A production method for producing granule-integrated sulfur-based high-nitrogen compound fertilizer by using a drum

A technology of high-nitrogen compound fertilizer and production method, which is applied in the field of production of granule-integrated sulfur-based high-nitrogen compound fertilizer using rollers, which can solve the problems of large labor force, low nitrogen content, single nutrient, etc., and solve the shelling of finished products , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

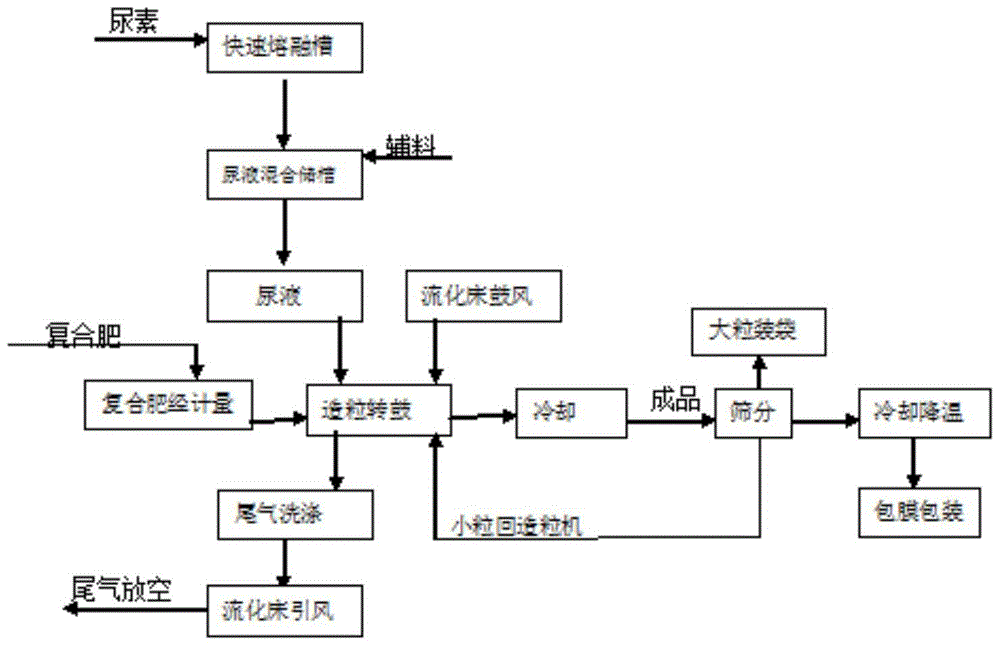

[0014] Embodiment 1: a kind of production method that utilizes drum to produce granular one-piece sulfur-based high-nitrogen compound fertilizer, such as figure 1 As shown, take 600Kg of 12-18-15 compound fertilizer with a particle size of 1mm and heat it to 50°C to obtain compound fertilizer seeds, enter the drum, take 388Kg of urea and heat it to 120°C to melt and transport it to the urine storage tank. Add 12Kg of a mixture of zinc sulfate monohydrate and magnesium sulfate heptahydrate into the urine storage tank, mix and store, and then mix the urine-trace element mixture with 1.5m 3 The speed of / s is added to the drum, and the 12-18-15 compound fertilizer enters the drum granulator as a crystal seed, and the mixed urine atomized by the spray gun with 3 high-pressure nozzles is evenly sprayed on the compound fertilizer seed On the formed material curtain, keep the distance between the material curtain and the edge of the material curtain and the edge of atomization as 10c...

Embodiment 2

[0016] A production method for producing granule-integrated sulfur-based high-nitrogen compound fertilizer by using a drum. After heating 400Kg of 12-18-15 compound fertilizer with a particle size of 4.2mm to 80°C, the crystal seed of the compound fertilizer is obtained, enters the drum, and takes urea 95.2Kg is heated to 135°C and melted, and then transported to the urine storage tank. At the same time, add 4.8Kg of sulfur, borax, and boric acid mixture into the urine storage tank, mix and store, and then mix the urine-trace element mixture with 3m 3 It is added into the drum at a speed of / s, atomized by a spray gun with 3 high-pressure nozzles, and the atomized mixed urine is evenly sprayed on the material curtain formed by the compound fertilizer seed crystal, and the edge of the material curtain and the material curtain is kept. The distance between the atomized edge and the atomized edge is 30cm, and the angle between the liquid surface of the mixed urine and the horizon...

Embodiment 3

[0018] A production method for producing granule-integrated sulfur-based high-nitrogen compound fertilizer by using a drum. After heating 700Kg of 12-18-15 compound fertilizer with a particle size of 2.2mm to 65°C, the crystal seed of the compound fertilizer is obtained, enters the drum, and takes urea 288.5Kg is heated to 128°C and melted, and then transported to the urine storage tank. At the same time, a mixture of 11.5Kg magnesium sulfate heptahydrate, sulfur, borax, boric acid, and sodium octaborate is added to the urine storage tank, and the urine is mixed and stored. liquid-trace element mixture at 2.2m 3 It is added into the drum at a speed of / s, atomized by a spray gun with 3 high-pressure nozzles, and the atomized mixed urine is evenly sprayed on the material curtain formed by the compound fertilizer seed crystal, and the edge of the material curtain and the material curtain is kept. The distance from the edge of atomization is 20cm, and the angle between the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com