Modified sulfur granules and preparation method and application thereof

A technology of modification of sulfur particles, applied in building components, building insulation materials, construction, etc., can solve the problems of high production cost, poor suppression effect, uneven mixing, etc., achieve good effect, facilitate storage and transportation, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

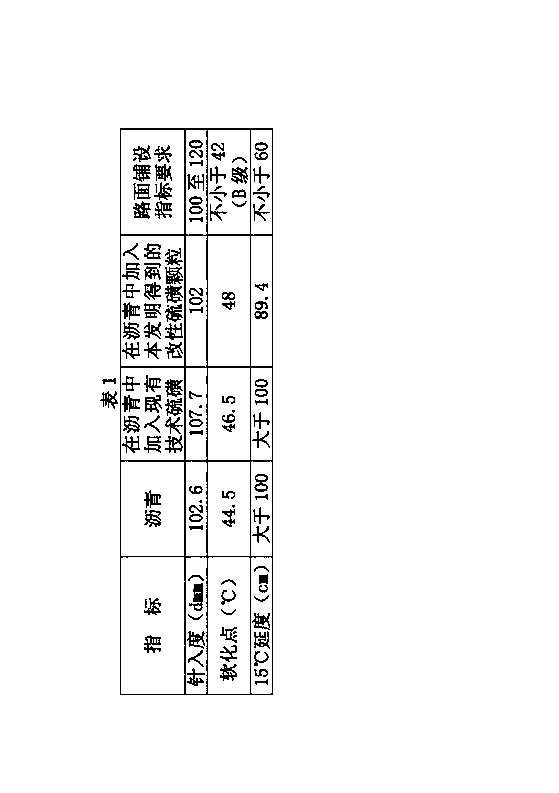

Embodiment 1

[0016] Embodiment 1, the modified sulfur particles, the raw material contains 80 to 100 parts of sulfur and 1 to 10 parts of hydrogen sulfide inhibitor in parts by weight; the modified sulfur particles are obtained according to the following steps: the first step, the The required amount of sulfur and hydrogen sulfide inhibitor is added to the reaction vessel and mixed evenly, and then the mixed sulfur and hydrogen sulfide inhibitor are heated in an oil bath at 130°C to 140°C until the sulfur and hydrogen sulfide inhibitor are melted After reacting for 25 minutes to 35 minutes, a bright gray-black mixture is obtained; in the second step, the reacted mixture in the reaction vessel is poured into cold water to cool and disperse into solid particles, and the modified sulfur particles are obtained after filtering. The modified sulfur particles obtained in the present invention are dense and uniform, and are solid particles at normal temperature, with a particle diameter of 3 mm t...

Embodiment 2

[0017] Embodiment 2, the modified sulfur particles, the raw material contains 80 parts or 100 parts of sulfur, 1 part or 10 parts of hydrogen sulfide inhibitor in parts by weight; the modified sulfur particles are obtained according to the following steps: the first step, the The required amount of sulfur and hydrogen sulfide inhibitor is added to the reaction vessel and mixed evenly, and then the mixed sulfur and hydrogen sulfide inhibitor are heated in an oil bath at 130°C or 140°C until the sulfur and hydrogen sulfide inhibitor are melted React for 25 minutes or 35 minutes, and then obtain a bright gray-black mixture; in the second step, pour the reacted mixture in the reaction vessel into cold water to cool and disperse into solid particles, and obtain modified sulfur particles after filtration. The modified sulfur particles obtained in the present invention are dense and uniform, and are solid particles at normal temperature, with a particle diameter of 3 mm to 5 mm, sta...

Embodiment 3

[0018] Embodiment 3, as the optimization of above-mentioned embodiment, the hydrogen sulfide inhibitor of embodiment 3 comprises hydrogen sulfide main inhibitor and hydrogen sulfide synergistic inhibitor; The mass percentage of hydrogen sulfide main inhibitor in hydrogen sulfide inhibitor is 1 % to 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com