Ultra-low and mobile tail for belt conveyer

A belt conveyor, ultra-low technology, used in conveyors, conveyor objects, underground transportation, etc., can solve the problems of low production efficiency, high labor intensity, and long downtime in coal mining, saving labor, improving The effect of working efficiency and saving equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

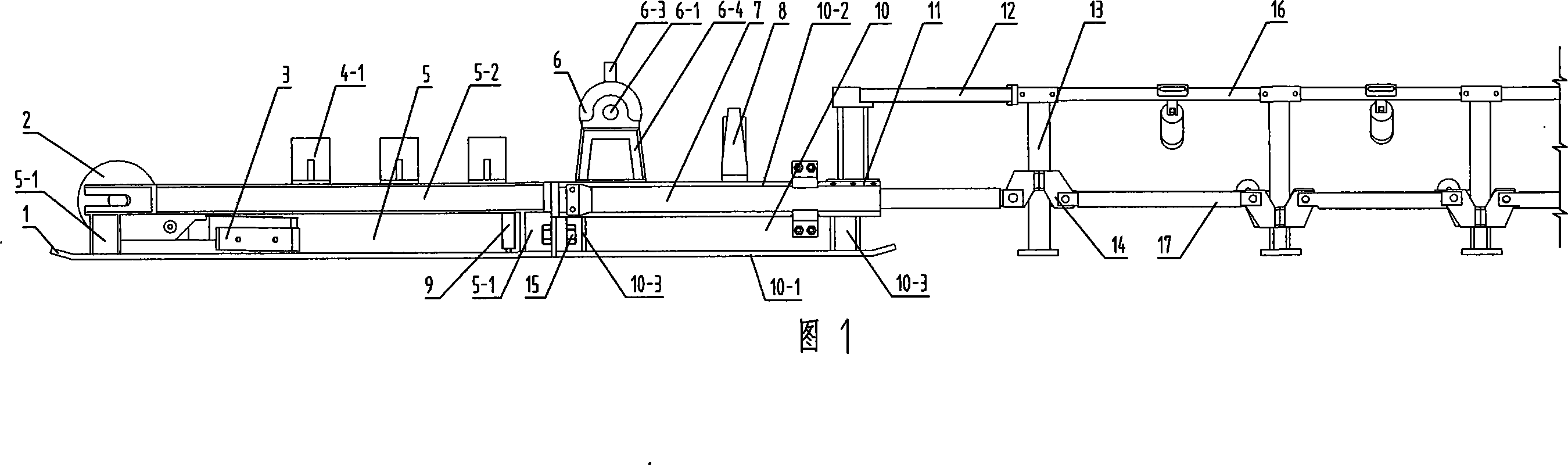

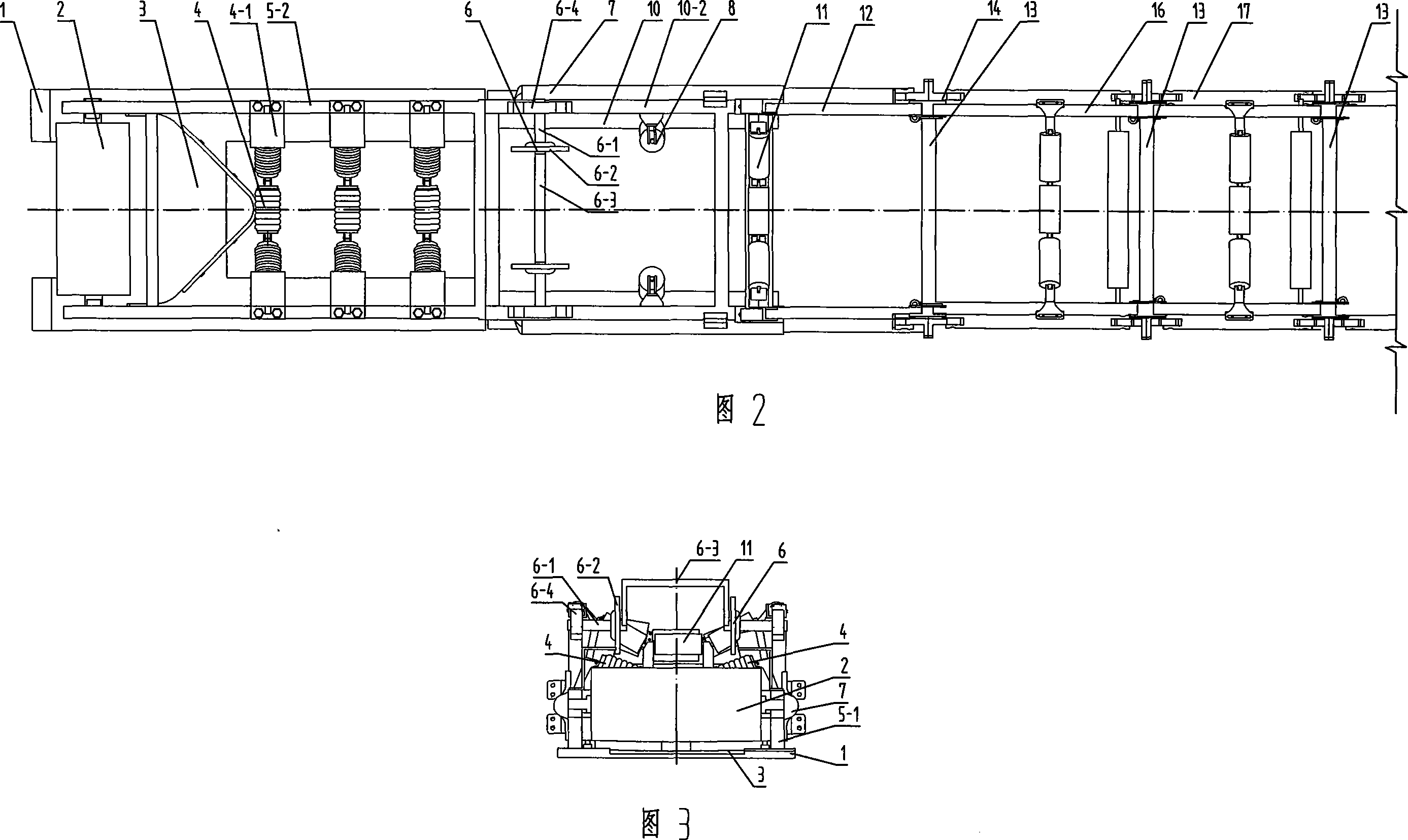

[0017] As shown in Figure 1, Figure 2, Figure 3, a belt conveyor ultra-low type, mobile tail, including a tailstock connected to the tail end of the belt conveyor, a belt steering roller installed on the tailstock, its The characteristic lies in that: the tailstock includes a front tailstock section 5 and a tailstock rear section 10, and the ends of the tailstock front section 5 and the tailstock rear section 10 are connected and fixed by strong bolts 15; The frame of section 5 is a rectangular frame of steel structure, and its lower part is two long strip bottom plates 1 with upright ends. The ends of the two upper beams 5-2 are fixed on the upper end surface of the bottom plate 1 through four uprights 5-1. ; The two ends of the shaft of the belt steering roller 2 are installed on the front end of the upper beam 5-2 through the bearing seat; the cleaner 3 is installed on the upper beam 5-2 by screws; the two ends of the three sets of rubber ring support rollers 4 are passed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com