Environment-friendly energy-saving chip water-scrubbing process and production line apparatus

A production line equipment, environmental protection and energy-saving technology, applied in the field of wood chip cleaning, can solve the problems of unclean slag-water separation, water waste, waste water discharge, etc., and achieve the effect of solving high production cost, low production cost and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

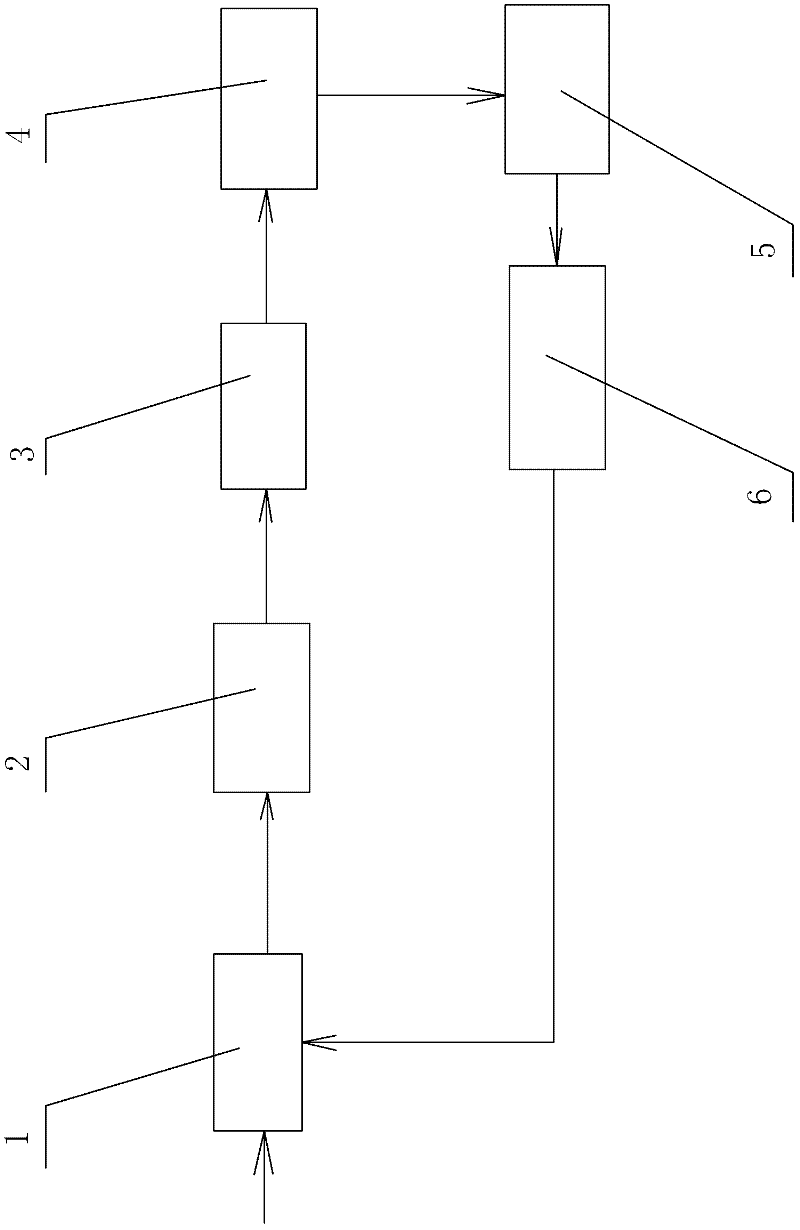

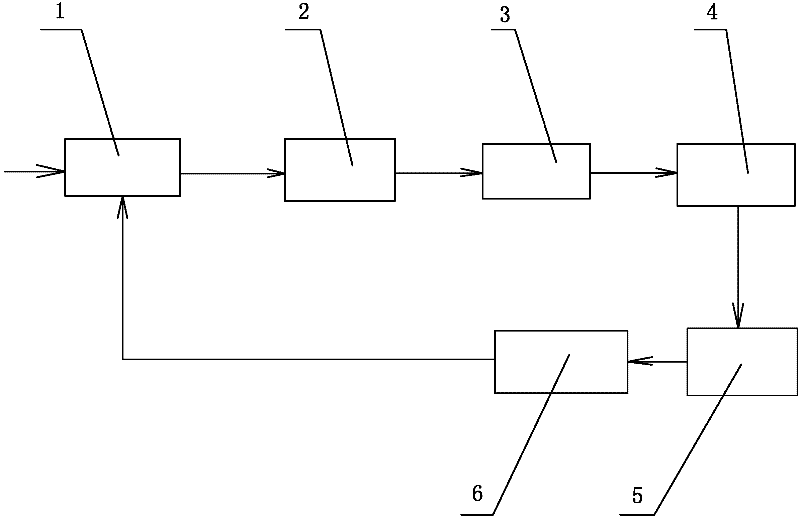

[0024] The environmental-friendly and energy-saving wood chip water washing process of the present invention includes the following steps:

[0025] 1. The wood chips are transported to the washing machine 1 through the conveying equipment for washing process. The wood chips are initially separated from the heavy objects in the washing machine 1, and the heavy objects such as stones and iron are discharged outside.

[0026] 2. Water and wood chips enter the dehydration screw machine 2, and the dehydration process is carried out in the dehydration screw machine 2, and the dehydrated wood chips enter the hot abrasive bin to wait for grinding.

[0027] 3. The slag-water separation process for the water, sediment, and fine suspended matter discharged from the 2-hole plate of the dehydration screw machine has three steps:

[0028] (1) Separating suspended solids and coarse slag with rotary grille 3.

[0029] (2), sedimentation silt with hydrocyclone tank 4.

[0030] (3), filter wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com