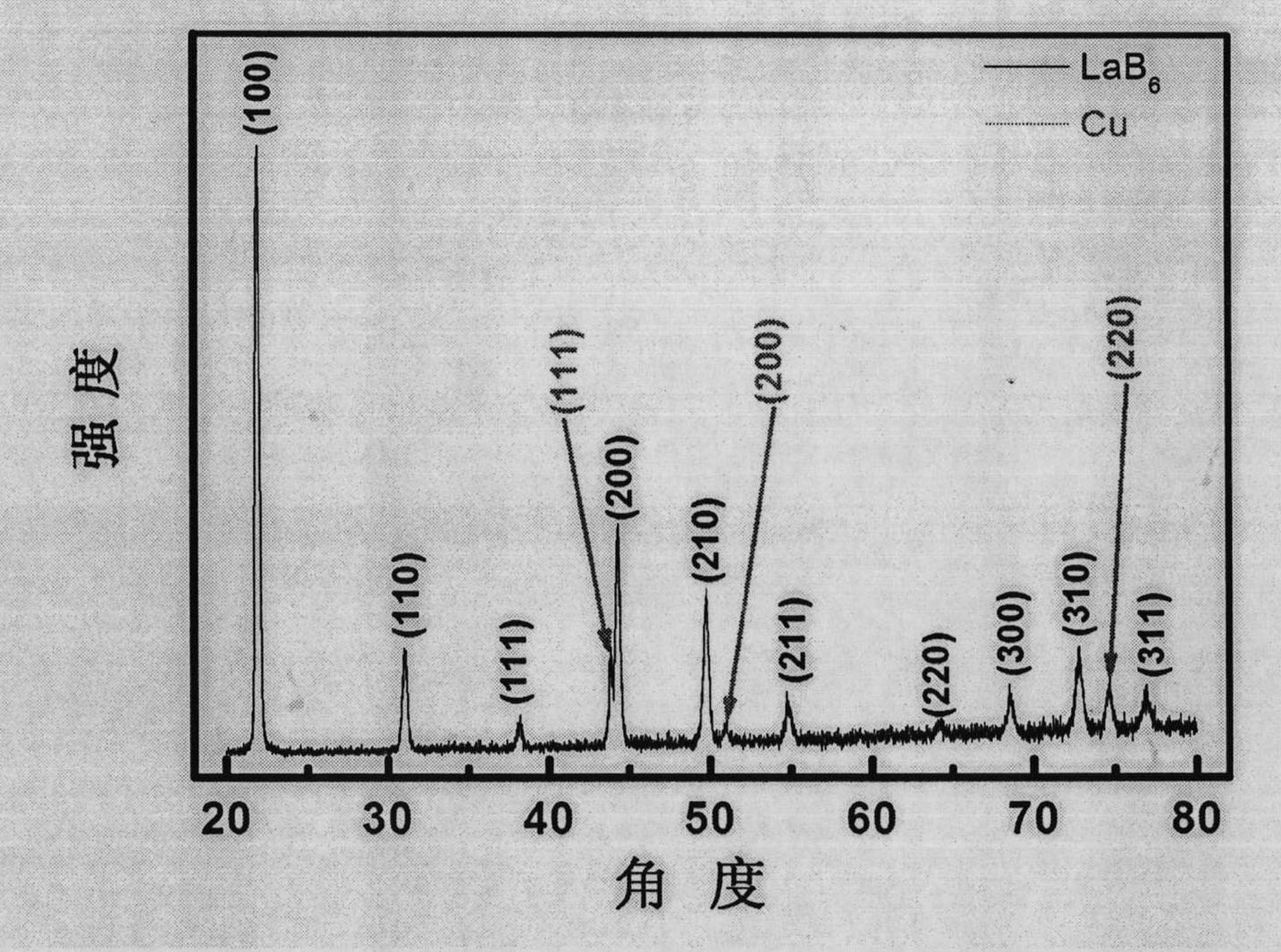

Lanthanum hexaboride nanowire and method for preparing same

InactiveCN102616799AThe experiment process is simpleEasy to operateMetal boridesNanowireField electron emission

The invention discloses a method for preparing a lanthanum hexaboride nanowire on a copper substrate. The method comprises the following steps of: (1) cleaning the copper substrate, and removing oil stain from the copper substrate; (2) placing a lanthanum source in the middle of a quartz tube of an electric tube furnace, placing the copper substrate in the down gas flow direction of a precursor, sealing the quartz tube, filling protective and reduction gas, and vacuumizing the quartz tube and raising temperature; (3) heating the quartz tube to 900 to 1,020 DEG C, introducing diborane gas and reacting at constant temperature for 10 to 30 minutes; and (4) stopping introducing diborane, and reducing temperature at vacuum atmosphere. The method for preparing the lanthanum hexaboride nanowire on the copper substrate is simple, and any catalyst is not needed; and the prepared LaB6 nanowire can be used as a cold cathode electron source, and is applied to field electron emission flat-panel displays, cold cathode fluorescent tubes, field emission pressure sensors and the like, and has good application prospect in the aspect of field electron emission display materials.

Owner:XINYANG NORMAL UNIVERSITY

Nano-rare earth heat-insulated transparent coating and preparation method thereof

InactiveCN101831224AGood light transmissionGood heat insulationPolyurea/polyurethane coatingsWater basedAlcohol

The invention discloses a nano-rare earth heat-insulated transparent coating and a preparation method thereof. The preparation method comprises the following steps of: firstly, forcibly stirring a nano-rare earth material lanthanum hexaboride in pure water for 10 minutes, then performing ultrasonic dispersion on the mixture for 30 minutes, and adding the mixture into a sand grind to perform grinding and dispersion for 24 hours to obtain a pure water dispersion liquid of the nano-lanthanum hexaboride; secondly, adding an appropriate amount of the dispersion liquid into a water-based acrylic resin or water-based polyurethane resin, composite alcohol and an additive; and finally, forcibly stirring and dispersing the mixture for 30 minutes to obtain the nano-rare earth heat-insulated transparent coating. The nano-rare earth heat-insulated transparent coating can reduce the indoor temperature by 7 to 10 DEG C when used on glass, and the light transmittance of the nano-rare earth heat-insulated transparent coating is up to over 80 percent.

Owner:中国建筑科学研究院有限公司深圳分公司

Heat-insulating material for agricultural or horticultural facility

InactiveUS20060008639A1Climate change adaptationSynthetic resin layered productsPolyvinyl alcoholPolystyrene

A heat shielding material for an agricultural and horticultural facility according to this invention includes a heat shield layer constituted of a substrate resin and a heat shield filler in the form of fine particles dispersed in the resin. The heat shield filler is at least one selected from lanthanum hexaboride and antimony-doped tin oxide, and the substrate resin is at least one selected from among resins of polyethylene, polyvinyl chloride, polyvinylidene chloride, polyvinyl alcohol, polystyrene, polypropylene, poly(ethylene-vinyl acetate) and polyester. This heat shielding material for an agricultural and horticultural facility has a visible light transmittance of 30 to 90% and a solar radiation transmittance of 10 to 80%, the visible light transmittance being larger by 10% or above than the solar radiation transmittance.

Owner:SUMITOMO METAL MINING CO LTD

Lanthanum hexaboride sintered body, target and lanthanum hexaboride film each comprising same, and process for production of the sintered body

ActiveUS20130017137A1High purityHigh crystallinityVacuum evaporation coatingSputtering coatingThin membraneLanthanum

Disclosed are: a lanthanum hexaboride sintered body which contains lanthanum hexaboride as the main component, has an element nitrogen content of 0.1 to 3 mass % inclusive, contains an impurity composed of element carbon and / or at least two elements selected from La, C, O and B at a content of 0.3 vol % or less, and has a relative density of 88% or more; and a target comprising the lanthanum hexaboride sintered body. An LaB6 sintered body can be provided, which enables the production of a highly pure and dense LaB6 thin film having excellent crystallinity and a good work function and which is suitable for a sputtering target or the like.

Owner:SUMITOMO OSAKA CEMENT CO LTD

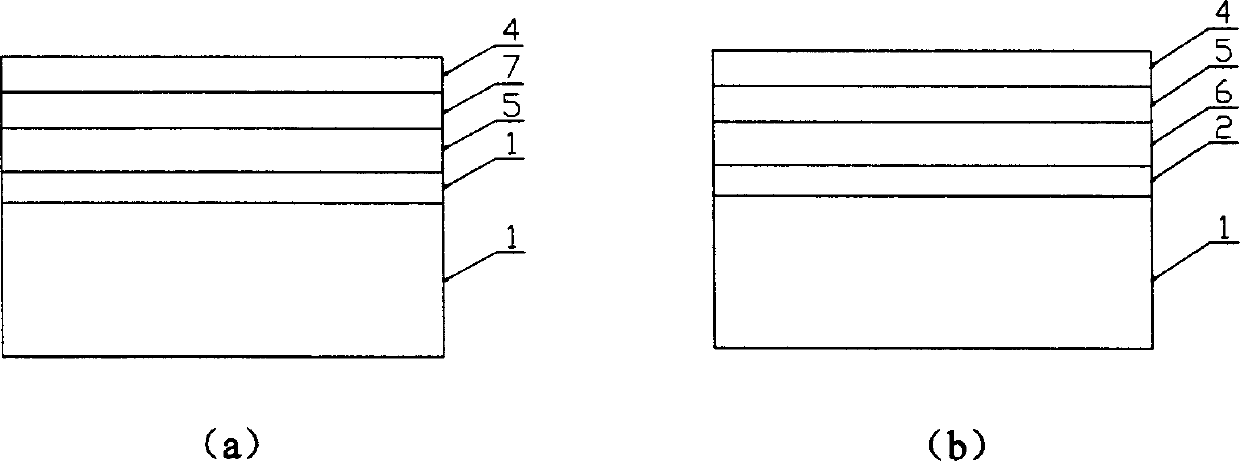

Interlayers comprising stabilized infrared absorbing agents

InactiveUS20070134499A1Resist environmentalDiffusing elementsSynthetic resin layered productsEpoxyEngineering

The present invention is in the field of polymer sheets and multiple layer glazing panels comprising infrared absorbing agents, and, more specifically, the present invention is in the field of polymer sheets and multiple layer glazing panels comprising infrared absorbing agents that selectively absorb infrared radiation. In various embodiments of the present invention, an interlayer includes lanthanum hexaboride, which effectively absorbs infrared radiation at about 1,000 nanometers, and an epoxy, which stabilizes the lanthanum hexaboride agent.

Owner:SOLUTIA INC

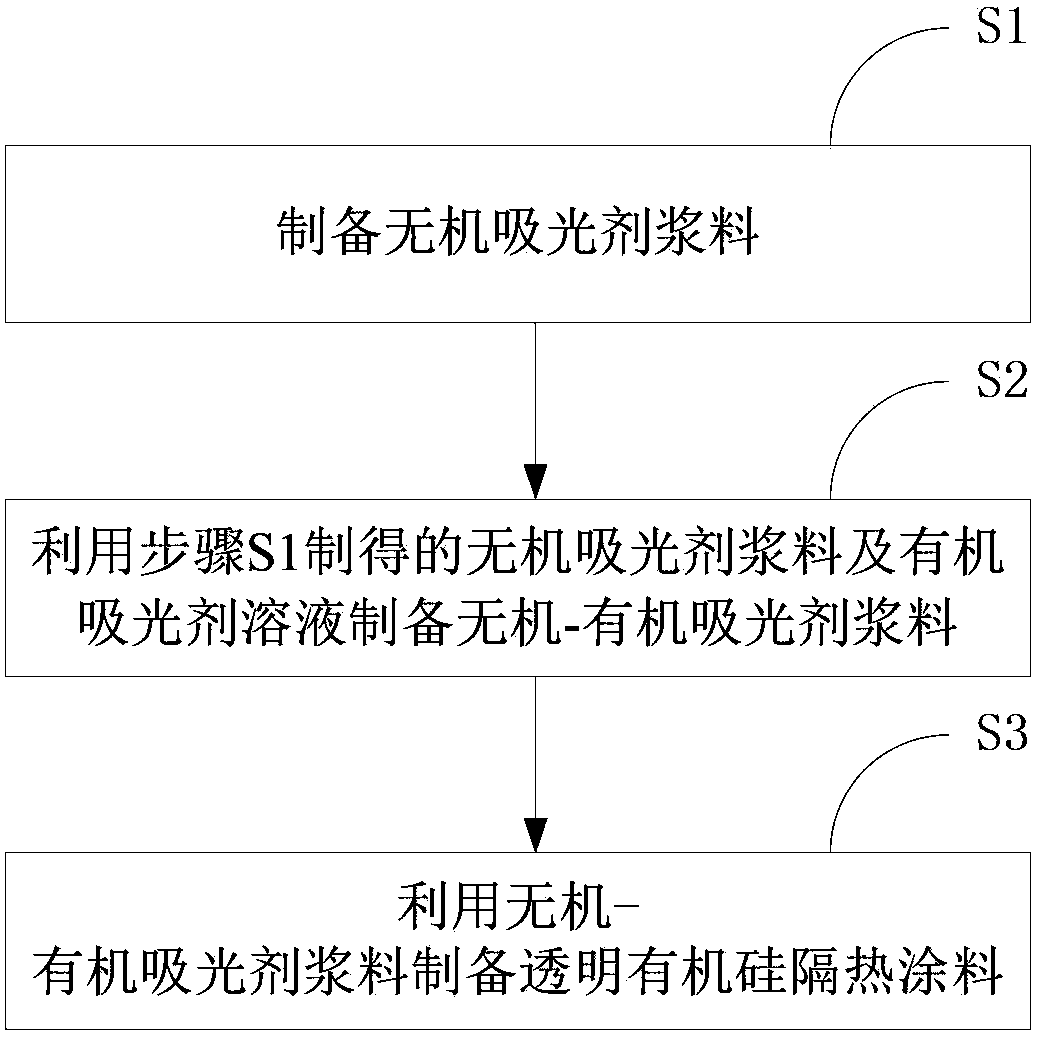

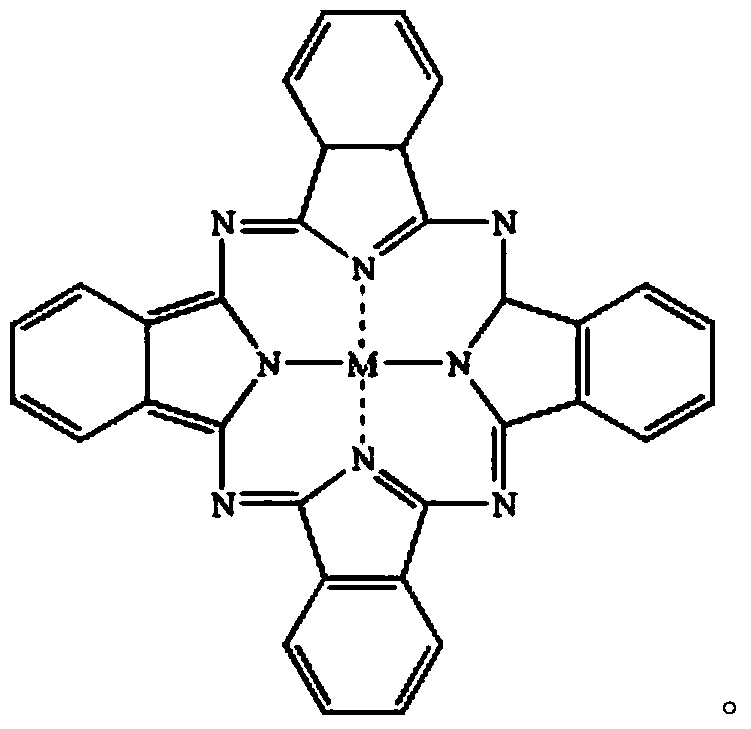

Organic dye enhanced transparent and heat-insulating coating material, preparation method and application thereof

InactiveCN104250487ALowered byAchieve energy saving effectPolyurea/polyurethane coatingsPolyester coatingsOrganic dyeSlurry

The present invention discloses an organic dye enhanced transparent and heat-insulating coating material and a preparation method thereof. The coating material comprises, by mass, 3-50% of a functional light absorbing agent, 10-90% of a film-forming agent, 0-50% of a solvent, and 0-10% of an additive, wherein the functional light absorbing agent comprises an inorganic light absorbing agent and a main body light absorbing agent, and the main body light absorbing agent is indium tin oxide, antimony tin oxide, vanadium oxide or lanthanum hexaboride. The preparation method comprises: adopting 3-50% by mass of the functional light absorbing agent, 10-90% by mass of the film-forming agent, 0-50% by mass of the solvent and 0-10% by mass of the additive to prepare the inorganic light absorbing agent slurry, adopting the prepared inorganic light absorbing agent slurry and the organic light absorbing agent solution to prepare the inorganic-organic light absorbing agent slurry, and adopting the inorganic-organic light absorbing agent slurry to prepare the transparent organosilicon heat-insulating coating material. According to the heat-insulating glass prepared by using the organic dye enhanced transparent and heat-insulating coating material of the present invention, the sunlight passing-through can be reduced so as to achieve the purpose of energy saving.

Owner:方俐善

New type organic electroluminous appliance

InactiveCN1620214ALow electron work functionChemically stableElectrical apparatusElectroluminescent light sourcesOrganic electroluminescenceLanthanum hexaboride

This invention discloses organic electroluminescence device which contains lanthanum hexaboride (LaB6) used as cathode, the surface of lanthanum hexaboride (LaB6) can be covered with metal membrane and ITO membrane to increase cathode conductivity or make cathode verification, the transparent cathode or nontransparent cathode can be obtained according to different thickness of lanthanum hexaboride (LaB6) and different property of covering layer. Said invention has long service life and high luminous brightness and efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

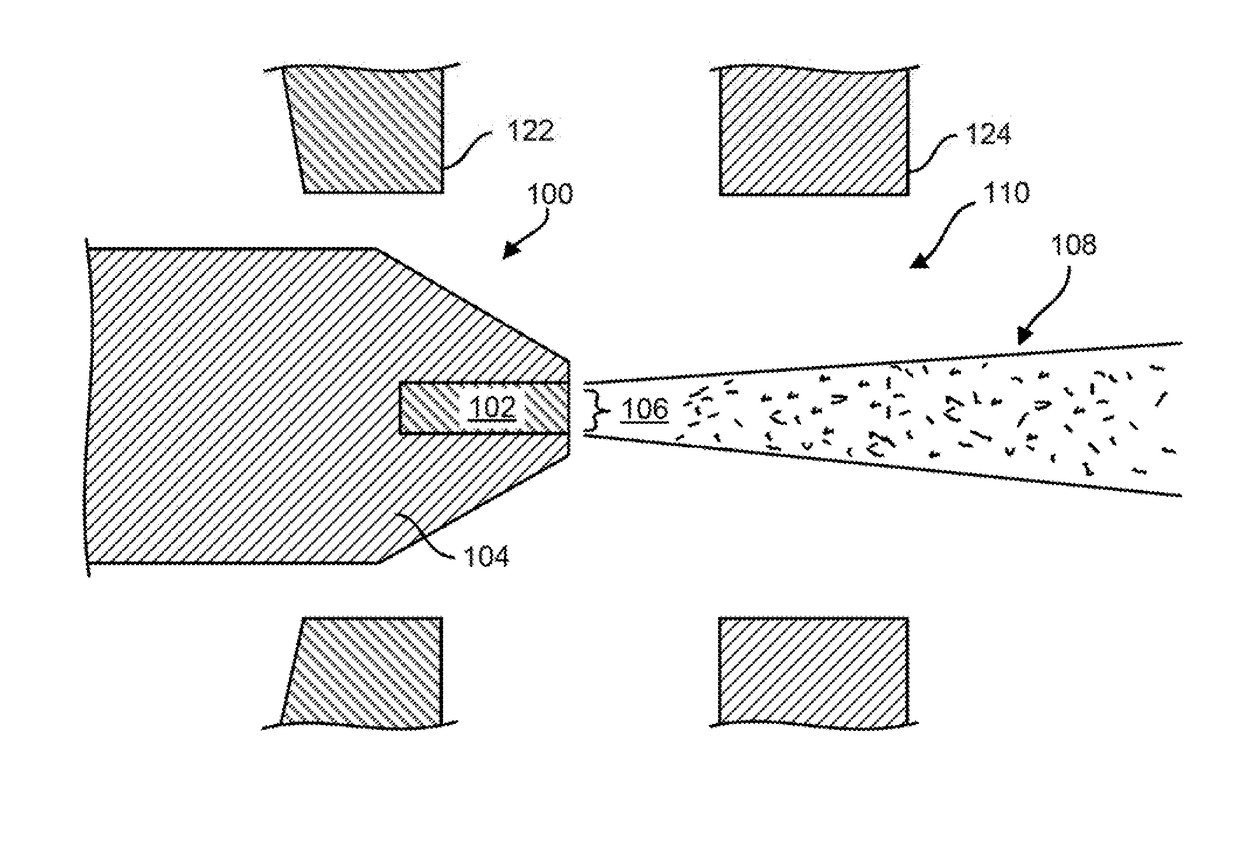

Electron emitter source

An electron emitter that consists of: a low work function material including Lanthanum hexaboride or Iridium Cerium that acts as an emitter, a cylinder base made of high work function material that has a cone shape where the low work function material is embedded in the high work function material but is exposed at end of the cone and the combined structure is heated and biased to a negative voltage relative to an anode, an anode electrode that has positive bias relative to the emitter, and a wehnelt electrode with an aperture where the cylindrical base protrudes through the wehnelt aperture so the end of the cone containing the emissive area is placed between the wehnelt and the anode.

Owner:OREGON PHYSICS +1

Heat shielding materials for use in agricultural and horticultural facilities

InactiveUS20060116461A1Climate change adaptationSynthetic resin layered productsOptical transmittanceEngineering

A heat shielding material for use in an agricultural and horticultural facility according to the present invention includes a heat shielding layer containing a base resin, and a heat shielding filler in the form of microparticles dispersed in the base resin, wherein the heat shielding filler is at least one selected from lanthanum hexaboride and antimony-doped tin oxide. This heat shielding material for use in an agricultural and horticultural facility has a solar radiation transmittance of 10 to 80%, this transmittance being taken as a reference index for evaluating the level of a heat shielding property, a visible light transmittance of 30 to 90%, and a light transmittance of 5 to 80% at a 320 nm wavelength and a light transmittance of 0 to 70% at a 290 nm wavelength, respectively, in an ultraviolet region.

Owner:SUMITOMO METAL MINING CO LTD

Back electrode silver paste for crystalline silicon solar cell and preparation method of back electrode silver paste

InactiveCN106653148AReduced series resistanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilicon solar cell

The invention relates to back electrode silver paste for a crystalline silicon solar cell and a preparation method of the back electrode silver paste. The back electrode silver paste for the crystalline silicon solar cell is prepared from the following components in parts by weight: 25-35 parts of superfine spherical silver powder, 15-25 parts of flake silver powder, 2-6 parts of inorganic glass powder, 0.5-1 part of nano lanthanum hexaboride, 34-52 parts of organic carrier and 1-10 parts of organic additive. By adopting the combination of the superfine spherical silver powder and the flake silver powder, a gap between layers of the flake silver powder is filled with superfine silver powder particles, so that the conductivity of the silver paste is improved. The nano lanthanum hexaboride is added, so that the series resistance of a silver film can be reduced when the nano lanthanum hexaboride is used for the electrode silver paste, and the photoelectric conversion efficiency of the solar cell is greatly improved and can reach 18.88%.

Owner:HANGZHOU HANGSHUO NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com