Worm gear equipment with improved strength

A technology of worm gear and equipment, applied in the field of worm gear, which can solve the problems of poor sealing, infringement of worm gear and traction roller, external liquid droplets and impurities falling into the worm gear, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

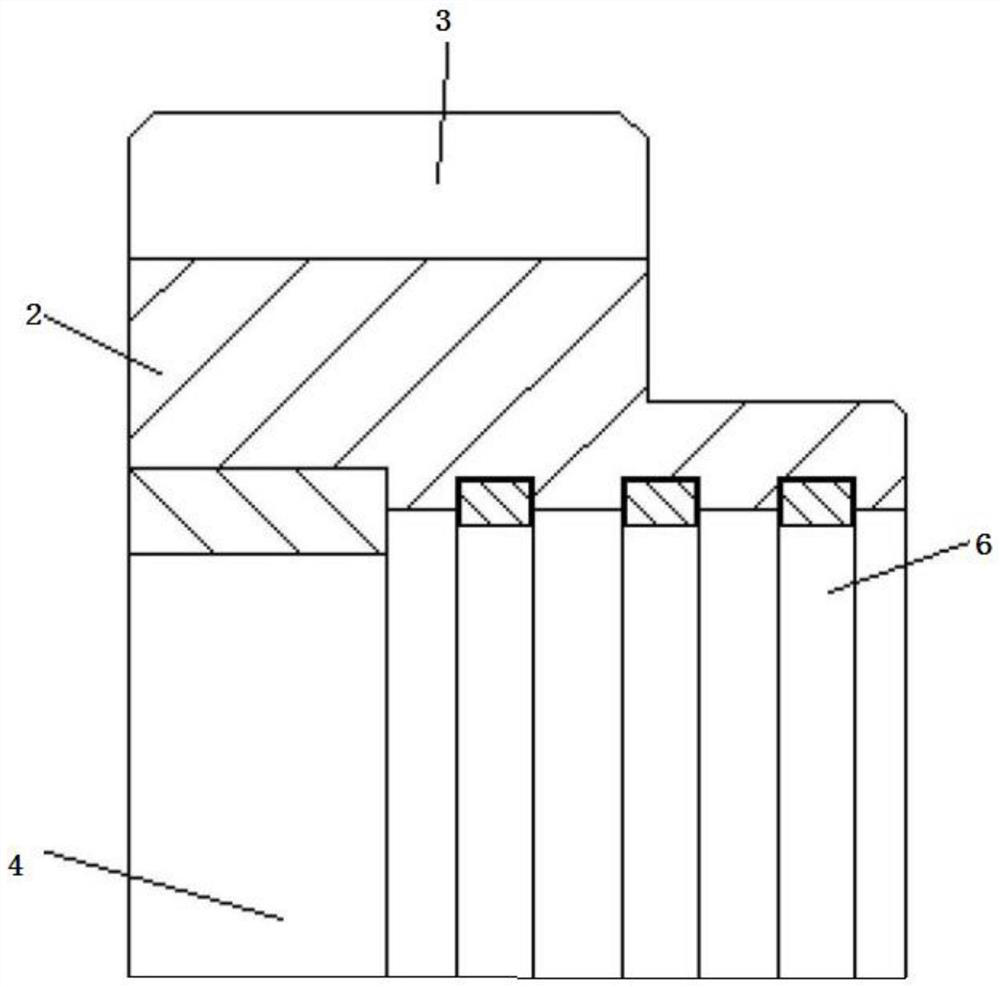

[0017] The worm gear is a common traction tool accessory. The automatic worm gear here is the one-to-one corresponding worm gear used for traction in the attached worm gear. It is widely used in traction equipment such as frequency converters, pipeline motors, and ejaculation motors; because of frequent operation in site conditions In the bad area, after the automatic worm gear and traction roller are installed, because of the poor sealing degree, external liquid droplets and impurities will fall into the worm gear, and a long cycle will cause considerable damage to the worm gear and traction roller. improved, such as Figure 1-Figure 2 As shown, the worm gear device for increasing strength includes a ring-column hoop 2, and a plurality of protruding teeth 3 are respectively arranged around the side periphery of the ring-column hoop 2.

[0018] A step opening 4 is provided in the center of the cylindrical hoop 2 .

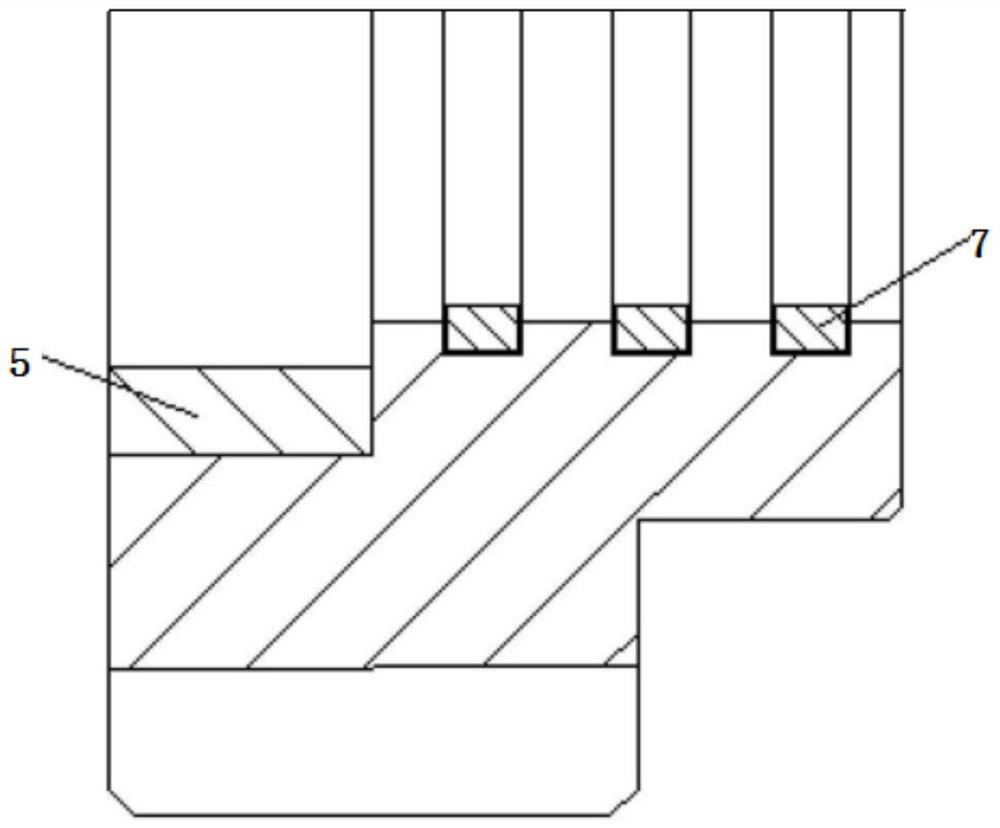

[0019] A rubber sealing ring 5 is hooped on the inner surfac...

Embodiment 2

[0023] Here, the automatic worm gear is the one-to-one corresponding worm gear used for traction in the auxiliary worm gear. It is widely used in traction equipment such as frequency converters, pipeline motors, and ejaculation motors; because it frequently operates in areas with poor site conditions, automatic After the worm gear and the traction roller are installed, due to the poor sealing degree, external liquid droplets and impurities will fall into the worm gear, and a long cycle will cause considerable damage to the worm gear and traction roller. improved, such as Figure 1-Figure 2 As shown, the worm gear device for increasing strength includes a ring-column hoop 2, and a plurality of protruding teeth 3 are respectively arranged around the side periphery of the ring-column hoop 2.

[0024] A step opening 4 is provided in the center of the cylindrical hoop 2 .

[0025] A rubber sealing ring 5 is hooped on the inner surface of the head of the stepped mouth 4 .

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com