Iron complex desulfurizer suitable for super-gravity desulfurization

A technology for complexing iron and desulfurizing agent, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low saturated sulfur capacity, poor desulfurization liquid stability, and high operating costs, and achieve high saturated sulfur capacity, Reduced operating costs and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

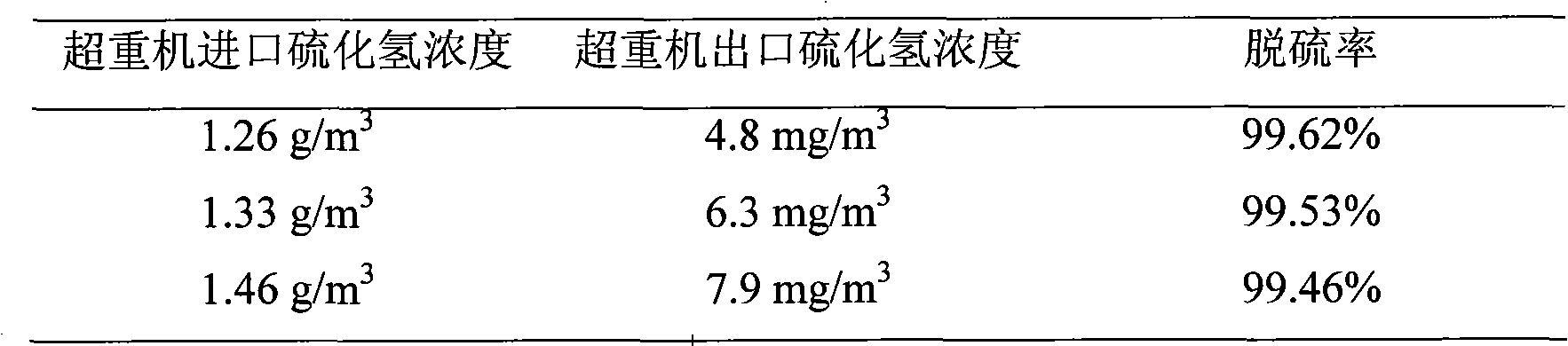

[0055] Use the desulfurization liquid of the present invention to treat sulfide containing 1.0-1.5g / m 3 of industrial waste gas (of which, H 2 S content > 96%, others are organic sulfur CS 2 , COS, etc.).

[0056] (1) Composition of desulfurization liquid:

[0057] Total iron: 0.5g / L, of which Fe 3+ The mass ratio to total iron is 0.95

[0058] Sulfosalicylic acid: 1.0g / L

[0059] Tartaric acid: 0.5g / L

[0060] Sodium carbonate: 10g / L

[0061] Diethanolamine: 0.80g / L

[0062] Mixture of sodium p-toluenesulfonate, sodium bisulfite, sucrose and 2,4-dichlorophenol in equal mass ratio: 0.4g / L

[0063] Sodium 2,7-anthraquinone disulfonate: 0.02g / L

[0064] Example e of sulfur particle sedimentation agent: 0.04g / L

[0065] Corrosion inhibitor example d: 0.3g / L

[0066] Adjust the pH value of the desulfurization solution: 8~9

[0067] Rest: water

[0068] The specific configuration method of the desulfurization solution: use water as the solvent, first add soluble iron s...

Embodiment 2

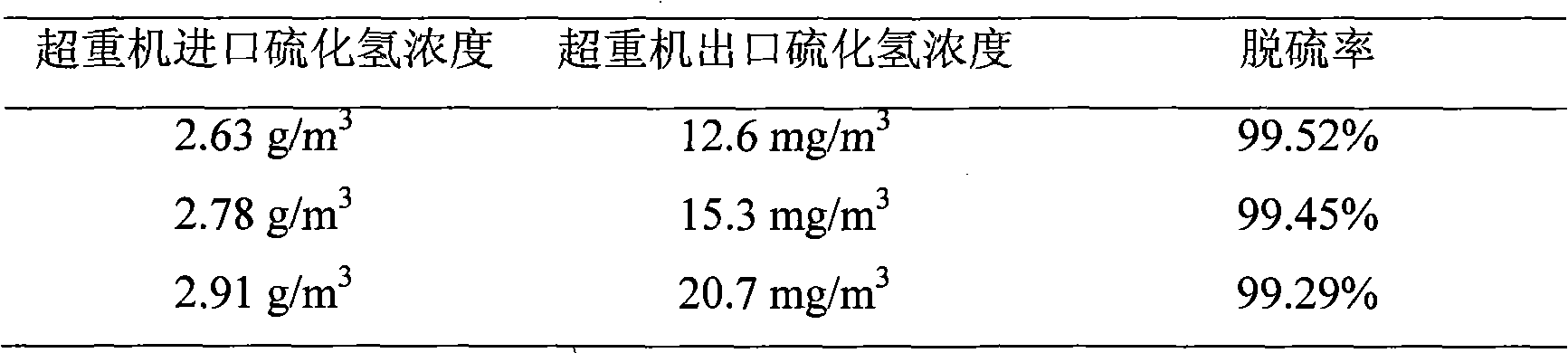

[0078] Use the desulfurization solution of the present invention to treat 2.5-3.0 g / m of sulfide 3 of industrial waste gas (of which, H 2 S content > 91%, others are organic sulfur CS 2 , COS, etc.).

[0079] (1) Composition of desulfurization liquid:

[0080] Total iron: 2.0g / L, of which Fe 3+ The mass ratio to total iron is 0.85

[0081] Lactic acid: 1.0g / L

[0082] Sodium tartrate: 1.5g / L

[0083] Salicylic acid: 1.5g / L

[0084] Sodium carbonate: 20g / L

[0085] Triethanolamine: 0.1g / L

[0086] Mixture of sodium p-toluene disulfonate, disodium hydrogen phosphate, maltose and 2,4-dichlorophenol in equal mass ratio: 1.6g / L

[0087] Sodium 2,6-anthraquinone disulfonate: 0.06g / L

[0088] Sulfur particle sedimentation agent example b: 0.42g / L

[0089] Corrosion inhibitor example c: 1.7g / L

[0090] pH value of desulfurization solution: 8~9

[0091] Rest: water

[0092] The specific configuration method of desulfurization liquid is as mentioned above.

[0093] (2) Th...

Embodiment 3

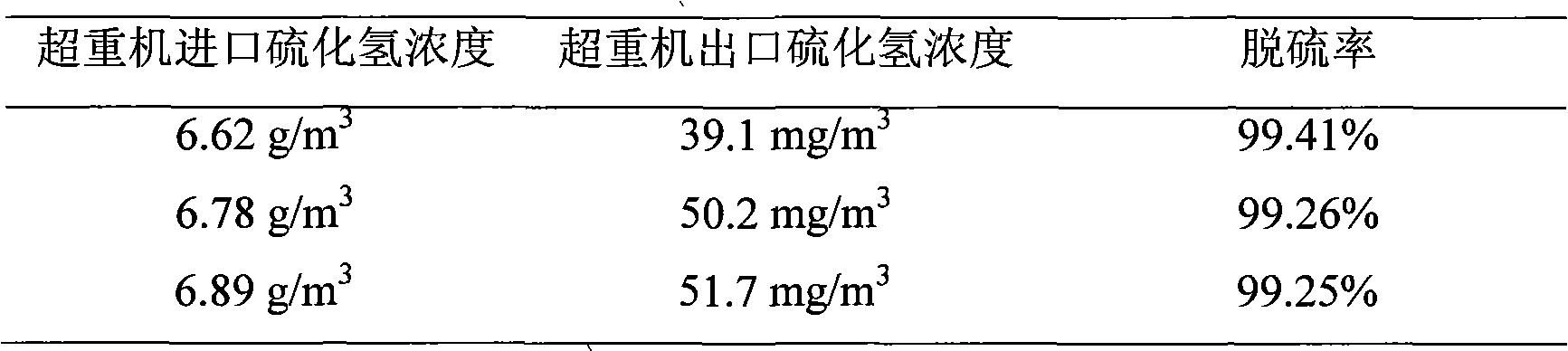

[0102] Use the desulfurization liquid of the present invention to treat 6.5-7.0 g / m of sulfide 3 of industrial waste gas (of which, H 2 S content > 88%, others are organic sulfur CS 2 , COS, etc.).

[0103] (1) Composition of desulfurization liquid:

[0104] Total iron: 5.5g / L, of which Fe 3+ The mass ratio to total iron is 0.8

[0105] Sulfosalicylic acid: 3.5g / L

[0106] Citric acid: 2.5g / L

[0107] Sodium tartrate: 2.5g / L

[0108] Sodium carbonate: 38g / L

[0109] Triethanolamine: 0.40g / L

[0110] Mixture of sodium p-toluene disulfonate, sodium dihydrogen phosphate, sucrose and 2,4,6-trichlorophenol in equal mass ratio: 2.9g / L

[0111] Sodium 2,7-anthraquinone disulfonate: 0.09g / L

[0112] Sulfur particle sedimentation agent example c: 0.93g / L

[0113] Corrosion inhibitor example b: 2.9g / L

[0114] pH value of desulfurization solution: 8~9

[0115] Rest: water

[0116] The specific configuration method of desulfurization liquid is as mentioned above.

[0117] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com