Polyethylene (PE) bottle scrap production process

A production process and chip technology, applied in the field of resource recycling, can solve problems such as insufficient awareness of the importance of PE bottle recycling, substandard cleanliness of plastic fragments, backward research and equipment, etc., to achieve good economic benefits and market prospects, and save production Cleaning time, the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work fall within the protection scope of the present invention:

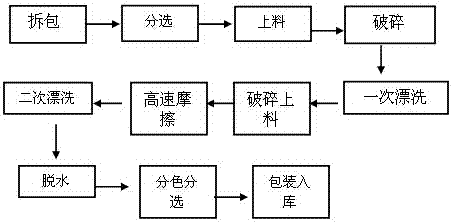

[0033] Such as figure 1 A kind of PE bottle flake production process shown, comprises the following steps:

[0034] Step 1, unpacking, automatically unpacking the packaging bag of the recovered plastic recycling bottle through the unpacking machine, as a preferred embodiment, in order to improve unpacking efficiency, the unpacking machine is set as a two-axis oil bottle Unpacking machine, so while improving the efficiency of unpacking, it can also save labor and reduce labor intensity.

[0035] Step 2, sorting, sorting and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com