High-barrier oxidized graphene/nylon 6 extended-chain crystal and preparation method

A technology of graphene and extended chain, which is applied in the field of high-barrier graphene oxide/nylon 6 extended chain crystal and its preparation, can solve the problem that the barrier property cannot meet the industrial requirements, achieve strong practical significance and industrial value, and strengthen the barrier Effect, effect of increasing crystallinity and crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

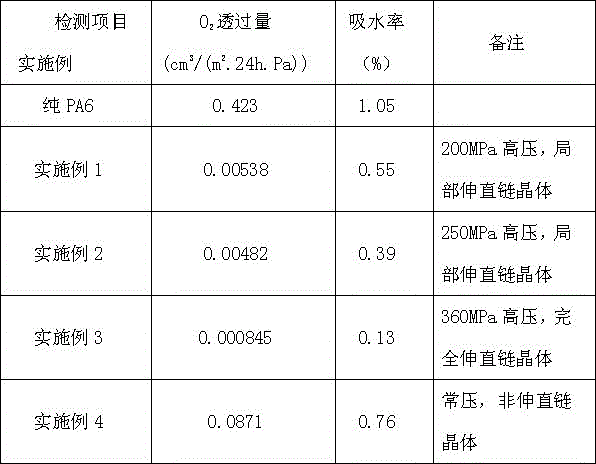

Embodiment 1

[0030] Example 1 The first step is the preparation of graphene oxide / nylon 6 composite material by in-situ synthesis method: put 1 part of graphene oxide and 99 parts of caprolactam into a flask, and ultrasonicate the mixture for 60 minutes at room temperature to obtain graphite oxide A mixed solution of graphene oxide and monomeric caprolactam; add the catalyst aminocaproic acid, install a mechanical stirring device and pass in an inert gas; while stirring, heat the mixture of graphene oxide and caprolactam to 170°C and keep it warm for 1h , then raise the temperature to 240°C and keep it warm for 4 hours to complete the in-situ polymerization; after the reaction, pour the melt into a surface container, wash it with boiling water for 3 times to remove monomers and low molecular weight oligomers, and obtain oxidation after drying. Graphene / nylon 6 composite.

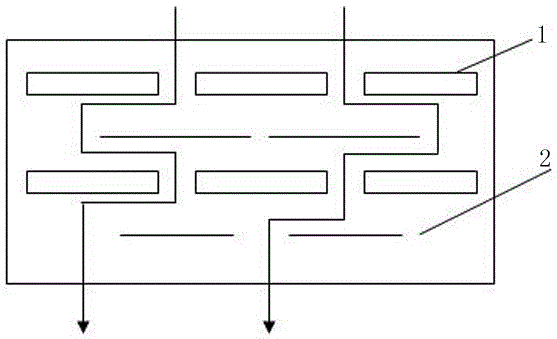

[0031] The second step is the acquisition of high-barrier graphene oxide / nylon 6 extended chain crystals: put the grap...

Embodiment 2

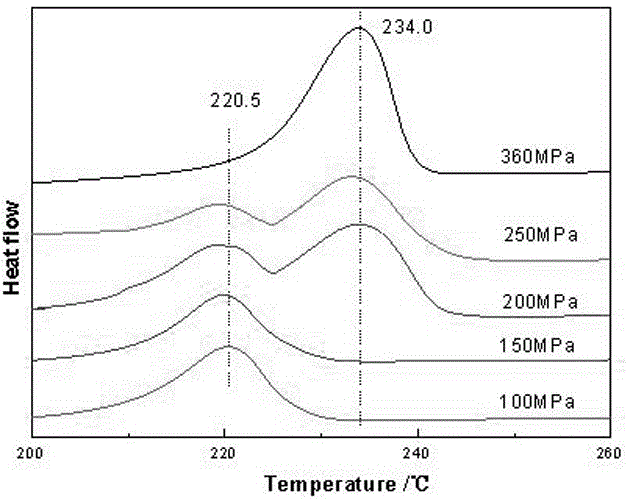

[0032] Example 2 According to the preparation method of Example 1, except that the pressure in the second step was changed from 200 MPa to 250 MPa, the extended chain graphene oxide / nylon 6 crystal was also obtained.

Embodiment 3

[0033] Example 3 According to the preparation method of Example 1, except that the pressure in the second step was changed from 200MPa to 360MPa, the extended chain graphene oxide / nylon 6 crystal was also obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com