Method for improving granularity and purity of chemical salt byproducts of acrid bittern

A technology of by-product salt and bittern, which is applied in the field of salt production, can solve the problems of fine particle size, high impurity content, and different quality of by-product salt products, and achieve the effect of improving quality and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

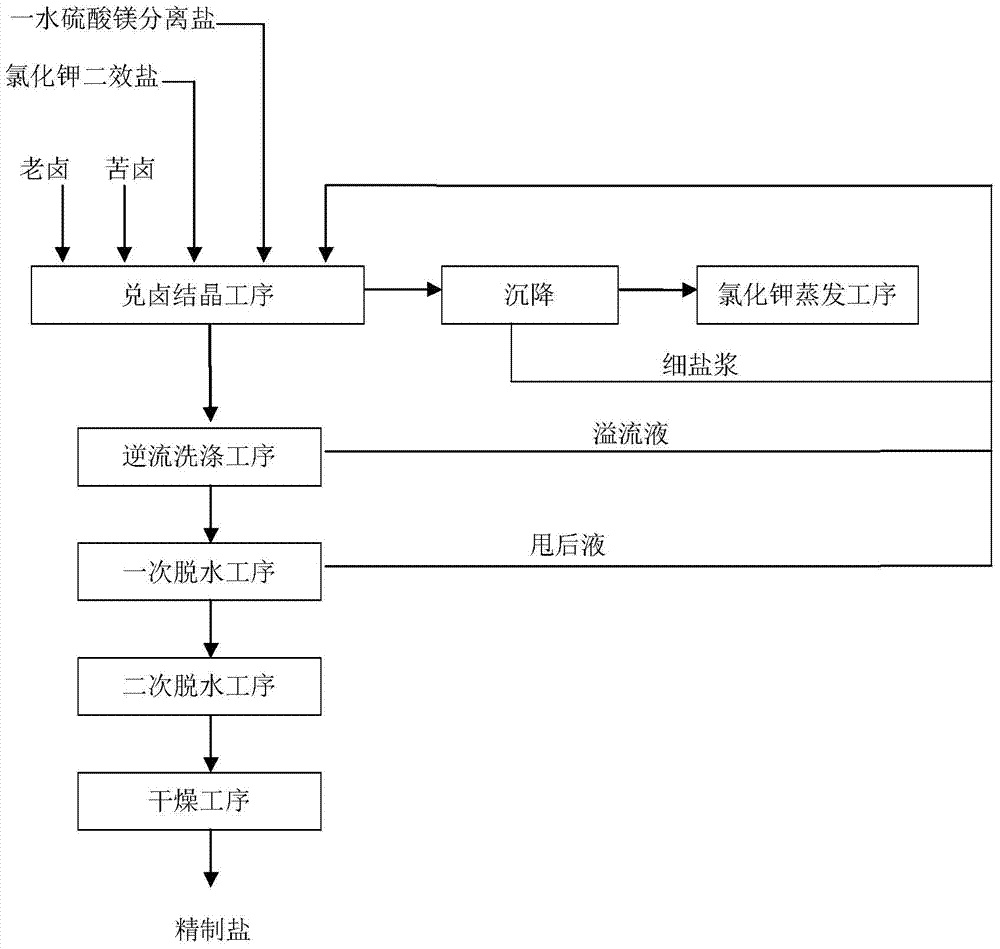

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] A method for improving the granularity and purity of bittern chemical by-product salt is carried out sequentially according to the following steps:

[0018] (1) In the brine-mixing crystallization process, the separated salt produced in the separation process in the production process of magnesium sulfate monohydrate and the two-effect salt discharged from the potassium chloride two-effect evaporator are added to the brine-blending crystallizer as crystal seeds, and then Add bitter bittern, the mother liquor of salt making, and old bittern, the mother liquor of potassium chloride, to blend and mix evenly. The mixed brine overflowed from the brine crystallizer is discharged into the settler for sedimentation and clarification, the bitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com