Water glass transparent reflecting heat-insulation coating material and preparation method thereof

A technology of reflective heat-insulating coatings and heat-insulating pastes, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of underutilization of resources, high material consumption and energy consumption, and achieve water permeability resistance and suppression Hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

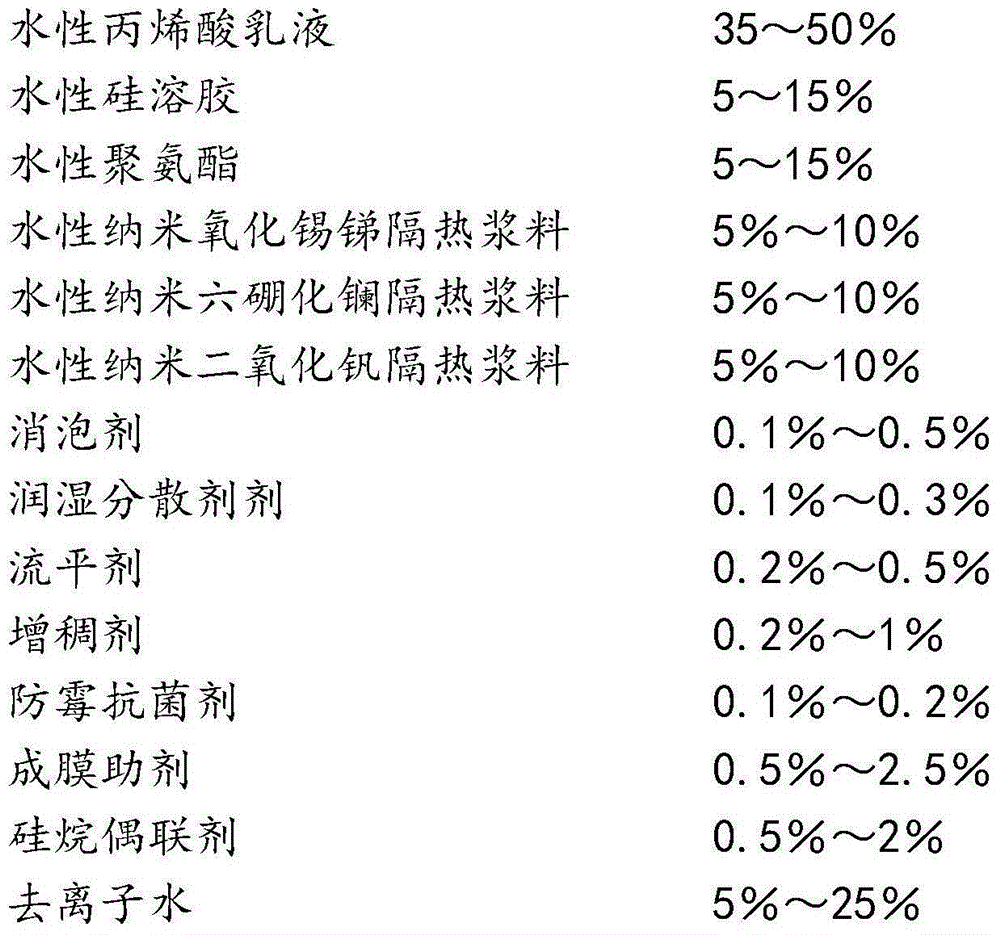

[0034] This example of water-based glass heat insulation transparent reflective heat insulation coating is used for heat insulation of glass, which can effectively prevent solar heat radiation without affecting any performance of the glass itself, especially the heat insulation effect is remarkable. It consists of the following mass fraction of raw materials Mixed: 35-50% water-based acrylic emulsion, 5-15% water-based silica sol, 5-15% water-based polyurethane, 5%-10% water-based nano-antimony tin oxide thermal insulation slurry, water-based nano-lanthanum hexaboride thermal insulation Slurry 5%-10%, water-based nano-vanadium dioxide thermal insulation slurry 5%-10%, defoamer 0.1%-0.5%, wetting and dispersing agent 0.1%-0.3%, leveling agent 0.2%-0.5% , 0.2% to 1% thickener, 0.1% to 0.2% antifungal and antibacterial agent, 0.5% to 2.5% film-forming aid, 0.5% to 2% silane coupling agent, 5% to 25% deionized water.

[0035] The preparation method of water-based glass heat-insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com