Wind generating set inhaul cable type steel cylinder tower and steel cylinder replacing method

A technology for a wind turbine generator set and a replacement method is applied in the directions of wind energy generation, installation/support of wind turbine configuration, engine components, etc. Power generation revenue time, improvement of mechanical performance, saving effect of demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

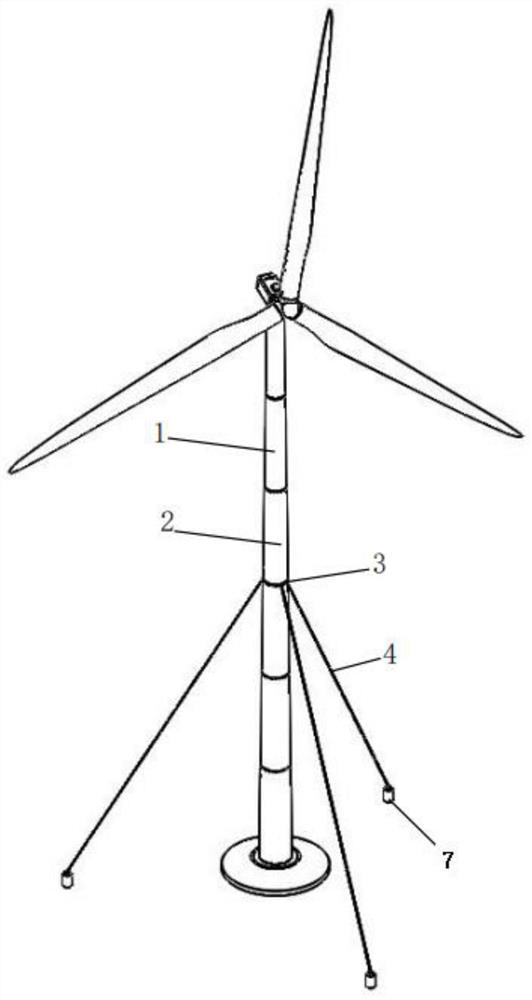

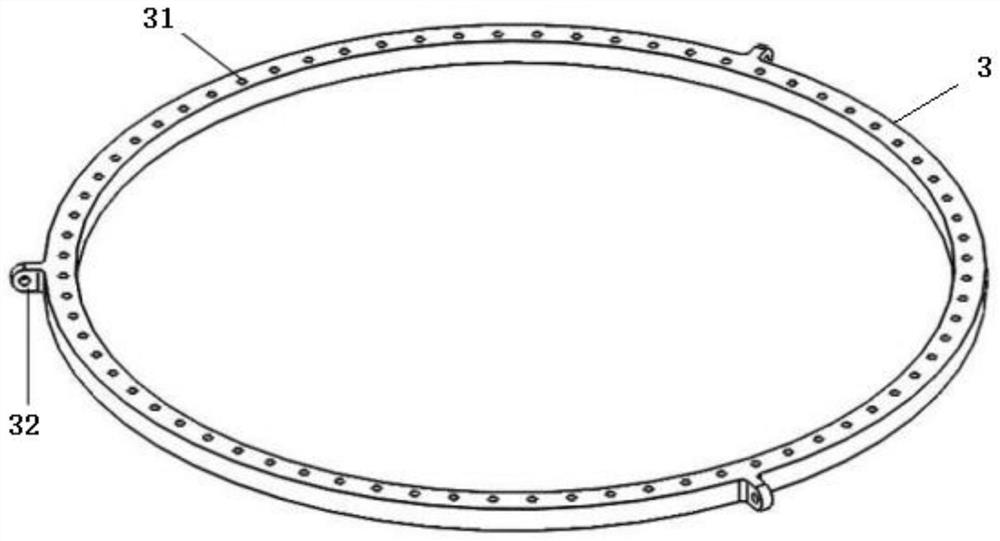

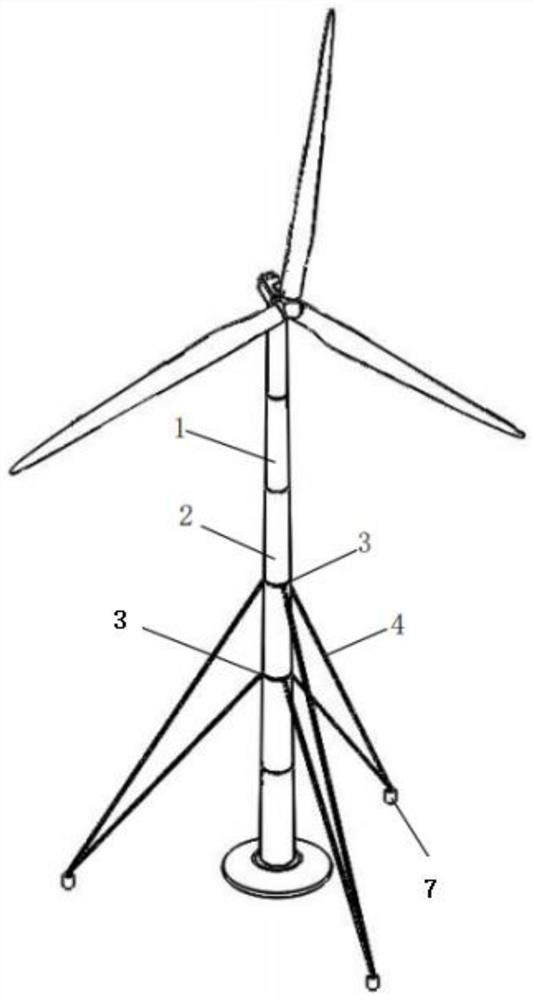

[0046] Such as figure 1 As shown, it is a structural schematic diagram of the cable-type steel cylinder tower of the wind power generating set in the present invention. Such as figure 2 Shown is a schematic structural view of the cable flange 3 in the present invention.

[0047] The cable-type steel tube tower of the wind power generating set includes: a tower tube section 1, a tower tube transition section 2, a cable flange 3, and a cable 4; the tower tube transition section 2 is provided with a tower tube transition section flange 21 at both ends, The flange 21 of the transition section of the tower is provided with flange bolt holes; the cable flange 3 is annular in shape, and is provided with a plurality of cable flange bolt holes 31 arranged in a circle, and a plurality of cable flange ears are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com