Transparent heat insulation coating material, preparation method and application thereof

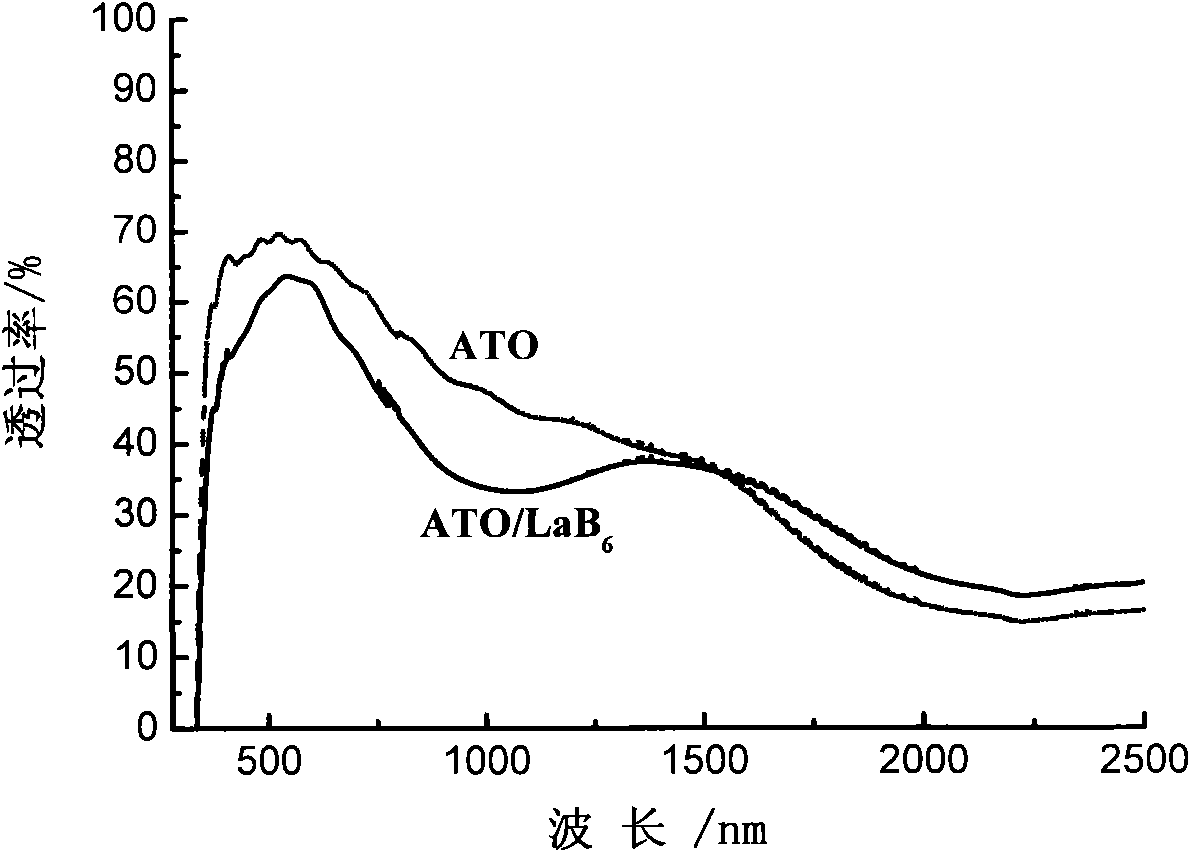

A coating and transparent technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of nano-particles easy to agglomerate, easy to aggregate and precipitate, easy to reverse coarse, etc., to achieve good infrared barrier performance, improve the barrier effect, reduce the effect of solar radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

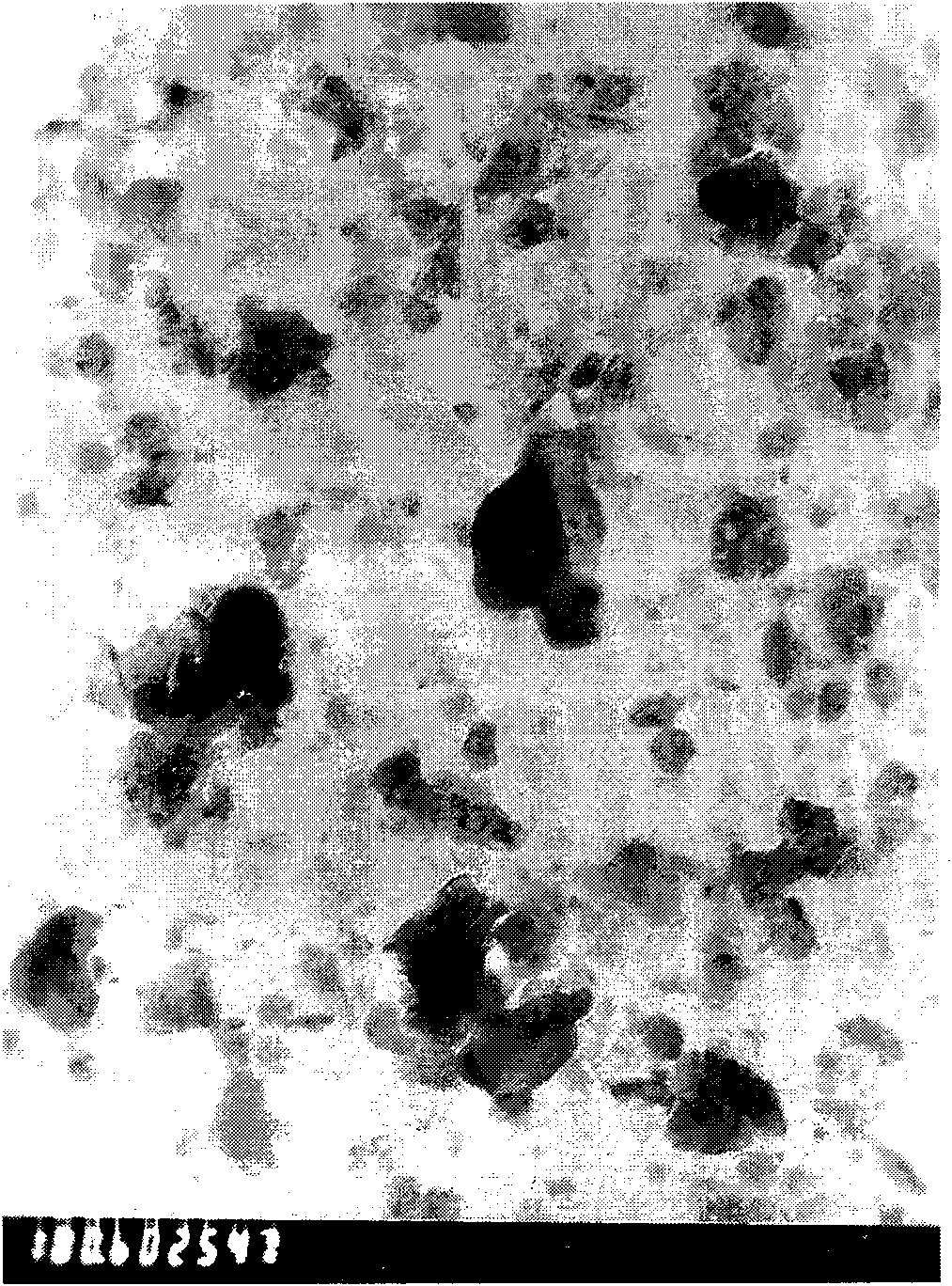

[0045] Preparation of water-based thermal insulation nano slurry:

[0047] Lanthanum hexaboride 1

[0048] Wetting and dispersing agent (Disperbyk-190) 0.8

[0049] Hyperdispersant (Hyperdisper-5410) 2.0

[0050] water 87

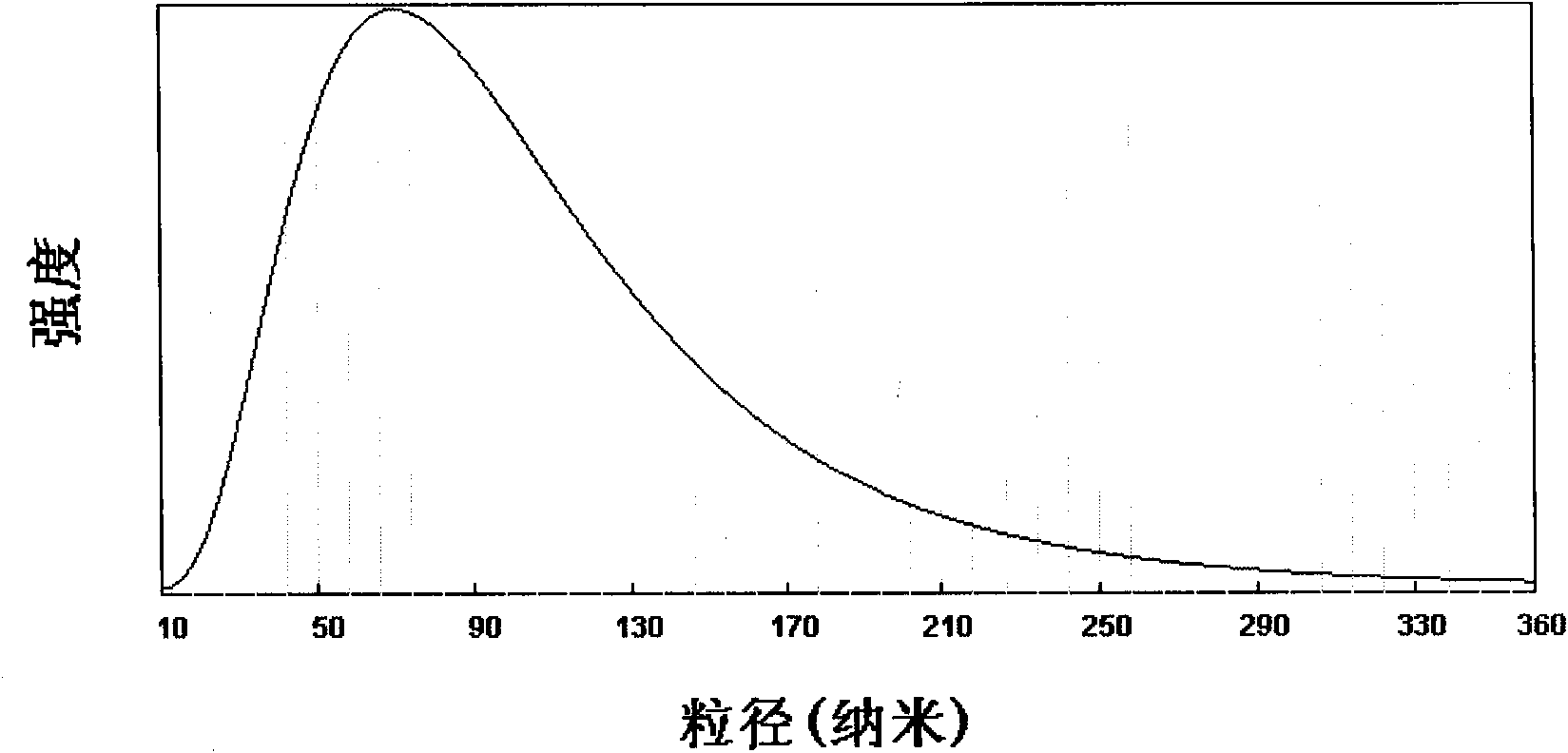

[0051] Add the wetting dispersant and hyperdispersant to the water first, after stirring evenly, add the above powder under medium speed stirring, after the powder is evenly mixed in the water, disperse ultrasonically for 1 hour, and sand in the sand mill After 36 hours, a slurry with an average particle diameter of about 80 nm was obtained.

Embodiment 2

[0053] Preparation of alcohol-soluble thermal insulation nano-slurry:

[0055] Lanthanum hexaboride 2

[0056] Wetting and dispersing agent ByK 160 (acrylate) 1.5

[0057] Hyperdispersant (Hyperdisper-5410) polyester) 1.5

[0058] Ethanol 63

[0059] leveling agent 2

[0060] Defoamer 0.3

[0061] Add the wetting and dispersing agent ByK 160 and the hyperdispersant (Hyperdisper-5410) into ethanol first, after stirring evenly, add the above powder under medium-speed stirring, and after the powder is uniformly mixed in water, disperse ultrasonically for 3 hours , Sand mill in a sand mill for 50 hours, add leveling agent and defoamer to obtain a slurry with an average particle size of about 100nm.

Embodiment 3

[0063] Preparation of solvent-based thermal insulation nano-slurries:

[0064] Indium tin oxide (ITO) 59

[0065] Lanthanum hexaboride 1

[0066] Wetting and dispersing agent (Disperbyk-161) 6

[0067] Hyperdispersant (BSK 32800SH) 2.0

[0068] Xylene 32

[0069] Add the wetting dispersant and hyperdispersant to xylene first, and after stirring evenly, add the above-mentioned powder under medium-speed stirring. After the powder is uniformly mixed in water, ultrasonically disperse for 0.5 hours, and put it in a sand mill Sand mill for 28 hours to obtain a slurry with an average particle diameter of about 180nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com