Bentonite inorganic gel for washing powder and preparation method thereof

A technology of inorganic gel and bentonite, which is applied in the field of daily cleaning products, can solve the problems of difficulty in reflecting bentonite, low preparation efficiency, poor dispersing and dissolving properties, etc., and achieves excellent adsorption and cation exchange performance. The effect of dirt

Active Publication Date: 2022-06-03

苏州中材非金属矿工业设计研究院有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Yet there is following technical problem in above-mentioned technical scheme: (1) the concentration in the bentonite aqueous solution in its preparation method is relatively low, so the amount of the modified bentonite product that obtains in follow-up centrifugation, getting upper layer slurry, drying step is relatively few , the preparation efficiency is low, so the cost is high; this is very fatal for the washing powder additives in the fast-moving consumer goods industry; (2) due to the low concentration in the bentonite aqueous solution in its preparation method, the final The purity of modified bentonite products is low, so it is difficult to reflect the advantages of bentonite itself. In addition, due to the synergistic blending of modified siloxane and modified bentonite, the soft function is mainly reflected by modified polysiloxane. And the cost of modified polysiloxane is much higher than the cost of modified bentonite, and finally the cost of soft and functional particles has also been increased; (3) because modified bentonite is in the state of particles (particles), there are The problem of dispersibility and solubility, although it improves the dispersion and solubility of particles in water through sodium citrate, but its own dispersion and solubility are poor, and still need to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0054]

[0057]

Embodiment 2

[0079]

[0082]

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

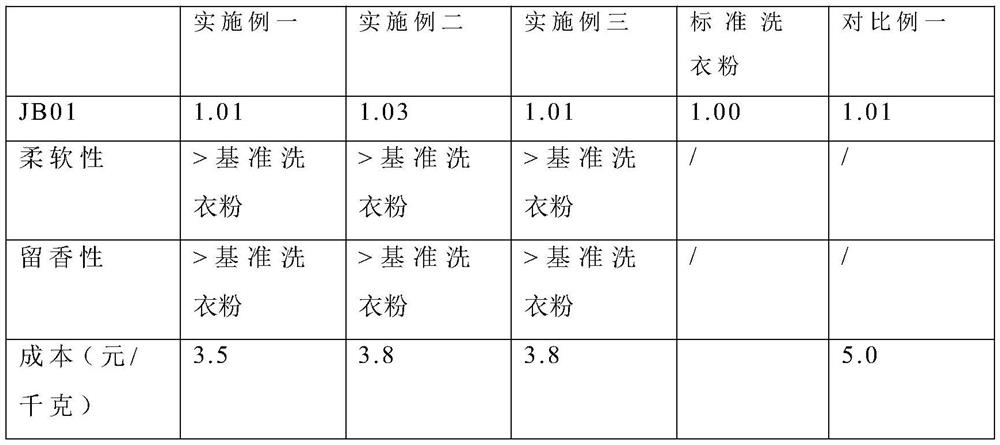

The invention discloses a preparation method of bentonite inorganic gel used in washing powder, comprising the following steps: (1) crushing to obtain bentonite particles; (2) fully dispersing the bentonite to obtain pulp A; (3) centrifuging the pulp A Separation and purification treatment to obtain slurry B; (4) adding inorganic salt to slurry B for sufficient modification to obtain viscous slurry C; (5) drying. The present invention not only can obtain high-purity and high-whiteness products, but also greatly improves the preparation efficiency and saves costs. The experiment proves that compared with the Chinese invention patent application CN108004054A, the cost is saved by about 25%, and a remarkable effect has been achieved; at the same time, The products of the present invention have better stain removal and softening properties.

Description

Bentonite inorganic gel for washing powder and preparation method thereof technical field The present invention relates to a kind of bentonite inorganic gel that is used for washing powder and preparation method thereof, belongs to daily washing articles technical field. Background technique [0002] At present, the vast majority of domestic washing powders use anionic surfactants as the main active substance. and supple The agent is mainly a cationic surfactant. Therefore, the existing washing powder (or washing liquid, detergent) and softener cannot be Otherwise, the anionic and cationic surfactants will react and cause the washing powder to fail. At present, people basically use laundry Machine to wash clothes, washing powder and softener cannot be added at the same time, which brings great trouble to the washing process. On the other hand, my country's bentonite resources are rich in species, and the reserves are huge, due to the unique nano-level layered stru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09C1/42C09C3/04C09C3/06C09C3/10C01B33/40C11D3/12C11D3/10C11D3/37C11D3/60C11D17/06

CPCC09C1/42C09C3/006C09C3/04C09C3/043C09C3/06C09C3/10C01B33/40C11D3/001C11D3/126C11D3/10C11D3/3761C11D17/06C01P2006/60C11D2111/12

Inventor 雷东升

Owner 苏州中材非金属矿工业设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com