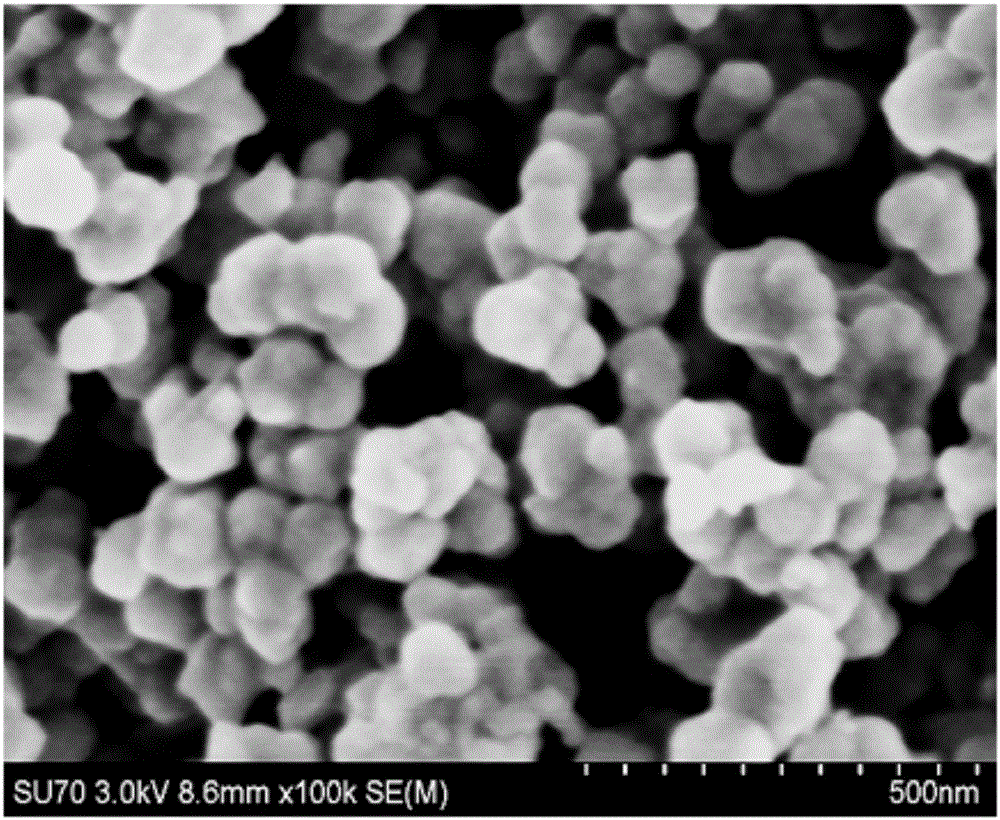

Preparation of nano single crystal lanthanum hexaboride and application of nano single crystal lanthanum hexaboride in electron microscope filament preparation

A nano-single crystal, lanthanum boride technology, applied in nanotechnology, boron/boride, metal boride, etc., can solve the problem of inability to mass industrial production, current efficiency not higher than 50%, borides not easy to be continuous, etc. problems, to achieve broad industrialization prospects, low cost, and the effect of improving the consistency of single crystal particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: take lanthanum oxide and lithium borohydride as the synthesis of lanthanum boride of raw material

[0039] Weigh 0.001 moles (0.326g) of lanthanum oxide and 0.006 moles (0.26g) of lithium borohydride according to the molar ratio of lanthanum and boron being 1:6 (La:B=1:6) and add them to the ball mill jar, and ball mill at 400rpm After 16 hours, a mechanical mixture of lanthanum oxide and lithium borohydride was obtained, which was placed in a reactor, heated from room temperature to 300° C. at a heating rate of 2° C. / min, and then kept for 2 hours.

[0040] La 2 o 3 +12LiBH 4 →2LaB 6 +3Li 2 O+6LiH+21H 2

[0041] Release hydrogen gas, cool to room temperature and wash with water. During water washing, LiH reacts with water to generate hydrogen and lithium hydroxide. Lithium hydroxide is dissolved in water, centrifuged, and vacuum-dried at 80°C to obtain nano single crystal lanthanum boride.

Embodiment 2

[0042] Embodiment 2: take lanthanum hydroxide and sodium borohydride as the synthesis of lanthanum boride of raw material

[0043] Weigh 0.001 mole (0.19g) of lanthanum hydroxide and 0.006 mole (0.227g) of sodium borohydride as the molar ratio of lanthanum to boron is 1:6 (La:B=1:6) After ball milling for 2 hours, a mechanical mixture of lanthanum hydroxide and sodium borohydride was obtained, which was placed in a reactor at a heating rate of 2°C / min and heated to 500°C for 2 hours.

[0044] La(OH) 3 +6NaBH 4 →LaB 6 +3Na 2 O+13.5H 2

[0045] Release the hydrogen gas, cool to room temperature and wash with water. During water washing, sodium oxide reacts with water to form sodium hydroxide. Sodium hydroxide is dissolved in water, centrifuged, and vacuum-dried at 80°C to obtain nano single crystal lanthanum boride.

Embodiment 3

[0046] Embodiment 3: take lanthanum carbonate and potassium borohydride as the synthesis of lanthanum boride of raw material

[0047] Weigh 0.01 mole (0.458g) of lanthanum carbonate and 0.06 mole (0.646g) of potassium borohydride as the molar ratio of lanthanum and boron is 1:6 (La:B=1:6) and add them to the ball mill jar, and ball mill at 400rpm After 2 hours, a mechanical mixture of lanthanum carbonate and potassium borohydride was obtained, which was placed in a reactor and heated to 700°C at a heating rate of 2°C / min for 2 hours.

[0048] La 2 (CO 3 ) 3 +12KBH 4 →2LaB 6 +3K 2 CO 3 +6KH+21H 2

[0049] Release hydrogen gas, cool to room temperature and wash with water. KH reacts with water to generate hydrogen and potassium hydroxide during water washing. Potassium hydroxide is dissolved in water, centrifuged, and vacuum-dried at 80°C to obtain nano single crystal lanthanum boride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com