Organic dye enhanced transparent and heat-insulating coating material, preparation method and application thereof

A technology for thermal insulation coatings and organic dyes, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of unstable coatings, insignificant energy-saving effect, low energy-saving effect, etc., and reduce the penetration of sunlight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The invention discloses an organic dye-enhanced transparent heat-insulating coating, which comprises: 3-50% by mass of a functional light-absorbing agent, 10-90% of a film-forming agent, and 0-50% of a solvent , 0-10% additives.

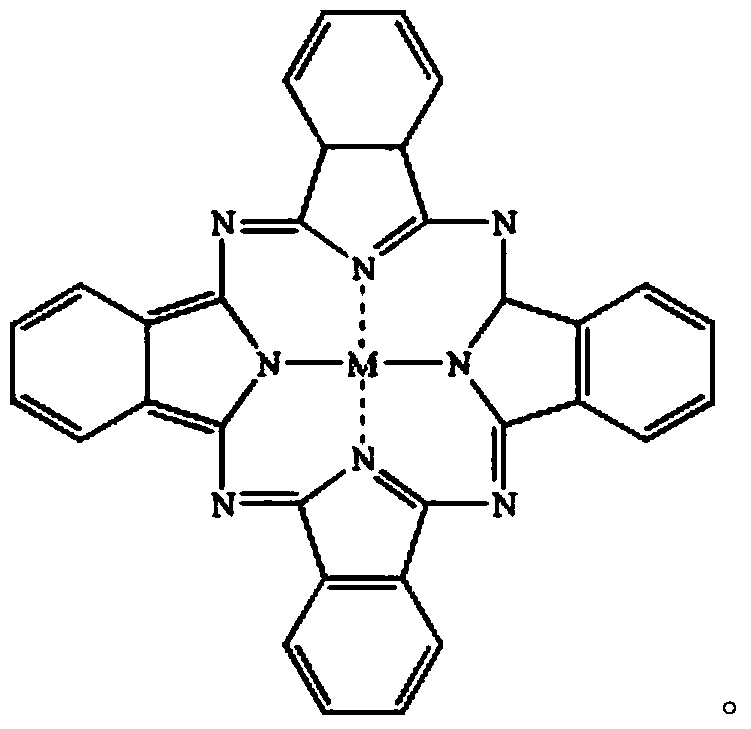

[0048] The functional light absorbing agent includes inorganic light absorbing agents, including indium tin oxide or antimony tin oxide as the main light absorbing agent, supplemented by lanthanum hexaboride, vanadium oxide, zirconium oxide, tungsten oxide, etc., and the particle size is controlled at 5-150nm. The functional light-absorbing agent also includes organic light-absorbing agents, mainly including metal phthalocyanine complexes and derivatives (such as metal phthalocyanine complexes, one of vanadyl phthalocyanine, oxygen copper phthalocyanine, and metal phthalocyanine derivative complexes) or more), its basic structure is as follows:

[0049]

[0050] The film-forming agent mainly includes one or more of polyacrylic resin, polyu...

Embodiment 2

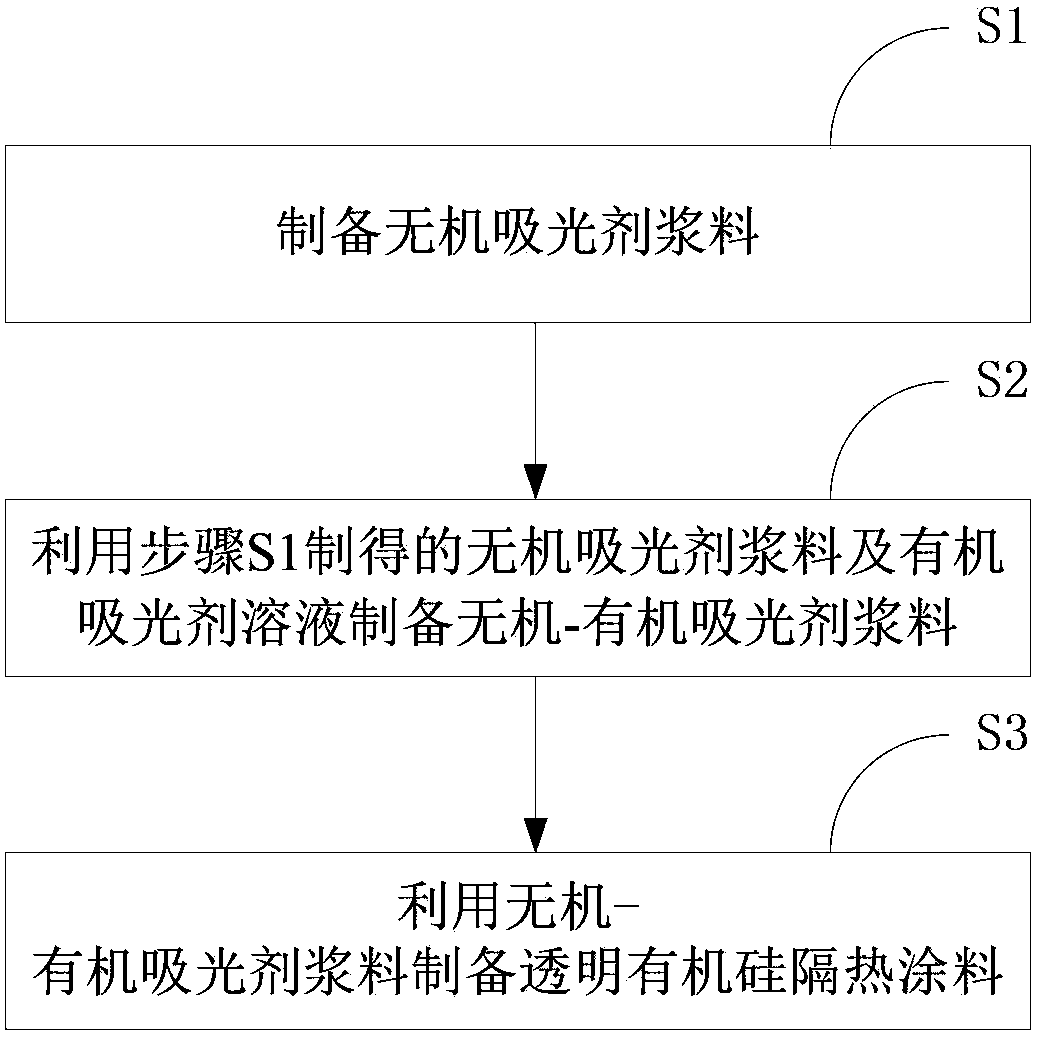

[0055] The present invention discloses a preparation method for implementing the organic dye-enhanced transparent heat-insulating coating, and the preparation method includes the following steps:

[0056] Step S1: preparing an inorganic light absorbing agent slurry by using a functional light absorbing agent with a mass percentage of 3-50%, a film-forming agent of 10-90%, a solvent of 0-50%, and an additive of 0-10%;

[0057] Step S2: using the inorganic light absorber slurry and the organic light absorber solution prepared in step S1 to prepare an inorganic-organic light absorber slurry;

[0058] Step S3: using the inorganic-organic light-absorbing agent slurry to prepare a transparent silicone heat-insulating coating.

[0059] In this embodiment, the preparation method specifically includes the following steps:

[0060] [Step S1] preparing inorganic light absorbing agent slurry;

[0061] According to the following number of copies

[0063] Ant...

Embodiment 3

[0075] The invention discloses a method for preparing the organic dye-enhanced transparent heat-insulating paint.

[0076] In this embodiment, the preparation method specifically includes the following steps:

[0077] [Step S1] preparing inorganic light absorbing agent slurry;

[0078] According to the following number of copies

[0079] Antimony tin oxide 20,

[0080] Lanthanum hexaboride 5,

[0081] Dispersant 2,

[0082] Methanol 70,

[0083] leveling agent 3

[0084] Defoamer 0.5

[0085] After blending, use ultrasonic dispersion for 30 minutes, strong ultrasonic stirring for 30 minutes, and sand mill for 24 hours to obtain a uniformly dispersed slurry with a particle size of 50-80nm.

[0086] [Step S2] preparing inorganic-organic light absorbing agent slurry;

[0087] Take 20 parts of organic light-absorbing agent solution (light-absorbing agent (vanadyl phthalocyanine): methanol: dimethyl sulfoxide = 20:70:10), under high-speed stirring, add 80 parts of inorganic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com