Steel strand inhaul cable filled or coated with polyurea protective material and manufacturing method of steel strand inhaul cable

A technology of protective materials and production methods, which can be used in textile cables, construction, textiles and papermaking, etc., and can solve the problems of high rigidity of steel strands, easy cracking of coatings, aging phenomena, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

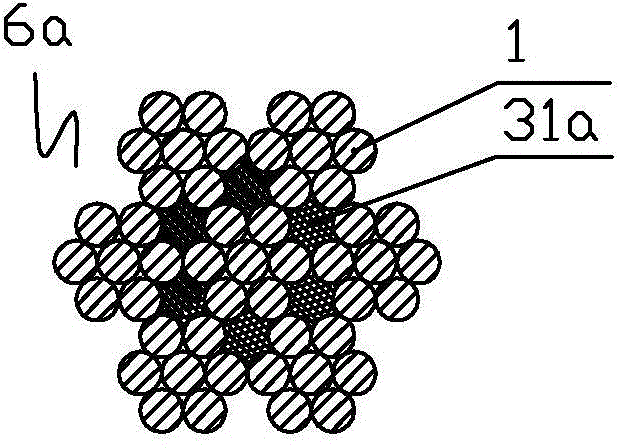

[0125] A steel strand cable filled with polyurea material in the middle of n steel strands or coated with polyurea protective material:

[0126] Such as Picture 1-1 , the steel strand cables filled with polyurea materials in the middle or coated with polyurea protective materials include a steel strand assembly composed of 7 steel strands, and each steel strand in the middle of the 7 steel strands The gap between them is filled with polyurea material 31a, which constitutes the steel strand cable Ia of the present invention filled or coated with polyurea protective material (see Picture 1-1 ).

[0127] The single steel strand is either a smooth steel strand made of smooth steel wire or a steel strand with epoxy coating, galvanized coating, plastic coating, anti-corrosion grease coating attached to the outer periphery of the smooth steel wire. Anti-corrosion steel strands composed of anti-corrosion steel wires with coatings or coatings attached to the surface of oily wax or ...

Embodiment 2

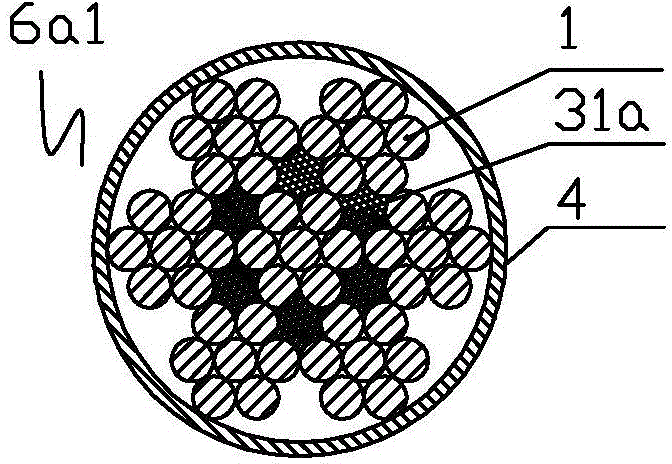

[0133] A steel strand cable filled or coated with polyurea protective material composed of a layer of polyurea protective coating I coated on the outermost layer of the steel strand assembly:

[0134] Such as diagram 2-1 As shown, the outer circumference of the steel strand assembly of a steel strand cable Ia filled with polyurea material or coated with polyurea protective material described in Embodiment 1 is coated with a layer of polyurea protective material. Coating I31b, thereby constituting steel strand cables Ib filled or coated with polyurea protective material (see diagram 2-1 ).

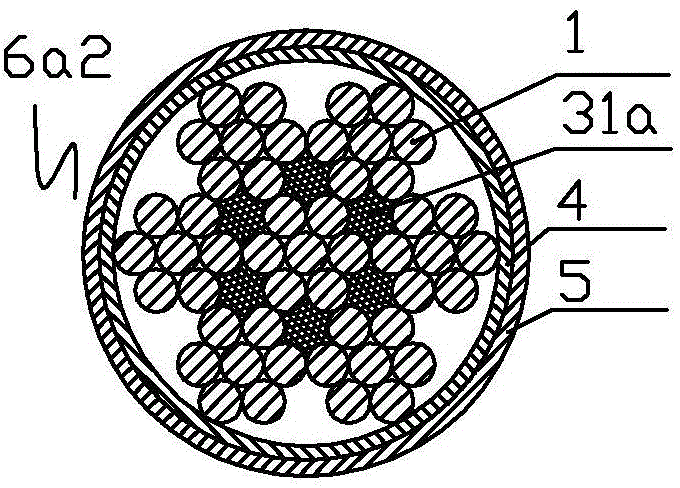

[0135] As a change in the embodiment of the present invention, the outer layer of the steel strand cable Ib filled or coated with polyurea protective material has a single-layer HDPE sheath 4 or has an inner HDPE sheath 4 and an outer layer A double-layer HDPE sleeve composed of HDPE sheath 5, constituting a steel strand cable Ib1 filled or coated with polyurea protective material (see ...

Embodiment 3

[0138] The outer layer of the wrapping tape of steel strand cable Ia filled or coated with polyurea protective material is coated with a layer of polyurea protective coating IIb, which has multiple protective layers filled or coated with polyurea protective material The strand guy cables:

[0139] Such as Figure 3-1 As shown, a kind of middle part is filled with polyurea material described in embodiment one or is coated with polyurea protective material steel strand cable Ia the outer periphery of steel strand assembly is also wrapped around a wrapping tape 2 , constituting steel strand cables Ia0 filled or coated with polyurea protective material (see Figure 3-1 ); then the outer layer of the wrapping tape 2 of the steel strand cable Ia0 filled or coated with polyurea protective material is coated with a layer of polyurea protective coating II31c, forming a steel wire filled or coated with polyurea protective material Stranded cable Ia0c (see Figure 3-2 );

[0140] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com