Crude oil dehydration device with ultrasonic wave and electric field and dehydration method

A crude oil dehydration and dehydration device technology, which is used in electrical/magnetic dehydration/demulsification, mechanical dehydration/demulsification, petroleum industry, etc. The quality cannot meet the industrial requirements and other problems, so as to achieve the effect of improving the dehydration efficiency, breaking through the limitations and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

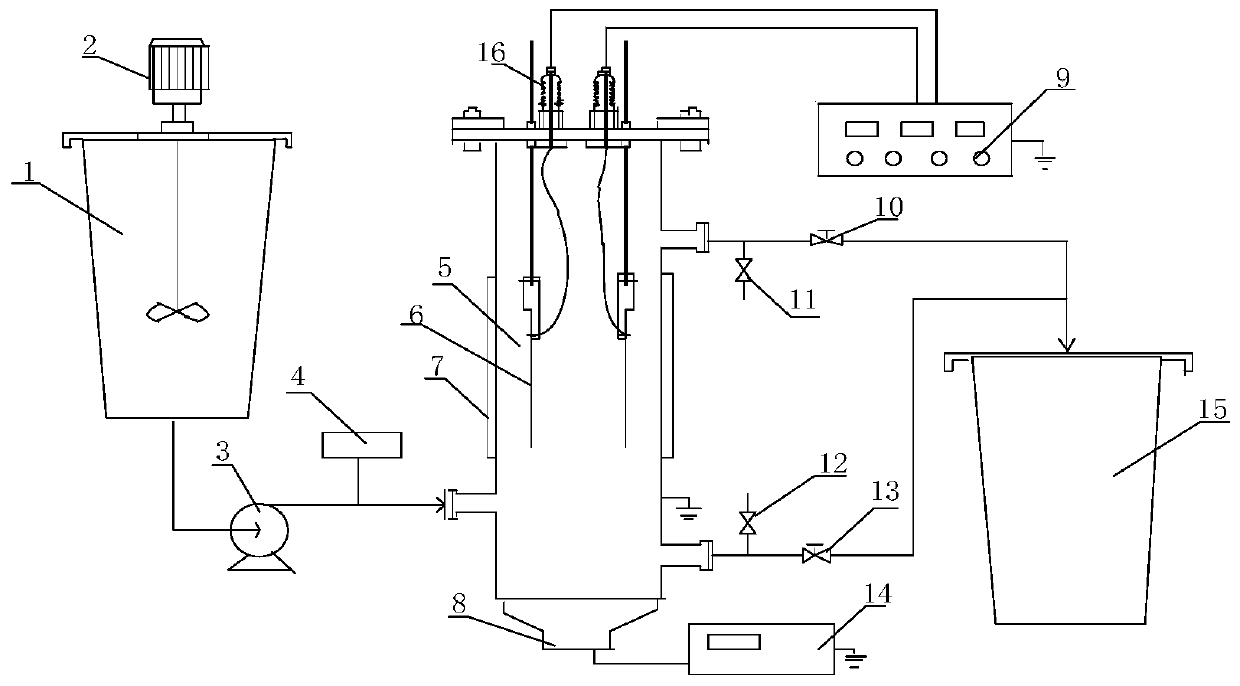

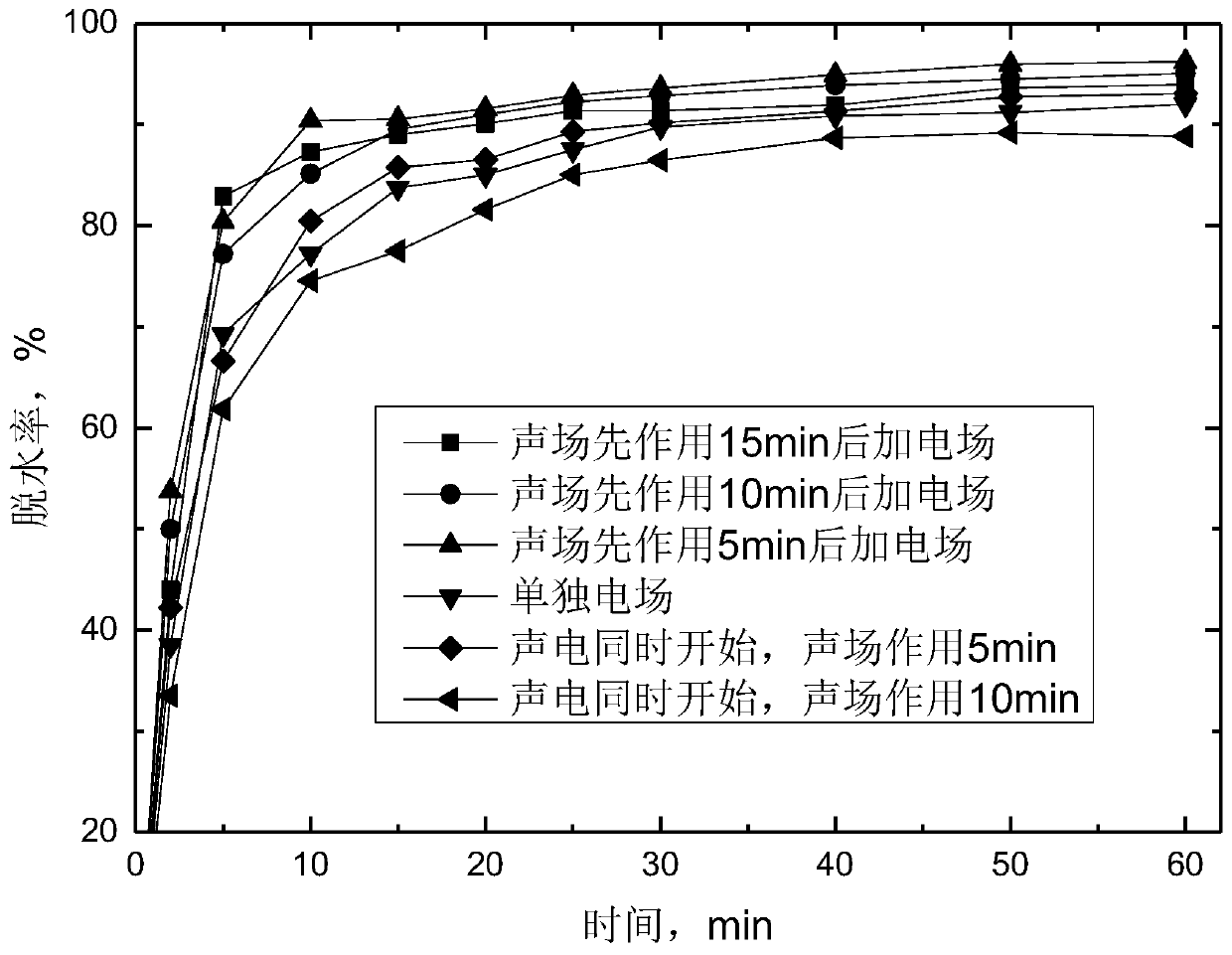

[0042] figure 1 It shows a crude oil dehydration device combined with ultrasonic and electric field according to an embodiment of the present invention. This figure and other included Figure 1 The descriptions are illustrative only and do not limit the possible embodiments or the claims of the invention.

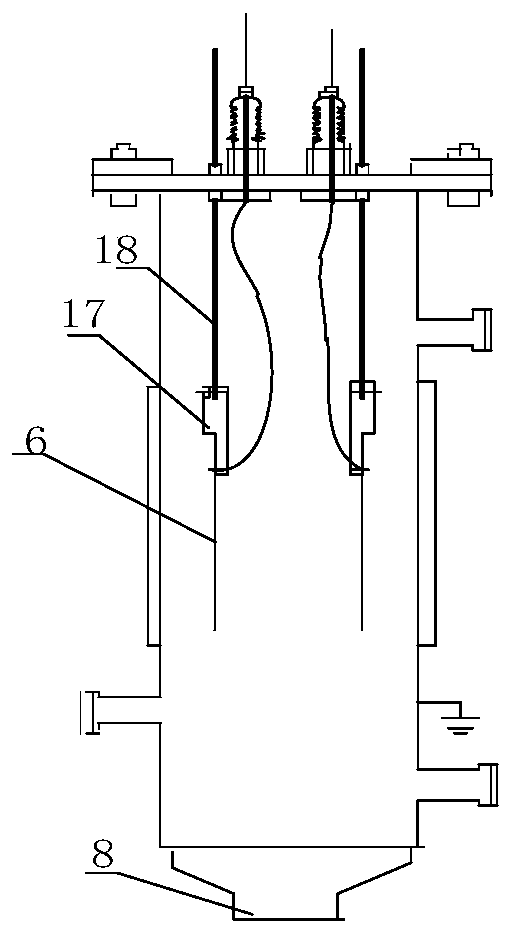

[0043] Depend on figure 1 It can be seen that this embodiment includes an emulsification blending tank, a dehydration tank and a waste liquid tank arranged in sequence along the oil flow direction. The crude oil emulsion is fully emulsified and sheared by the emulsification blending tank and then pumped into the dehydration tank from the oil inlet on the lower left of the dehydration tank. In the tank, after ultrasonic and electric field treatment for a certain period of time, it is discharged into the waste liquid tank through the water outlet and oil outlet on the right side of the tank.

[0044] Among them, the emulsification blending tank is equipped with a high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com