Double-phase calcium phosphate material and toothpaste containing same

A calcium-phosphorus and toothpaste technology, applied in the field of tooth restoration, can solve problems such as poor effect, slow tooth restoration process, inability to quickly realize hydroxyapatite crystallization, etc., and achieve the effect of avoiding flushing loss and long-term tooth structure restoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The above-mentioned embodiment provides a brand-new bioactive material: a dual-phase calcium-phosphorus material. Based on the same inventive concept as the above-mentioned embodiment, in another optional embodiment, a preparation of the above-mentioned dual-phase calcium-phosphorus material is provided. method, including the following steps:

[0048] S1: Prepare a calcium salt solution or Ca(OH) with a mass concentration of 1% to 20% 2 solution, adding glacial acetic acid during the stirring process, controlling the molar ratio of acetate and calcium ions to be 0.03-10:1 to obtain a mixed solution;

[0049] S2: Add dilute phosphoric acid with a mass percentage concentration of 1% to 30% to the mixed solution dropwise at a temperature of 15°C to 35°C until the pH value of the mixed solution is 5.0 to <7.0, and continue to stir the reaction after the addition is completed 1 ~16 hours to obtain emulsion;

[0050] S3: Centrifuge the emulsion, remove the supernatant, and ...

Embodiment 1

[0078] This embodiment provides a dual-phase calcium-phosphorus material, the preparation steps of which include:

[0079] The first step, configure Ca(OH) with 5% mass fraction 2 Emulsion 200mL, add 15mL glacial acetic acid under stirring, stir for about 1h;

[0080] In the second step, 130 mL of dilute phosphoric acid solution with a mass fraction of 14% was added dropwise at room temperature, and the drop was completed in 20 minutes, and the stirring speed was 500 r / min;

[0081] In the third step, continue to stir and react for 2 hours, then centrifuge, and wash the precipitate with deionized water until there is no obvious sour taste;

[0082] The fourth step is to dry the precipitate to obtain a dual-phase calcium-phosphorus material;

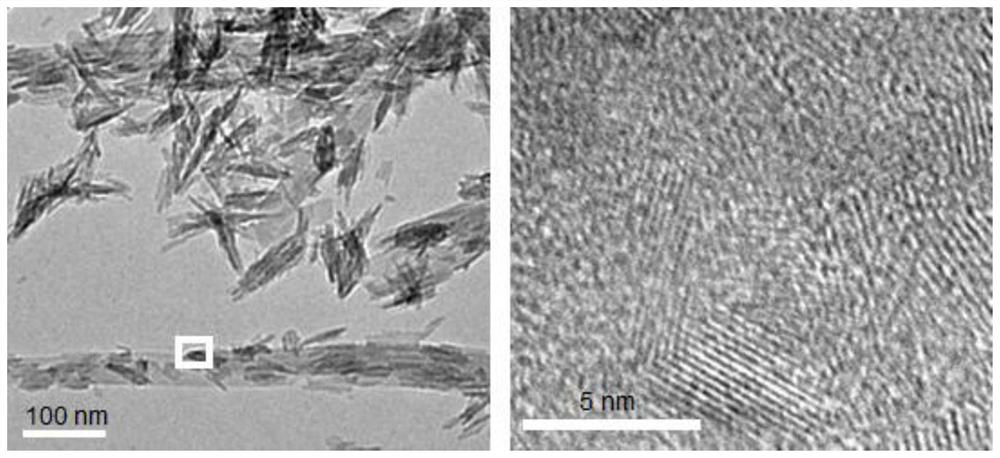

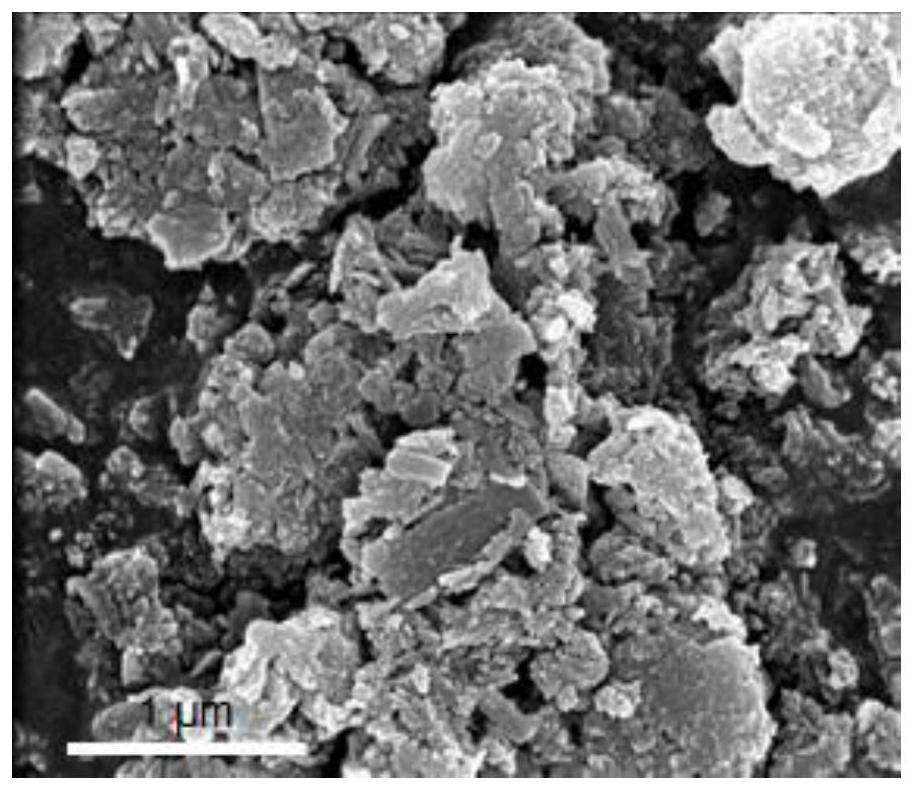

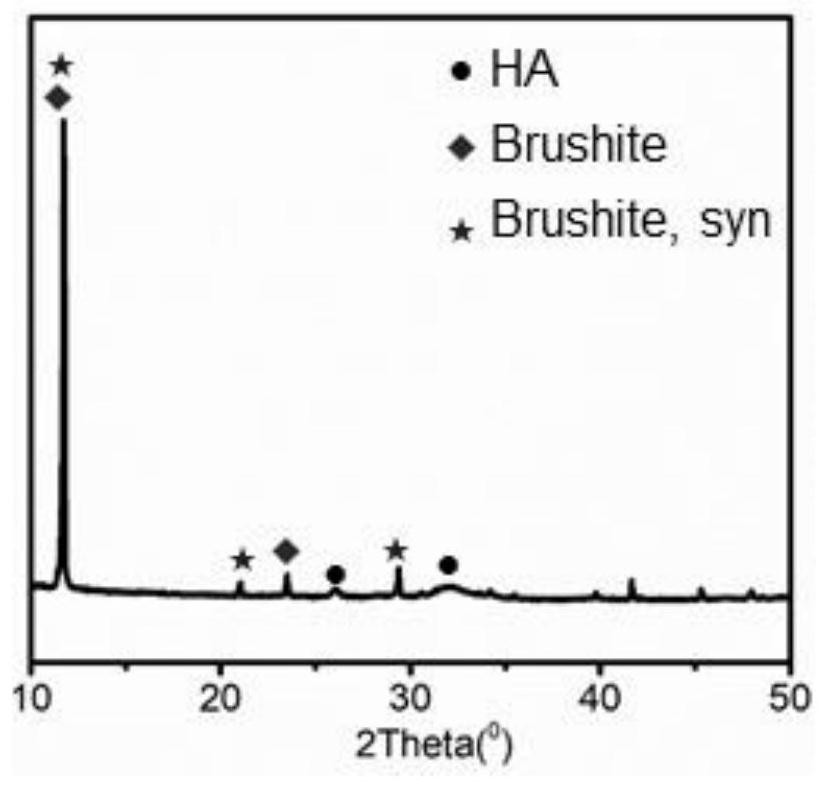

[0083] The TEM (transmission electron microscope) figure of the dual-phase calcium-phosphorus material prepared in this embodiment is as follows figure 1As shown, it can be seen that the nanoscale particle size of the prepared dual-pha...

Embodiment 2

[0090] This embodiment provides a dual-phase calcium-phosphorus material, the preparation steps of which include:

[0091] The first step, configure Ca(OH) with 8% mass fraction 2 Emulsion 160mL, add 30mL glacial acetic acid under stirring, stir for about 1h;

[0092] In the second step, 300 mL of dilute phosphoric acid solution with a mass fraction of 5% was added dropwise at room temperature, and the drop was completed in 40 minutes;

[0093] The third step is to continue the reaction for 3 hours, centrifuge, and wash the precipitate with deionized water until there is no obvious sour taste;

[0094] In the fourth step, the precipitate is dried to obtain a dual-phase calcium-phosphorus material.

[0095] Next, an anti-allergic / tooth restoration toothpaste is prepared by using the biphasic calcium-phosphorus material prepared above, and the mass percentage of the biphasic calcium-phosphorus material is 1% to 10%.

[0096] The material for preparing toothpaste is except two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com