A kind of high thermal conductivity near-eutectic cast aluminum-silicon alloy material and production method

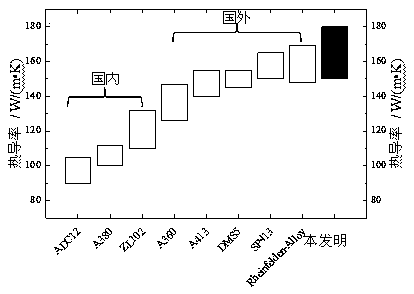

A technology of alloy material and production method, which is applied in the field of high thermal conductivity near-eutectic casting aluminum-silicon alloy material, can solve problems such as poor thermal conductivity, and achieve the advantages of eliminating casting stress, improving thermal conductivity, excellent casting performance and thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

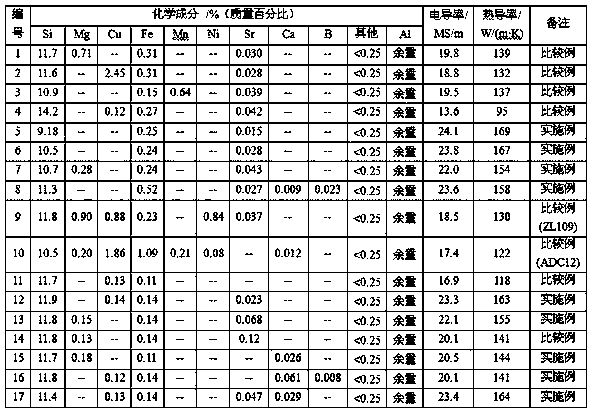

[0024] The beneficial effects of the present invention are further illustrated in conjunction with examples.

[0025] (1) Chemical composition control:

[0026] The high thermal conductivity near-eutectic cast aluminum-silicon alloy material of the present invention is a near-eutectic aluminum-silicon alloy, which contains at least one of the three components of Sr, Ca and B. Sr, Ca and B can effectively improve the performance of the aluminum alloy. The thermal conductivity of the material. In the alloy material of the present invention, Si 8.5~13%, Sr 0.005~0.1%, Ca 0.001~0.1%, B 0.001~0.1%, Fe less than 0.7%, Mg less than 0.5%, Cu less than 0.3% %, containing less than 0.1% of Mn, less than 0.1% of Ti, less than 0.05% of other single impurity elements, less than 0.25% in total, and the rest are Al and unavoidable impurities. The foregoing percentages are all percentages by mass.

[0027] The composition contained in the alloy material of the present invention can be any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com