Oval sheet beam electron gun

A strip injection and electron gun technology, which is applied in the electron/ion gun of the transit time type electron tube, the cathode of the transit time type electron tube, the focusing arrangement of the transit time type electron tube, etc., can solve the problem of low current density and cathode evaporation. High rate, short service life and other problems, to achieve the effect of improving operating frequency, high current density and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

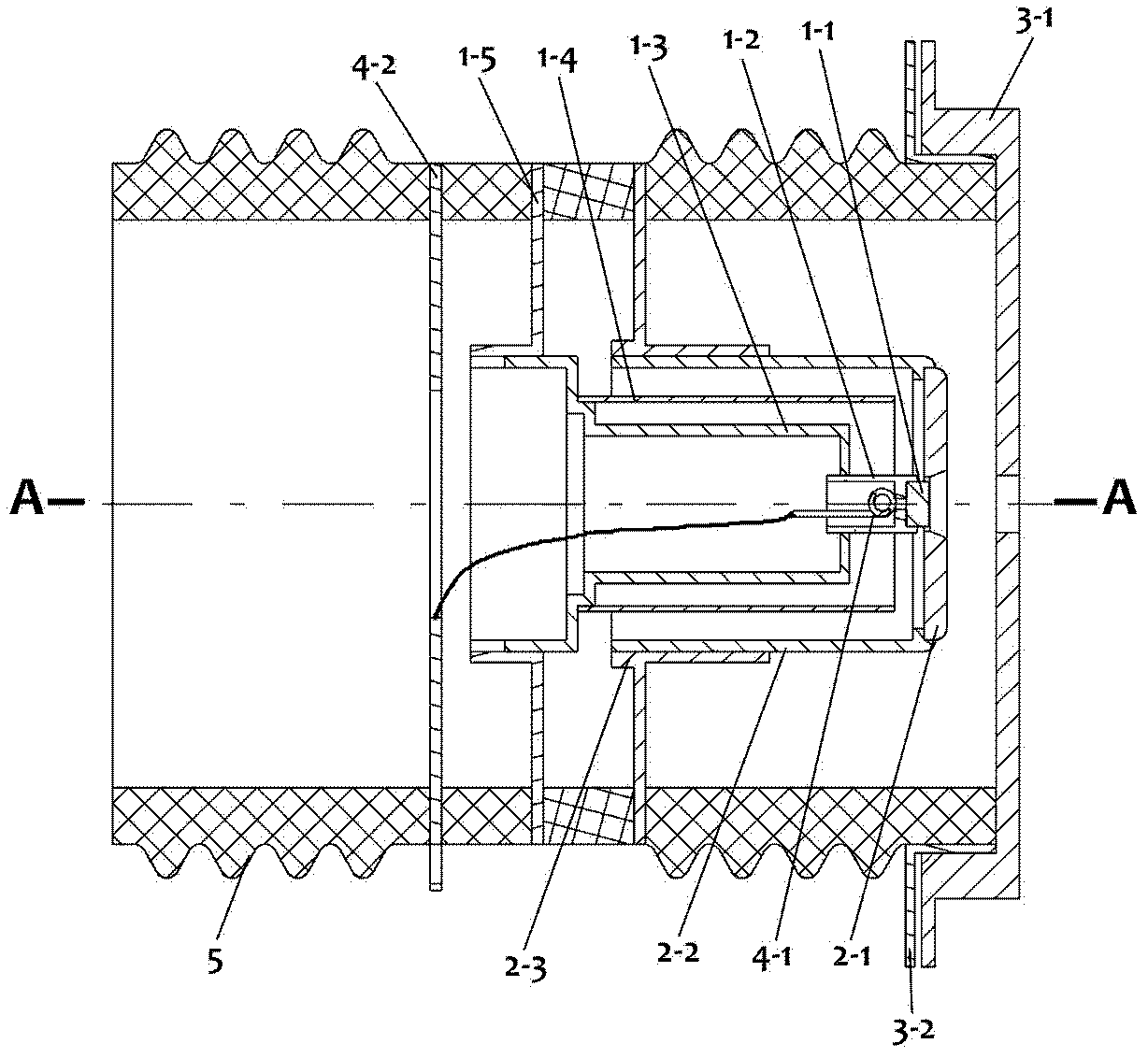

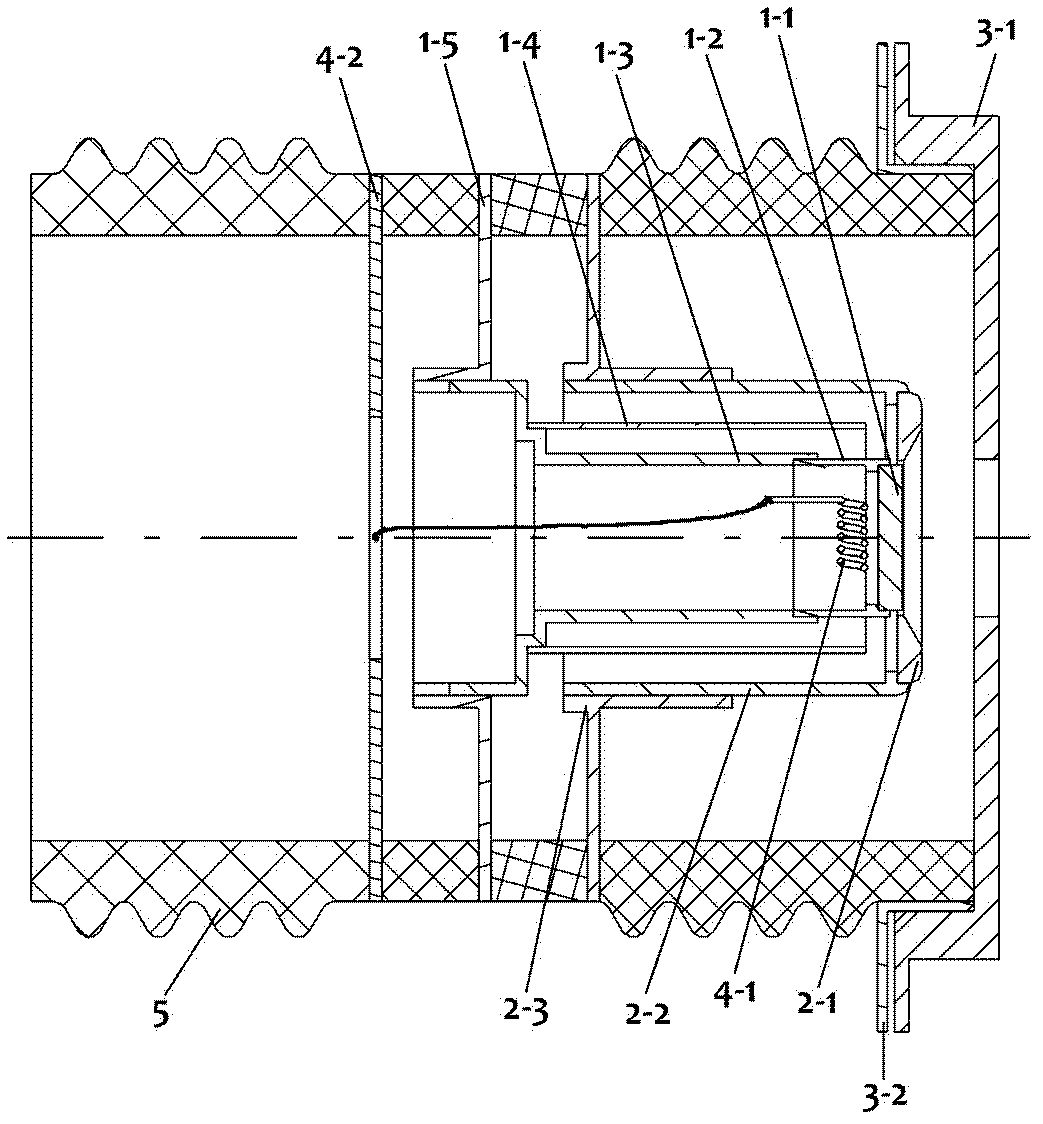

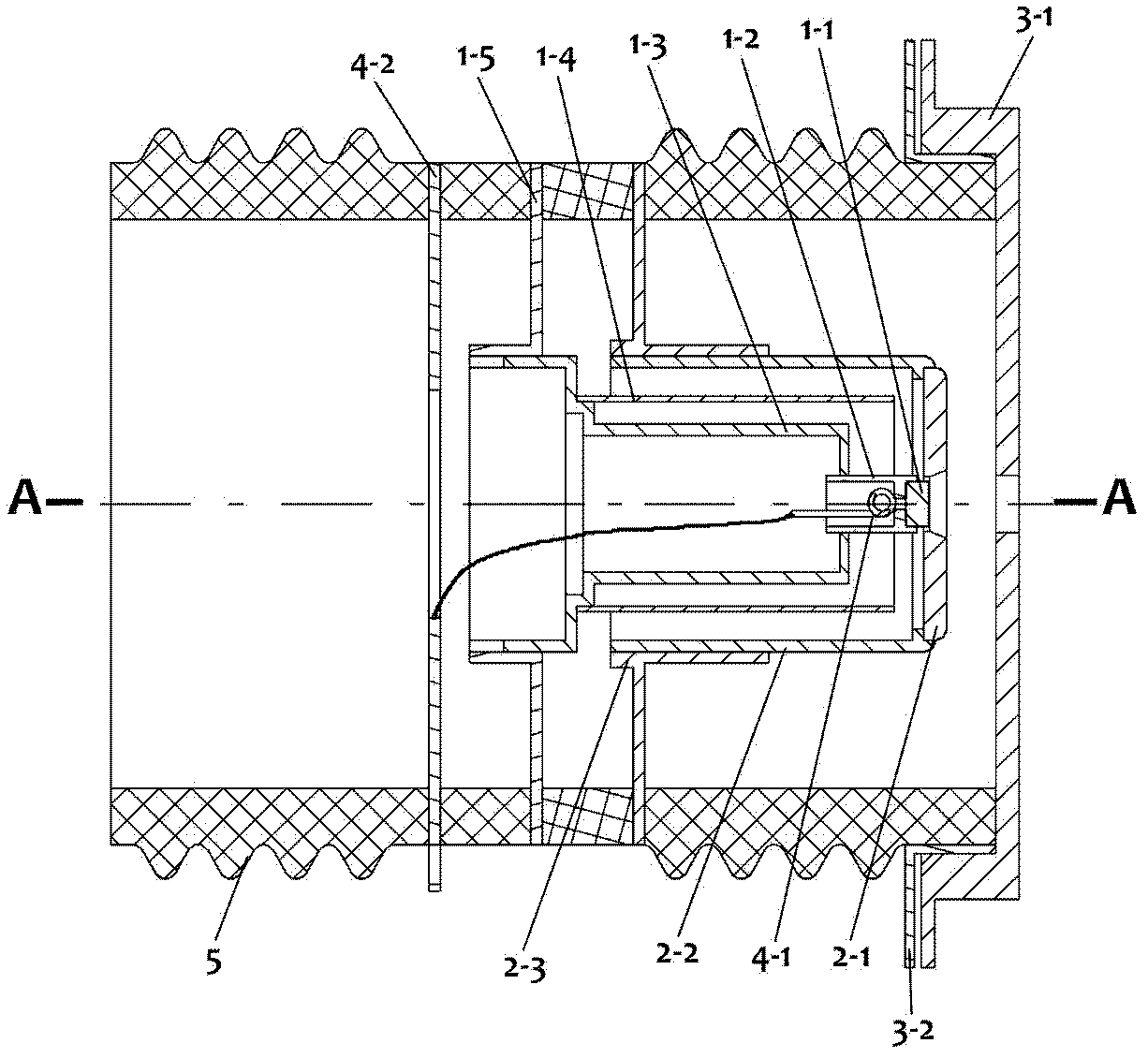

[0011] In this embodiment, the elliptical strip-shaped injection gun that works with the traveling wave tube and the return wave tube in the miniaturized flat-shaped strip-shaped injection device of 140 GHz is taken as an example: the emitting surface of the cathode head 1-1 is an elliptical plane with a thickness of 1.0 mm, The long axis is 3mm long, the short axis is 1mm long, and the material is lanthanum hexaboride (LaB 6 ), the wall thickness of cathode head fixing cylinder 1-2 is 0.2mm, the long axis is 3mm, the short axis is 1mm, the axial length is 3mm, and the material is metal tantalum. 15mm, the material is metal niobium, the outer heat insulation cylinder 1-4 has a wall thickness of 0.2mm, the inner diameter is 5mm, and the axial length is 14mm, the material is metal niobium, and the cathode component fixing seat 1-5 is fixed in a cylindrical shape with a ring plate in this embodiment Seat, ring plate thickness 0.4mm, outer diameter 20mm, cylindrical fixed seat inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com