Exhaust by-pass valve for turbocharging system

A turbocharging system and bypass valve technology, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of unrealized commercialization, inability to fully and effectively use bypass and discharge gas, and reduce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

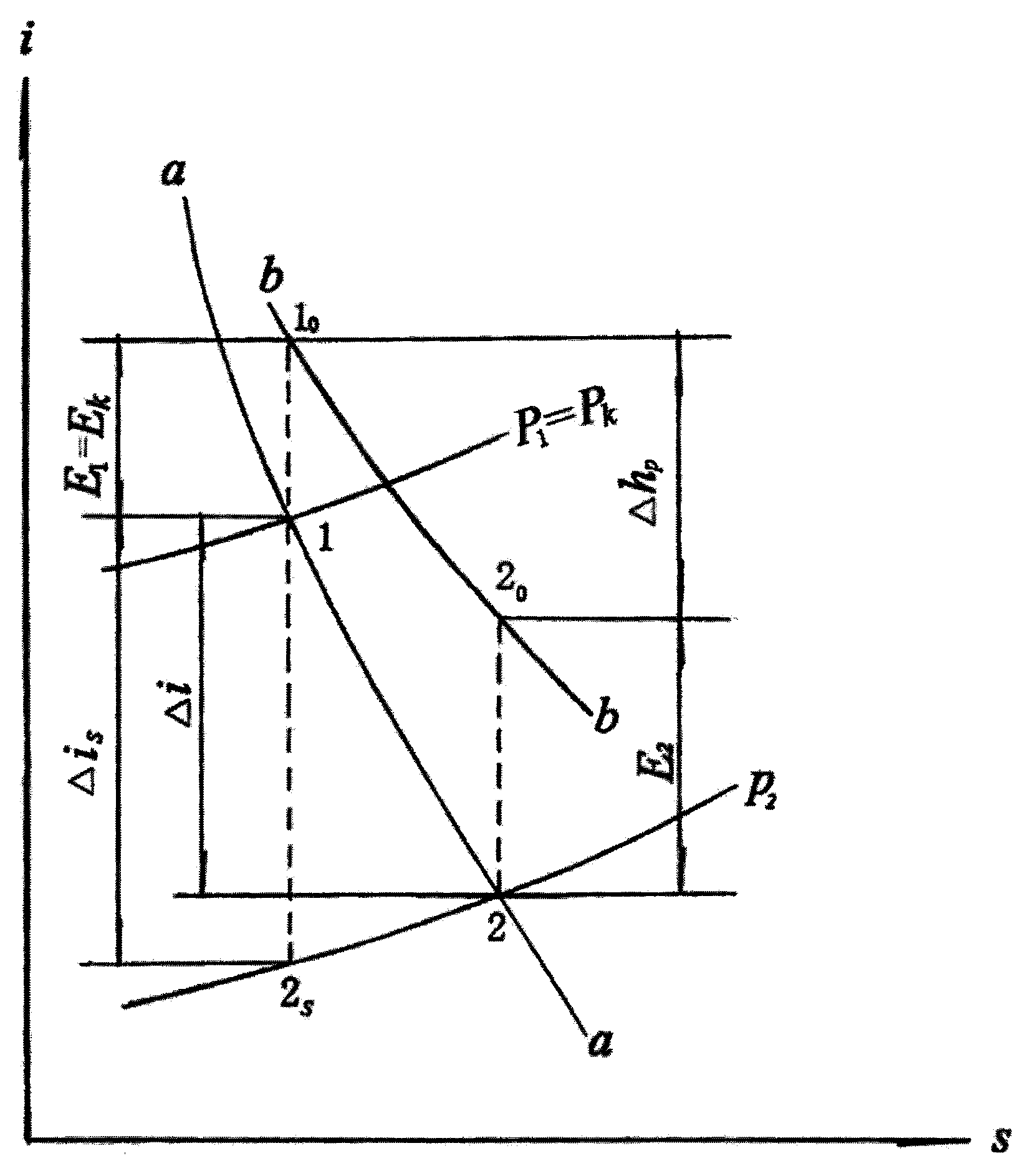

Method used

Image

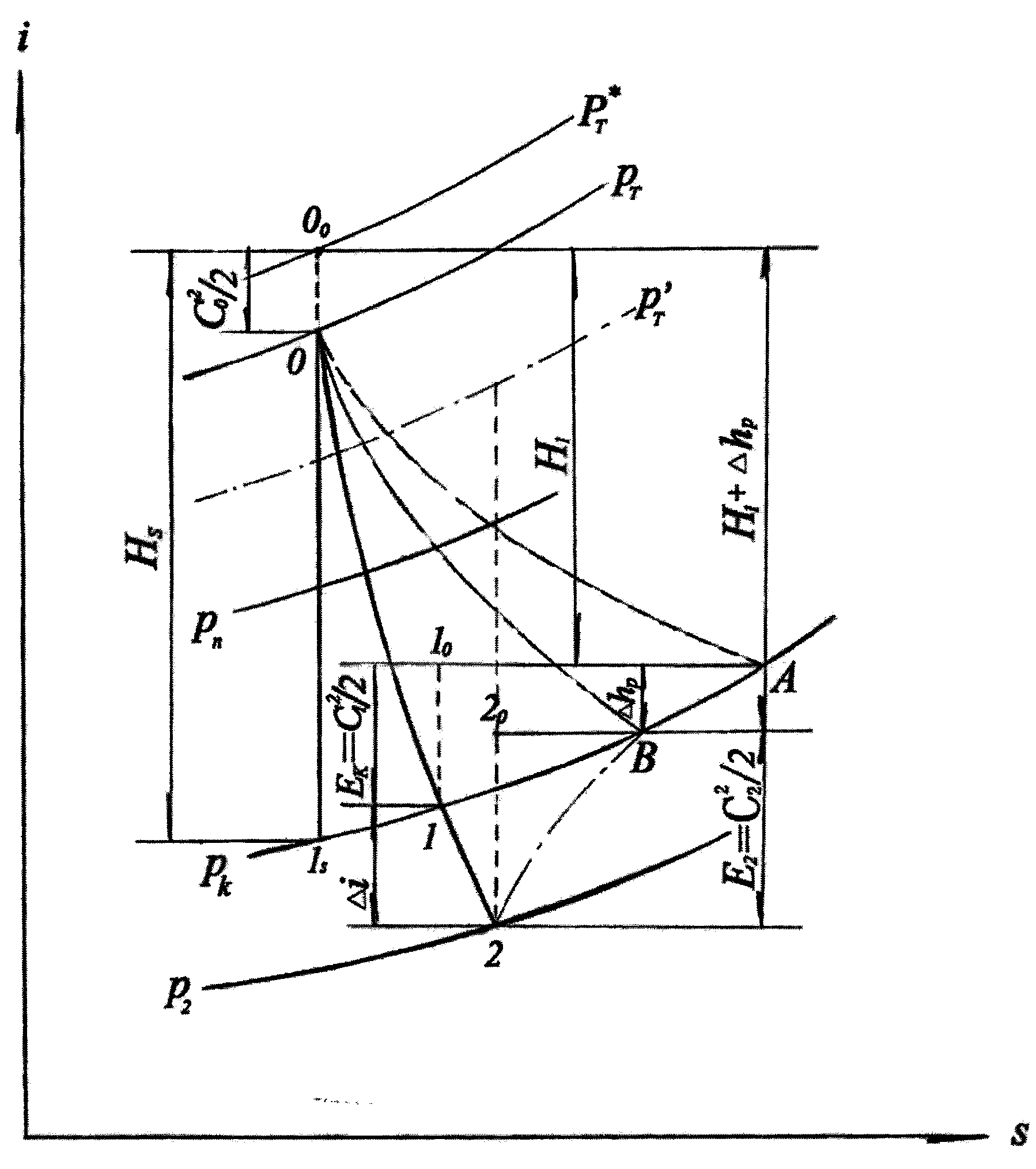

Examples

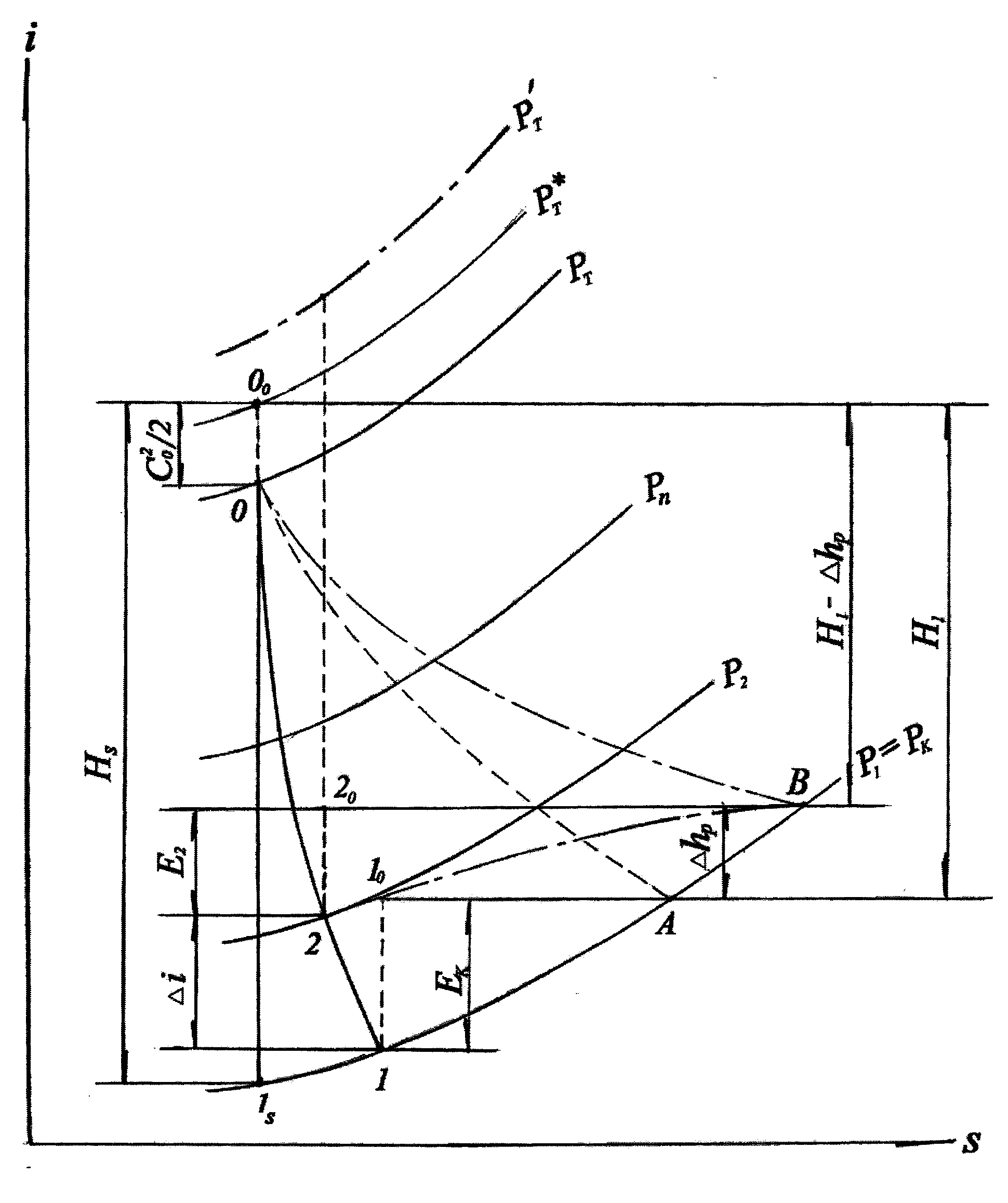

Embodiment 2

[0067] For medium and large vehicles / ships / stationary supercharged internal combustion engines designed according to the parameters of the rated working conditions of the internal combustion engine / selected with a turbocharger, in the medium and low speed conditions, the pressure will be between the amount of pressurized air supplied and the amount of fuel supplied. Serious mismatching occurs, resulting in too low supercharging pressure, insufficient supercharging air supply, low-speed torque reduction, poor combustion (black smoke), increased fuel consumption rate-the performance of the internal combustion engine is seriously deteriorated. The various schemes in the prior art to improve the performance of the low working condition cannot simply and effectively control the pre-vortex pressure P T Make a drop, but can't get out of trouble. However, the scheme of the present invention can easily pass through the ejection and suction effect of the gas ejector, causing the back pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com