Washing machine control method and washing machine

A control method and washing machine technology, applied in the field of washing machines, can solve the problems of inaccurate detection, waste of energy, inconvenient control, etc., and achieve the effects of high detection accuracy, high degree of automation, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

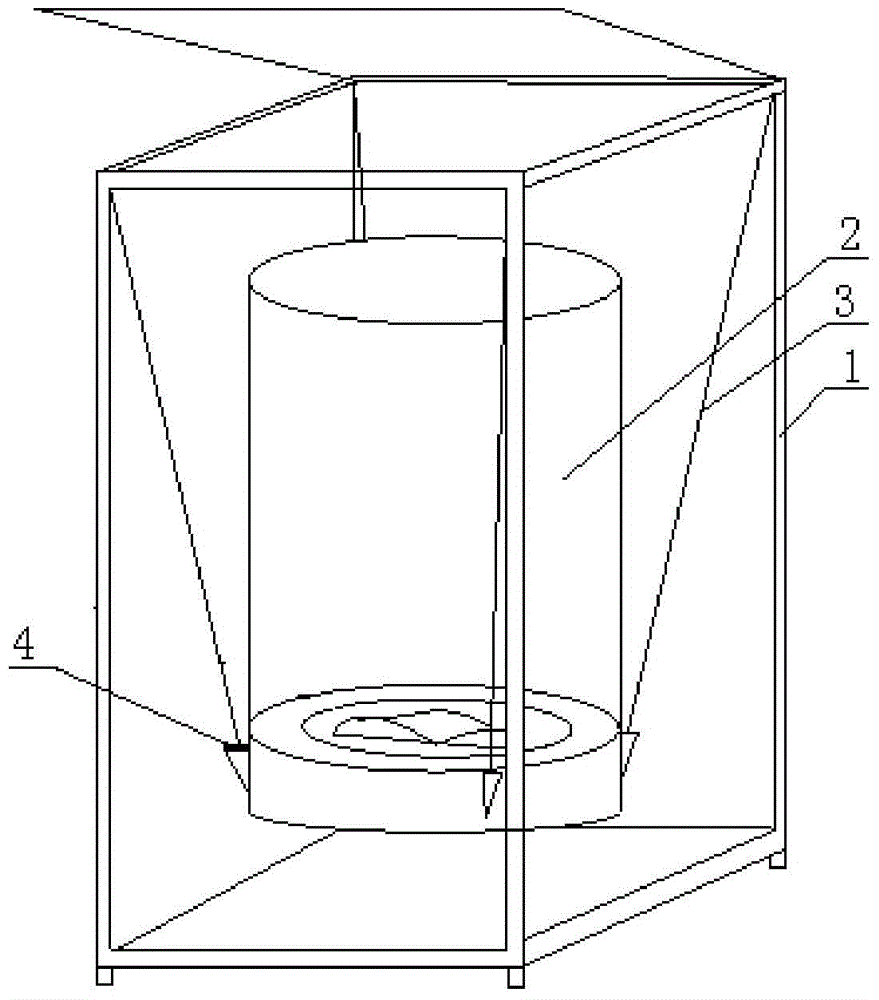

[0030] figure 1 It is a structural schematic diagram of the washing machine provided in this embodiment. As shown in the figure, the washing machine includes an outer shell 1 and an inner tub 2 disposed inside the outer shell 1 , a suspender 3 is connected to the inner tub 2 , and a pull pressure sensor 4 is arranged at the bottom of the suspender 3 .

[0031] Wherein the pull pressure sensor 4 also can be arranged on the foot of washing machine.

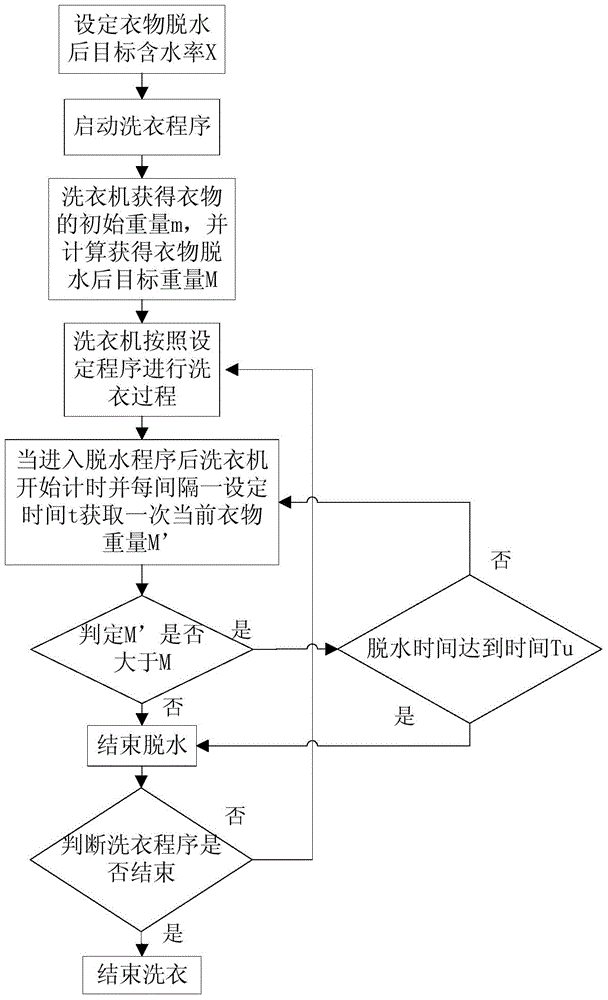

[0032] For the above-mentioned washing machine, this embodiment also provides a washing machine control method, the flow chart of which is as follows figure 2 shown. The control method is specifically:

[0033] Step A. The user sets the moisture content X to be achieved after the clothes are dehydrated through the control panel of the washing machine. For example, the user can select different dehydration levels on the control panel of the washing machine, such as gentle dehydration, normal dehydration, severe dehydration, etc.,...

Embodiment 2

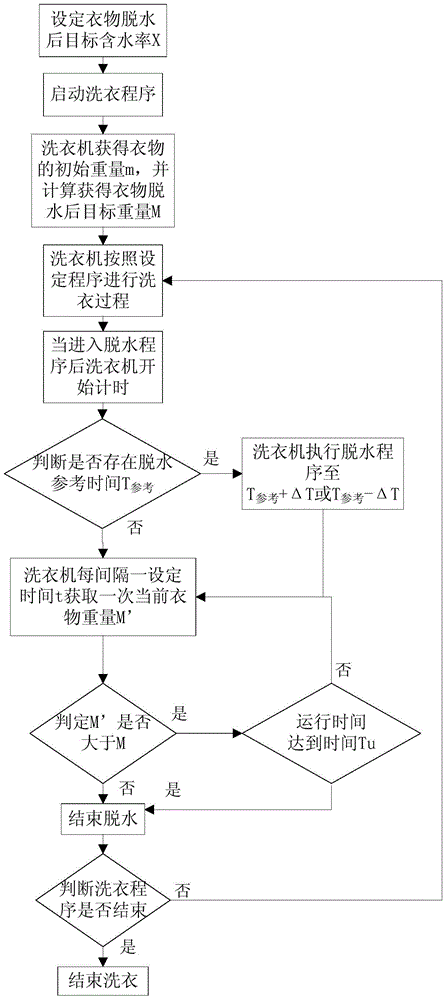

[0043] This embodiment provides a washing machine and a control method thereof, and the structure of the washing machine is the same as that of the first embodiment. The flow chart of its control method is as follows: image 3 As shown, the control method is specifically:

[0044]Step A. The user sets the moisture content X to be achieved after the clothes are dehydrated through the control panel of the washing machine. For example, the user can select different dehydration levels on the control panel of the washing machine, such as gentle dehydration, normal dehydration, severe dehydration, etc., each The dehydration level corresponds to the moisture content X to be achieved after dehydration of different clothes, or the user can input the moisture content X to be achieved after dehydration of the clothes on the control panel, such as 5%, 10%, 15%, etc.

[0045] Step B, start the laundry program, the washing machine obtains the initial weight m of the clothes in the inner tu...

Embodiment 3

[0056] This embodiment provides a washing machine and a control method thereof. This washing machine structure is identical with embodiment one, and its control method is specifically as follows:

[0057] Step A. There are multiple dehydration levels pre-stored in the washing machine, and each dehydration level corresponds to a range of moisture content. If the first level is pre-stored, the corresponding moisture content range is [X 1 , X 2 ), the second level, its corresponding water content range is [X 2 , X 3 ), the third grade, its corresponding water content range is [X 3 , X 4 ), can also be divided into mild dehydration, normal dehydration, severe dehydration and so on.

[0058] Step B. The user selects the dehydration level to be achieved after the clothes are dehydrated through the control panel of the washing machine, and obtains the corresponding moisture content range [X a , X b ).

[0059] Step C, start the laundry program, the washing machine obtains the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com