Method for detecting basic lanthanum carbonate impurities in lanthanum carbonate raw material or preparation thereof in solid state

A technology of lanthanum carbonate and lanthanum carbonate, which is applied in the field of analytical chemistry and can solve problems such as the inability to analyze and detect lanthanum carbonate degradation impurity lanthanum carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

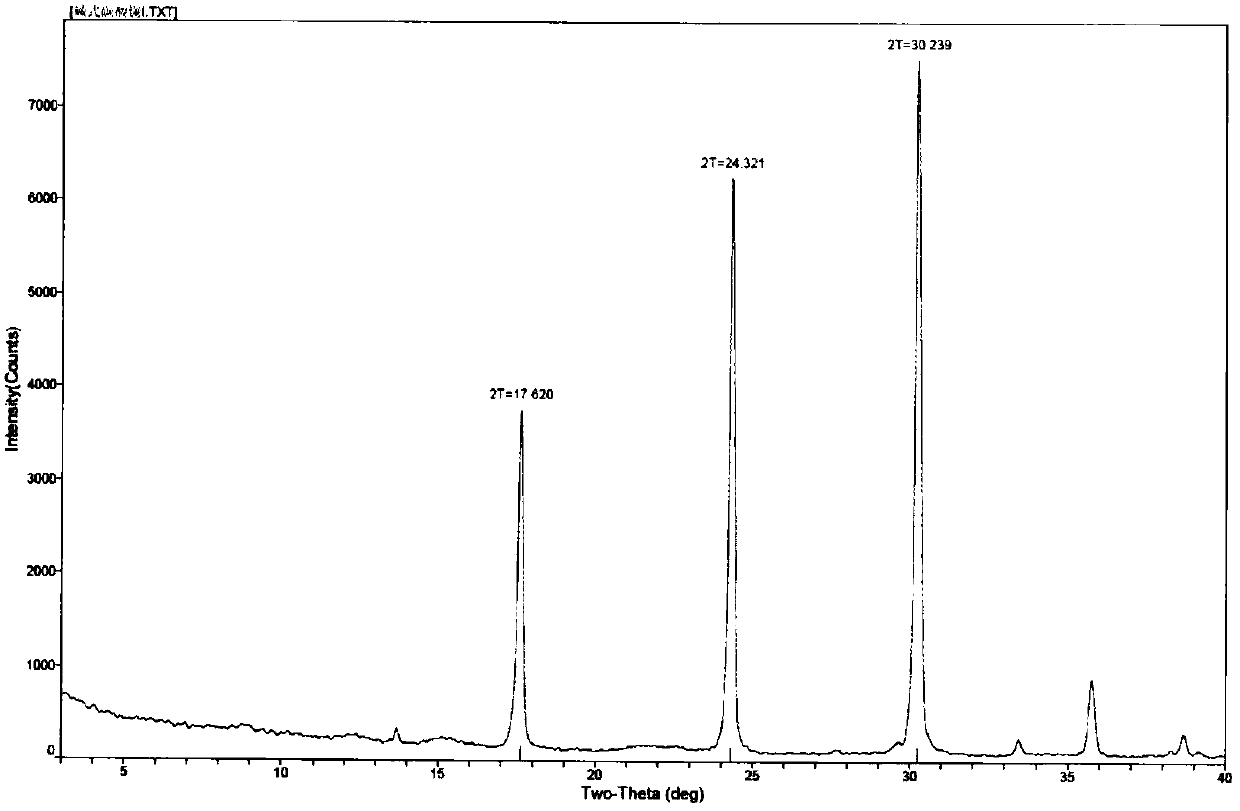

[0086] specificity test

[0087] Instrument test conditions: Rigaku D / max-rA X-ray diffractometer, using Cu Kα target, tube pressure and tube flow are 40KV and 100mA respectively; divergence slit and anti-scatter slit are 1°, receiving slit is 0.30mm , the detector is a sodium iodide scintillation counter, θ-2θ linkage continuous scanning, the scanning rate is 2° / min (0.02° step width), and the scanning range is 9-40°.

[0088] Test procedure: 1) lanthanum carbonate sub-carbonate I, 2) lanthanum subcarbonate II, 3) lanthanum carbonate raw material (excluding sub-lanthanum carbonate I and II), 4) lanthanum carbonate chewable tablet fine powder, 5) corundum , 6) lanthanum carbonate + lanthanum carbonate sub I + lanthanum sub carbonate II + corundum mixture, 7) lanthanum carbonate chewable tablet fine powder + lanthanum carbonate sub I + lanthanum sub carbonate II + corundum mixture, carry out PXRD scanning after sample preparation respectively, record Spectrum, see the results ...

Embodiment 2

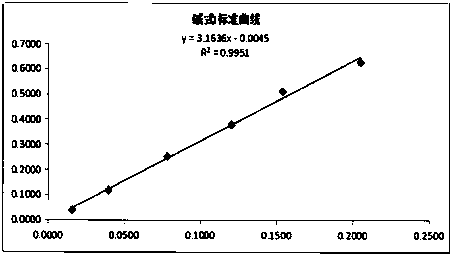

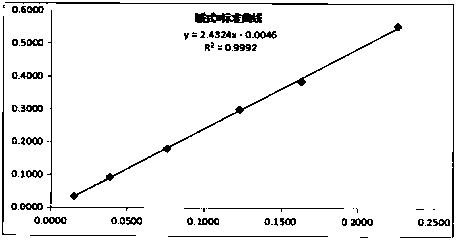

[0096] Linearity and Range Tests

[0097] A. the lanthanum carbonate sample that does not contain basic lanthanum carbonate I and II is fully pulverized to obtain the lanthanum carbonate sample fine powder;

[0098] b. add different quality lanthanum carbonate I and lanthanum carbonate II respectively in the lanthanum carbonate that does not contain lanthanum carbonate I and II,

[0099] Standard curve sample 1: lanthanum carbonate contains 8.16% lanthanum carbonate sub-II and 9.12% sub-lanthanum carbonate II;

[0100] Standard curve sample 2: Lanthanum carbonate contains 6.8% lanthanum carbonate sub-I and 7.6% sub-lanthanum carbonate II;

[0101] Standard curve sample 3: lanthanum carbonate contains 5.44% lanthanum carbonate sub-I and 6.08% lanthanum sub-carbonate II;

[0102] Standard curve sample 4: lanthanum carbonate contains 3.4% lanthanum carbonate sub-I and 3.8% lanthanum sub-carbonate II;

[0103] Standard curve sample 5: Lanthanum carbonate contains 1.36% of lanth...

Embodiment 3

[0118] repeatability test

[0119] When investigating repeatability, prepare 6 parts of samples in parallel by the method of standard curve sample 2, after scanning PXRD respectively, measurement result is substituted in embodiment 2 standard curve equations, calculates the recovery amount of lanthanum subcarbonate I and lanthanum subcarbonate II, Investigate the RSD of the calculation results among the 6 samples, the results are as follows:

[0120]

[0121]

[0122] Conclusion: The test results show that the repeatability of this method is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com