Dewatering process of washing machine

A washing machine and laundry technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve problems such as large vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

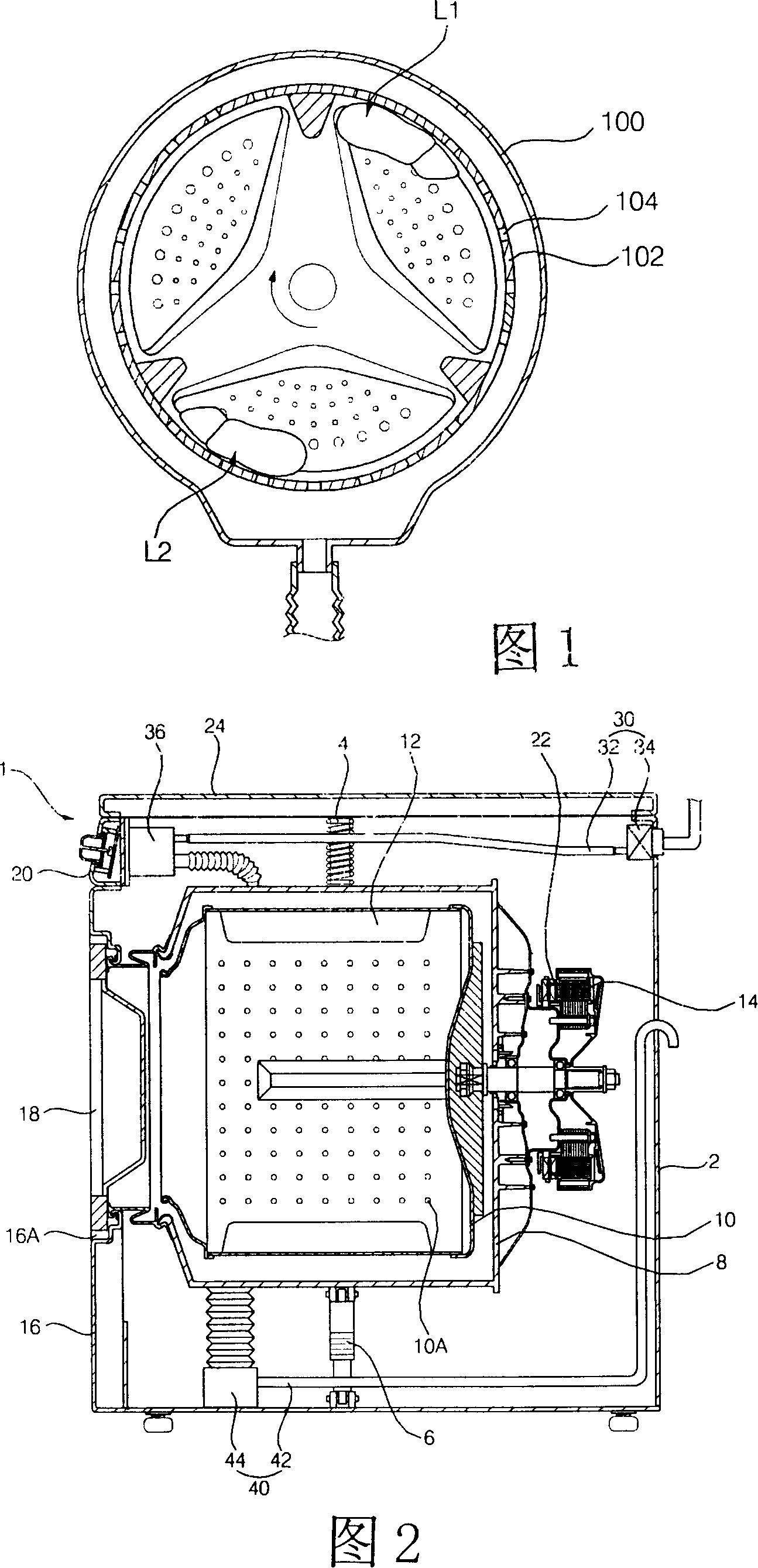

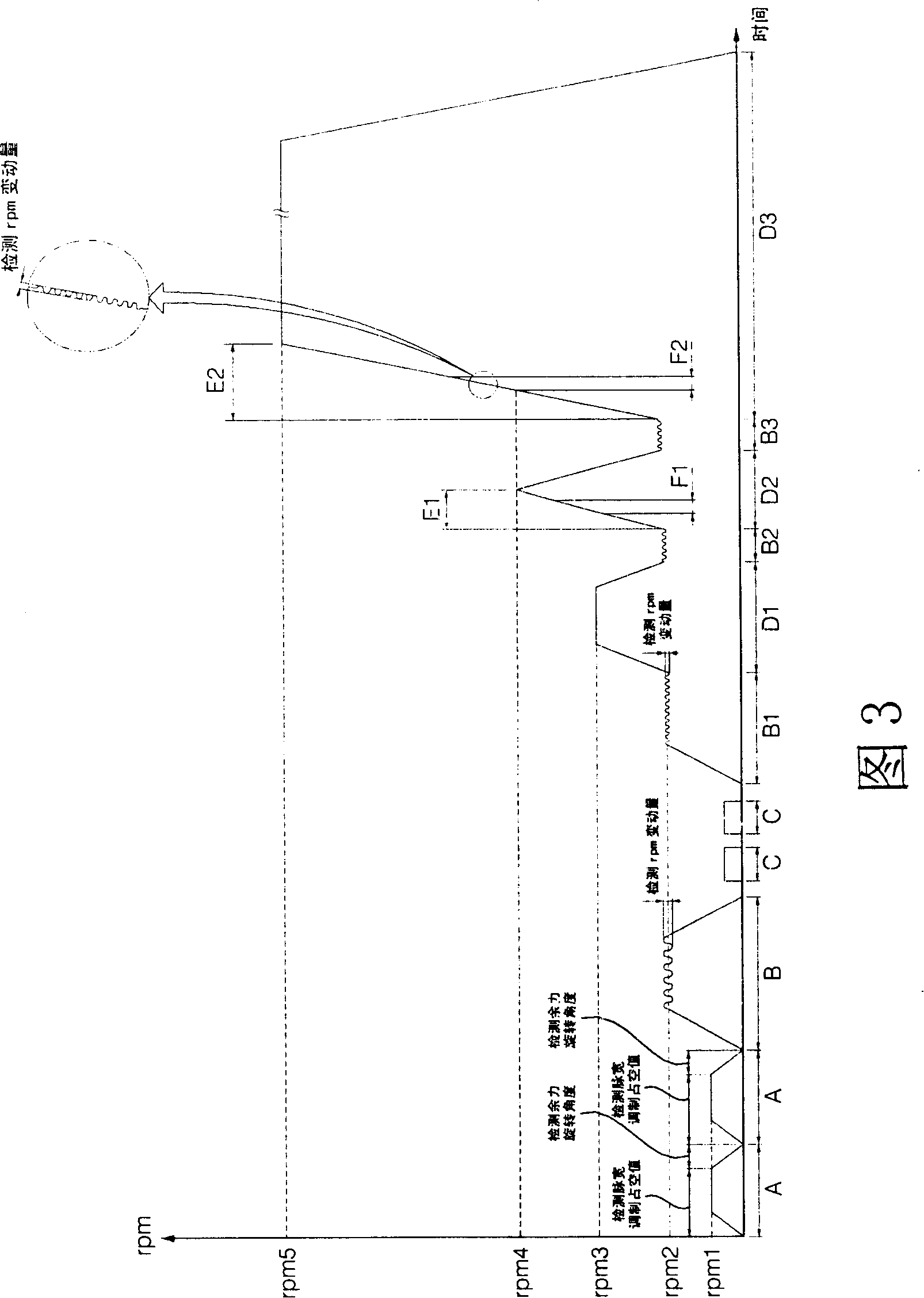

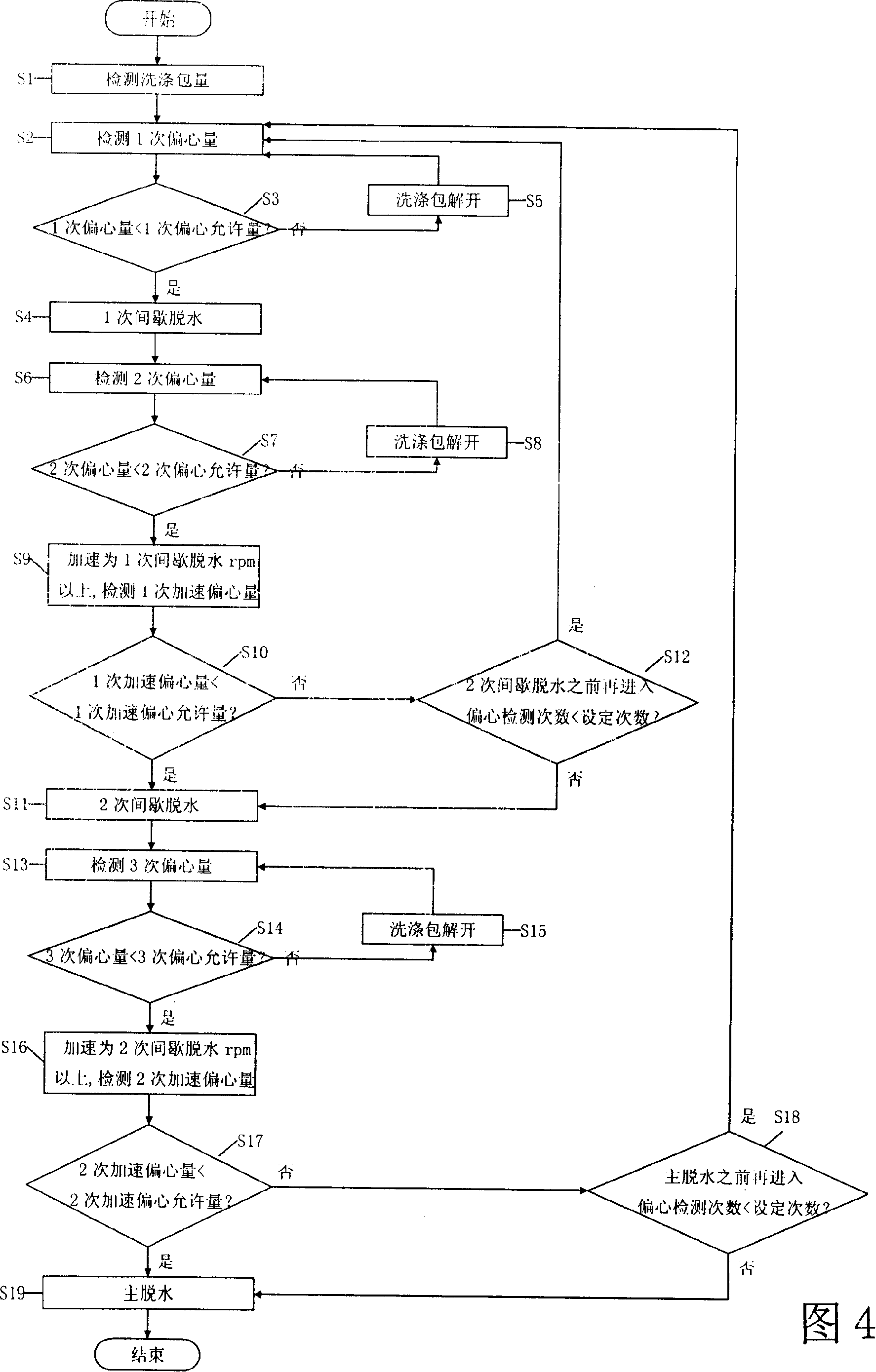

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0039] Fig. 2 is a sectional view of the structure of the drum washing machine in the present invention.

[0040]As shown in Figure 2, the drum washing machine in the present invention includes the following parts: a housing 2 that forms the appearance of the drum washing machine 1; inside the housing 2, it is buffered and supported by a spring 4 and a shock absorber 6 , and a washing tub 8 that can accommodate washing water inside; it is rotatably installed on the inside of the washing tub 8, and is formed with a plurality of water holes 10A through which the washing water passes, and a drum 10 that can accommodate laundry inside; Installed on the inner surface of the above-mentioned drum 10, in order to make the laundry fall by gravity when the above-mentioned drum 10 rotates, and lift the laundry to a certain height Lifting device 12; installed on the rear part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com