Connecting structure for washing cabins in tunnel washing machine

A technology for connecting structures and washing chambers, which is applied to washing devices, other washing machines, textiles and papermaking, etc., which can solve the problems of increasing the difficulty of transportation and on-site installation, wasting manpower and material resources, and long self-aligning platforms, so as to save manpower and Material resources, easy installation, and the effect of meeting the washing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

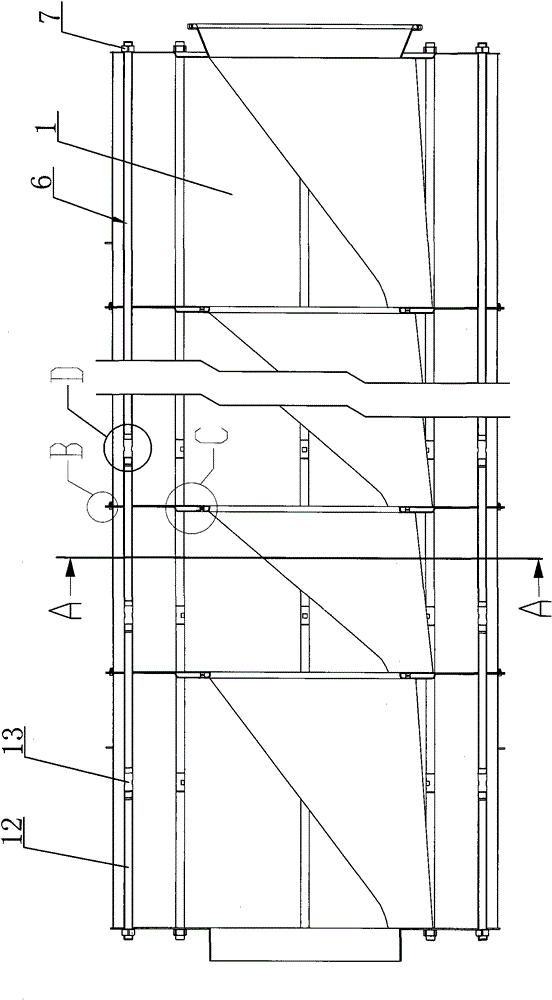

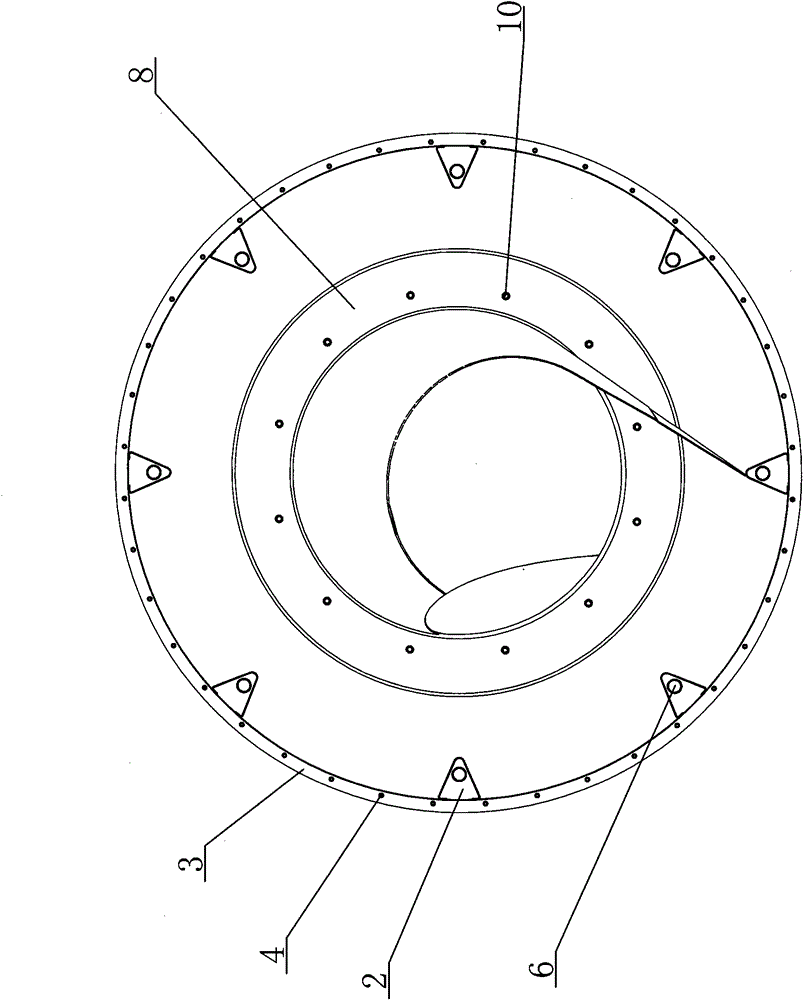

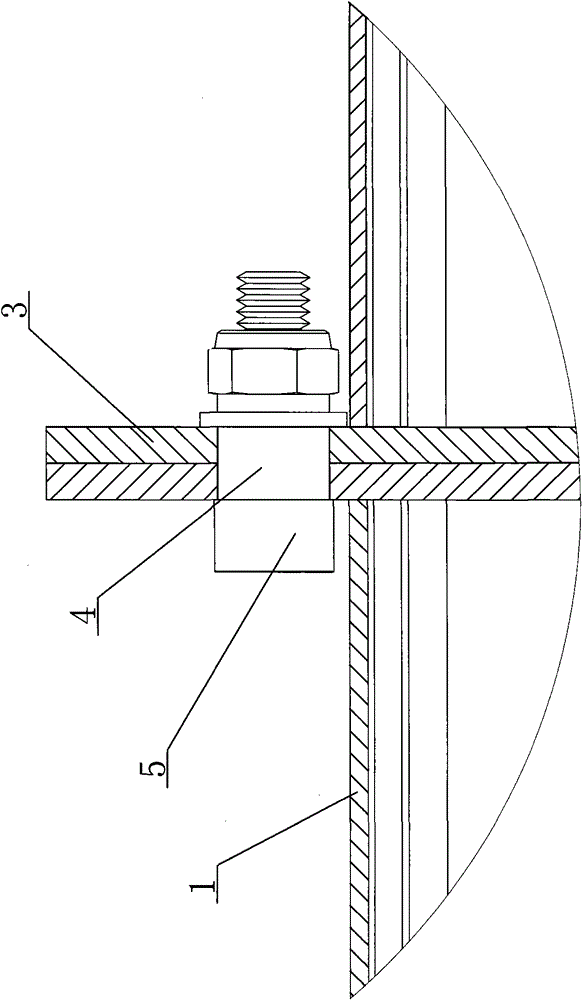

[0014] Such as figure 1 , figure 2 As shown, the connection structure of the washing chamber in the tunnel washing machine includes: several washing chambers 1, and several V-shaped ribs 2 are uniformly arranged on the inner drum wall of the washing chamber 1. Such as image 3 As shown, outer flanges 3 are respectively provided on the sides of the adjacent washing bins 1 that cooperate with each other, and bolt holes 4 that cooperate with each other are respectively provided on the outer flanges 3, and bolt holes 4 that cooperate with each other are provided in the bolt holes 4. Cooperating bolts 5 . Such as figure 1 , figure 2 As shown, the V-shaped ribs 2 are respectively provided with a number of mounting holes that cooperate with each other, and a connecting rod 6 that cooperates with it is provided in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com