Dehydration control method and device, computer readable storage medium and washing machine

A control method and control device technology, which is applied to the control device of washing machine, washing device, textile and paper making, etc., and can solve problems such as barrel collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

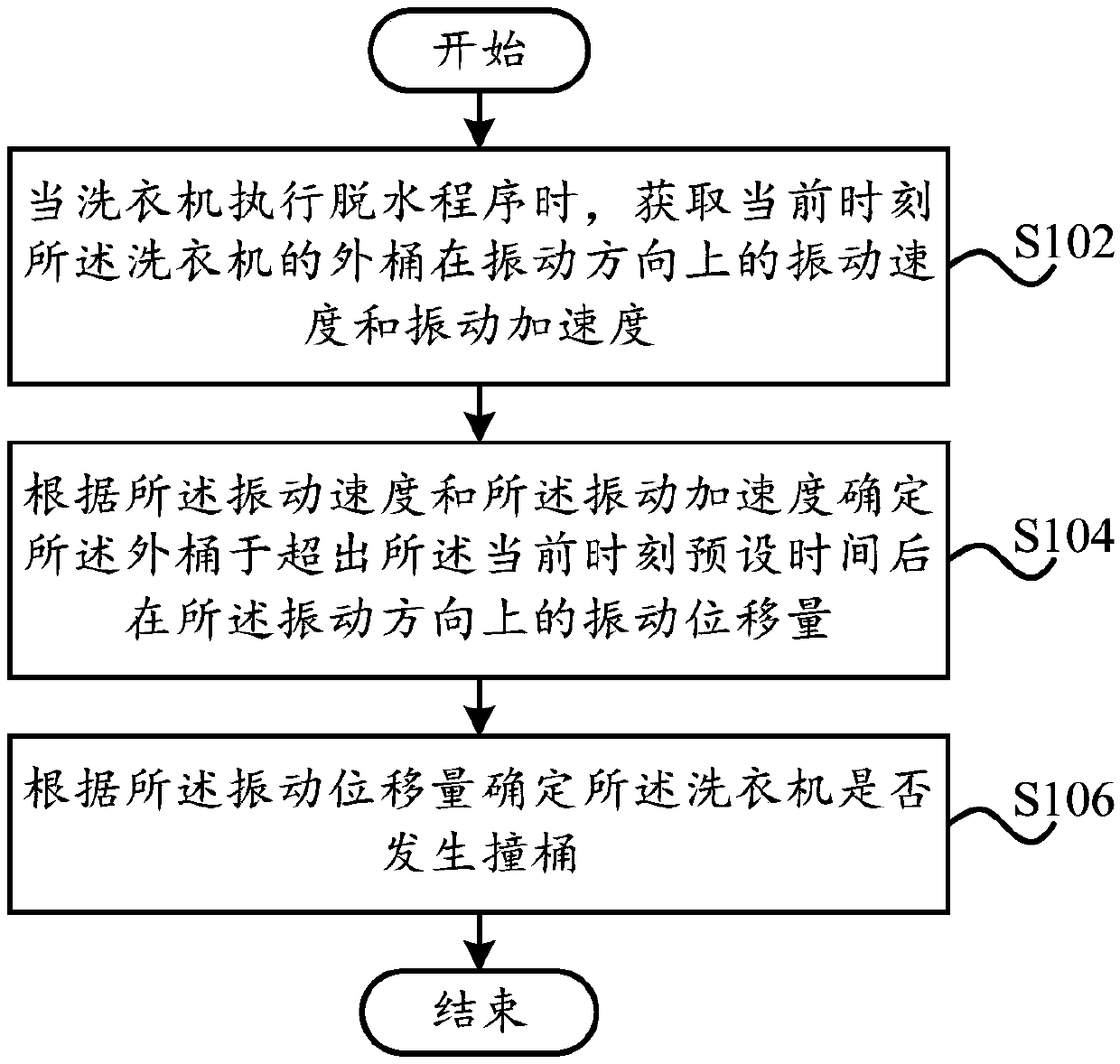

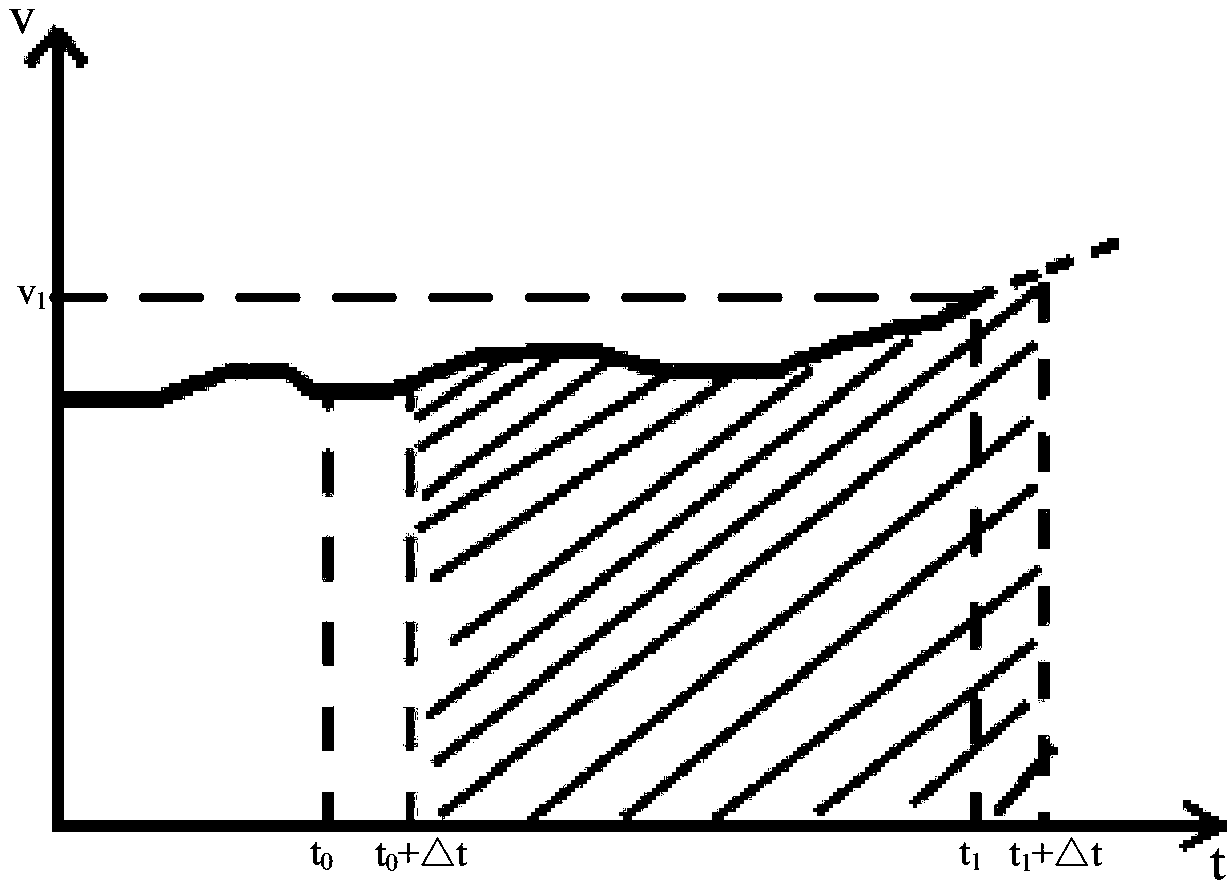

[0036] Combine below figure 1 and figure 2The dehydration control method of the embodiment of the present invention will be described in detail.

[0037] Such as figure 1 As shown, the dehydration control method according to the embodiment of the present invention specifically includes the following process steps:

[0038] Step S102, when the washing machine executes the dehydration program, acquire the vibration velocity and vibration acceleration of the outer tub of the washing machine in the vibration direction at the current moment.

[0039] Wherein, the vibration direction includes an X-axis direction, a Y-axis direction and a Z-axis direction in a spatial Cartesian coordinate system.

[0040] That is to say, it can be predicted that the outer tub of the washing machine can predict the vibration displacement in one or more vibration directions in the X-axis direction, the Y-axis direction and the Z-axis direction of the spatial rectangular coordinate system, so as to ...

Embodiment 2

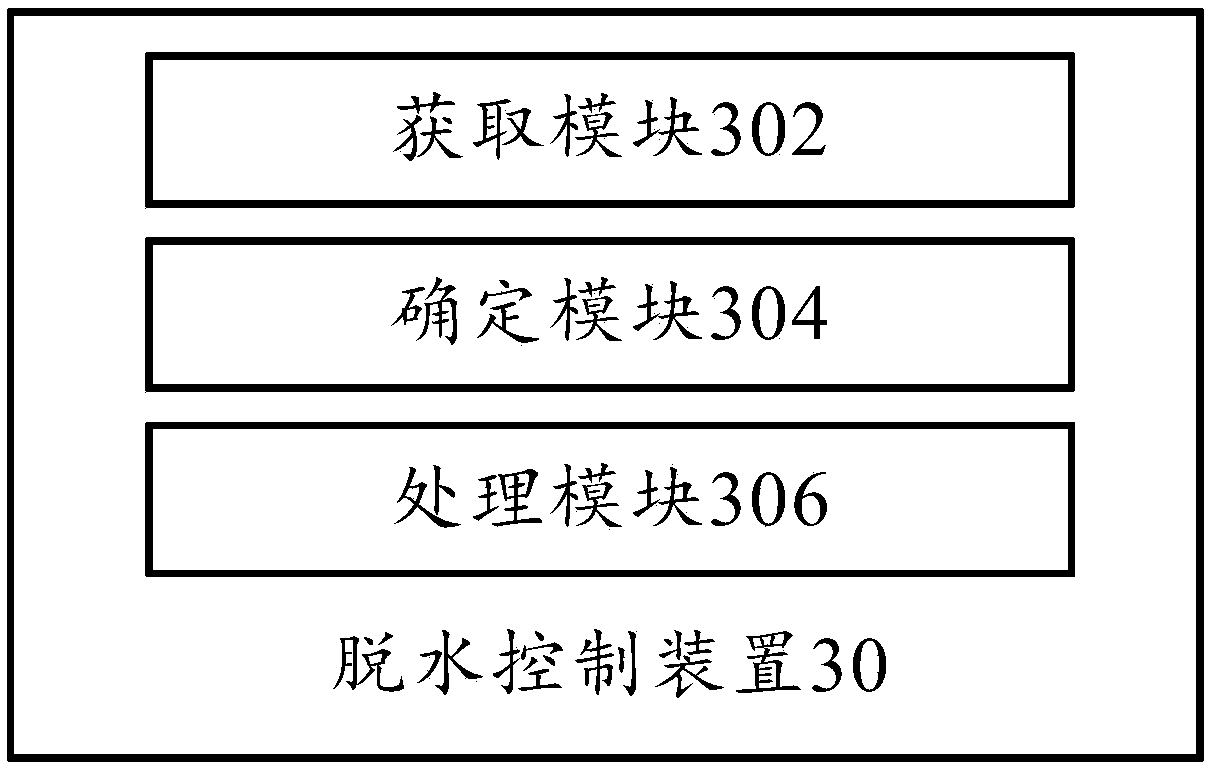

[0060] Such as image 3 As shown, the dehydration control device 30 according to the embodiment of the present invention includes: an acquisition module 302 , a determination module 304 and a processing module 306 .

[0061] Wherein, the obtaining module 302 is used to obtain the vibration speed and vibration acceleration of the outer tub of the washing machine in the vibration direction at the current moment when the washing machine executes the dehydration program; The vibration acceleration determines the vibration displacement of the outer tub in the vibration direction after the preset time exceeds the current moment; the processing module 306 is used to determine whether the washing machine hits the tub according to the vibration displacement .

[0062] In this embodiment, during the process of executing the dehydration program, the washing machine calculates in real time the current vibration velocity and vibration acceleration of the outer tub of the washing machine i...

Embodiment 3

[0076] Such as Figure 4 As shown, the dehydration control device according to the second embodiment of the present invention includes:

[0077] A processor 404; a memory 402 for storing executable instructions of the processor, wherein the processor 404 is used for implementing the corresponding dehydration in the first embodiment above when executing the executable instructions stored in the memory 402 The steps of the control method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com