Device for detecting performances of electromagnetic valves and weft stop pins

A solenoid valve and weft stop pin technology is applied in the field of devices for detecting the performance of the solenoid valve and the weft stop pin, which can solve the problems affecting the normal operation and production efficiency of an air-jet loom that affect product quality, affecting the opening efficiency of the air-jet loom, and the effects of the air-jet loom. Illegal parking and other problems, to achieve the effect of improving detection efficiency and reliability, convenient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

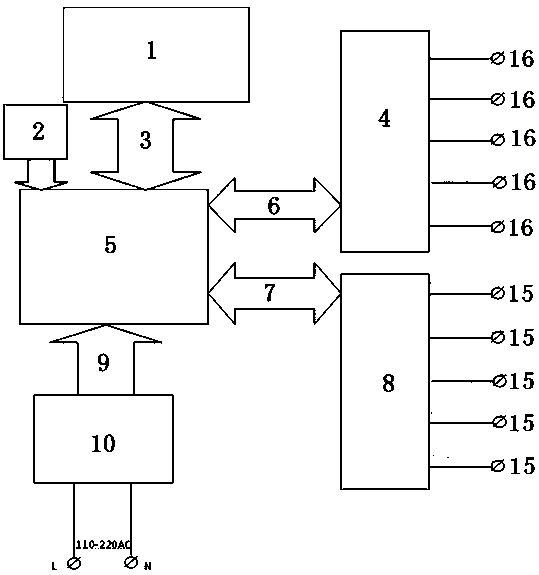

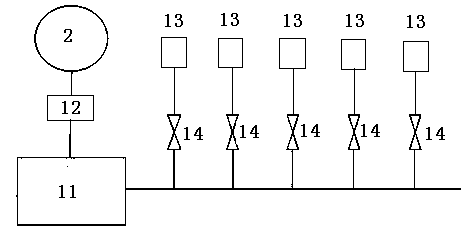

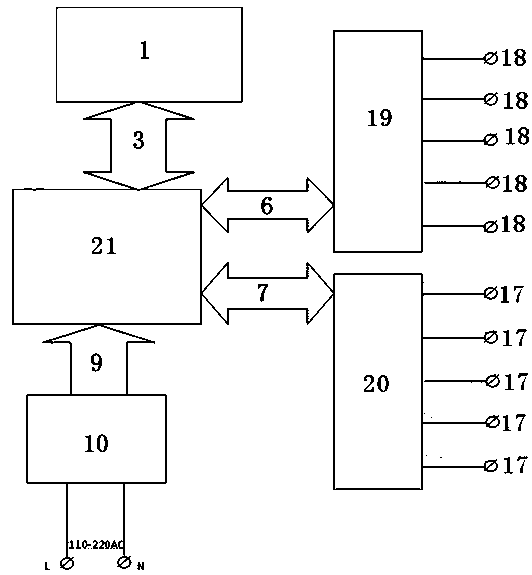

[0017] Such as figure 1 , figure 2 As shown, the gas outlet side of the gas source 11 of the present invention is connected with the digital pressure gauge 2 through the pressure reducing valve 12, the gas outlet side of the gas source 11 communicates with the inlet of the valve 14, and the gas outlet of the valve 14 is connected with the solenoid valve 13, and the solenoid valve 13 gas outlets are connected with sensor circuit one 8 by air pressure sensor 15, the output end one 16 of drive circuit one 4 is connected with the driving coil of solenoid valve 13, and drive circuit one 4 drives solenoid valve 13 work; Described drive circuit one 4 passes through Power supply and control line one 6 are connected with control circuit 5, sensing circuit one 8 is connected with control circuit one 5 through power supply and control line two 7, control circuit one 5 is connected with touch display screen 1 with data line 3, control circuit one 5 Connect with the switching power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com