Lithium-sulfur battery anode material, preparation method thereof, anode piece and lithium-sulfur battery

A lithium-sulfur battery and cathode material technology, applied in the field of electrochemical energy storage, can solve problems such as complex methods, lack of strong affinity, and inability to achieve cathode performance, and achieve the effects of promoting conversion, promoting utilization, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

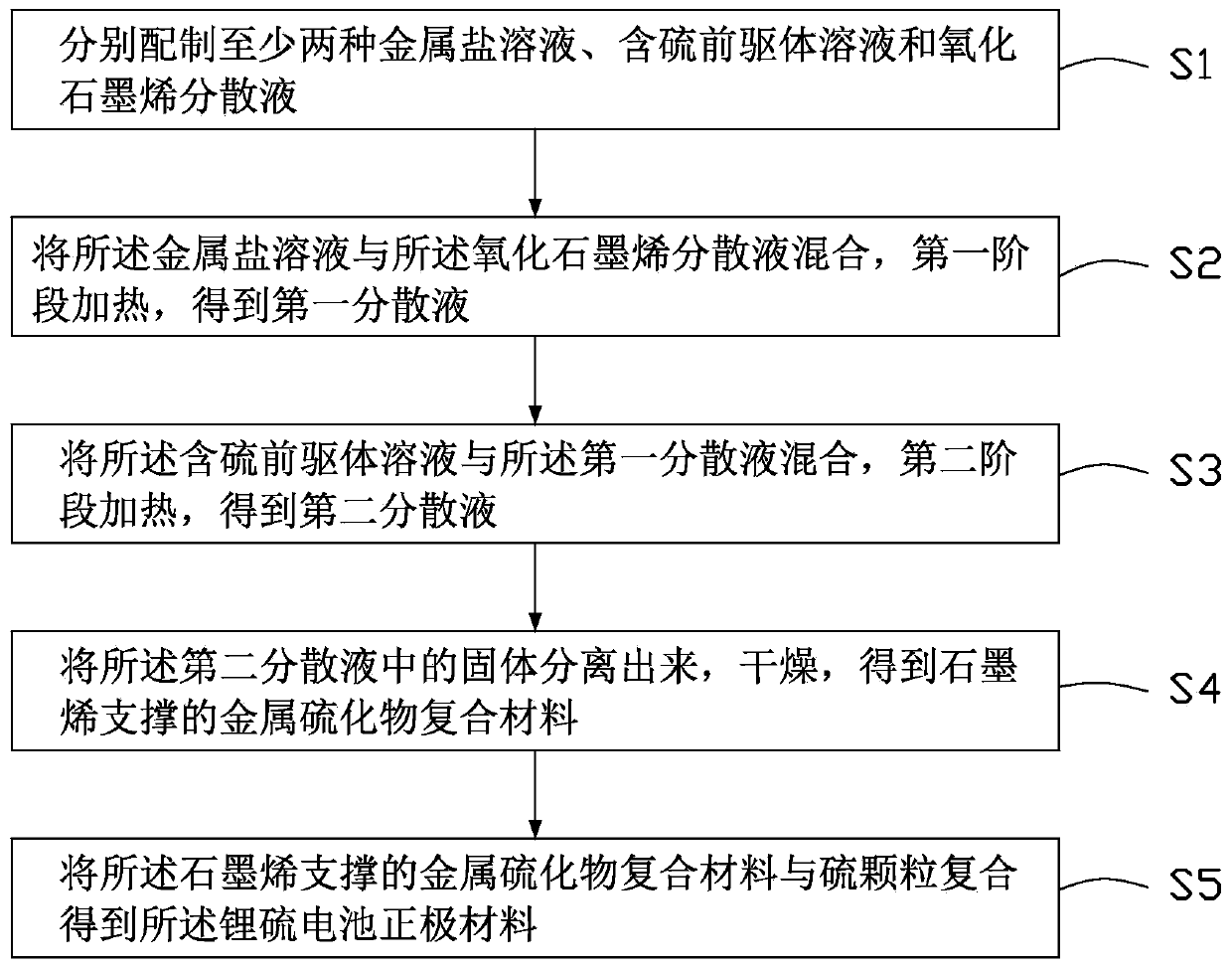

[0036] refer to figure 2 , the preferred embodiment of the present invention also provides a preparation method of lithium-sulfur battery cathode material, comprising the following steps:

[0037] Step S1, providing at least two metal salts, a sulfur-containing precursor and graphene oxide;

[0038] Step S2, adding the metal salt and the graphene oxide into a solvent for mixing, and heating in the first stage to obtain a first dispersion;

[0039] Step S3, mixing the sulfur-containing precursor with the first dispersion, and heating in the second stage to obtain a second dispersion;

[0040] Step S4, separating the solid in the second dispersion liquid and drying to obtain a graphene-supported metal sulfide composite material; and

[0041] Step S5, compounding the graphene-supported metal sulfide composite material and sulfur particles to obtain the lithium-sulfur battery cathode material.

[0042] In step S1, the sulfur-containing precursor in the sulfur-containing precur...

Embodiment 1

[0055] Add 160 mg of graphene oxide into 80 mL of deionized water and sonicate for 2 hours to obtain a concentration of 2 gL -1 Graphene oxide dispersion liquid, then take nickel chloride and cobalt chloride as metal salt, weigh 20mg nickel chloride and cobalt chloride respectively and join in the described graphene oxide dispersion liquid and stir for 1h, obtain mixed solution; The mixed solution was heat-treated at 120° C. for 6 hours to obtain the first dispersion containing nickel and cobalt hydroxide; 80 mg of thiourea was added to the first dispersion as a sulfur-containing precursor, and then at 180 Insulate at ℃ for 6 hours to carry out the second-stage heat treatment to obtain a second dispersion liquid containing nickel-cobalt sulfide supported by graphene; suction filter and freeze-dry the second dispersion liquid to obtain a graphene-supported metal sulfide composite material; After uniformly mixing the graphene-supported metal sulfide composite material and sulfur...

Embodiment 2

[0057] The difference from Example 1 is that the metal salt is tungsten chloride and cobalt chloride, and the heat treatment process in the first stage is 180° C. for 12 hours.

[0058] Other steps are the same as in Example 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The size of granule | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com