A kind of cobalt nickel extraction separation method that reduces co-extraction

A separation method and extraction technology, which is applied in the field of cobalt and nickel separation and recovery, can solve the problems of reduced cobalt and nickel separation efficiency, reduced nickel co-extraction, and reduced co-extraction, so as to reduce co-extraction phenomenon, improve extraction and separation efficiency, and reduce co-extraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The steps of the separation method of the present embodiment are as follows:

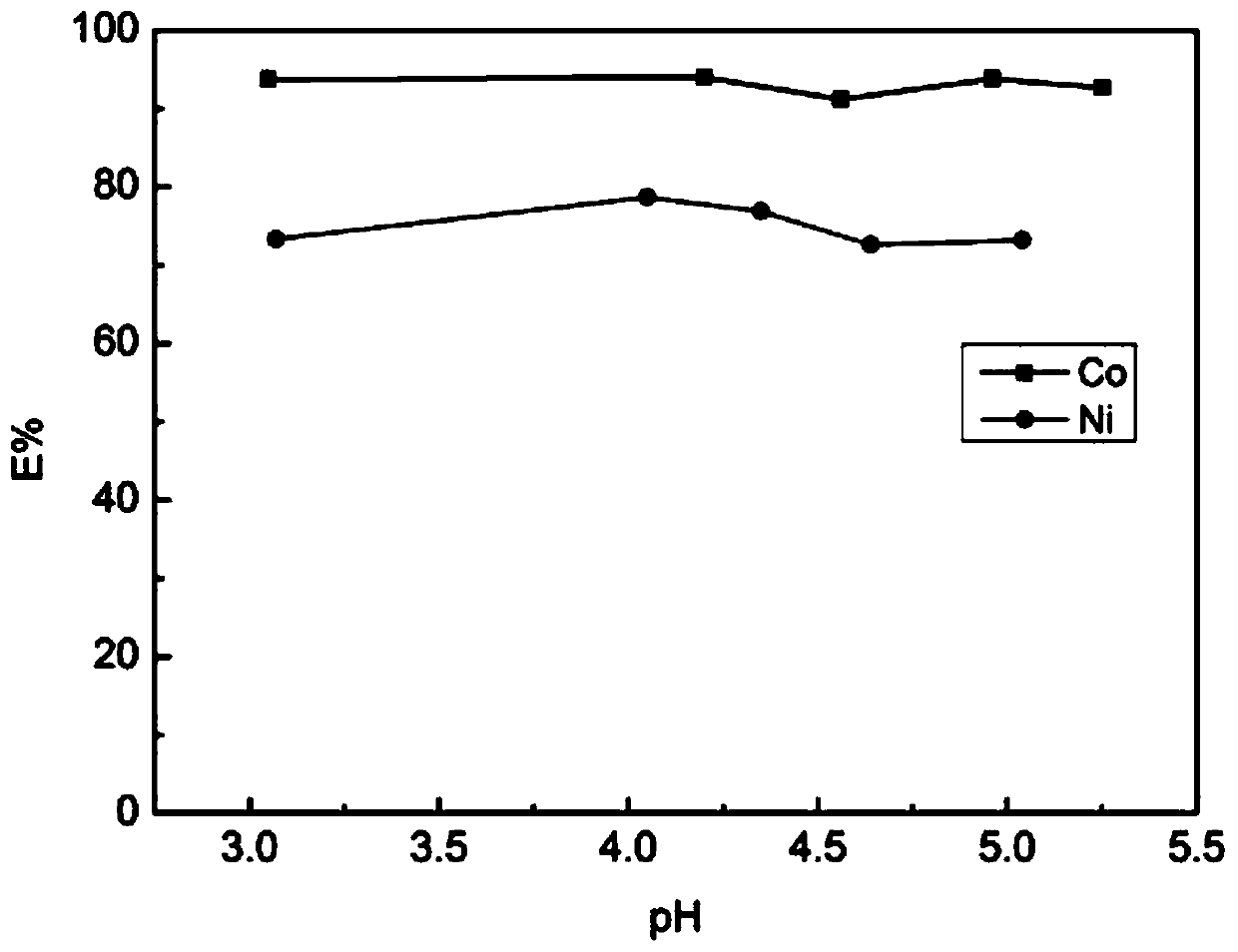

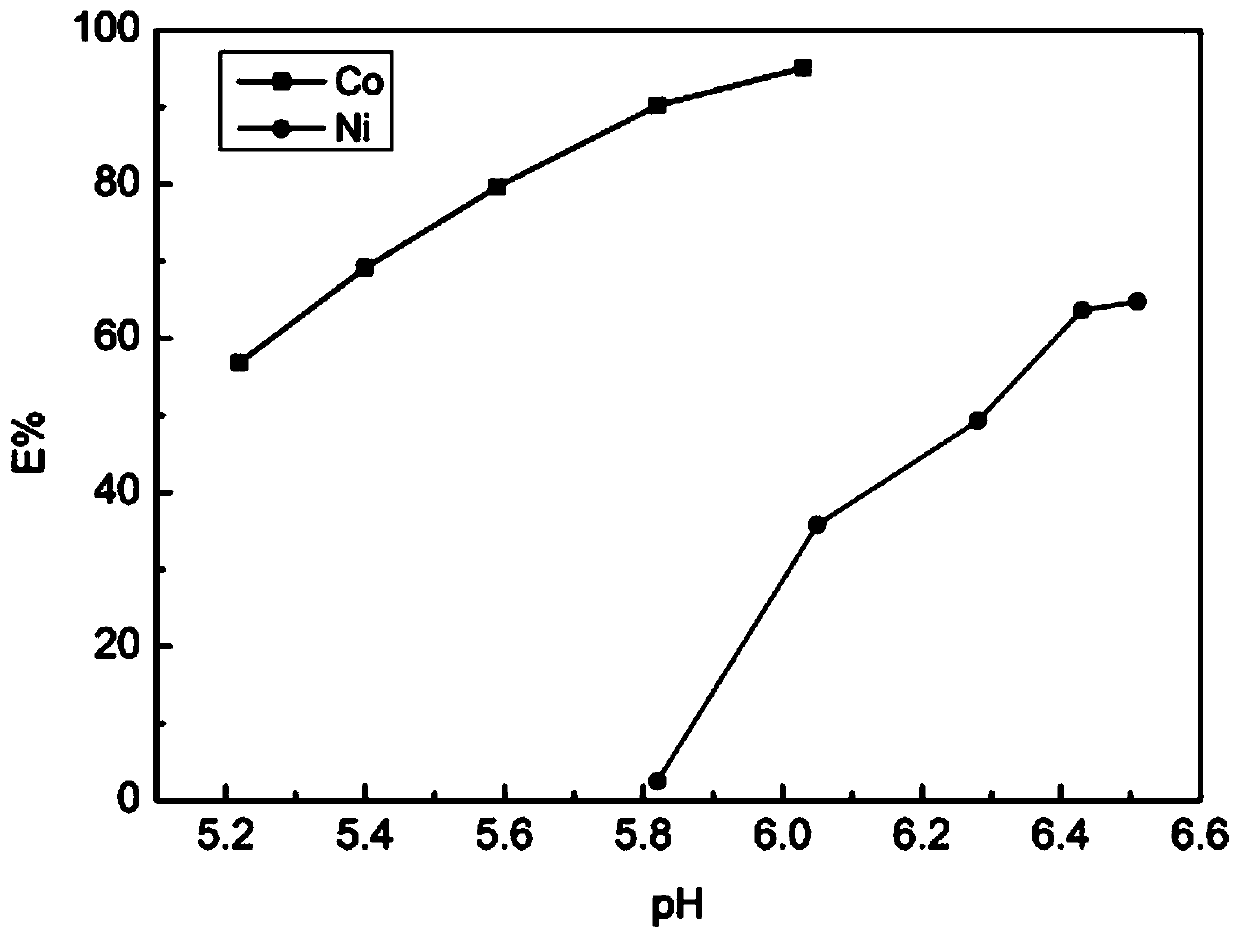

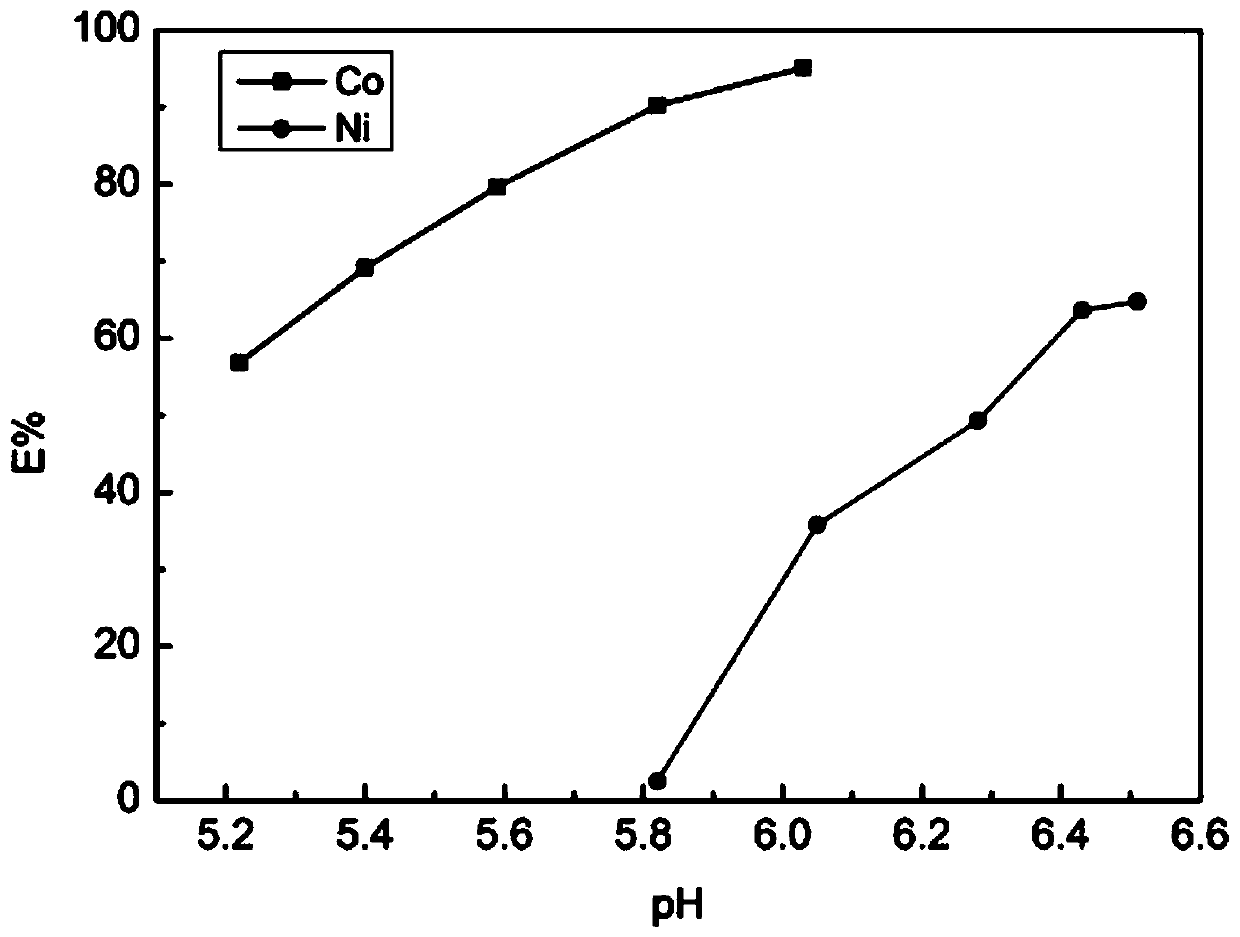

[0057] (1) Extraction of cobalt in sulfuric acid leaching solution

[0058] The concentration of cobalt and nickel in the sulfuric acid leaching solution of the positive electrode material of lithium ion battery is 17.10g / L and 4.53g / L respectively. First adjust the pH to 4.0~4.5 with sodium hydroxide, filter to remove trace impurities, and then adjust with glacial acetic acid and sodium hydroxide The pH of the leaching solution was adjusted to 5.2 (n(Co):n(acetic acid)=1:34.5), while the leaching solution was diluted 5 times. Extraction with 0.4mol / L P507 with a saponification rate of 70%, O / A ratio of 1:1, 25°C, rotating speed of 150 rpm, shaking extraction for 15min, cobalt and nickel in the raffinate (water phase) The content of 0.10g / L and 0.82g / L respectively, equilibrium pH=5.45, ΔpH=0.25, the primary extraction efficiency of cobalt and nickel were 97.0% and 9.49%, respectively.

[0...

Embodiment 2

[0065] The steps of the separation method of the present embodiment are as follows:

[0066] (1) Extraction of cobalt in sulfuric acid leaching solution

[0067] The concentration of cobalt and nickel in the sulfuric acid leaching solution of the cathode material of lithium ion battery is 16.40g / L and 4.85g / L, respectively, and the pH of the leaching solution is adjusted to 5.4 with glacial acetic acid and sodium hydroxide (n(Co):n(acetic acid)=1:38 ), at the same time the leachate was diluted 5 times, extracted with 0.4mol / L P507 with a saponification rate of 62%, compared to O / A of 1:1, 25°C, rotating speed 150 rpm / min, shaken for 15min extraction, raffinate The content of cobalt and nickel in (aqueous phase) were 0.12g / L and 0.89g / L, respectively, the equilibrium pH=5.58, ΔpH=0.18, and the primary extraction efficiencies of cobalt and nickel were 96.34% and 8.25%, respectively.

[0068] Under the same extraction conditions as above, the raffinate was extracted for the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com