Preparation method of large-size and high-performance lanthanum hexaboride single crystals

A lanthanum hexaboride, large-size technology, applied in the field of preparation of lanthanum hexaboride single crystal, can solve the problem of small size of lanthanum hexaboride single crystal, and achieve good performance and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

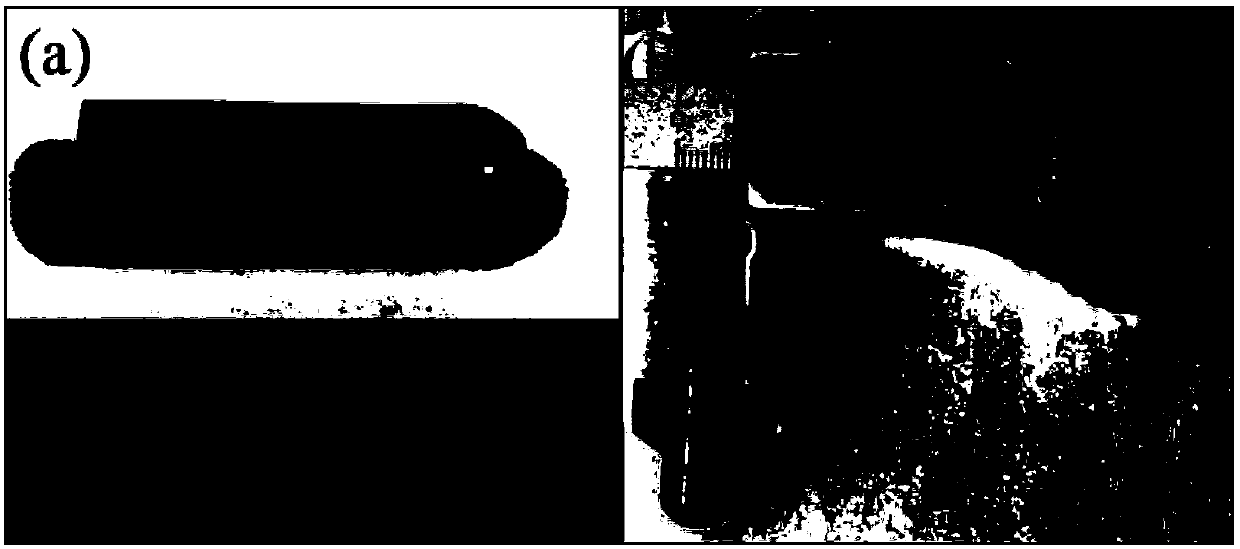

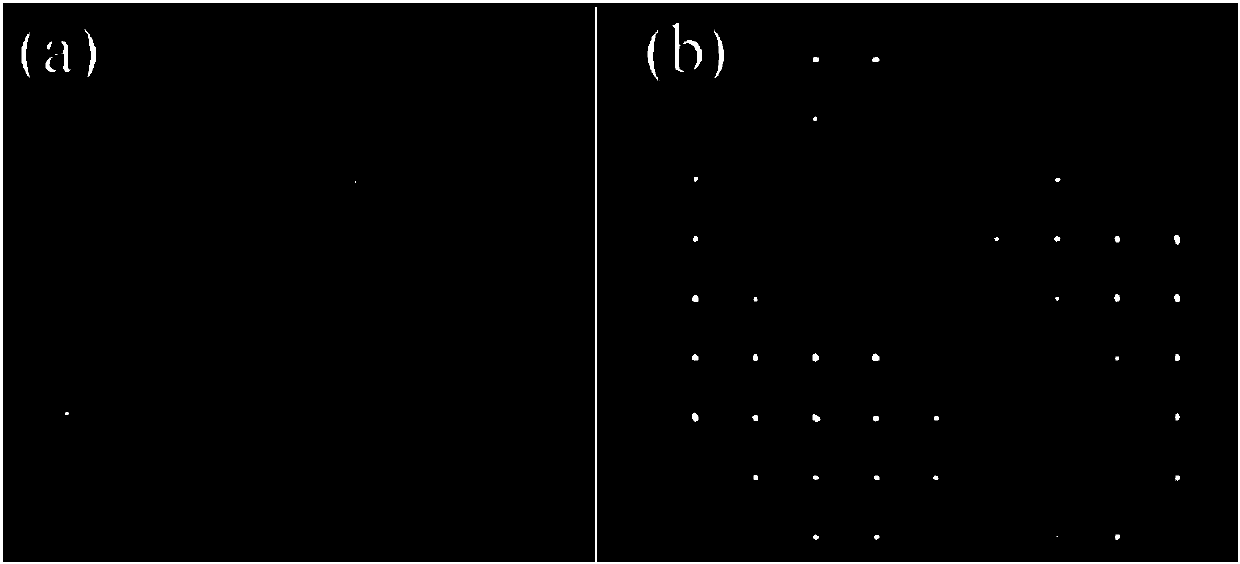

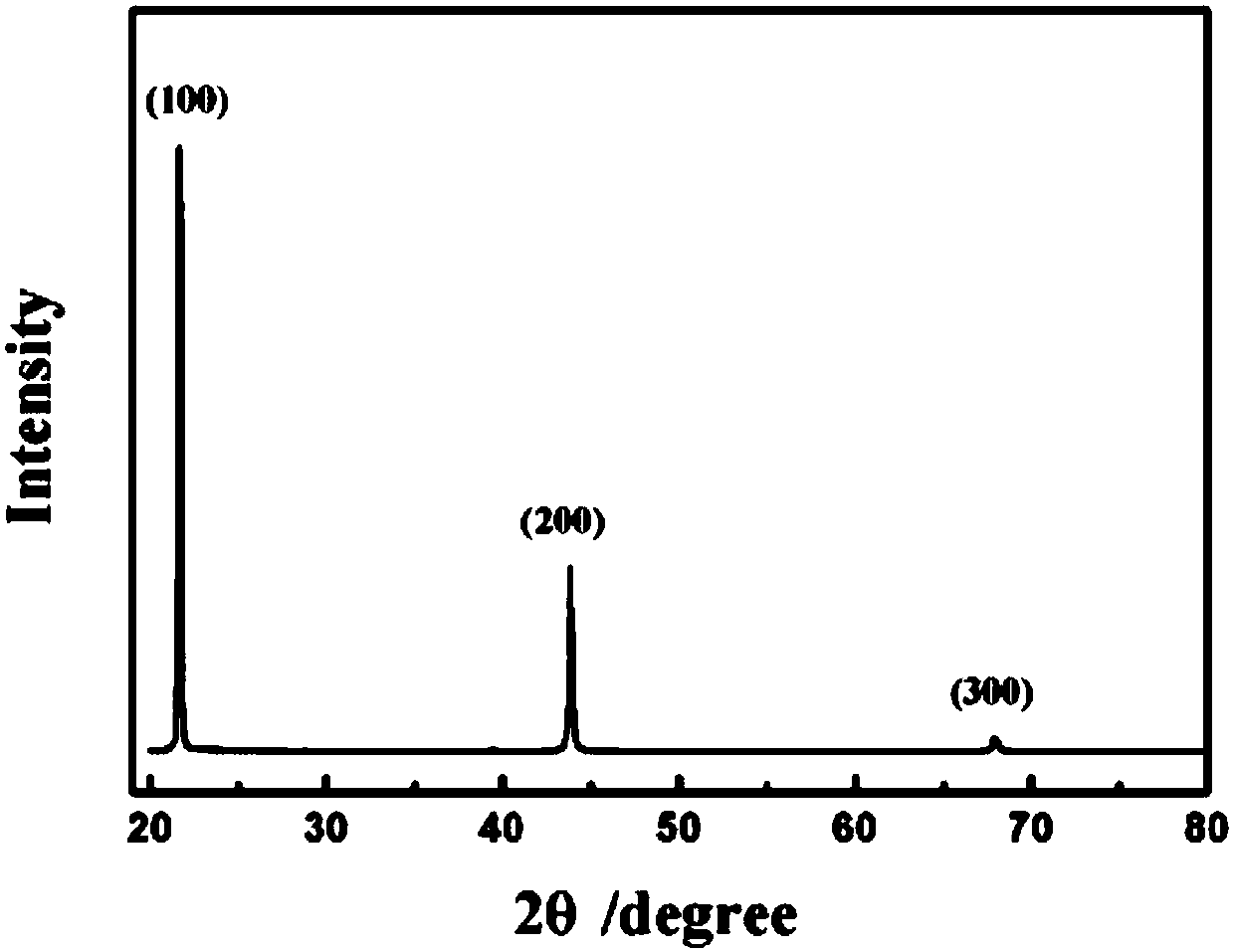

[0037] The present invention combines spark plasma sintering technology and optical region melting technology to prepare large-size, high-quality lanthanum hexaboride single crystal, including the following steps:

[0038] Step 1, polycrystalline block preparation

[0039] The lanthanum hexaboride powder with a purity of 99.9% was ball-milled in an Ar atmosphere for 2 hours so that the particle size of the powder was ≤2 μm; then the ball-milled powder was put into a graphite mold, and the graphite mold was placed in a spark plasma sintering furnace (LABOX- 350), sintering under vacuum conditions to obtain lanthanum hexaboride sintered polycrystalline rods;

[0040] The sintering process parameters are set as: heating rate 100-300°C / min (after many experiments, any value within this range can be achieved), pressure 30-50MPa (after many experiments, any value within this range can be achieved), the sintering temperature is 1300-1800°C (after many experiments, any value within t...

Embodiment 2

[0058] The present invention combines spark plasma sintering technology and optical region melting technology to prepare large-size, high-quality lanthanum hexaboride single crystal, including the following steps:

[0059] Step 1, polycrystalline block preparation

[0060] Ball-mill lanthanum hexaboride powder with a purity of 99.9% in an Ar atmosphere for 2 hours so that the particle size of the powder is ≤2 μm; then put the ball-milled powder into a graphite mold, and place the graphite mold in a spark plasma sintering furnace (LABOX-350), sintered under vacuum conditions to obtain lanthanum hexaboride sintered polycrystalline rods;

[0061] The sintering process parameters are set as: heating rate 100-300°C / min (after many experiments, any value within this range can be achieved), pressure 30-50MPa (after many experiments, any value within this range can be achieved), the sintering temperature is 1300-1800°C (after many experiments, any value within this range can be achie...

Embodiment 3

[0079] The present invention combines spark plasma sintering technology and optical region melting technology to prepare large-size, high-quality lanthanum hexaboride single crystal, including the following steps:

[0080] Step 1, polycrystalline block preparation

[0081] Ball-mill lanthanum hexaboride powder with a purity of 99.9% in an Ar atmosphere for 2 hours so that the particle size of the powder is ≤2 μm; then put the ball-milled powder into a graphite mold, and place the graphite mold in a spark plasma sintering furnace (LABOX-350), sintered under vacuum conditions to obtain lanthanum hexaboride sintered polycrystalline rods;

[0082] The sintering process parameters are set as: heating rate 100-300°C / min (after many experiments, any value within this range can be achieved), pressure 30-50MPa (after many experiments, any value within this range can be achieved), the sintering temperature is 1300-1800°C and any value within this range can be achieved after many experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com